Method and device for generating mechanical reciprocating bistable motion by virtue of electromagnetism

A bistable, mechanical technology, applied in electromechanical devices, electrical components, etc., can solve problems affecting system performance and reliability, achieve reliable bistable characteristics, simplify device structure, and reduce manufacturing and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

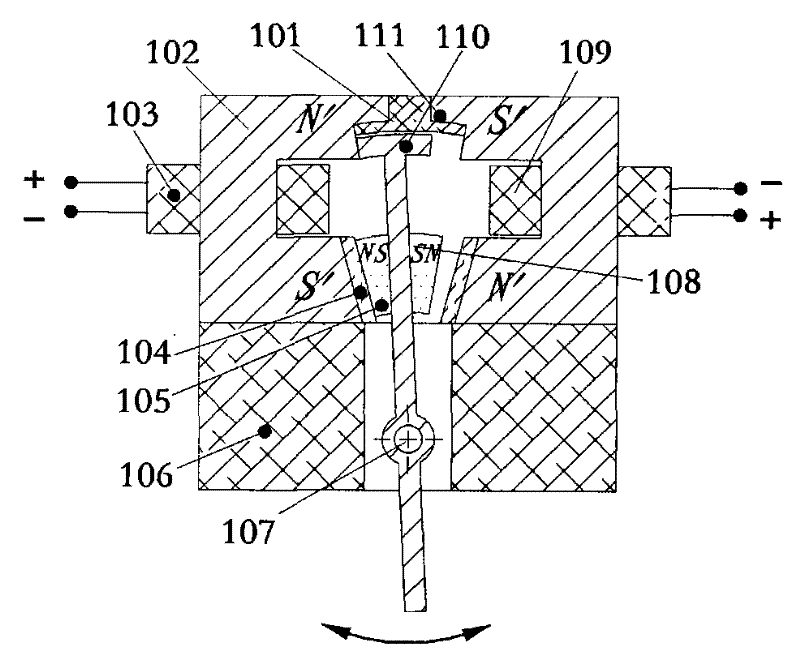

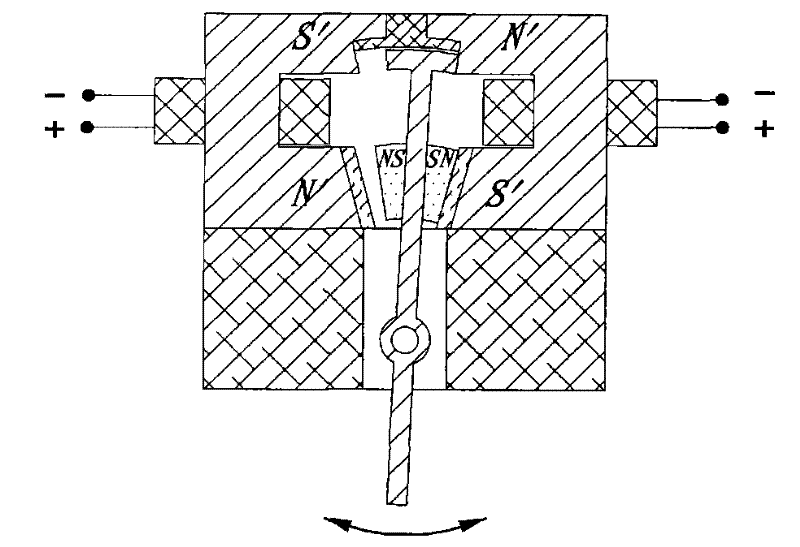

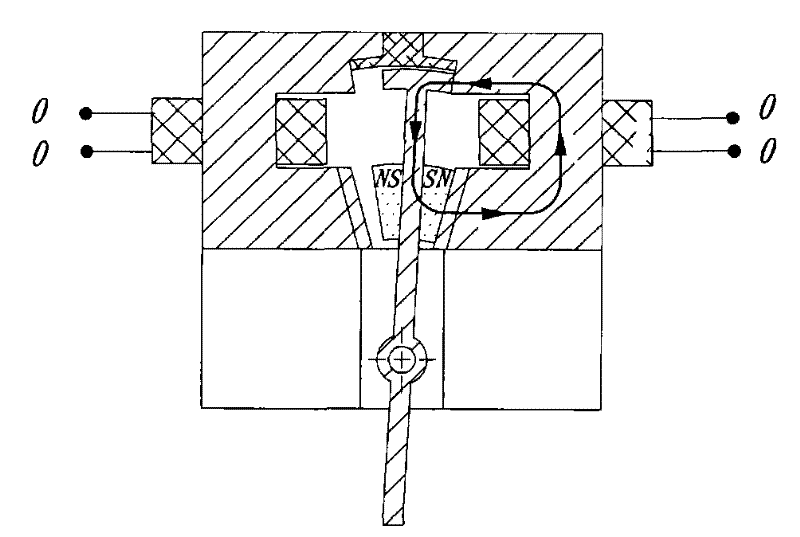

[0032] This embodiment is an example in which an alternating current is passed into an excitation coil to excite the soft magnet to generate an alternating magnetic field, thereby realizing mechanical reciprocating swing. The device structure of this embodiment is as attached figure 1 , 2 , 3 shown. Two "C"-shaped soft magnets 102, 111 have opposite openings, and excitation coils 103, 109 wrap the soft magnets 102, 111. The magnetic field leads above the two "C"-shaped soft magnets are separated by the magnetic circuit 101, and the two "C" There is a large magnetic field air gap at the magnetic field lead-out end under the "shaped soft magnet, and the permanent magnets 105 and 108 are symmetrically attached to the active arm of the magnetic pendulum 110, and the S poles of the two permanent magnets are relatively attached to the magnetic pendulum 110. On the left and right sides, the permanent magnets 105 and 108 attached to the magnetic pendulum bar 110 are placed between t...

Embodiment 2

[0036] This embodiment is an example of generating an alternating magnetic field on the soft magnet by rotating the permanent magnet, thereby generating mechanical reciprocating swing. The device structure of this embodiment is as attached Figure 4 , 5 , 6 shown.

[0037]In this example, the four pieces of soft magnets are divided into left and right sides, the upper left soft magnet 203 and the lower left soft magnet 206 are separated by the magnetic circuit 204, the upper right soft magnet 216 and the lower right soft magnet 211 The magnetic circuit is cut off by the spacer magnet 214, the soft magnet 203 and the soft magnet 206 surround the left rotating permanent magnet 205, and there is a very small air gap between the left rotating permanent magnet, and the soft magnetic body 216 and the soft magnet 211 surround the right rotating permanent magnet. Magnet 215, and there is a very small air gap between the right side rotating permanent magnet, the magnetic circuit is a...

Embodiment 3

[0040] This embodiment is an example in which an alternating current passes through an excitation coil to excite the soft magnet to generate an alternating magnetic field, thereby realizing mechanical reciprocating linear motion. The device in this example is attached Figure 7 , 8 , as shown in 9.

[0041] In this example, a push rod 301 of non-magnetic material is fixed vertically at the center of a magnetically conductive substrate 306, and two permanent magnets 304 of the same size and opposite polarity are pasted on the upper and lower surfaces of the magnetically conductive substrate 306 And the permanent magnet 310, that is, the two permanent magnet N poles are relatively attached to the upper and lower sides of the magnetically conductive substrate 306, and the magnetic pole directions of the two permanent magnets are consistent with the axial direction of the push rod 301, and the push rod is fixedly attached to the position of the permanent magnet It is placed betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com