Method for implementing mutual pressurization/depressurization among pressurized gasification furnace coal locks

A technology for pressurized gasification and gasification furnace, which is applied in the field of coal gasification, can solve the problems of damage to compressor gas valves and piston ring components, increased equipment investment and maintenance and operation costs, and large fluctuations in the amount of coal locked gas, so as to reduce environmental protection. The effect of reducing pressure, reducing maintenance costs and maintenance operating costs, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

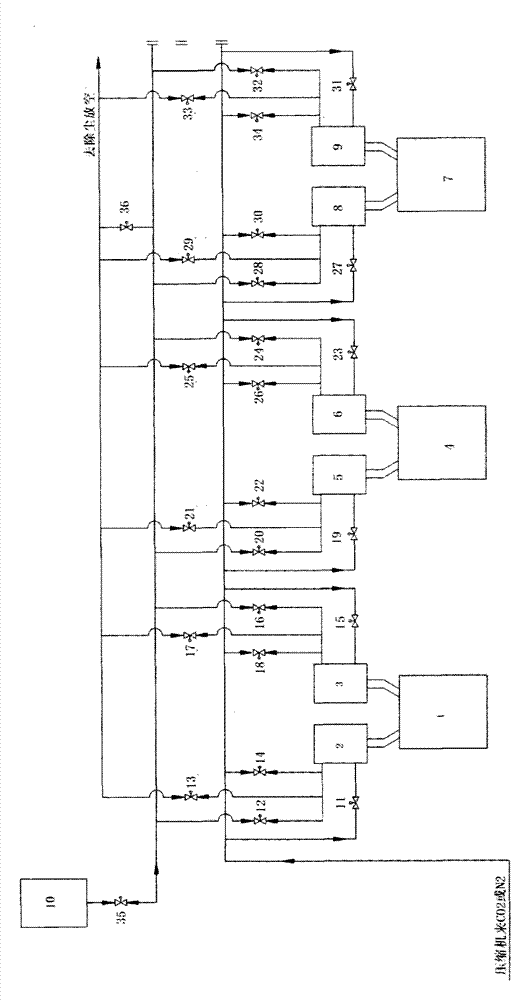

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] Such as figure 1 As shown, the method for filling and releasing pressure between coal locks of pressurized gasifiers of the present invention includes three gasifiers and matching coal locks and control valves. Each gasifier coal lock is equipped with a pressure-filling and releasing pipeline, a final pressure-charging pipeline, a gas-sealing pipeline and a venting pipeline, and corresponding control valves are installed on the pipelines.

[0026]The gasifier 1 is provided with a coal lock 2 and a coal lock 3, a pressure discharge control valve 12 is installed on the pressure discharge pipeline of the coal lock 2, a final pressure control valve 14 is installed on the final pressure pipeline, and a gas seal is installed on the gas seal pipeline A venting control valve 13 is arranged on the control valve 11 and the venting pipeline. The chargin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com