Patents

Literature

34results about How to "The industry has good economic benefits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

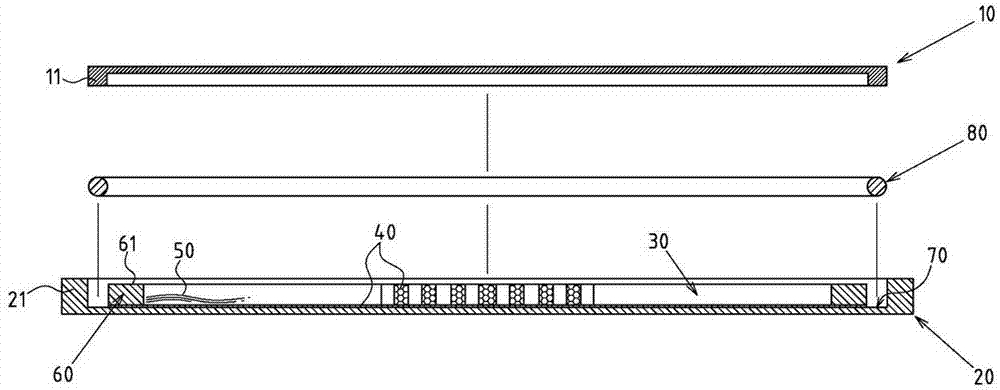

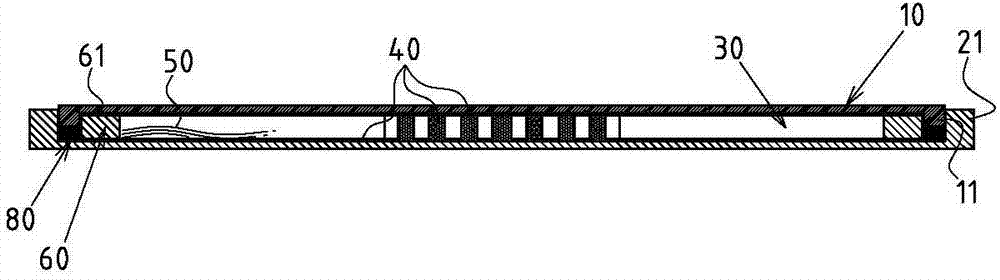

Vapor chamber vacuum sealing structure and making method thereof

InactiveCN104121797ASimplify the manufacturing processReduce practical progressIndirect heat exchangersManufacturing cost reductionEngineering

A vapor chamber vacuum sealing structure and a making method thereof; the vapor chamber is formed by stacking an upper cover plate and a lower cover plate; a vacuum sealing hollow cavity is formed between the upper cover and the lower cover; an upper cover periphery is provided with an upper sealing ring, and a lower cover plate periphery is matched with a lower sealing ring; an inner ring rack is arranged in an inner side of the lower sealing ring; an annular nested slot is formed between the inner ring rack and the lower sealing ring inner side so as to allow the upper sealing ring of the upper cover to fit in; a top of the inner ring rack is provided with a limit surface; the annular nested slot is assembled with an elastic stop sealing ring; when the upper sealing ring is nested in the annular nested slot, the elastic stop sealing ring is pressed to deform and expand so as to combine with the annular nested slot, so a vacuum state of the hollow cavity can be kept; the limit surface on the top of the inner ring rack can press against the upper cover plate so as to limit a maximum depth of the sealing ring nesting in the annular nested slot; the vapor chamber vacuum sealing structure can simplify making steps and reduce making cost.

Owner:SUZHOU FORCECON ELECTRIC

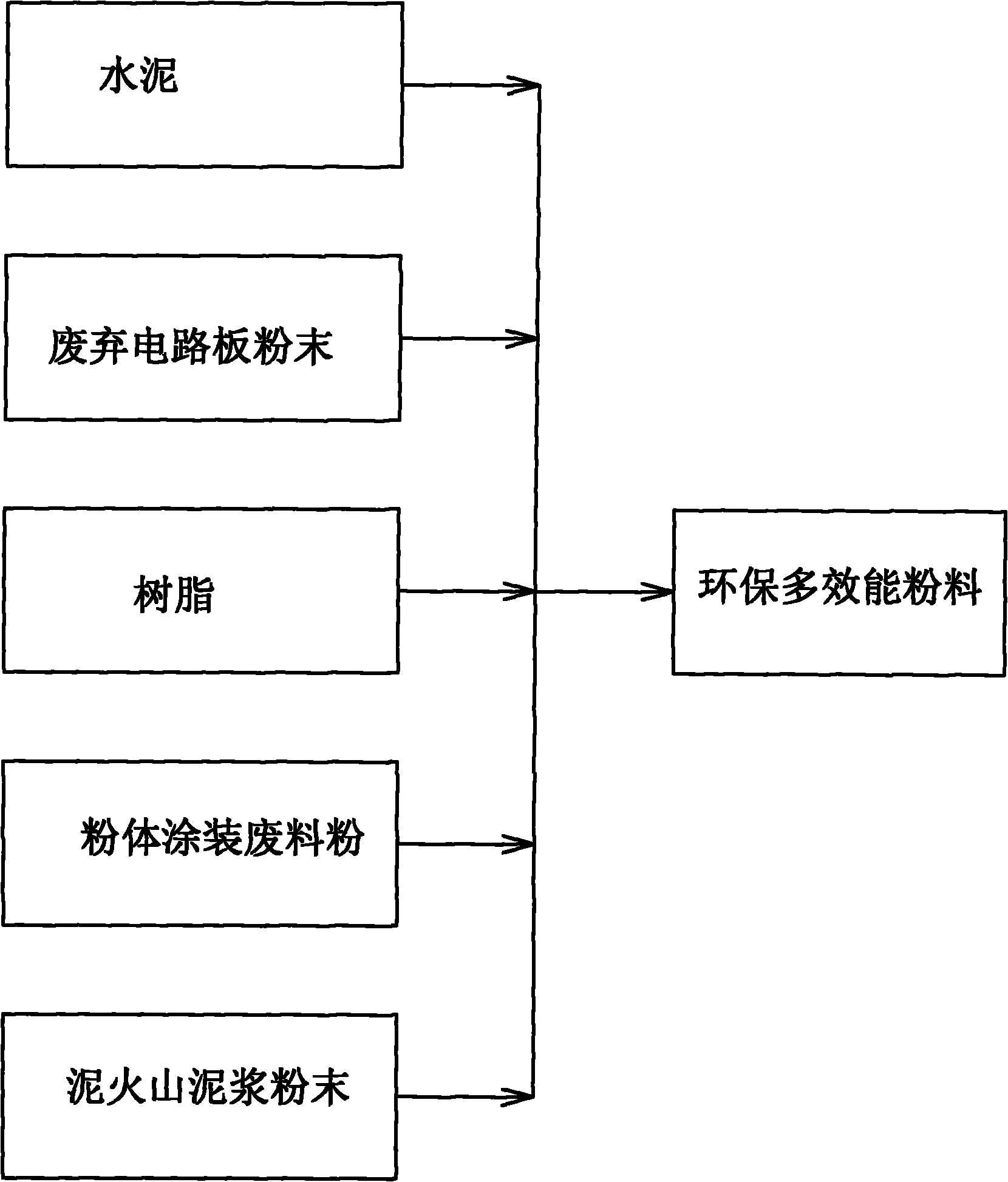

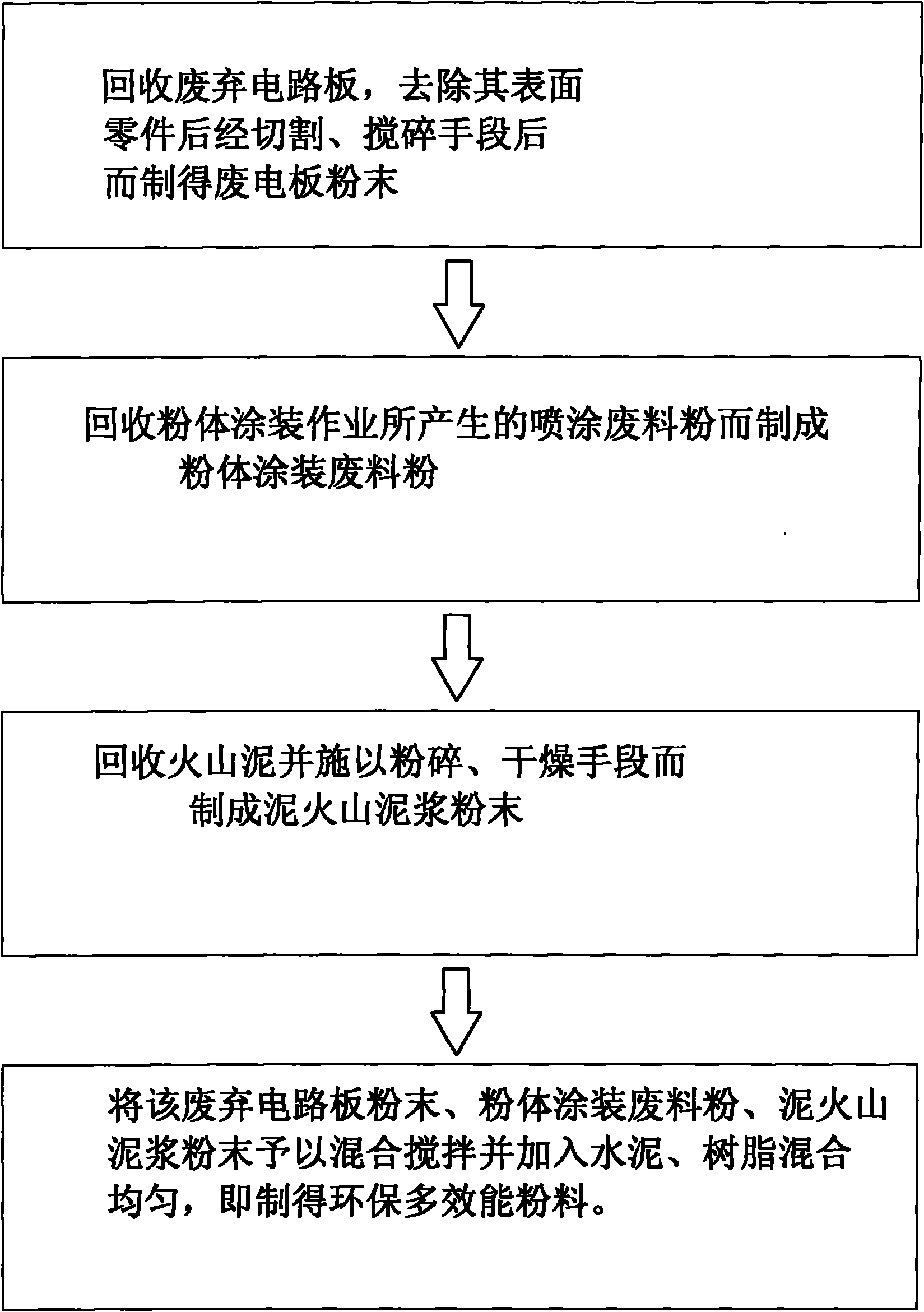

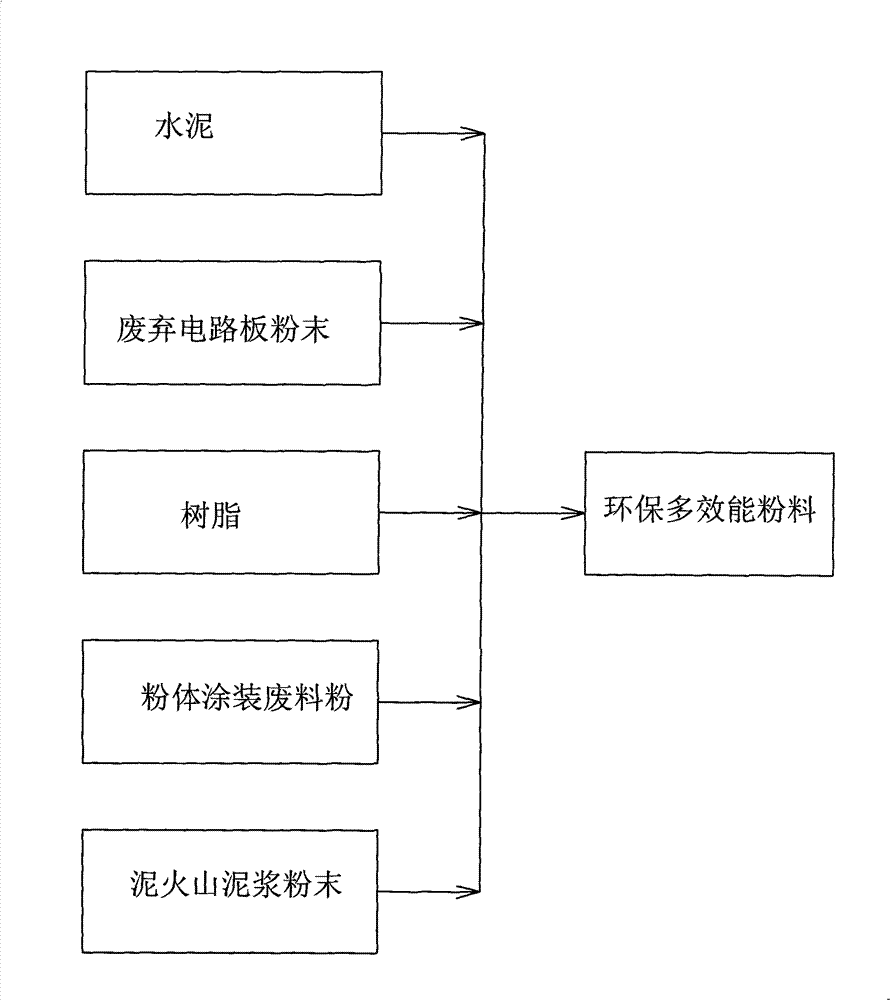

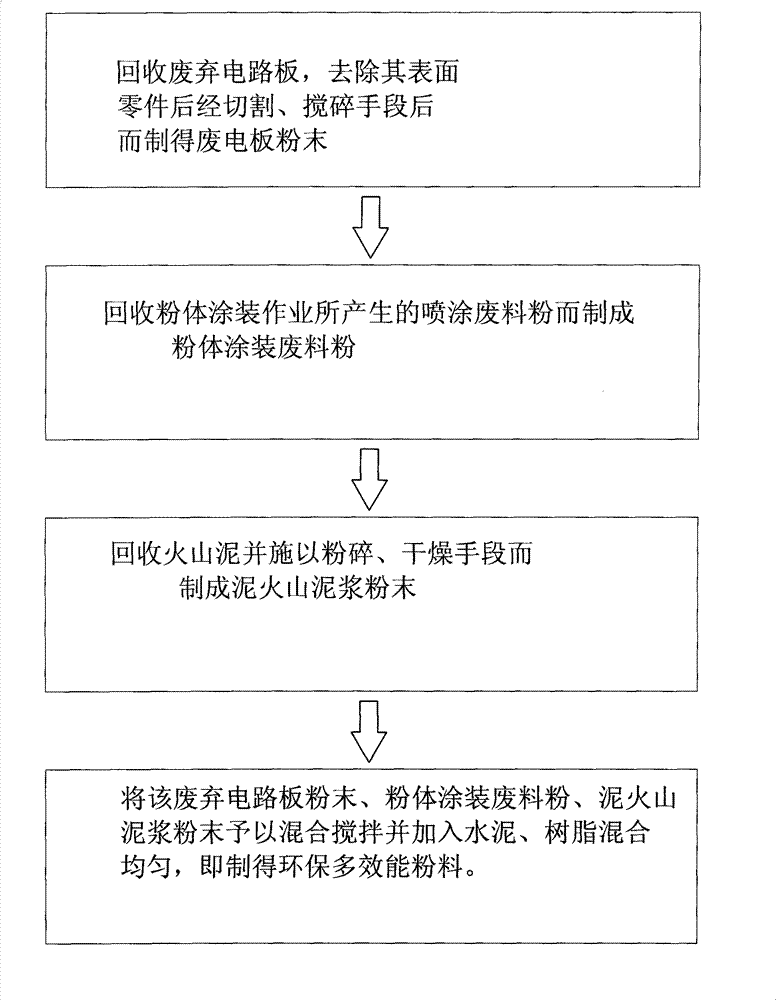

Environmental-protection and multiple-effect powder composite and production method thereof

InactiveCN101805152AGood physical propertiesThe industry has good economic benefitsSolid waste managementSlurryPolyresin

The invention discloses an environmental-protection and multiple-effect powder composite and a production method thereof. The environmental-protection and multiple-effect powder composite is prepared by mixing cement, waste circuit board powder, resin, powder coating waste powder and mud volcano powder. The method for producing the environmental-protection and multiple-effect powder composite comprises the following steps of: recycling the waste circuit boards, removing the parts on the surface, cutting, crushing and separating to produce the waste circuit board powder; recycling the spraying waste powder generated in the powder coating operation to produce powder coating waste powder; recycling mud volcano slurry, crushing and drying to produce mud volcano powder; mixing the waste circuit board powder, the powder coating waste powder and the mud volcano powder together, adding the cement and resin, and uniformly mixing to obtain the environmental-protection and multiple-effect powder. The invention is widely applied to the places with the need of using environmental-protection and multiple-effect powder compositions and provides a good production method for producers.

