Ethanol-guiding straw bio-refining full-sealing integration system

A technology of straw biology and integrated system, which is applied in the direction of fertilizers, microorganisms, microorganisms, etc. made from biological waste, and can solve environmental pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

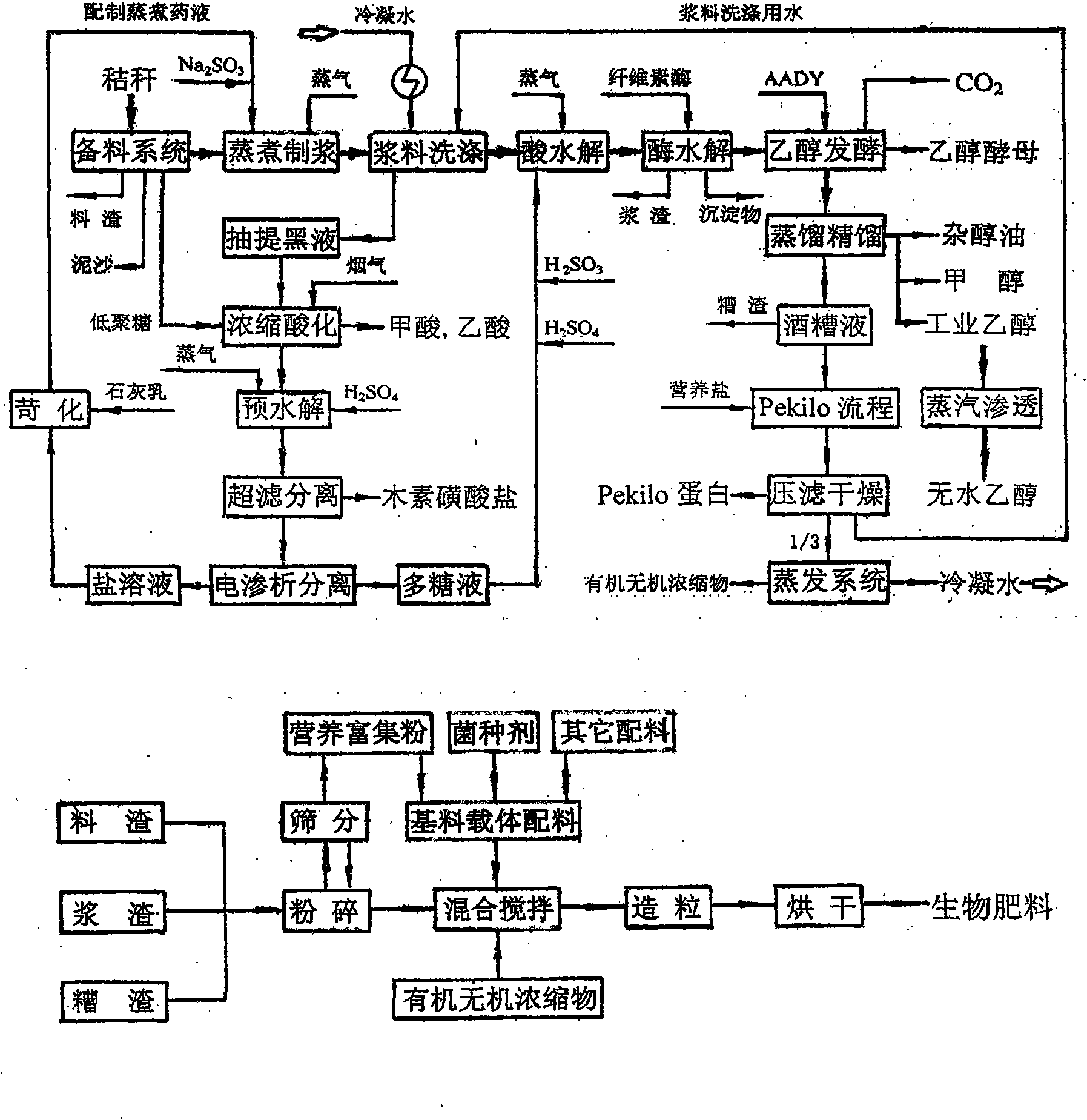

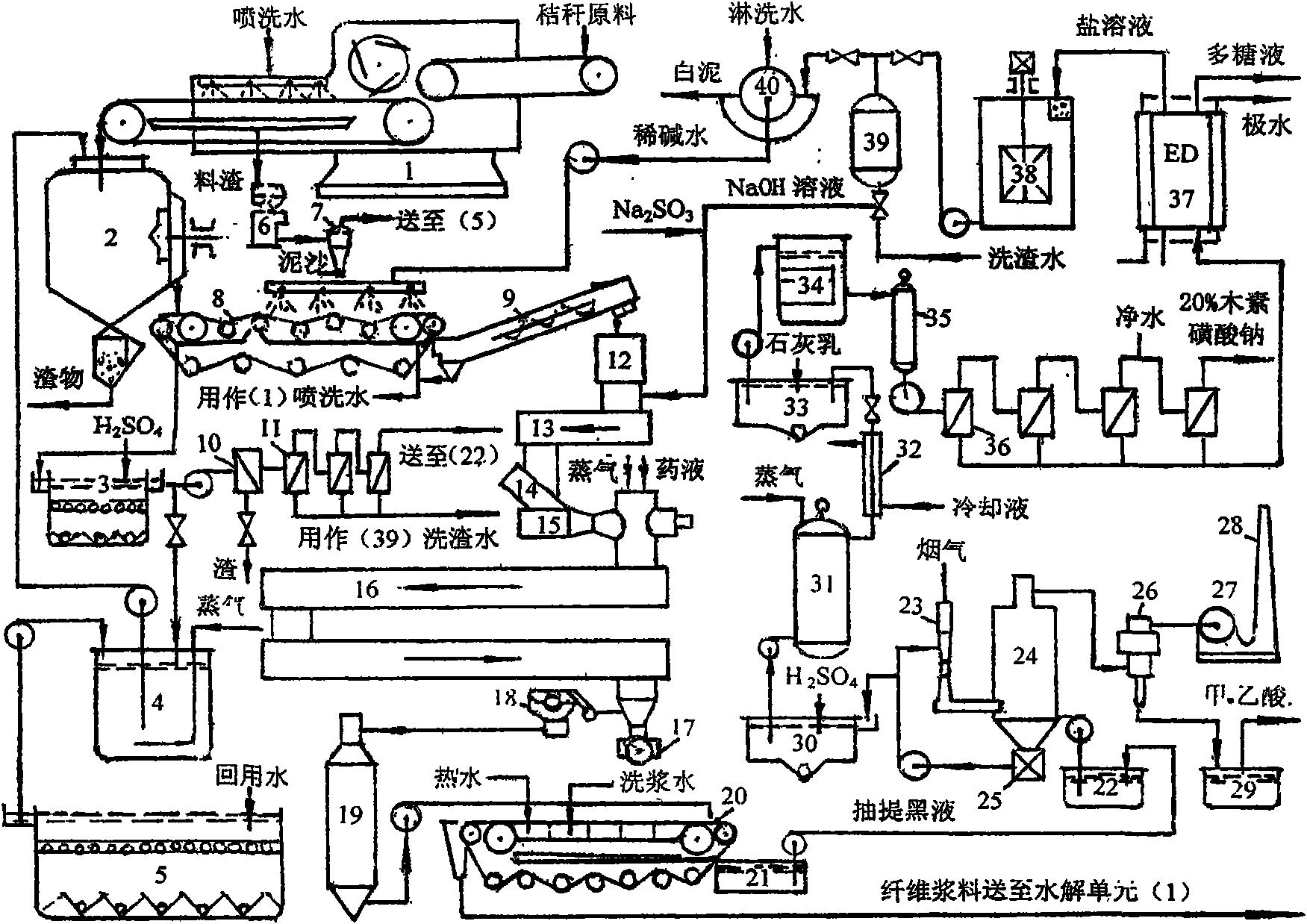

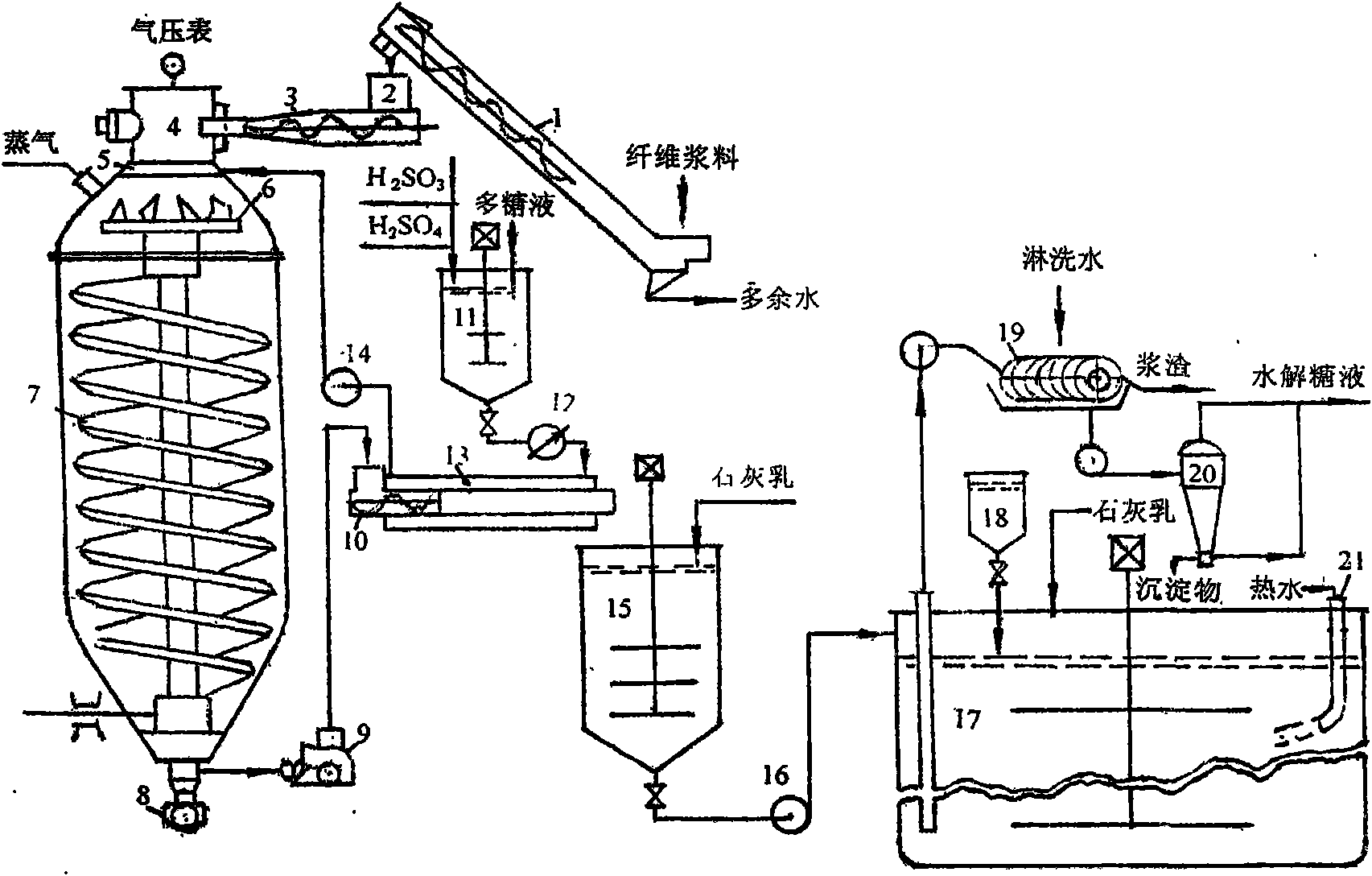

[0093] Figure 1 The process flow of the fully closed integrated system of ethanol-oriented straw biorefining is shown. In the clean pulping operation unit consisting of material preparation, cooking pulping and comprehensive utilization of cooking waste liquid, the purified straw raw material is first separated into cellulose (containing hemicellulose) pulp, oligosaccharides, volatile organic acids ( salt) and lignin sulfonate and other components. The cellulose pulp enters the pulp hydrolysis unit after multi-stage countercurrent washing, and the volatile organic acid salt and lignosulfonate in the extracted black liquor are processed into formic acid, acetic acid, Lignosulfonate and other products. The remaining salt-sugar mixture is separated by electrodialysis, and the sodium-salt solution is causticized to prepare cooking liquid. The polysaccharide solution that meets the salt content control standard enters the slurry hydrolysis unit at the same time as the cellulose ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com