Method for producing L-lactic acid by using vinasse

A technology of liquor and waste residues, which is applied in the field of advanced processing and fermentation of agricultural and sideline products to prepare L-lactic acid, which can solve the problems of high cost of liquor waste and reuse, low efficiency of enzymatic hydrolysis of liquor, etc., to increase energy consumption and improve selection adaptability , the effect of reducing particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

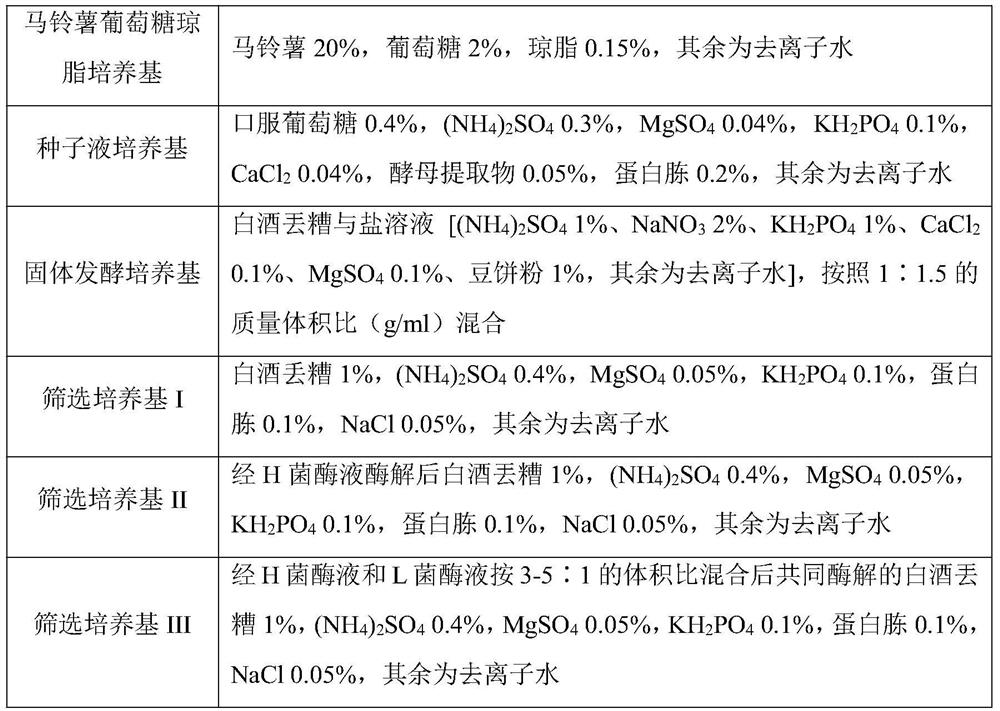

[0049] The preparation method of above-mentioned mixed bacteria enzyme liquid comprises the steps:

[0050] a. Sampling was taken from pit mud, waste grains, and surrounding soil of the winery, and was screened and enriched with a screening medium using liquor waste grains as a carbon source. After separation and purification, bacterial samples were obtained; after the bacterial samples were activated, use The solid fermentation medium is fermented and cultured, and the inoculation amount of the activated bacteria sample is 9-11% of the solid fermentation medium, and then it is extracted, filtered, and centrifuged to obtain the bacterial enzyme liquid A, and the bacterial enzyme liquid A is used for liquor Enzymatic hydrolysis of discarded grains, screening to obtain H bacteria, and fermenting H bacteria enzyme liquid, the enzyme activity of H bacteria enzyme liquid is 5.0-5.8IU / ml;

[0051] b. Sampling from the pit mud, waste grains, and surrounding soil of the winery, screen...

Embodiment 1

[0088] A. Mix the distilled grains with tap water at a solid-to-liquid ratio of 1:3 g / ml, soak for 4 hours, wet-grind the soaked grains to 200 mesh, and filter to obtain crushed grains;

[0089] B. Mix PEG-8000 with the mixed bacterial enzyme solution (H bacterial enzyme solution: L bacterial enzyme solution: M bacterial enzyme solution is 16:3:1) in a ratio of 0.004:1g / ml to obtain a mixed solution;

[0090] C. Mix the crushed and discarded grains obtained in step A with the mixed solution obtained in step B according to the ratio of 1:10g / ml, oscillate at 50°C and 140rpm for 72 hours for enzymolysis, and filter to obtain the initial sugar solution, Evaporate the initial sugar solution under reduced pressure to a reducing sugar concentration of 60g / L to obtain a concentrated sugar solution;

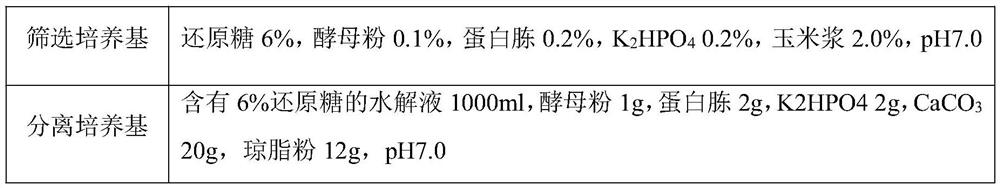

[0091] D. Use CaO to adjust the pH of the concentrated sugar solution to 6.5, then add yeast powder 0.6%, peptone 1.0%, K 2 HPO 4 0.2%, CaCO 3 6% mixed and then sterilized at 100°C to...

Embodiment 2

[0094] A. Mix the distilled grains with tap water at a solid-to-liquid ratio of 1:3 g / ml, soak for 4 hours, wet-grind the soaked grains to 250 mesh, and filter to obtain crushed grains;

[0095] B. Mix PEG-8000 with the mixed bacterial enzyme solution (H bacterial enzyme solution: L bacterial enzyme solution: M bacterial enzyme solution is 15:4:1) in a ratio of 0.005:1g / ml to obtain a mixed solution;

[0096] C. Mix the crushed and discarded grains obtained in step A with the mixed solution obtained in step B according to the ratio of 1:10g / ml, oscillate at 50°C and 140rpm for 72 hours for enzymolysis, and filter to obtain the initial sugar solution. Evaporate the initial sugar solution under reduced pressure to a reducing sugar concentration of 65g / L to obtain a concentrated sugar solution;

[0097] D. Use CaO to adjust the pH of the concentrated sugar solution to 6.5, then add yeast powder 0.6%, peptone 1.0%, K 2 HPO 4 0.2%, CaCO 36% mixed and then sterilized at 100°C to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com