Integrated heat supply system for flue gas source heat pump waste heat recovery, flue gas white smoke removal and off-peak electricity phase change energy storage gradient temperature rise

A waste heat recovery and source heat pump technology, which is applied in heat recovery systems, climate change adaptation, and machines using waste heat, etc., can solve the problems of large heat loss, harsh use conditions, high cost of initial melting and emptying, and improve energy efficiency ratio , Eliminate white smoke and reduce the loss of high-grade heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

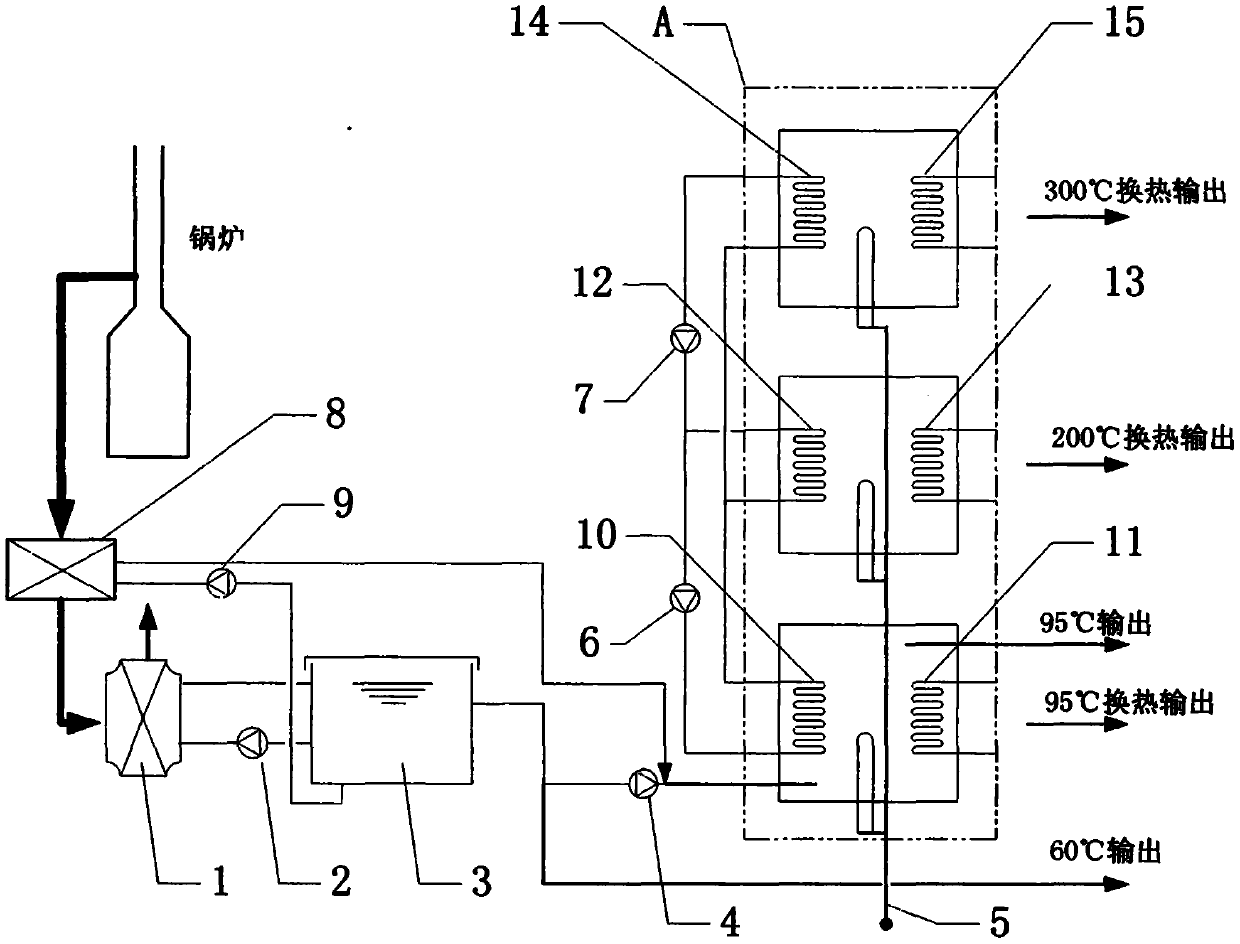

[0042] Embodiment 1: (attach image 3 )

[0043] This embodiment is a waste heat recovery system from a flue gas source heat pump and an integrated heating system of flue gas dewhitening and valley electricity phase change energy storage to generate 95°C hot water for recycling and utilization.

[0044] Such as image 3 As shown, an integrated heating system through a flue gas source heat pump waste heat recovery, flue gas dewhitening and valley electricity phase change energy storage cascade heating, mainly consists of flue gas source heat pump 1, water tank circulation pump 2, low temperature heat pump Water heat storage adjustment pool 3, temperature rise water pump 4, valley power input terminal 5, low temperature heat charging circulation pump 6, low temperature heat charging heat exchange tube 7, high temperature air-water heat exchanger 8, high temperature flue gas heat exchange circulation pump 9, The low-temperature exothermic heat exchange tube 10, the medium-tempe...