Owner:王武添 +7

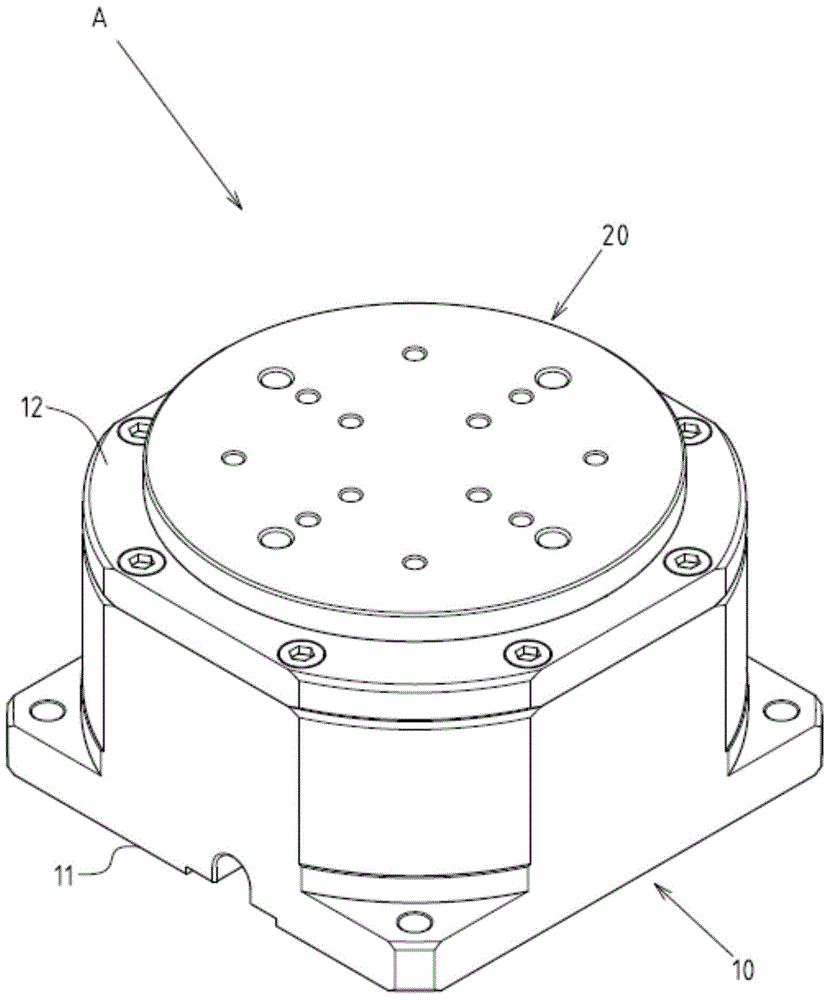

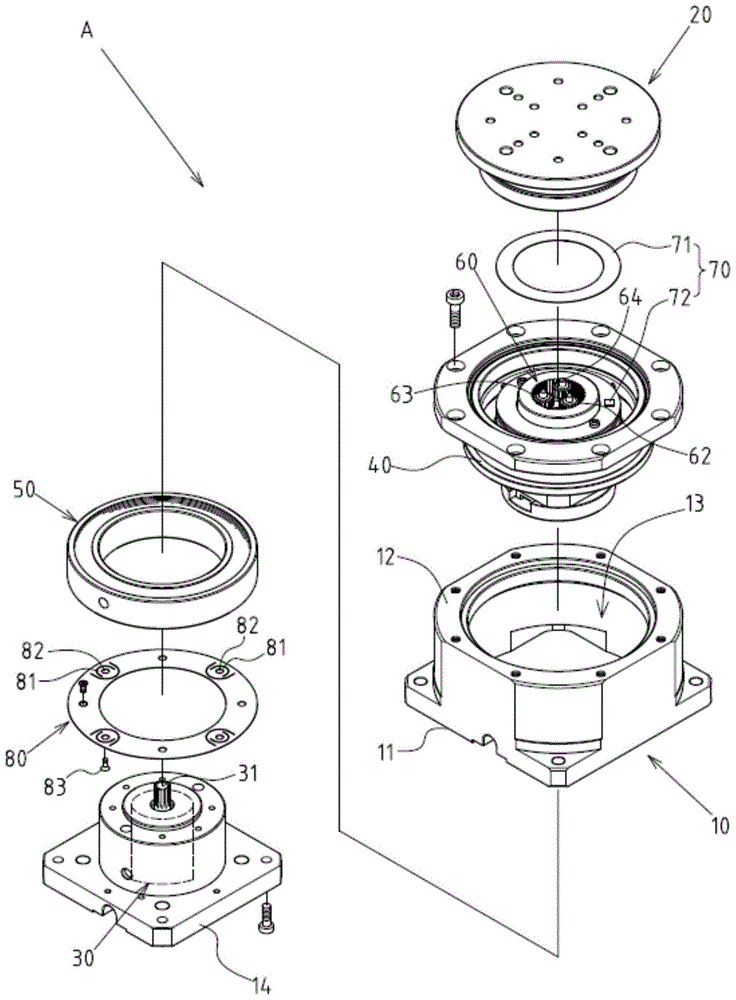

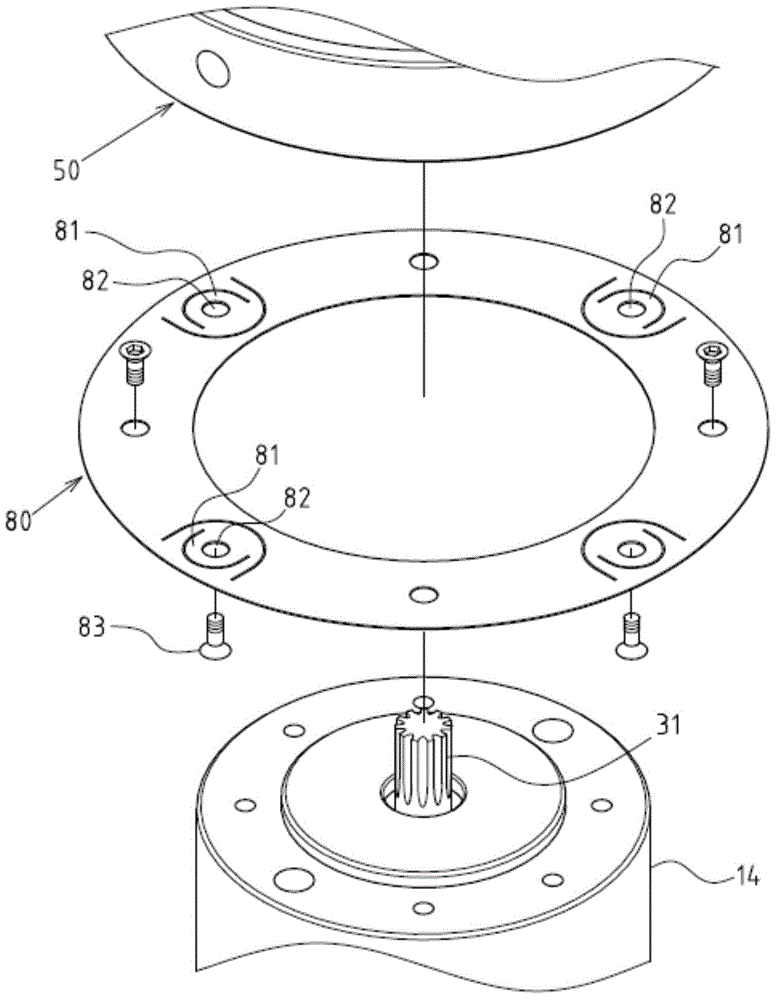

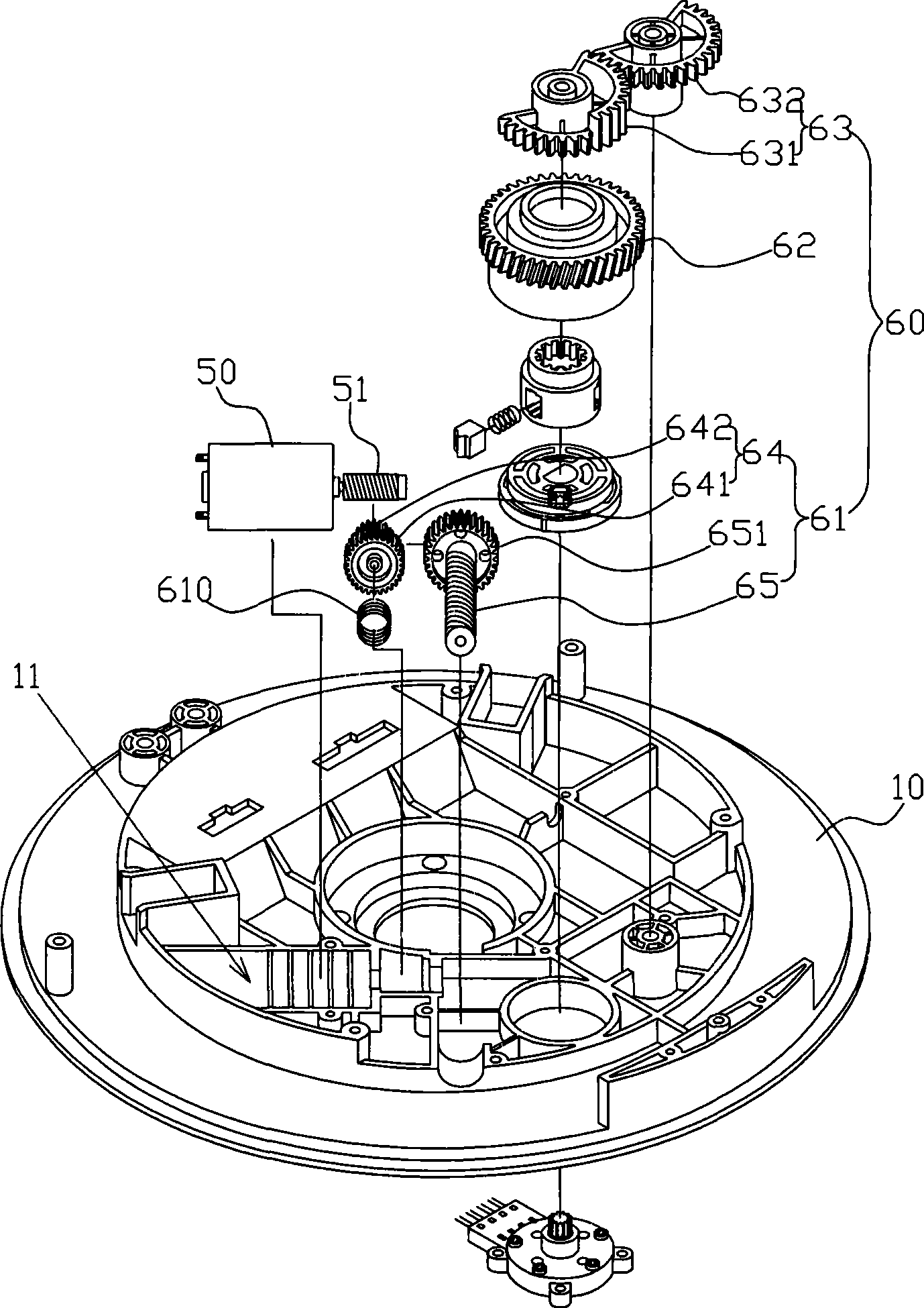

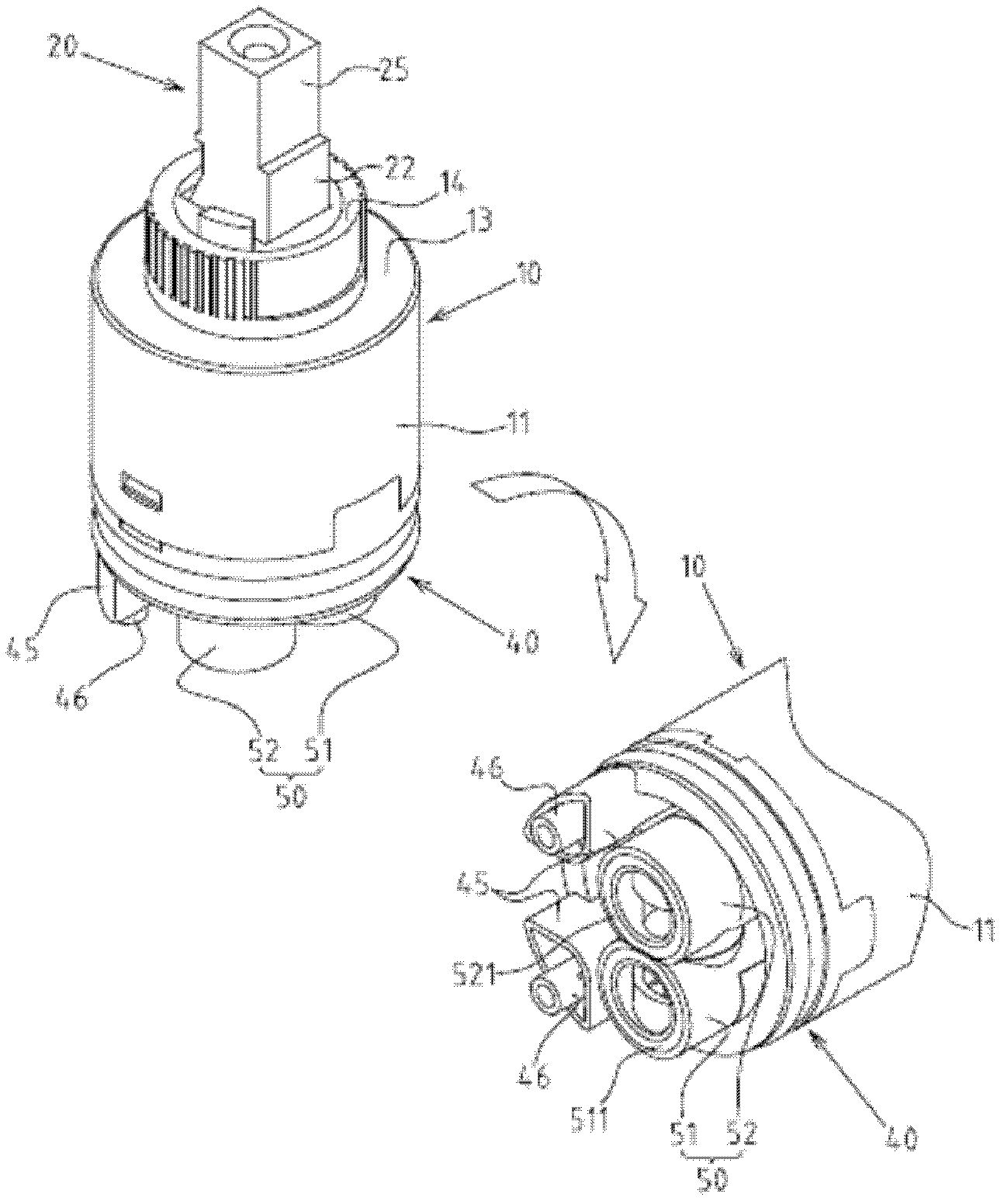

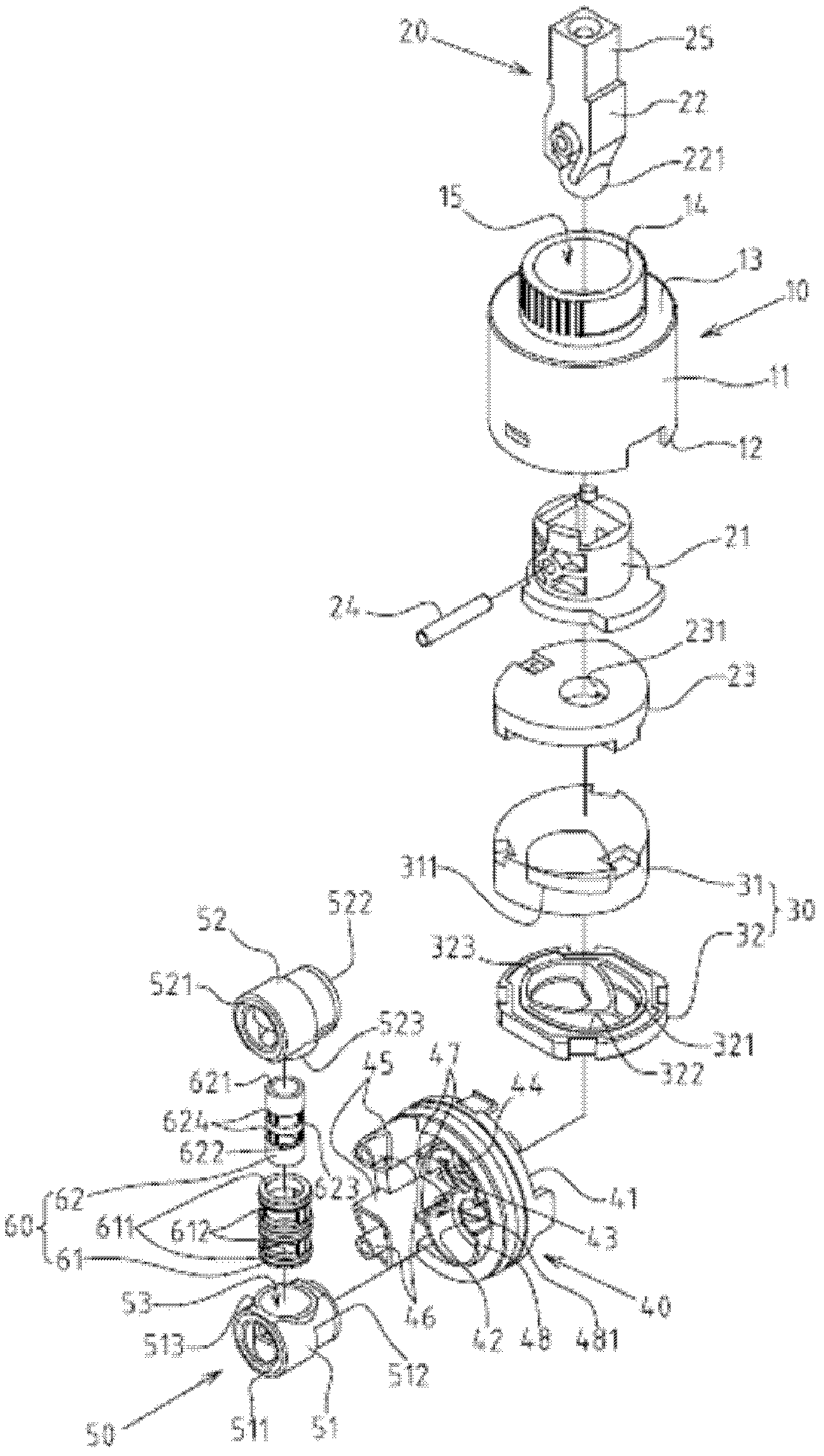

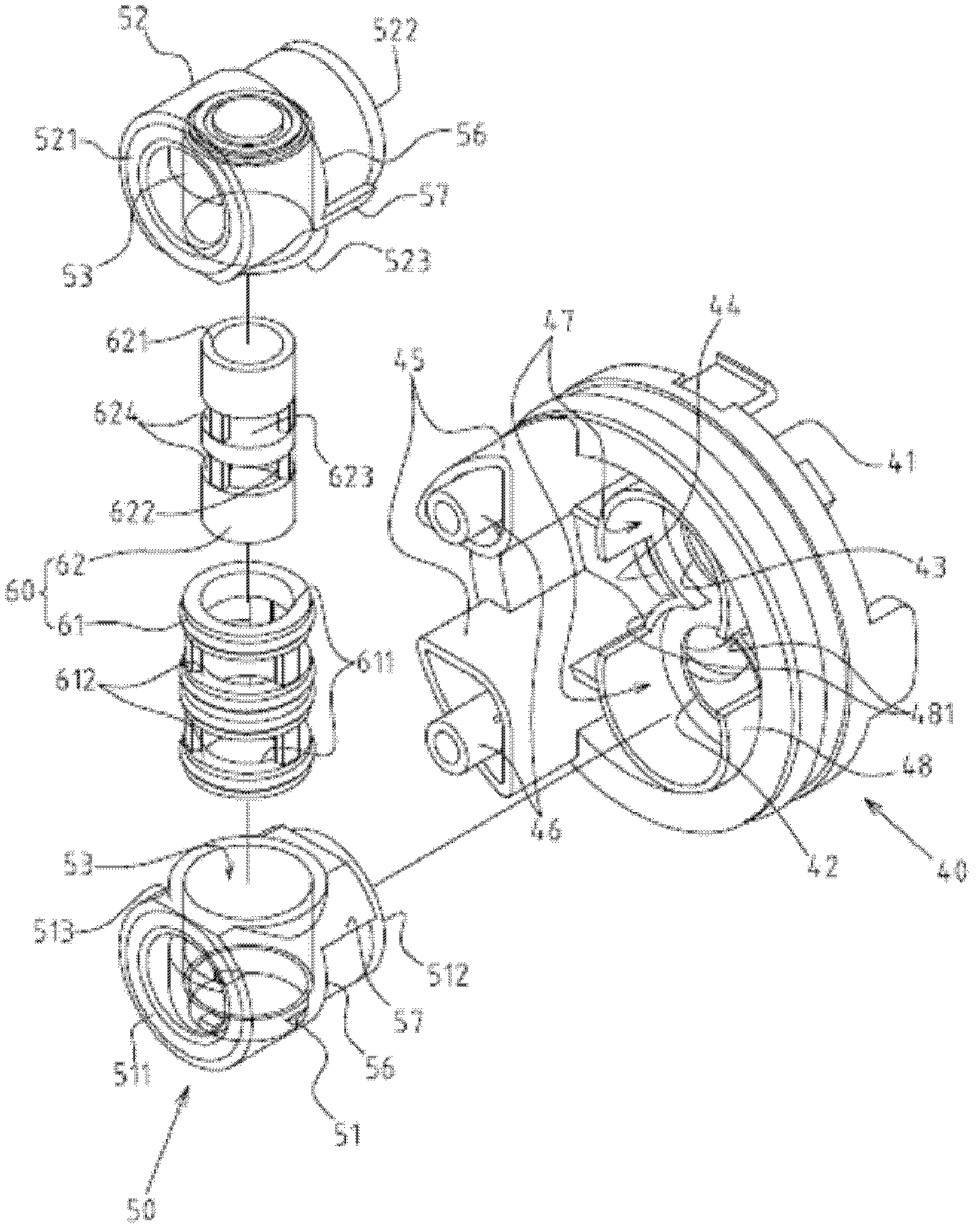

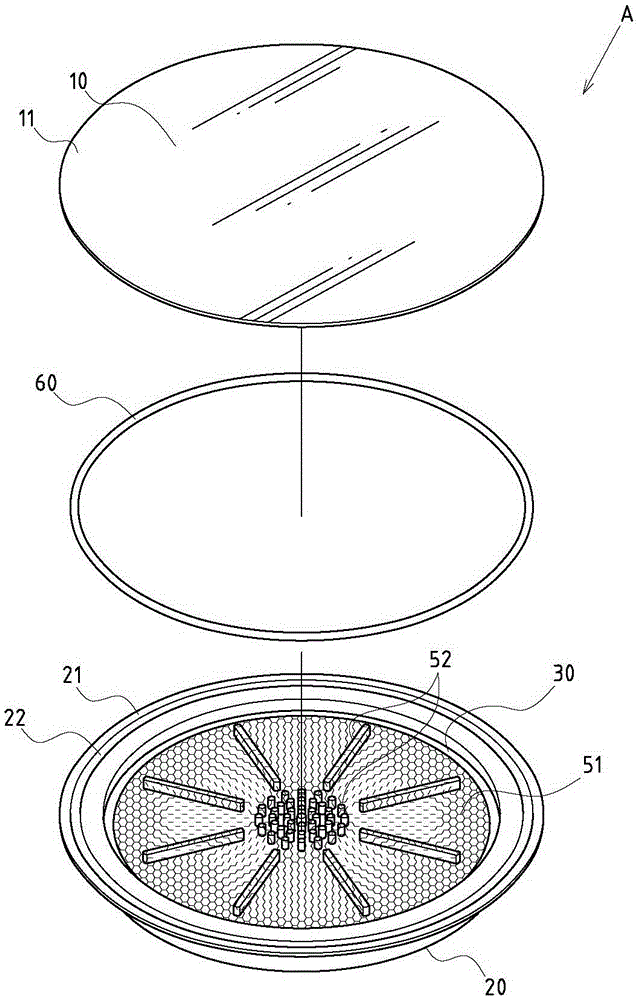

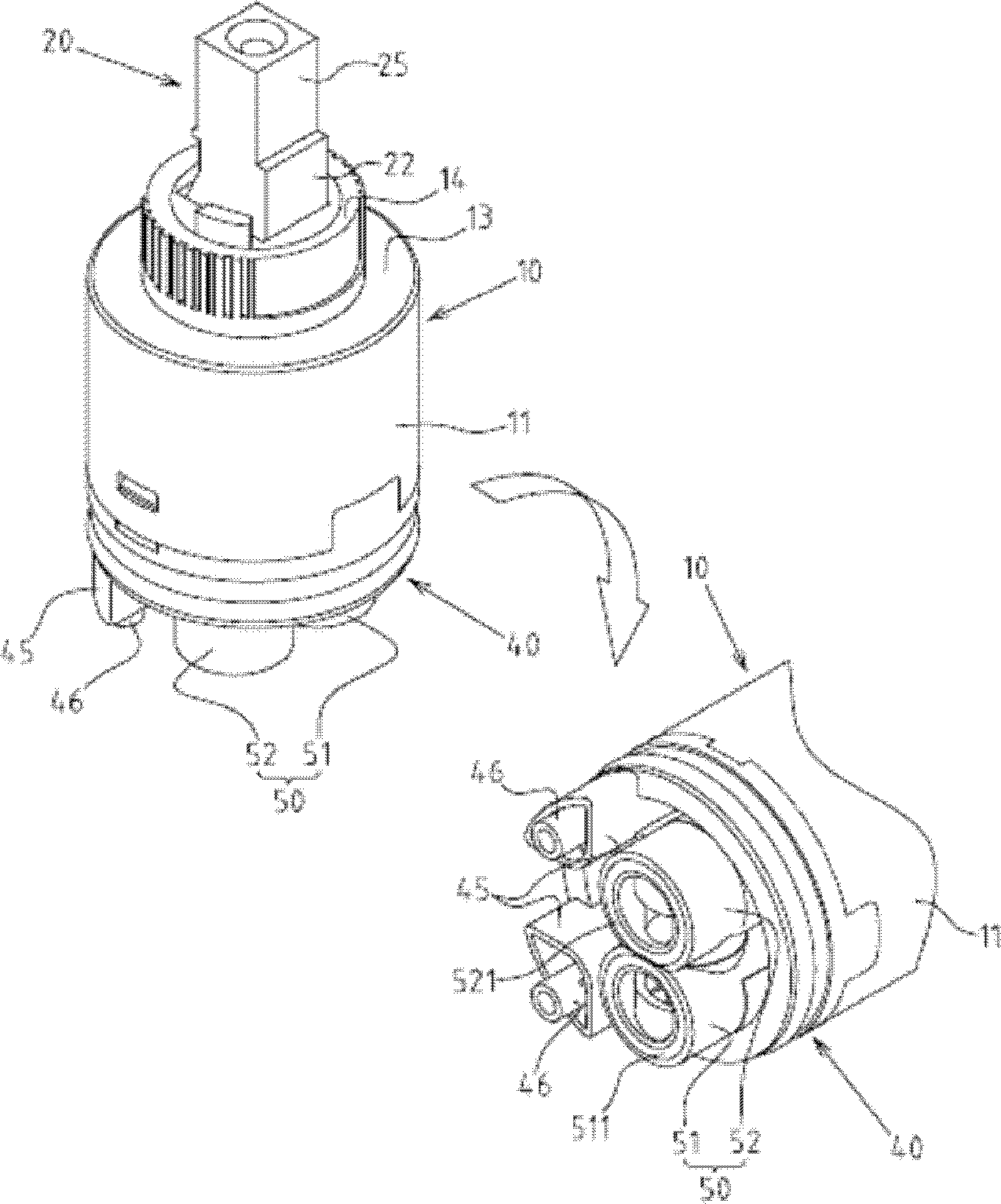

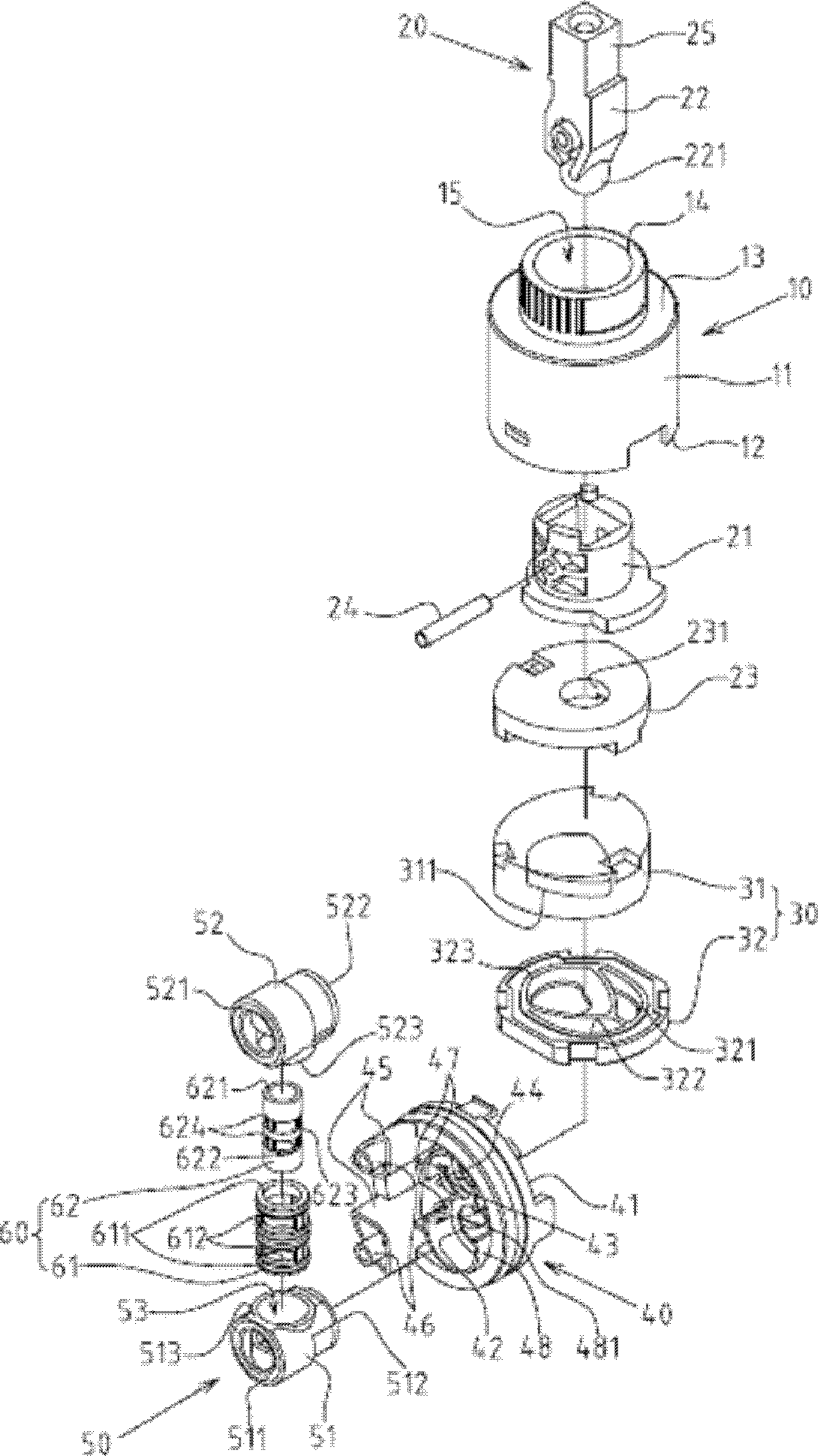

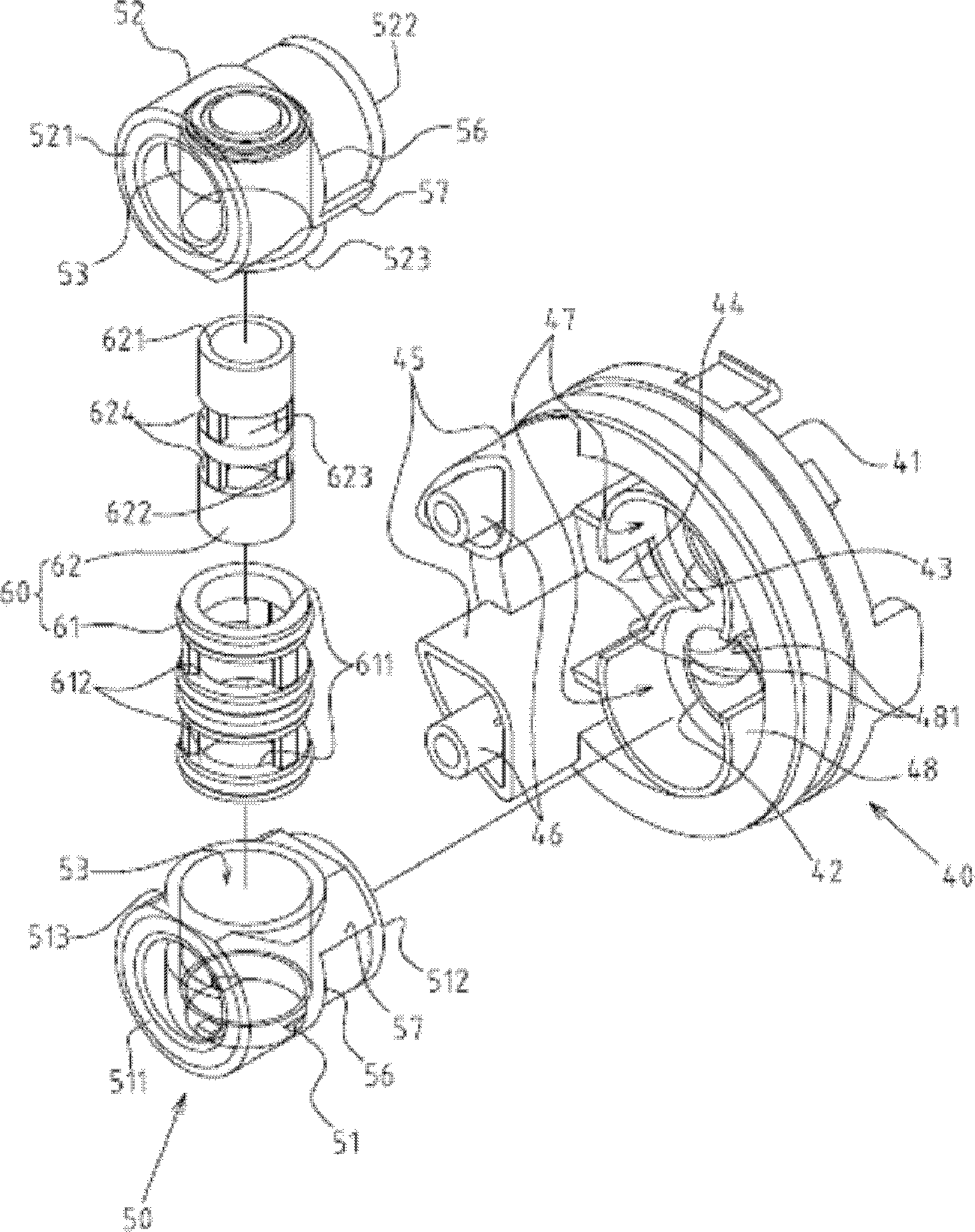

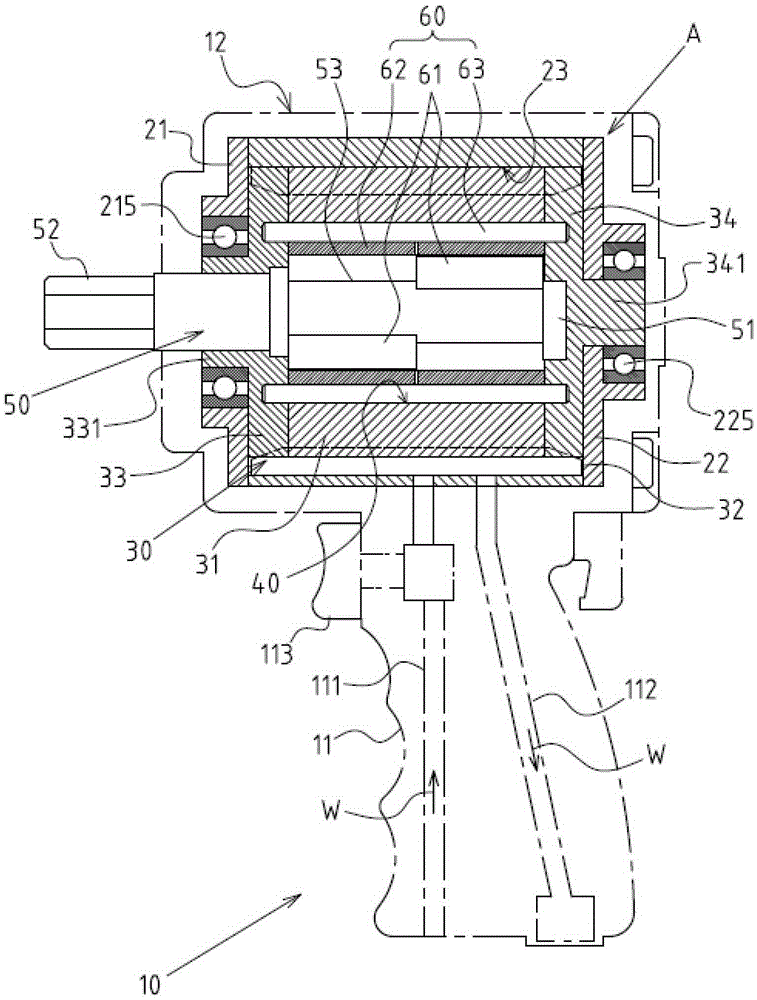

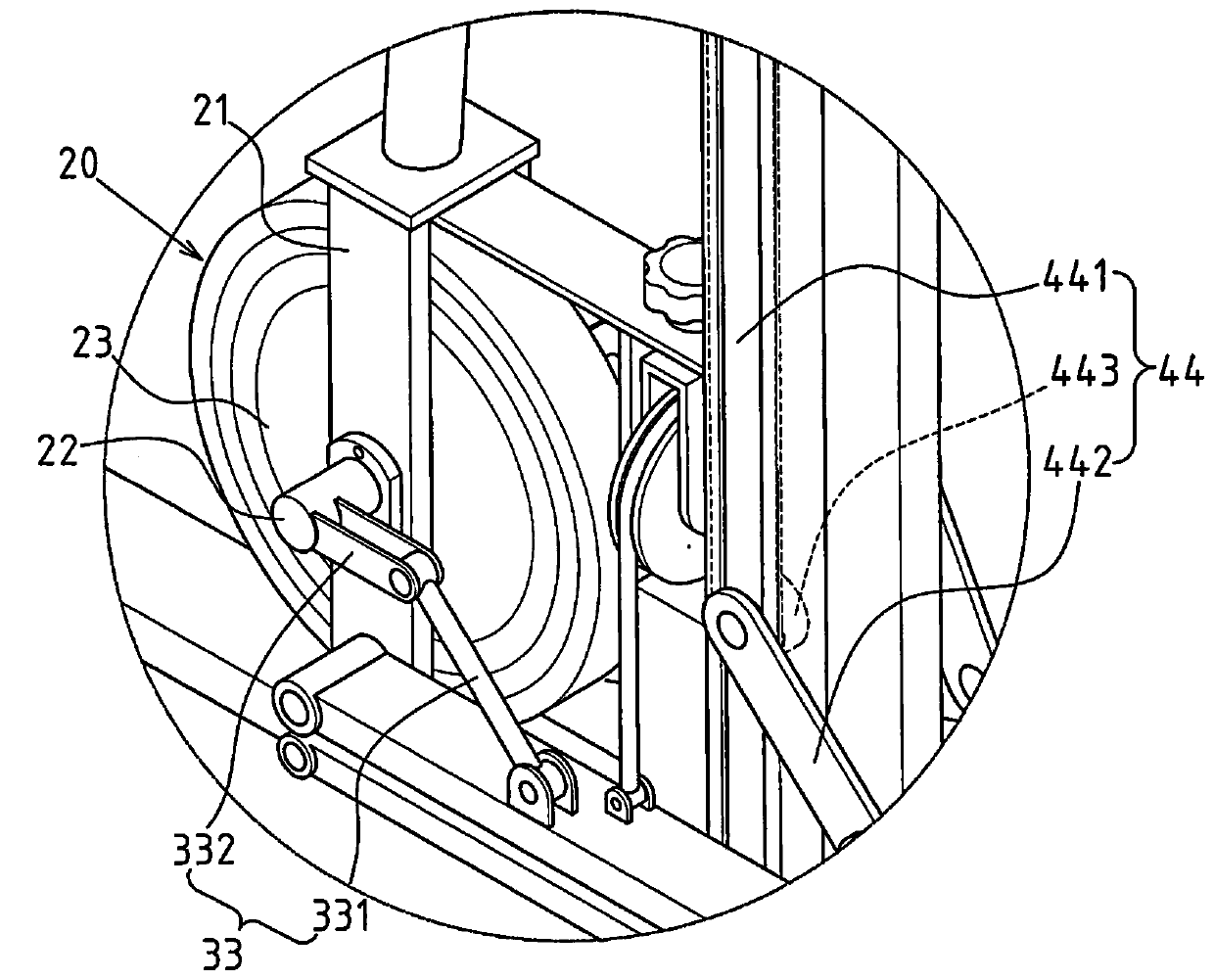

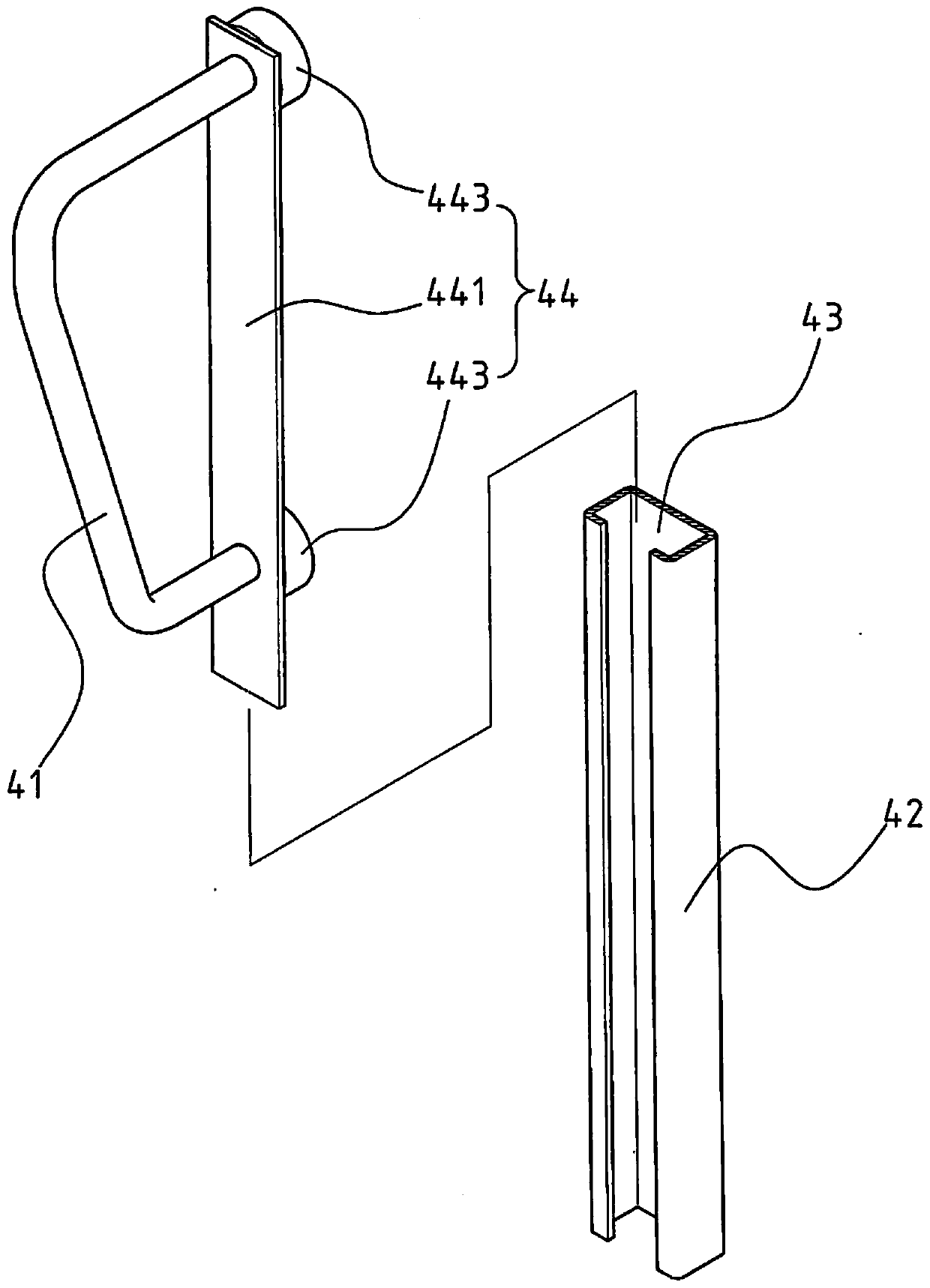

Magnetic attracting positioning type rotary platform

InactiveCN105459045AHigh strength positioning functionImprove responsivenessWork benchesLarge fixed membersMagnetic tension forceDrive shaft

The invention discloses a magnetic attracting positioning type rotary platform. The magnetic attracting positioning type rotary platform comprises a base, a rotary disc, an actuating device, a magnetic conduction positioning part, an electronic control magnetic attracting part and a speed change mechanism, wherein the base comprises a containing part, a top and a hollow containing part, and an installation seat is arranged at the bottom end of the hollow containing part. The rotary disc is assembled at the top of the base in a pivoted mode. The actuating device is arranged in the installation seat of the base, and a driving shaft rod is arranged at the top end of the actuating device. The magnetic conduction positioning part is arranged at the bottom of the rotary disc, extends into the hollow containing part of the base in a protruding mode and moves together with the rotary disc. The electronic control magnetic attracting part is assembled and positioned on the installation seat of the base, corresponds to the position below the magnetic conduction positioning part, and can be powered on to generate magnetism so that the magnetic conduction positioning part and the rotary disc can be attracted and positioned. The speed change mechanism is arranged between the top end of the actuating device and the bottom of the rotary disc. In this way, the magnetic attracting positioning type rotary platform achieves the function of high-strength positioning.