Embodiment 2

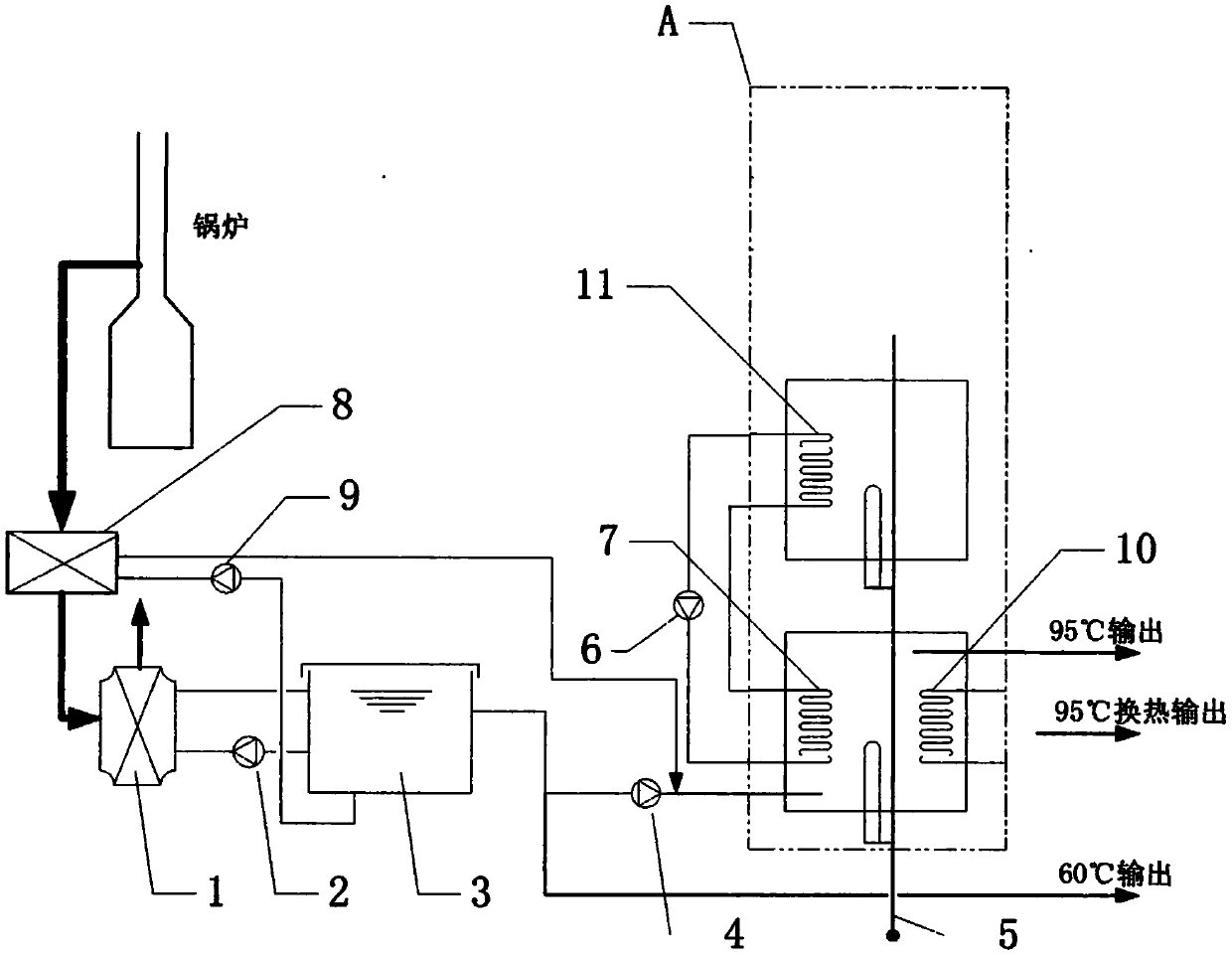

[0050] Embodiment 2 (attached Figure 4 )

[0051] It is a steam generation system for an integrated heating system of flue gas source heat pump waste heat recovery and flue gas dewhitening and valley electricity phase change energy storage cascade temperature increase.

[0052] Such as Figure 4 As shown, this embodiment is a recovery and utilization system for generating steam at 180°C and below through the flue gas source heat pump and valley electricity energy storage warming device, including: flue gas source heat pump 1, water tank circulation pump 2, low temperature hot water heat storage adjustment Pool 3, heating water pump 4, valley power input 5, low-temperature heating circulation pump 6, medium-temperature heating circulation pump 7, high-temperature air-water heat exchanger 8, high-temperature flue gas heat-exchanging circulation pump 9, low-temperature heating and heat-exchanging Tube 10, low-temperature exothermic heat exchange tube 11, medium-temperature hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com