Owner:GMT GLOBAL

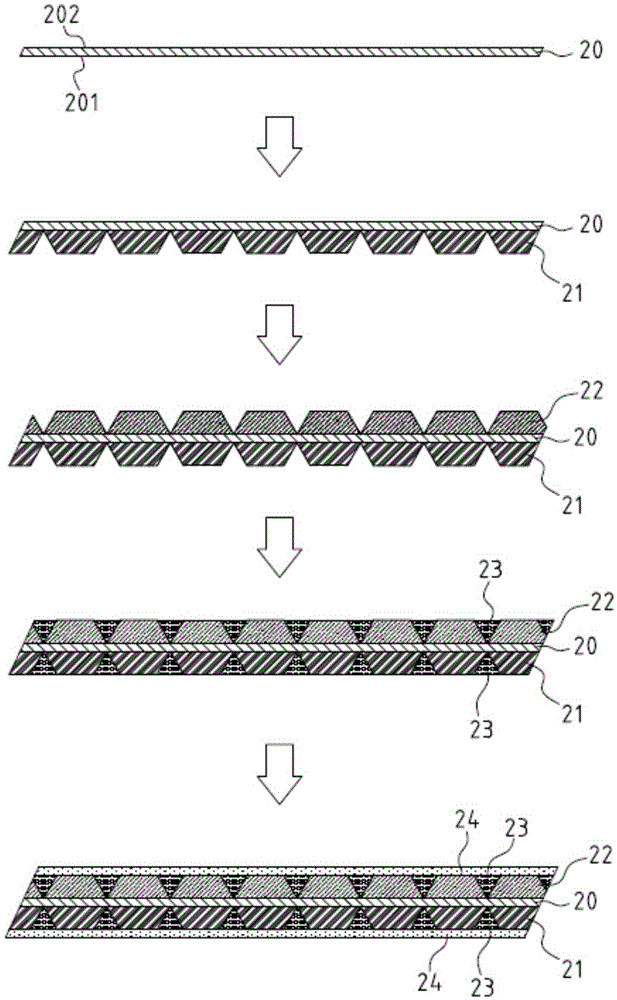

Forming method sheet material with hollow sandwich layer and die thereof

InactiveCN101456208AReduce weightReduce shipping and material costsMouldsSurface layering apparatusHollow coreSurface layer

The invention discloses a shaping method for a board with a hollow core layer and a mould, which is used for solving the problems that the prior board has a heavy structure, is not easy to move, has high transportation cost and material cost, and has no firmness and durability. The shaping method comprises the following steps: manufacturing the mould and coating a curing material first, removing the mould after solidification, combining a shaped concave-convex mask layer and a cover board into the hollow core layer, providing an enclosure mould to place the hollow core layer into a space of a core layer formed by the enclosure mould, and combining and fixing the hollow core layer and the enclosure mould through a surface layer material; and after solidification, separating and demoulding the hollow core layer, the surface layer material and the enclosure mould to obtain a board product. The shaping method is suitable for the board for manufacturing a stone facing table board.

Owner:杨淑芬

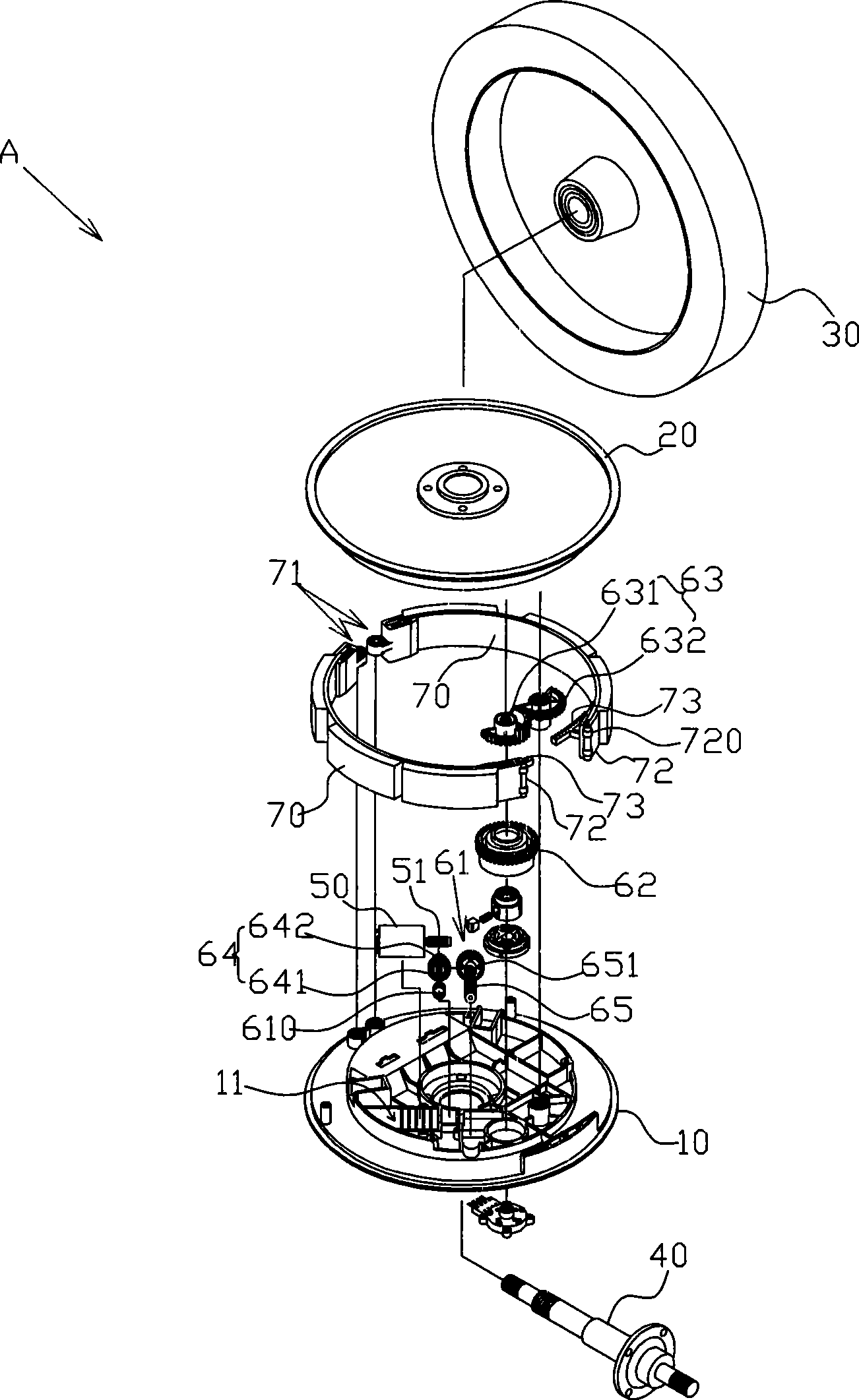

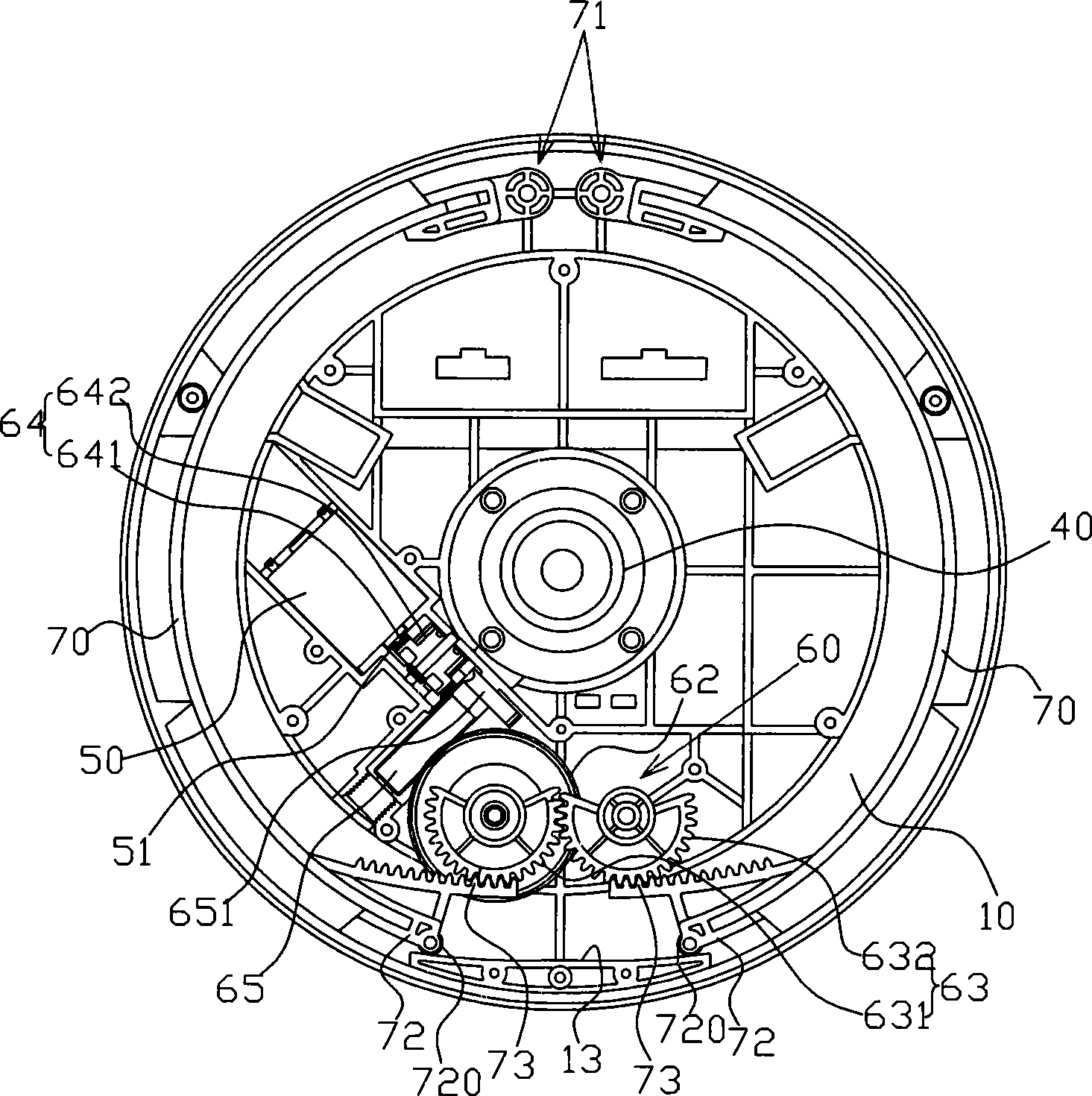

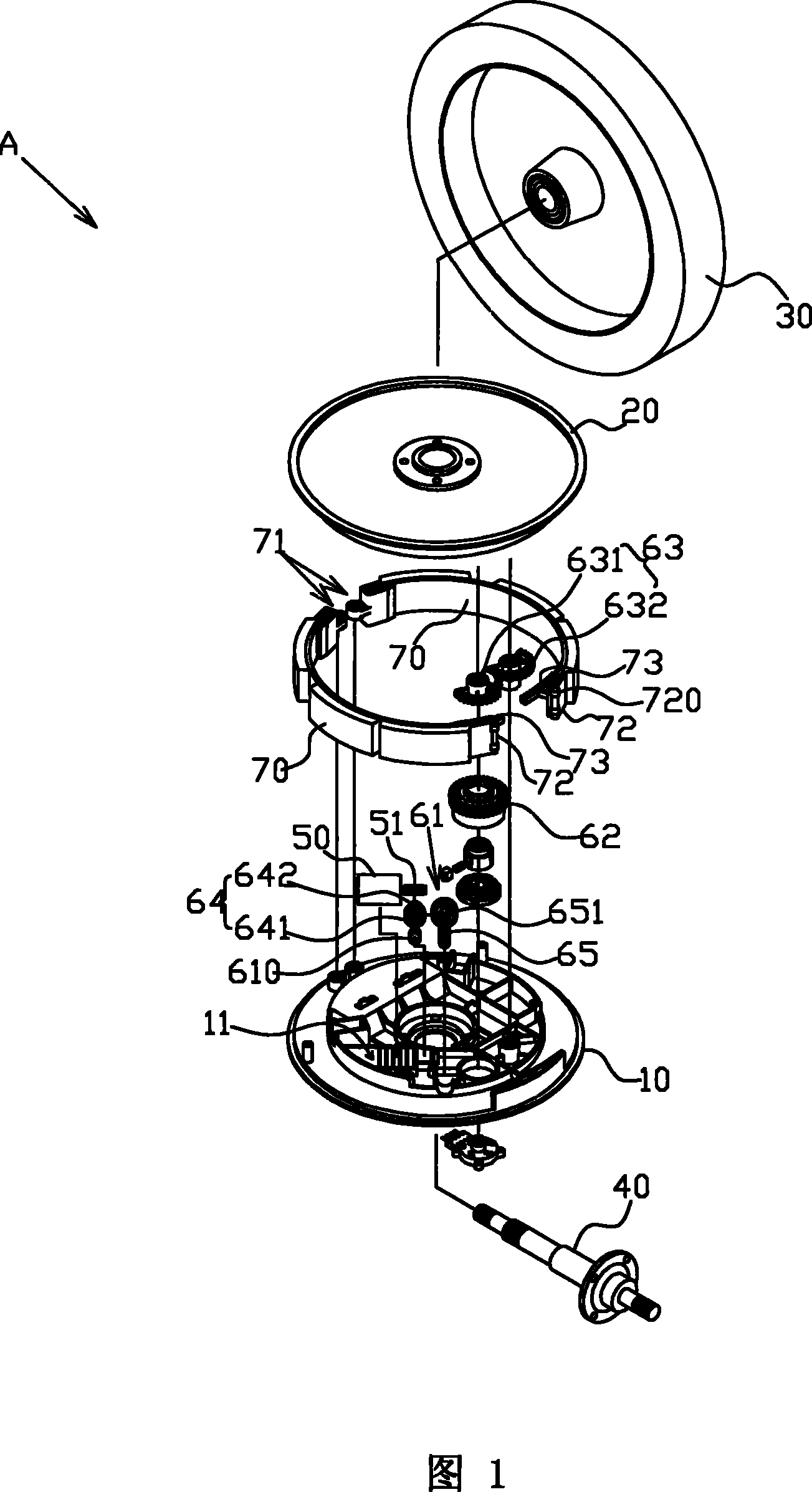

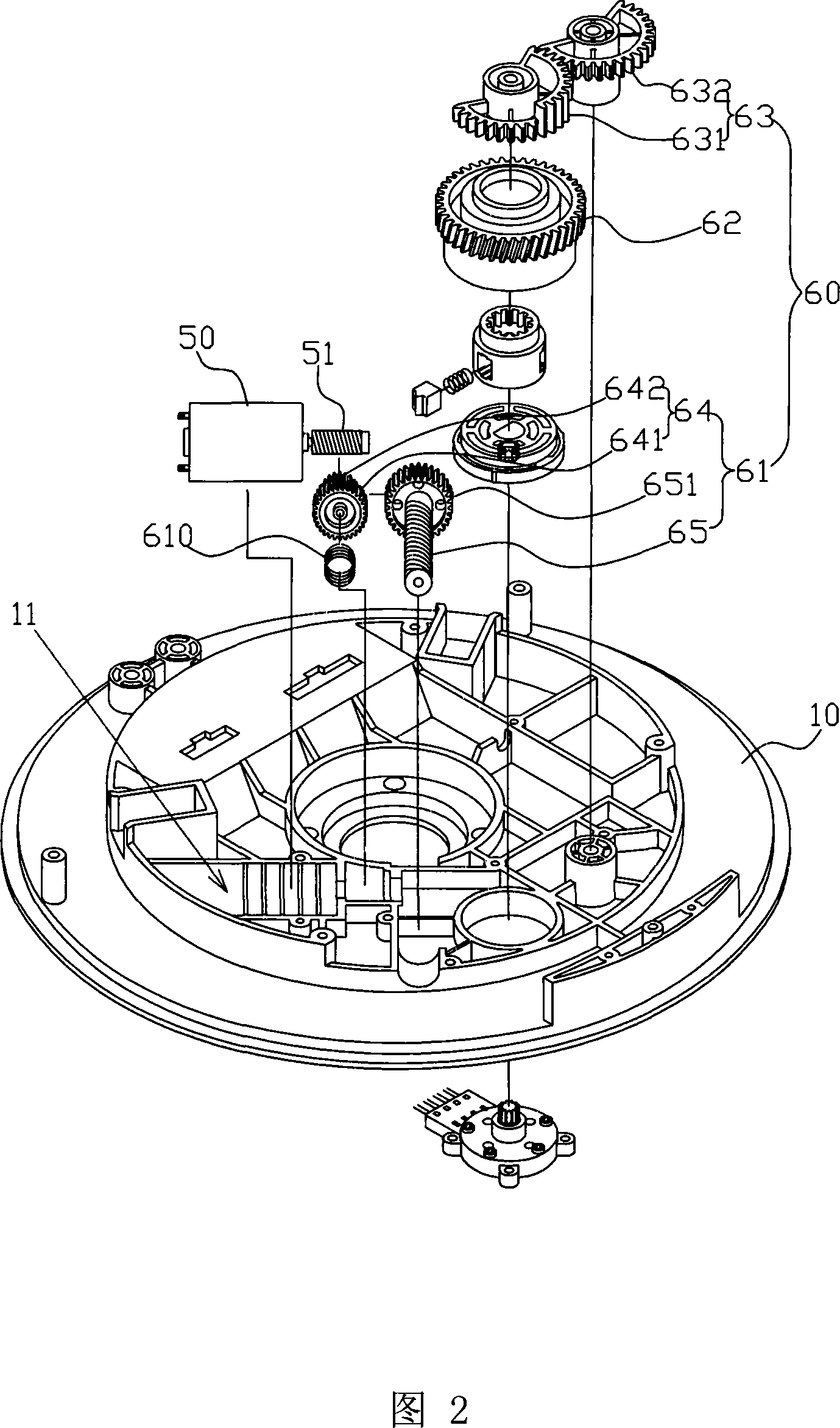

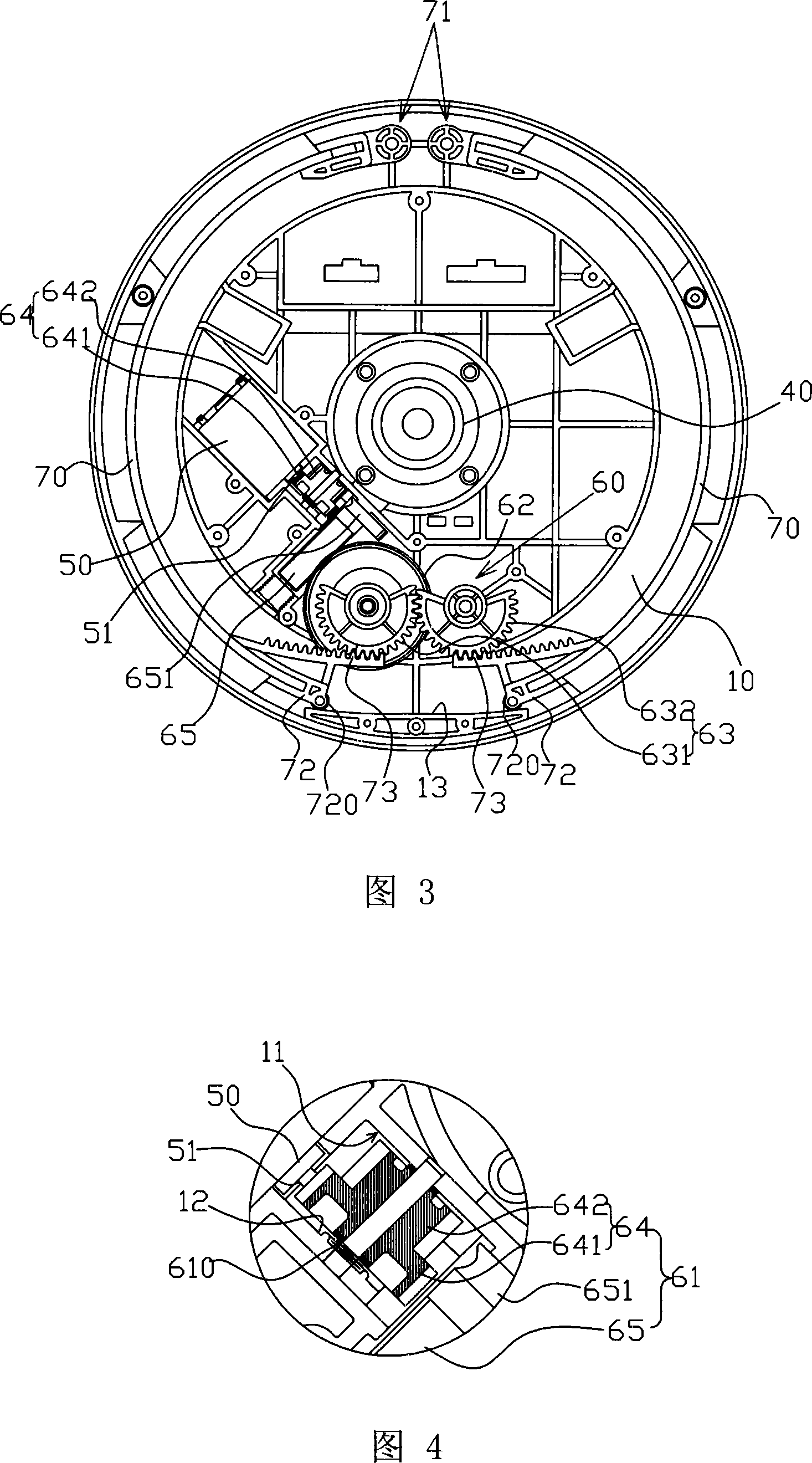

Magnetic-control wheel

InactiveCN101450247AReduce manufacturing difficultyReduce defective rateMuscle exercising devicesMagnetic tension forceGear wheel

The invention discloses a magnetic control wheel configuration for solving problem of high cost, poor action quality and high transfer resistance of the magnetic control wheel driving gear mechanism by using oblique cone mating surface shape; the magnetic control wheel includes a base body, a cover body, a flying wheel, a center axis, a driven motor, a transfer gear group and two magnetism control pieces; the transfer gear group includes a speed change turning group, an interlock piece and a rear gear; a setting axial direction of the interlock piece and the rear gear is same with the magnetic control center axis; a gear row set by two magnetism control pieces mesh transmit with the rear gear together, a spur gear meshing shape is in between the rear gear and the gear row set by the magnetic control piece; a spring component is top braced between one axial end of the speed change turning group of the transfer gear group and one resistance piece of the base body containing space mutually. The magnetic control wheel configuration can be used in sports facility configuration.

Owner:HER YUAN CHYUN

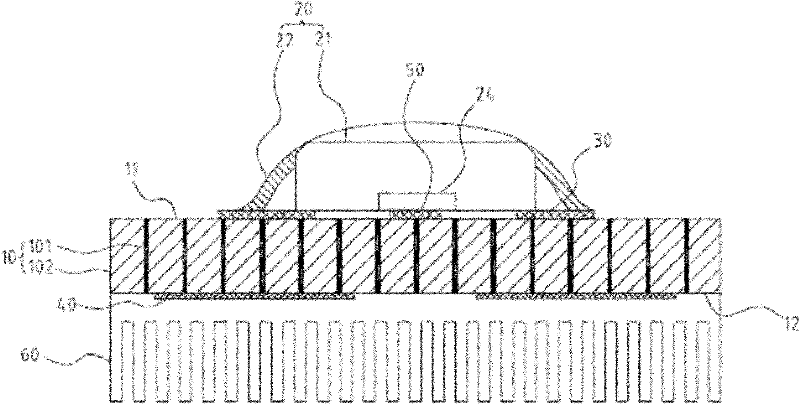

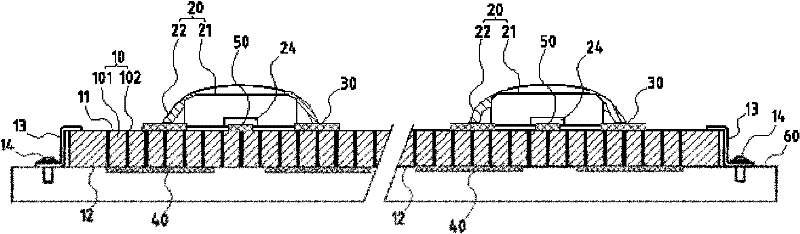

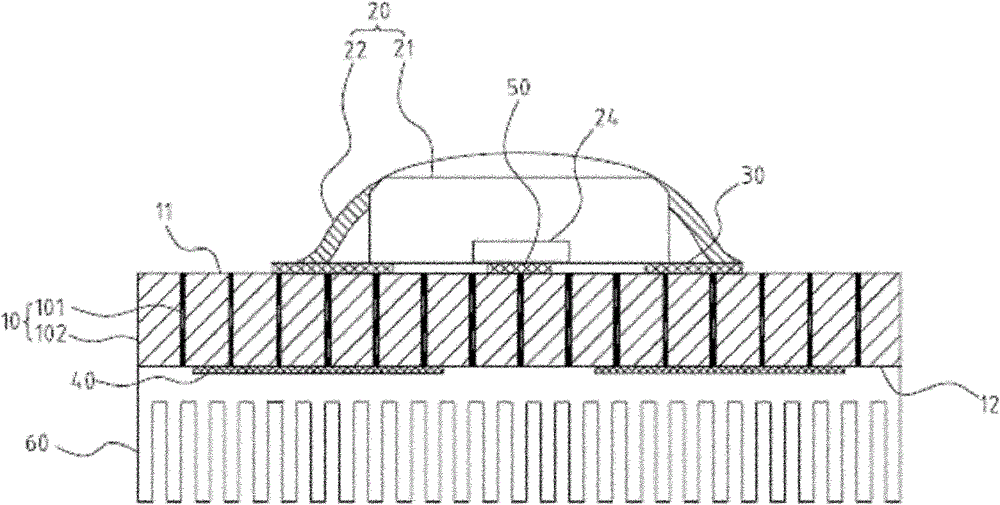

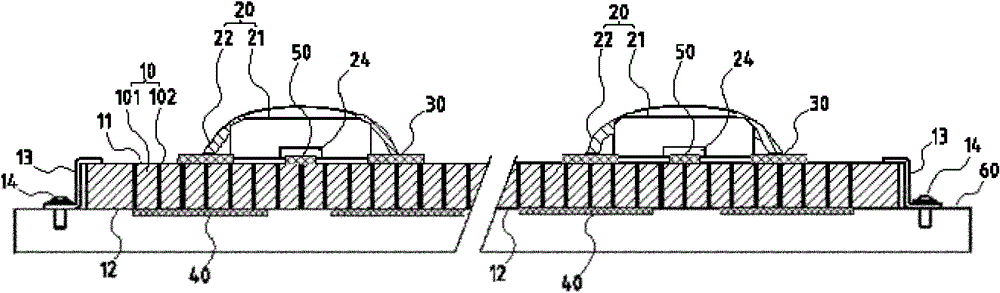

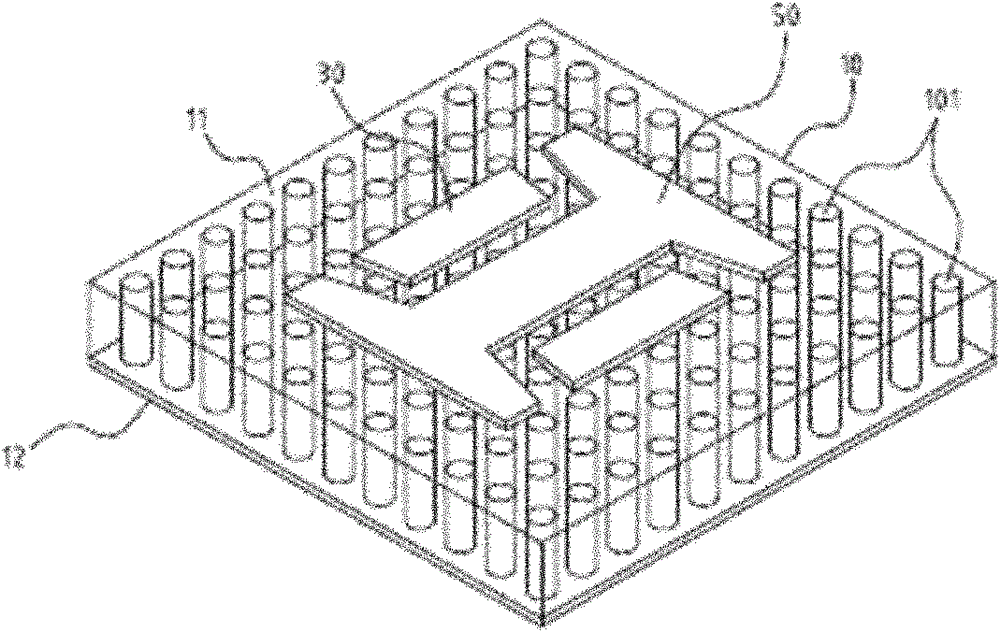

Heat-conducting substrate and radiating module structure of LED (light-emitting diode)

ActiveCN102412365AFast conductionThe industry has good economic benefitsSemiconductor devicesFiberHeat conducting

The invention provides a heat-conducting substrate and a radiating module structure of an LED (light-emitting diode). The heat-conducting substrate comprises a composite-material heat-conducting substrate formed by combination of a plurality of heat-conducting lines or fibers and an insulating material; the heat-conducting lines or fibers are distributed at intervals, penetrate through the front surface and the back surface of the composite-material heat-conducting substrate and are separated by the insulating material; electrode welding pads are combined on the front surface of the composite-material heat-conducting substrate so as to form electric connection with electrode pins of an LED member, and heat-conducting welding pads are also combined on the front surface of the composite-material heat-conducting substrate so as to form heat-conducting contact with heat-sink parts of an LED component of the LED member; and insulating layers corresponding to the electrode welding pads are combined on the back surface of the composite-material heat-conducting substrate. In the invention, the characteristics with high heat conductivity in the thickness direction but insulation in the plane direction can be achieved by a simple structure, so that the heat can be quickly conducted to a radiating member. The invention can be used for high-brightness LED illuminating products.

Owner:HO CHENG INDUSTRIAL CO LTD

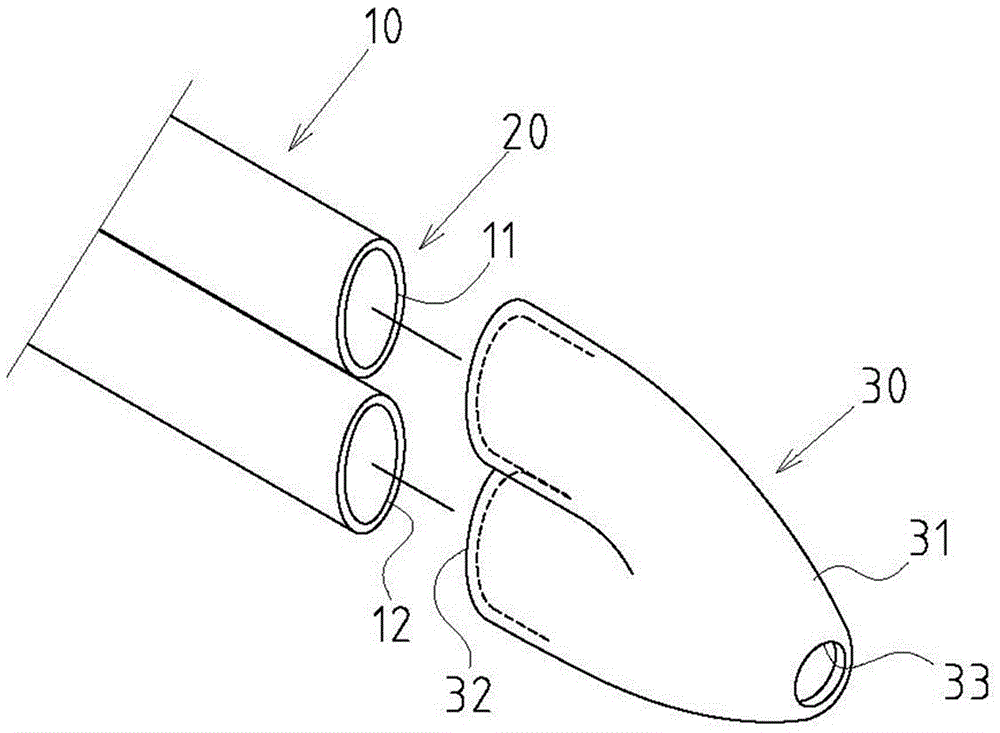

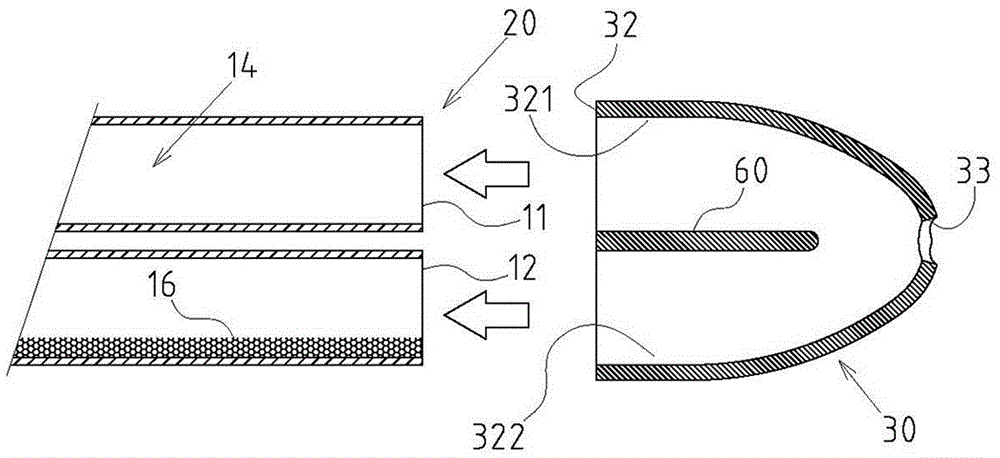

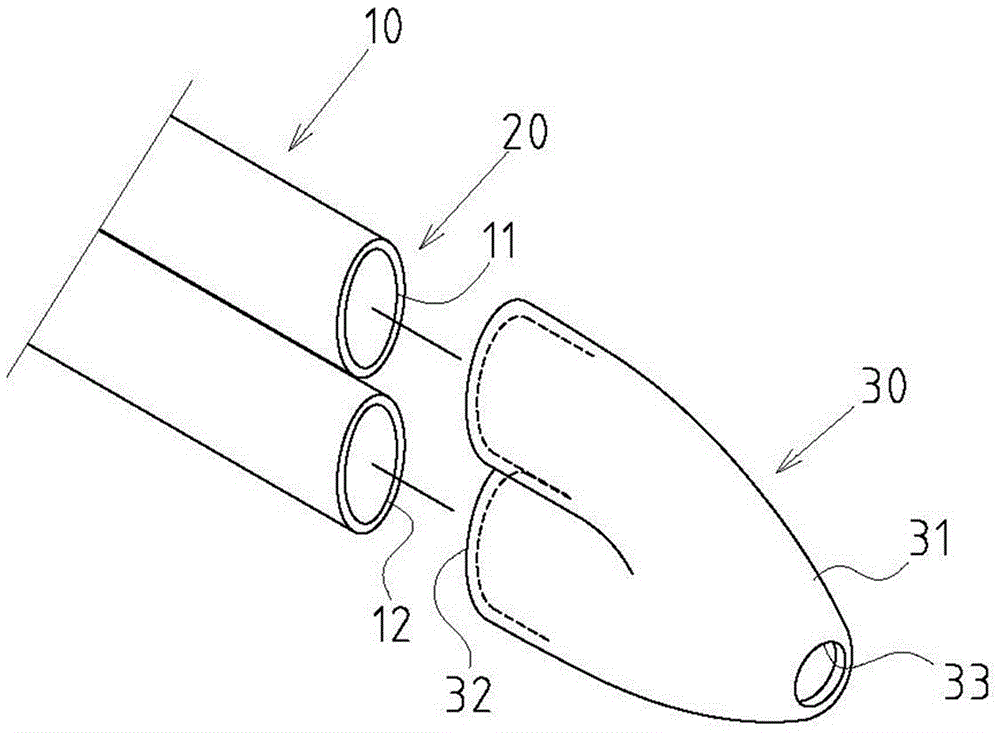

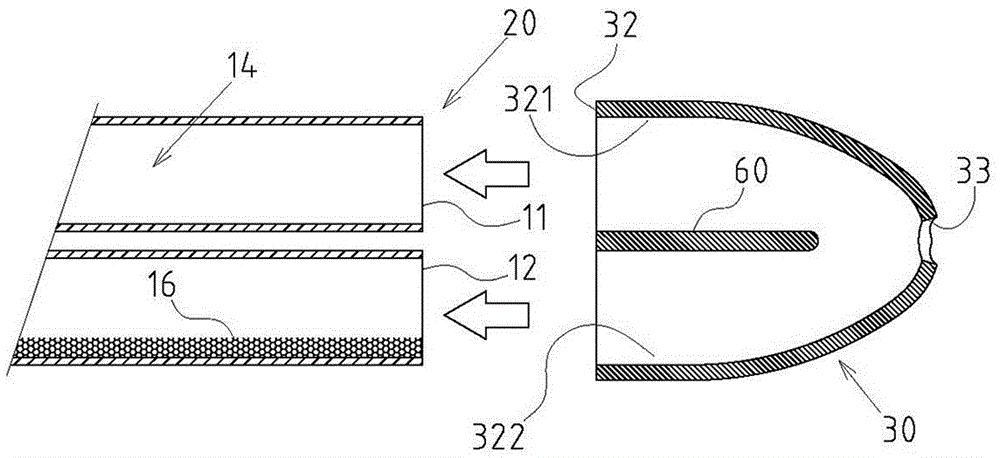

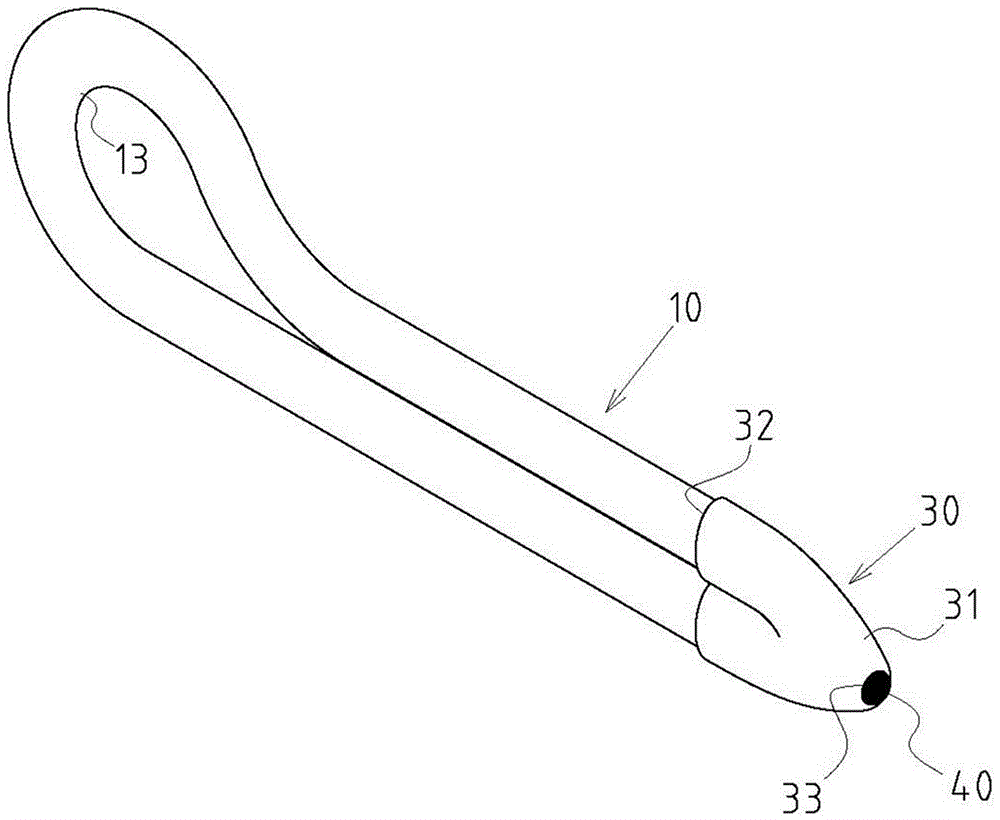

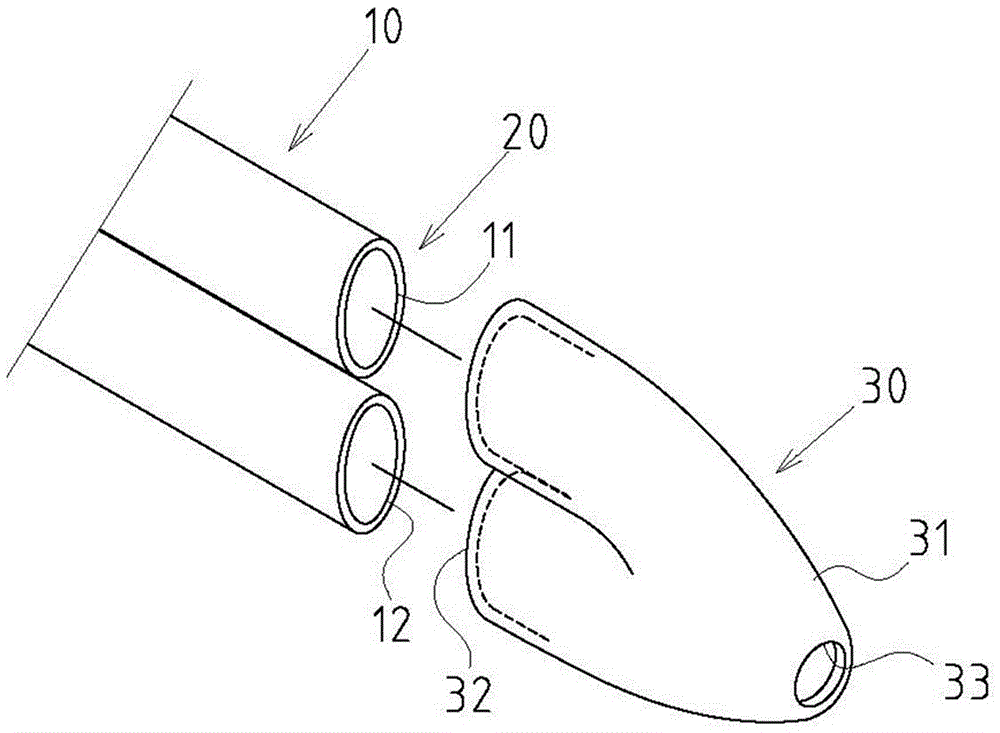

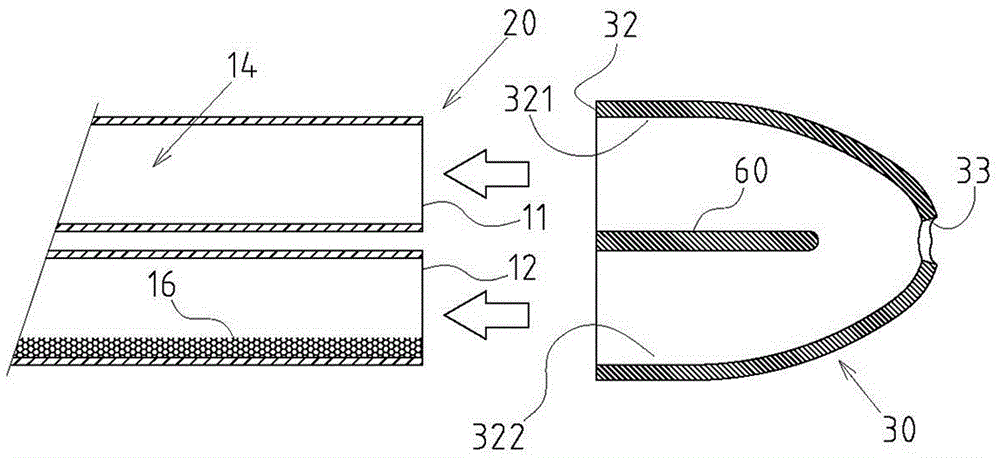

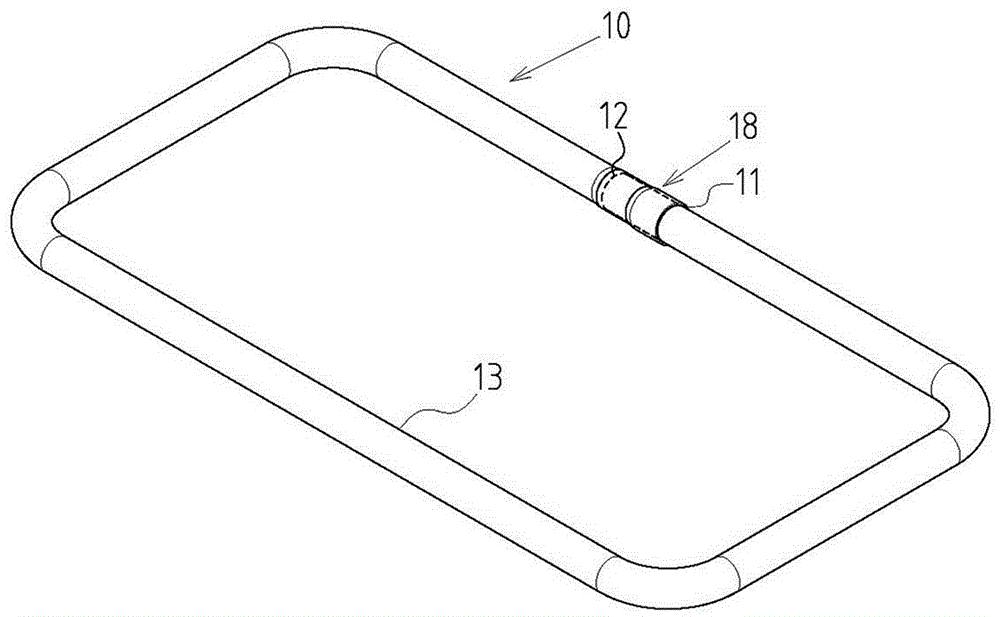

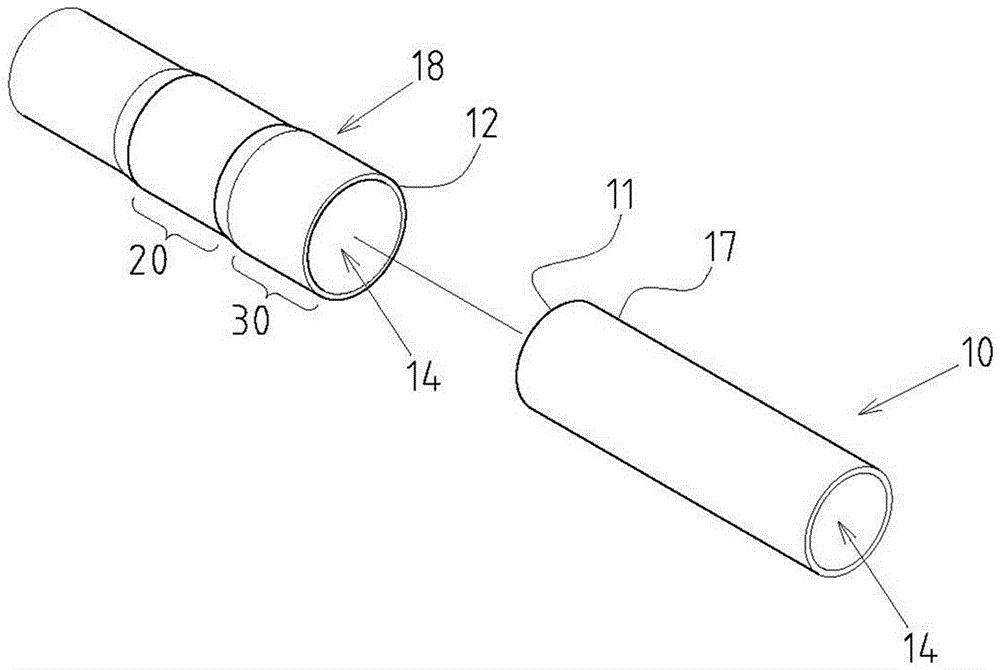

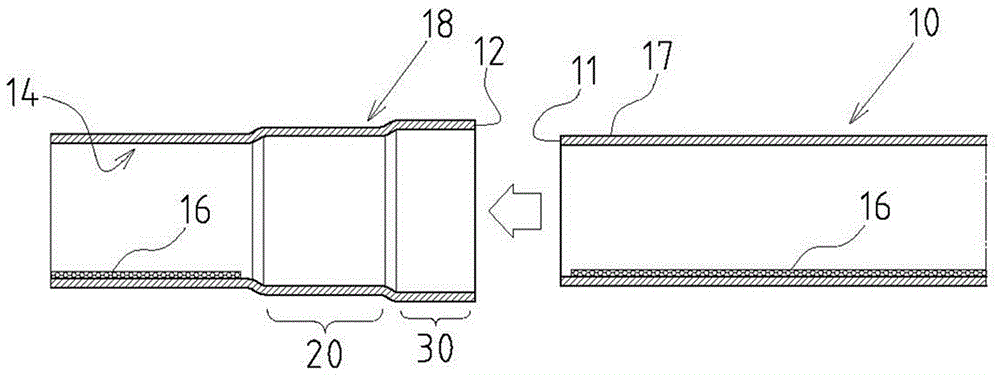

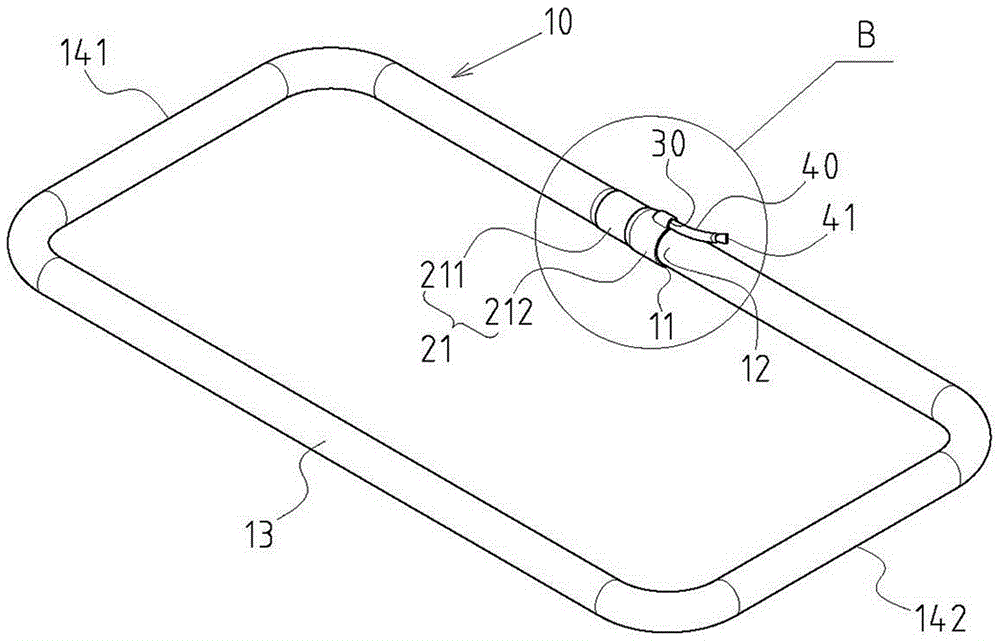

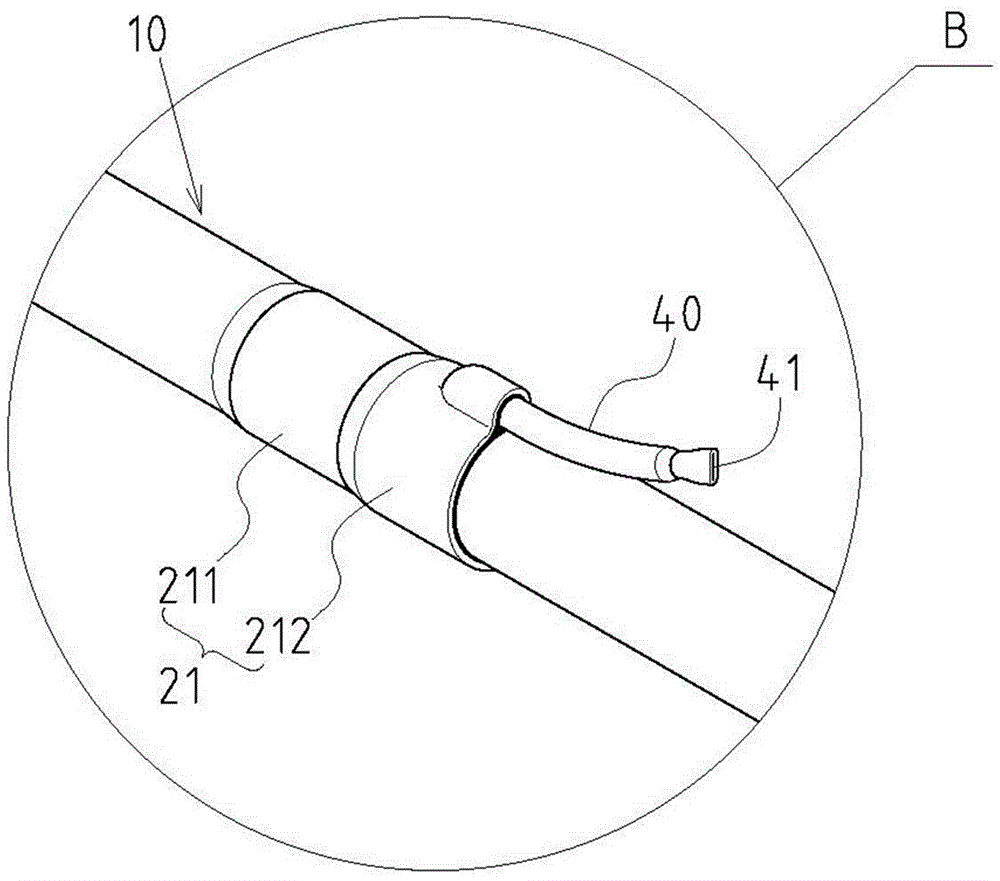

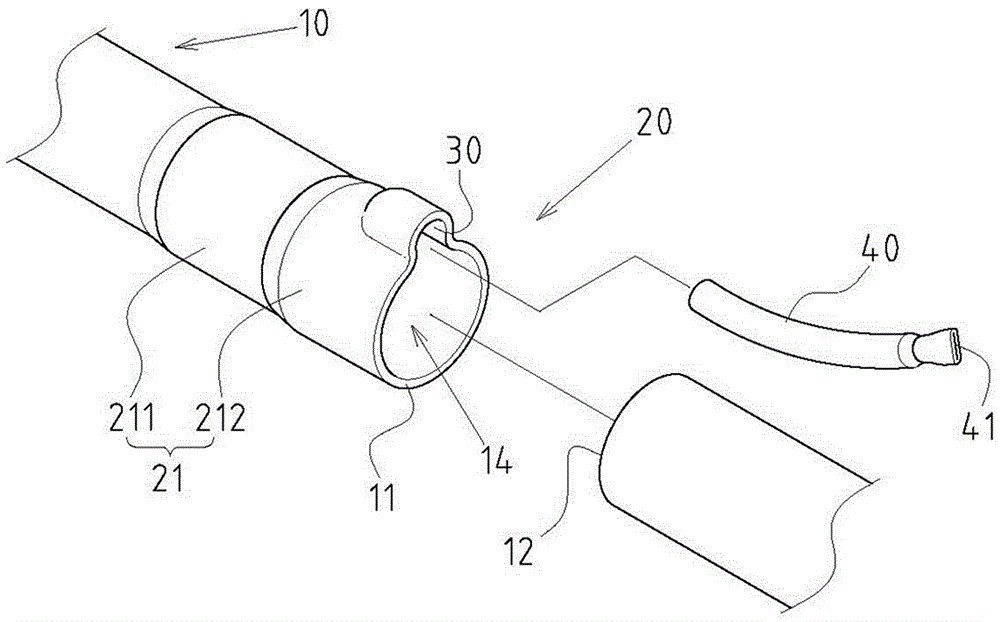

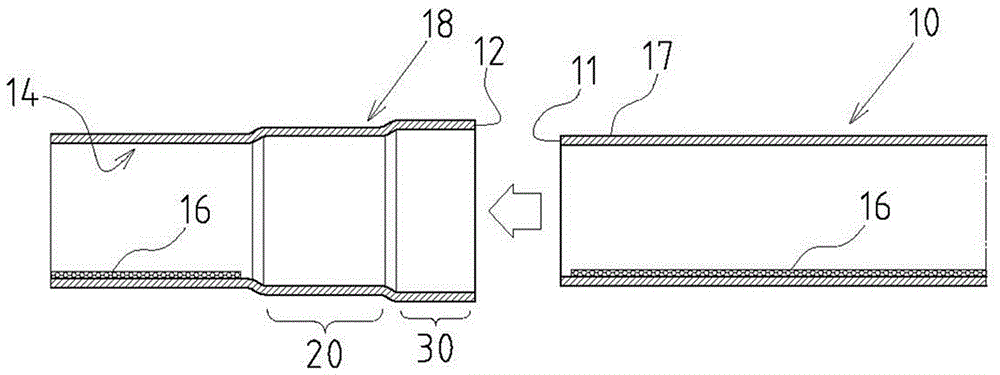

Parallel combining connecting part end cover closing structure of loop type heat pipe

InactiveCN106052449ASimple manufacturing, processing and moldingReduce manufacturing costIndirect heat exchangersVacuum pumpingWorking fluid

A parallel combining connecting part end cover closing structure of a loop type heat pipe is characterized by mainly comprising a hollow pipe body, a parallel combining connecting part and a closing end cover, wherein the hollow pipe body is bent into an inflection state and comprises two pipe end openings and a loop type section, inner runner space of the hollow pipe body comprises an evaporation section and a condensation section and contains working fluid, and at least the evaporation section is provided with a capillary structure; the parallel combining connecting part is formed in the state that the two pipe end openings of the hollow pipe body are the same in direction, and main pipe bodies are arranged in parallel; and the closing end cover is in a cap cover form and comprises a closing end and a sleeving and combining end, the sleeving and combining end comprises at least one sleeving opening so as to conduct sleeving and combining on the two pipe end openings of the parallel combining connecting part in an airtight state, the closing end is provided with an air removing hole, and after finishing the vacuum pumping and air removing state in the inner runner space in the hollow pipe body, the air removing hole is closed into a closed state. The parallel combining connecting part end cover closing structure has practical advancement that manufacturing, machining and forming are easier, and the manufacturing cost is reduced, and the good airtight effect is integrated and also has good industrial economic benefits.

Owner:SUZHOU FORCECON ELECTRIC

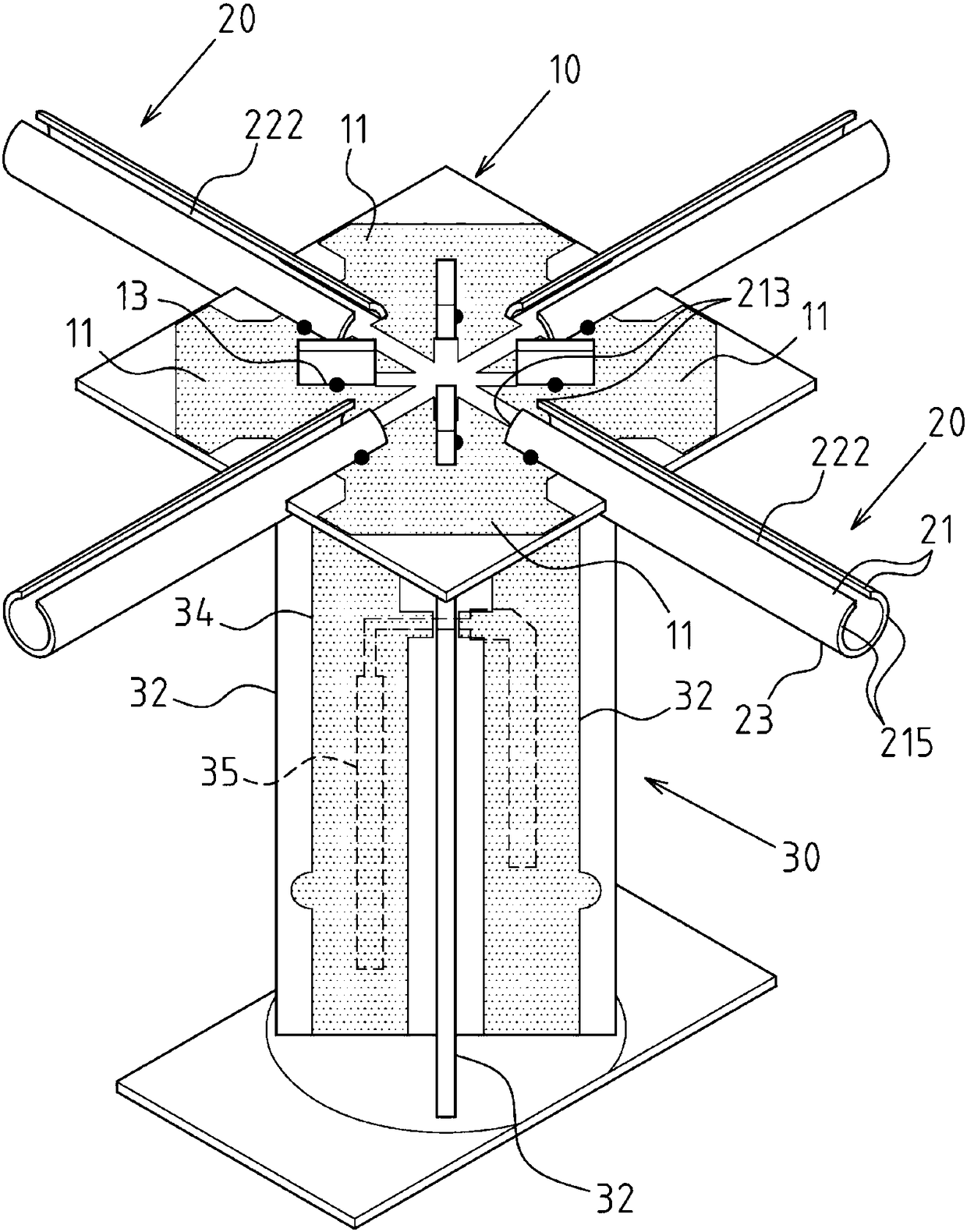

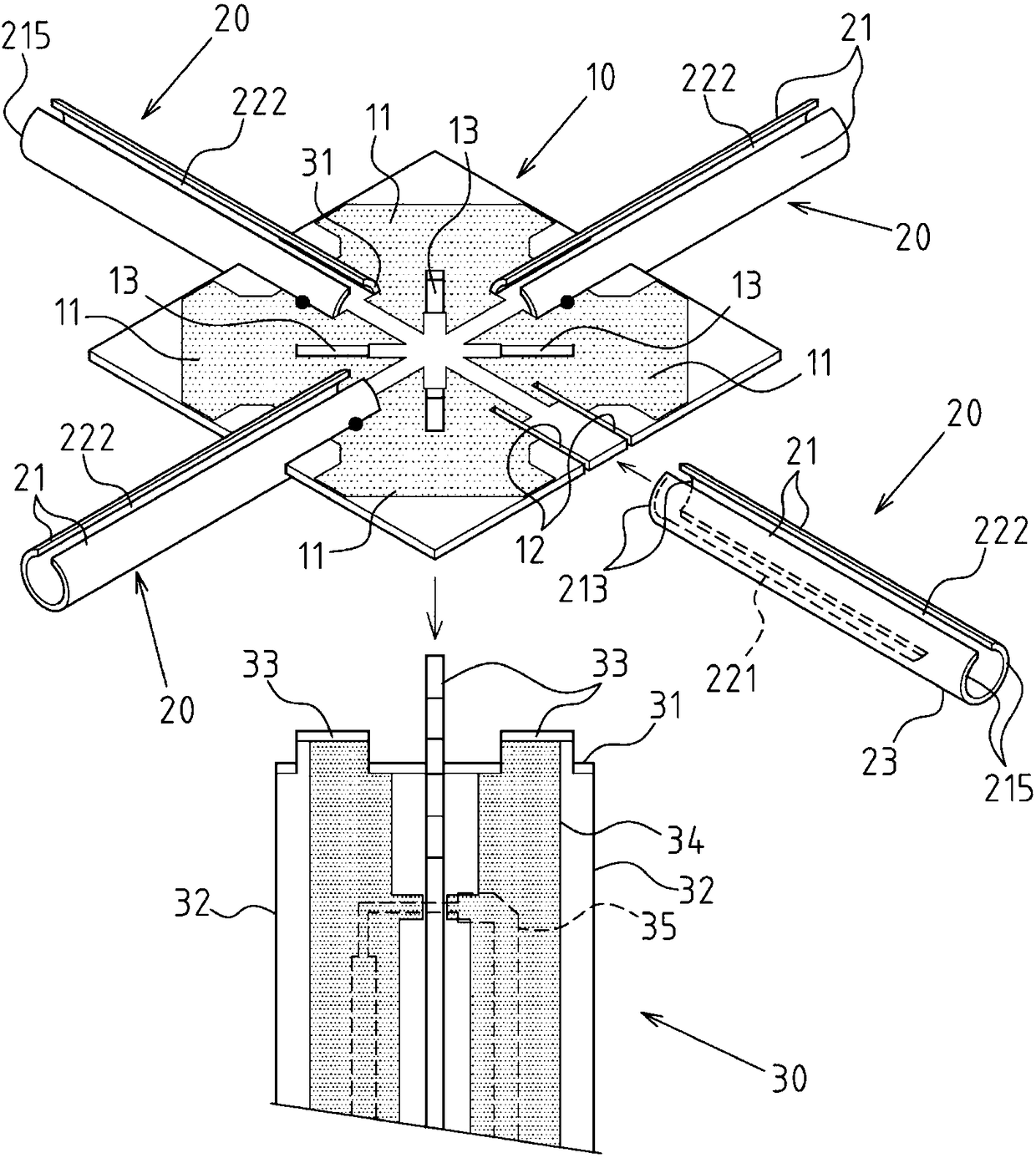

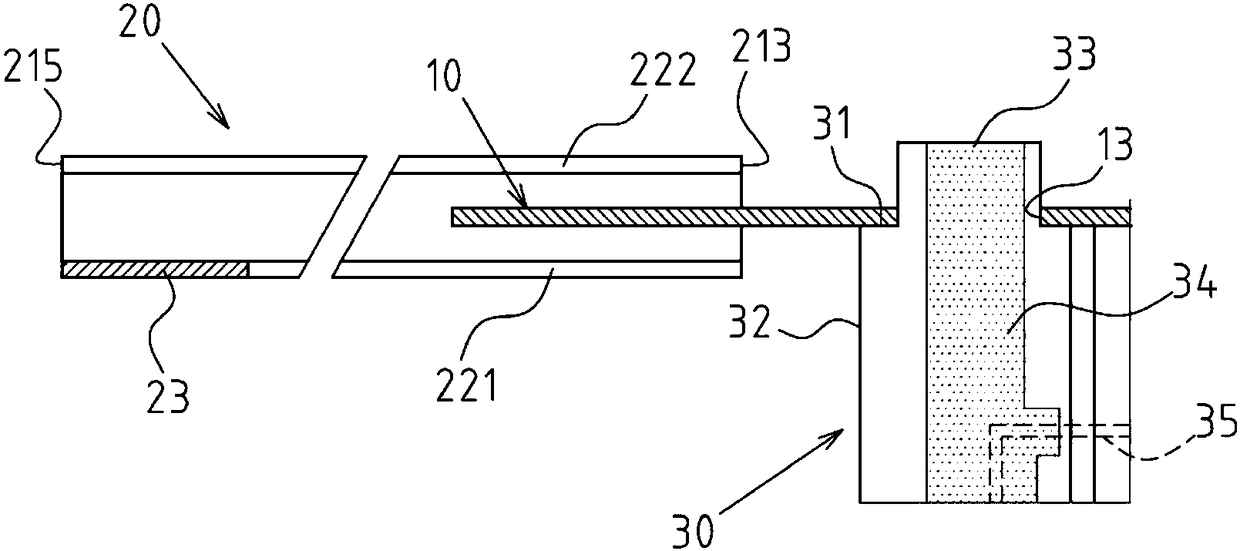

Dipole antenna oscillator

InactiveCN109390664AImprove practical progressSimple componentsAntenna arraysAntenna supports/mountingsPower flowFull wave

The present invention discloses a dipole antenna oscillator. The dipole antenna oscillator comprises a power distribution member provided with a plurality of power distribution blocks; and a pluralityof radiation racks arranged at the circumference side of the power distribution member, each radiation rack comprises two coupling arms arranged at intervals and respectively provided with electricalconnection ends connected with the adjacent power distribution blocks, first and second isolation gaps are formed between the two coupling arms, the portion from the electrical connection ends to theextension ends of the coupling arms forms a current path with a quarter wave length, a half wave length or a full wave length corresponding to a first isolation gap tail end to allow the length of the current path formed at the second isolation gap tail end to be larger than the length of the current path formed at the first isolation gap tail end; the two adjacently arranged radiation racks arerespectively provided with the coupling arms, the coupling arms and the power distribution member are electrically connected with the corresponding same power distribution block to commonly constructand form the radiation member.

Owner:WHA YU IND CO LTD +1

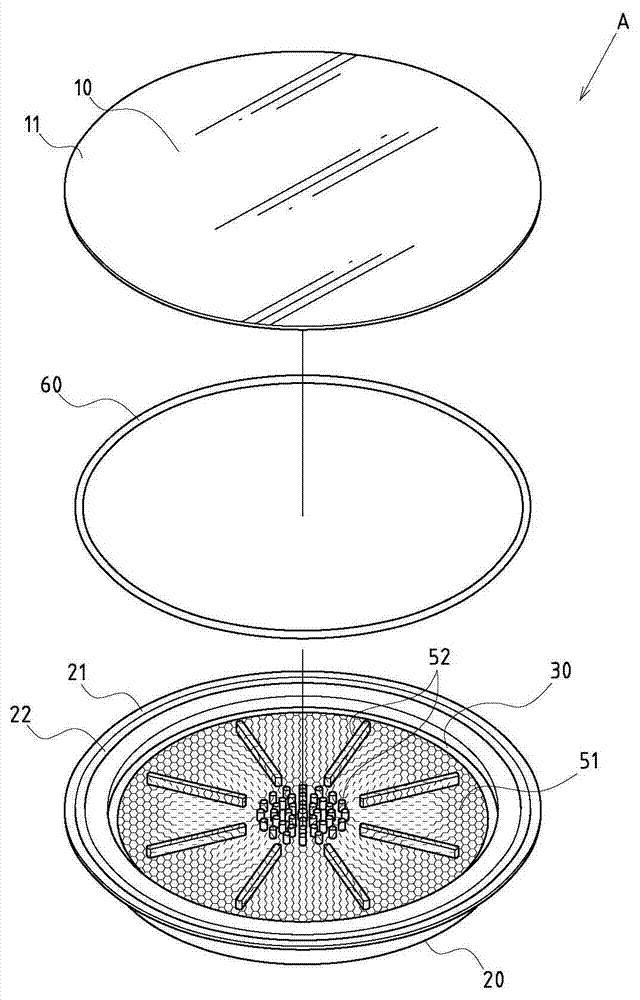

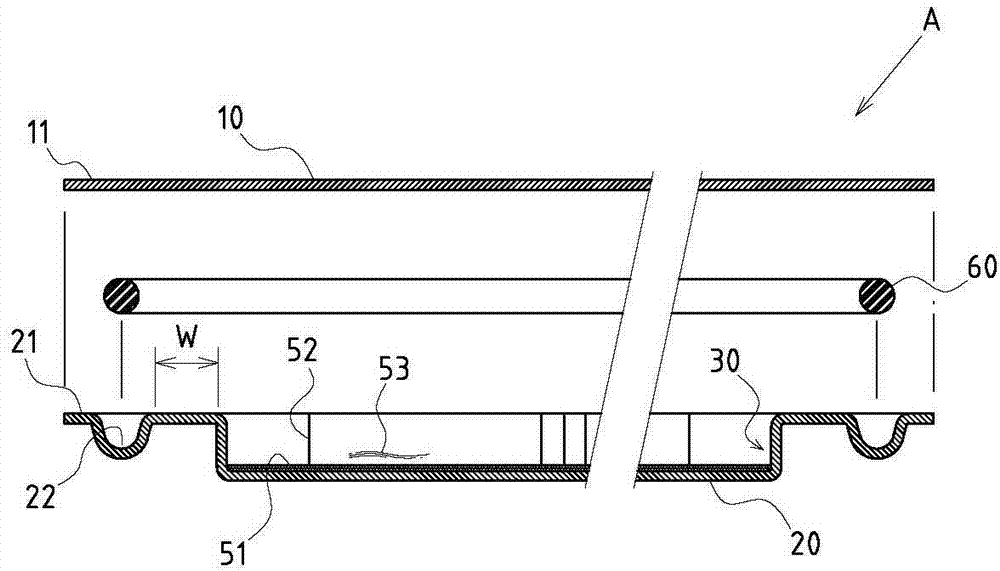

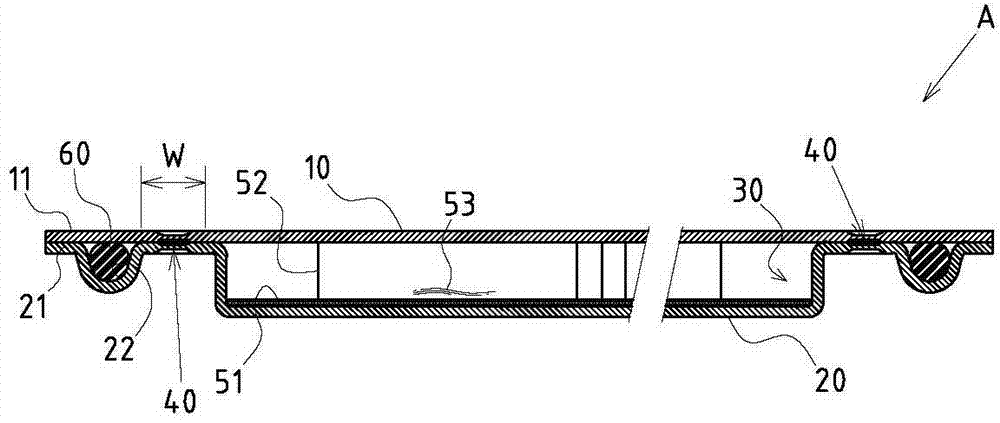

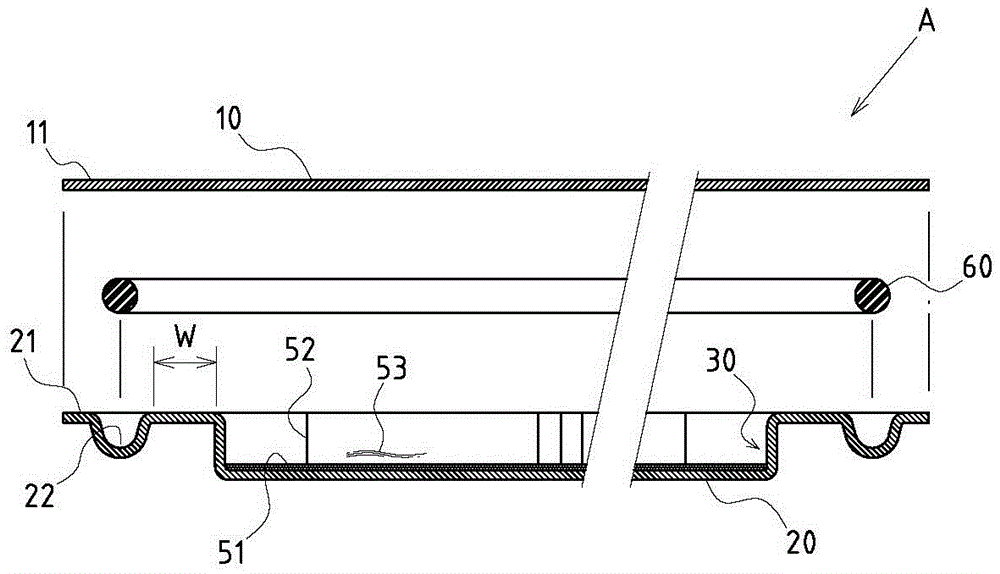

Vacuum sealing structure of uniform heat conductor and making method thereof

InactiveCN104121798ASimplify the manufacturing processReduce manufacturing costIndirect heat exchangersManufacturing cost reductionEngineering

A vacuum sealing structure of a uniform heat conductor and a making method thereof; an upper cover plate and a lower cover plate are arranged; a periphery of the upper cover plate is provided with an upper sealing annular edge; a periphery of the lower cover plate is provided with a lower sealing annular edge having an annular slot; an elastic stop sealing ring is assembled in the annular slot; the upper and lower cover plates are placed in a vacuum device, so the upper cover plate is clamped on the lower cover plate in vacuum environment condition; when the upper cover plate covers on the lower cover plate, the elastic stop sealing ring can be pressed to deform and expand, so sealing state can be formed between the upper and lower sealing annular edges; the upper and lower cover plates are then removed, and inner intervals of the elastic stop sealing ring positions of the upper and lower sealing annular edges are welded and bonded in an annular continuous welding mode, thus forming a solderless annular continuous welding bonding portion in a continuous annular welding bonding state; the vacuum sealing structure has simplified production process, reduces making cost, has practical advanced feature and better industry economic benefits.

Owner:SUZHOU FORCECON ELECTRIC

Novel parallel combining connecting part end cover closing structure of loop type heat pipe

InactiveCN106052448ASimple manufacturing, processing and moldingReduce manufacturing costIndirect heat exchangersHeat exhanger sealing arrangementVacuum pumpingWorking fluid

A novel parallel combining connecting part end cover closing structure of a loop type heat pipe is characterized by mainly comprising a hollow pipe body, a parallel combining connecting part and a closing end cover, wherein the hollow pipe body is bent into an inflection state and comprises two pipe end openings and a loop type section, inner runner space of the hollow pipe body comprises an evaporation section and a condensation section and contains working fluid, and at least the evaporation section is provided with a capillary structure; the parallel combining connecting part is formed in the state that the two pipe end openings of the hollow pipe body are the same in direction, and main pipe bodies are arranged in parallel; and the closing end cover is in a cap cover form and comprises a closing end and a sleeving and combining end, the sleeving and combining end comprises at least one sleeving opening so as to conduct sleeving and combining on the two pipe end openings of the parallel combining connecting part in an airtight state, the closing end is provided with an air removing hole, and after finishing the vacuum pumping and air removing state in the inner runner space in the hollow pipe body, the air removing hole is closed into a closed state. The novel parallel combining connecting part end cover closing structure has practical advancement that manufacturing, machining and forming are easier, and the manufacturing cost is reduced, and the good airtight effect is integrated and also has good industrial economic benefits.

Owner:SUZHOU FORCECON ELECTRIC

Parallel arrangement connection portion and end cover sealing structure for loop type heat pipe

InactiveCN106091761ASimple manufacturing, processing and moldingReduce manufacturing costIndirect heat exchangersWorking fluidEconomic benefits

A parallel arrangement connection portion and end cover sealing structure for a loop type heat pipe is characterized by mainly comprising a hollow pipe body, a parallel arrangement connection portion and a sealing end cover, wherein the hollow pipe body is bent into the inflection form and comprises two pipe end openings and a loop type section, a runner space in the hollow pipe body comprises an evaporation section and a condensation section and contains working fluid, and a capillary structure is at least arranged at the evaporation section; the parallel arrangement connection portion is formed in the form that the two pipe end openings passing the hollow pipe body are the same in orientation, and pipe bodies are arranged in parallel; the sealing end cover is in the form of a cap cover and comprises a sealing end and a nesting arrangement end, the nesting arrangement end comprises at least one nesting opening and the two pipe end openings which are arranged on the parallel arrangement connection portion in a nesting arrangement manner and are in an airtight state, the sealing end is provided with an air removal hole, and the air removal hole is sealed to be in the airtight form after completing the vacuumizing air removal state in the runner space in the hollow pipe body. The parallel arrangement connection portion and end cover sealing structure has the practical progressiveness that manufacturing, machining and forming are easier, manufacturing cost is lowered, and the airtightness effect is good and the good industrial economic benefits.

Owner:SUZHOU FORCECON ELECTRIC

Cold and hot balancing ceramic valve

ActiveCN103047446AReduce manufacturing costPractical progressMultiple way valvesMetallurgyEconomic benefits

The invention discloses a cold and hot balancing ceramic valve which is characterized in that under the condition that the outer diameter and height of a valve casing and a high-leg base meet the existing system specification condition of a ceramic valve product, a water inlet pipe accommodating groove is arranged at the bottom ends of a cold water hole and a hot water hole of the high-leg base and used for arranging a combined water inlet pipe group arranged in inclined mode. The combined water inlet pipe group is formed by a cold water pipe body and a hot water pipe body. Adjacent sides of the hot water pipe body and the cold water pipe body are opposite and combined to form a balancing valve accommodating space inside the adjacent sides, and the balancing valve accommodating space is used for accommodating a cold and hot balancing valve construction member. A cold and hot balancing ceramic valve structure capable of being applied to the existing system ceramic valve specification generally is provided, manufacture cost of the cold and hot balancing ceramic valve is greatly reduced, a cold and hot balancing function is achieved, practicality advancement and better industrial economic benefit are achieved.

Owner:童炳荣

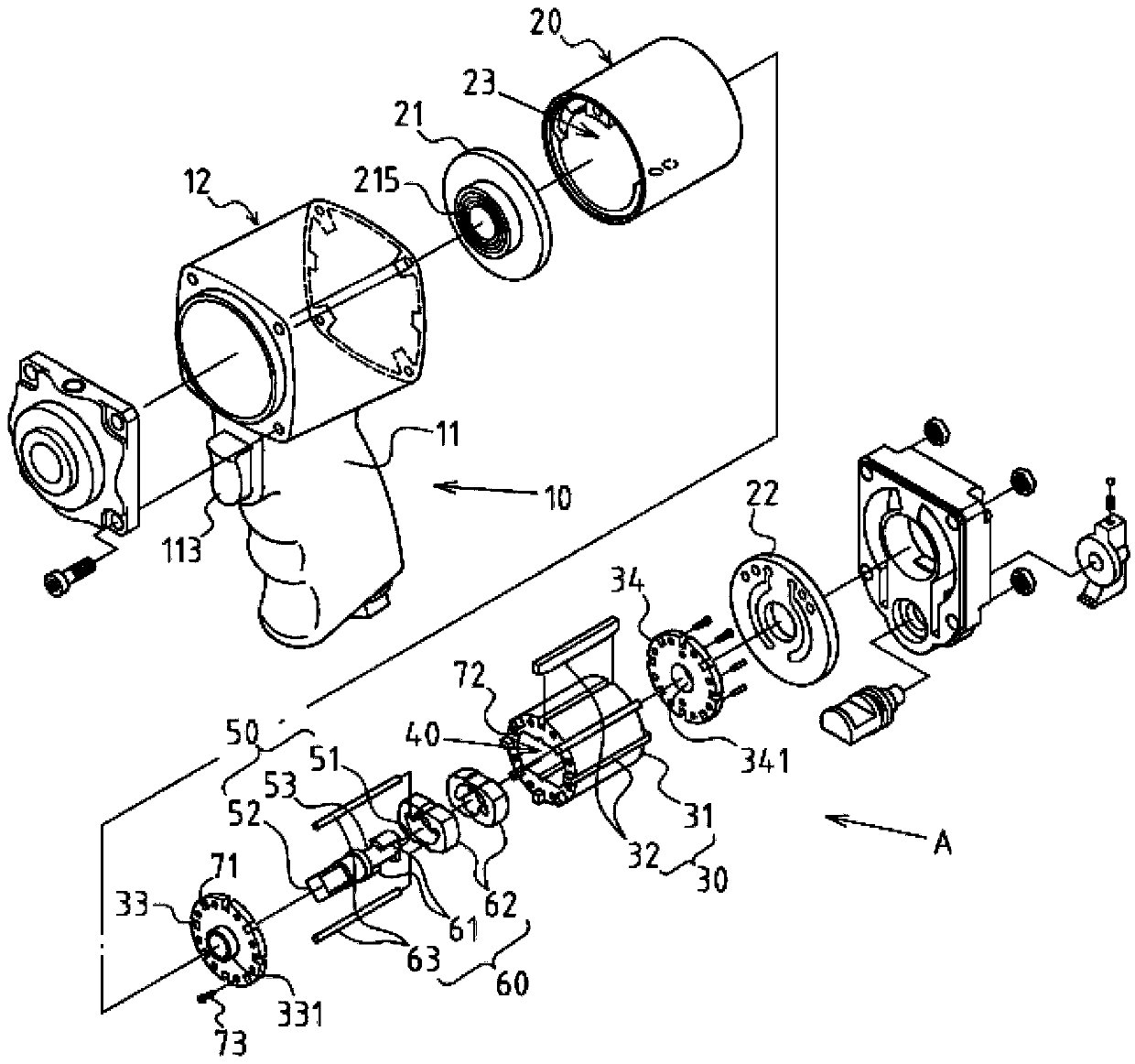

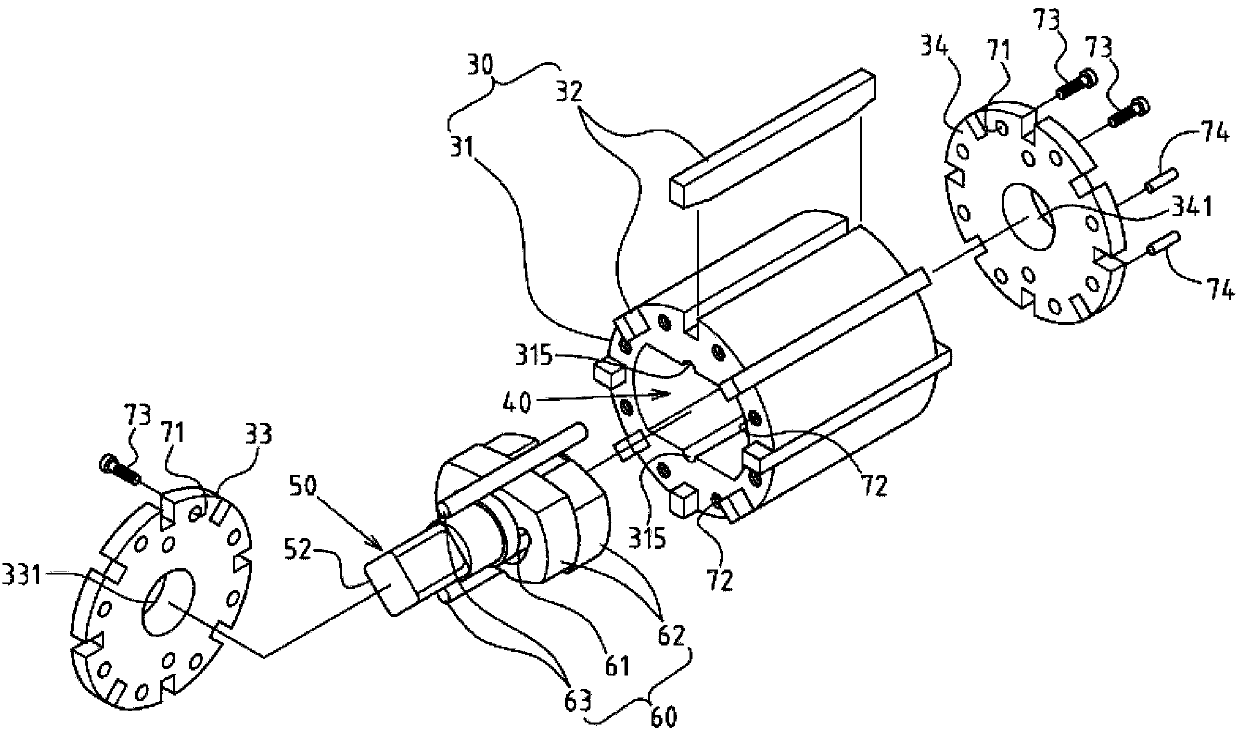

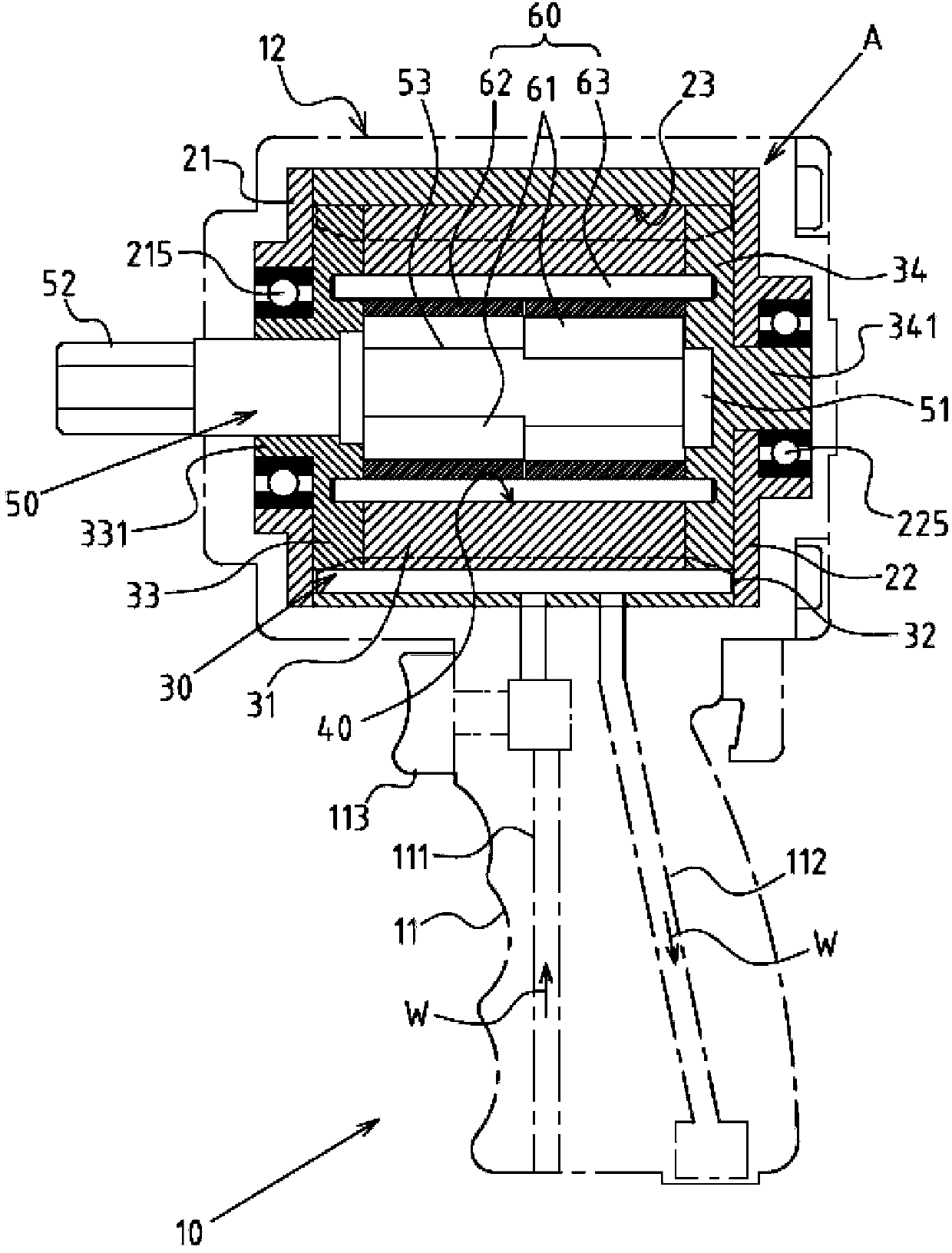

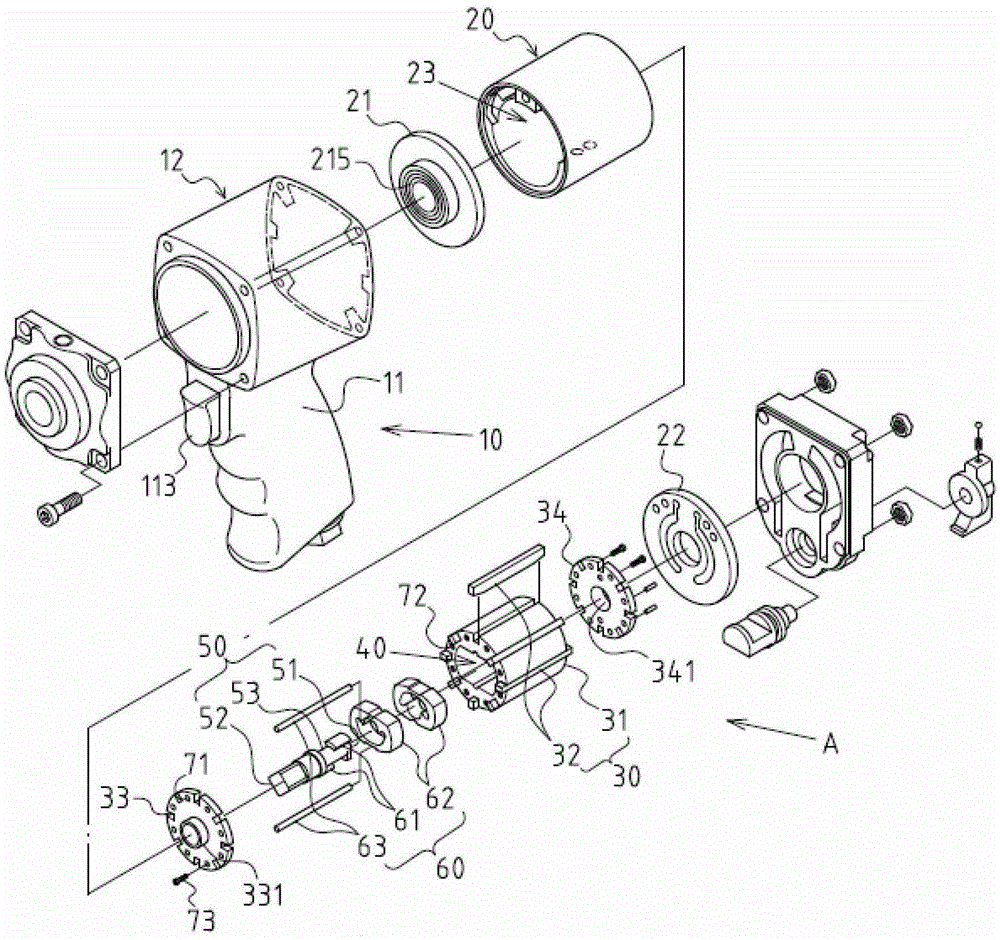

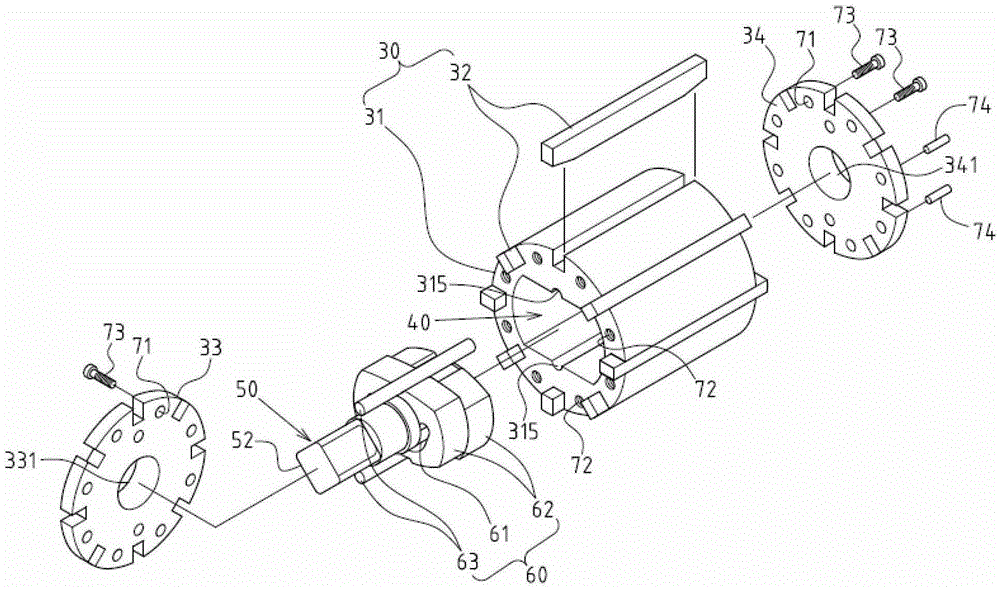

Pneumatic tool motor with built-in beating mechanism

InactiveCN104175269AReduced axial length volumeQuick and easy lock removalPower driven toolsRotary piston enginesEngineeringAxial length

The invention discloses a pneumatic tool motor with a built-in beating mechanism. The pneumatic tool motor comprises an air cylinder body, a rotor group and an output shaft rod, wherein the rotor group comprises a drum and a telescopic blade, and the output shaft rod can be driven by the drum; an inner containing chamber is formed in the inner part of the drum of the rotor group; the output shaft rod is provided with a beating action zone which is positioned in the inner containing chamber; the inner containing chamber is internally provided with the built-in beating mechanism, and the built-in beating mechanism comprises a beating convex block which is arranged in the beating action zone in a bulged way, a movable beating hammer which is arranged at the periphery of the beating convex block in a sleeving way and a supporting post which is axially located on the drum. According to the pneumatic tool motor with the built-in beating mechanism, disclosed by the invention, the axial length and the volume of the pneumatic tool motor can be substantially reduced, and the advantage and advancement that the use is more labor-saving and more convenient can be achieved; the built-in beating mechanism of the pneumatic tool motor has the advantages that the rotor group can be directly driven, a twisting force can be increased immediately, and the disassembling and the locking of components are quick and convenient, and thus the pneumatic tool motor has the advantages that the multi-aspect cost can be substantially reduced, and the better industrial economic benefit can be obtained.

Owner:陈秀如 +1

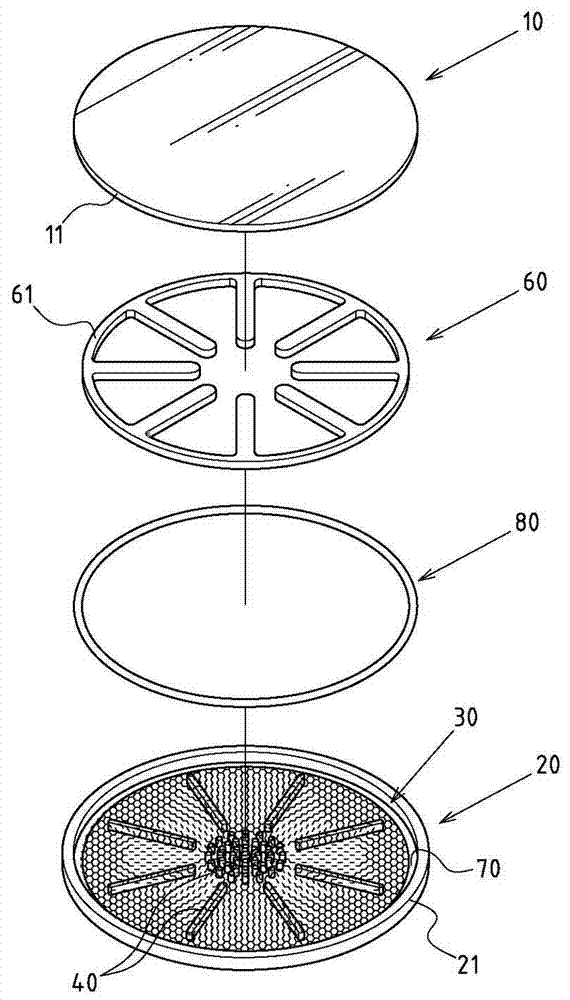

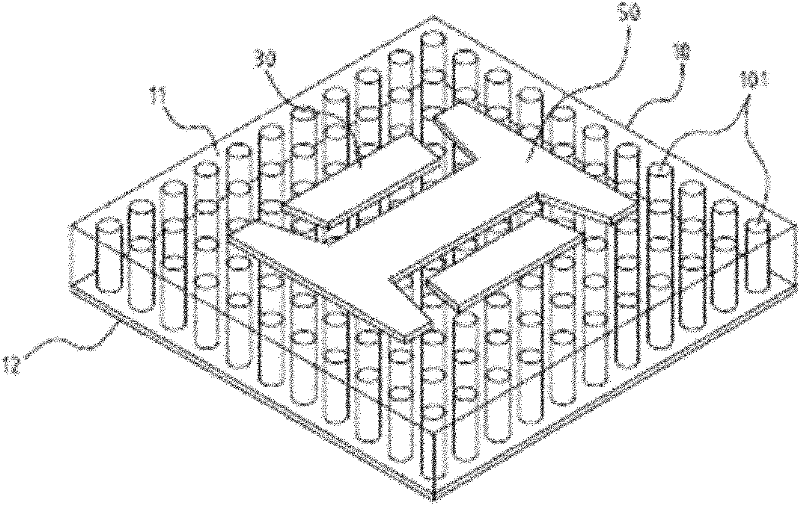

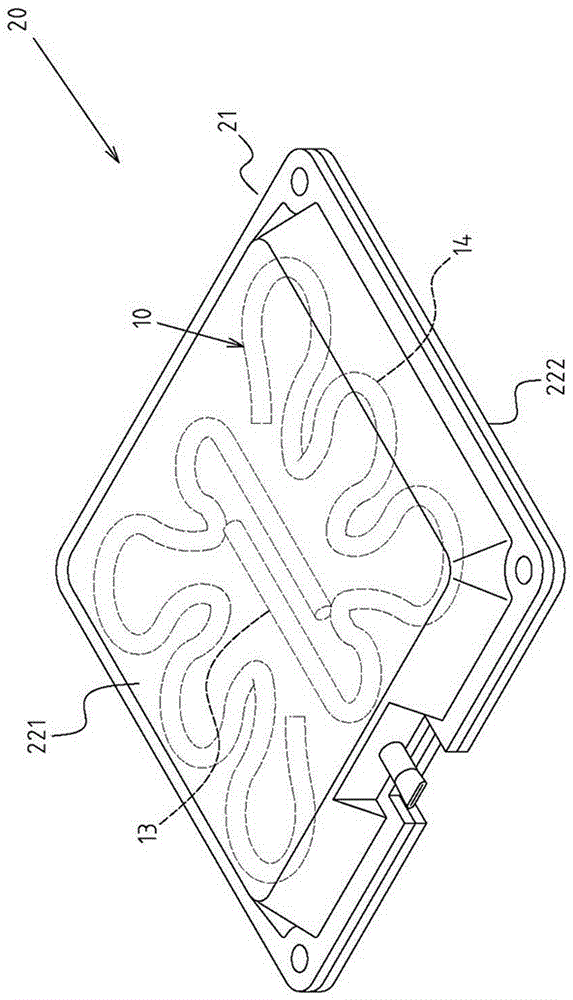

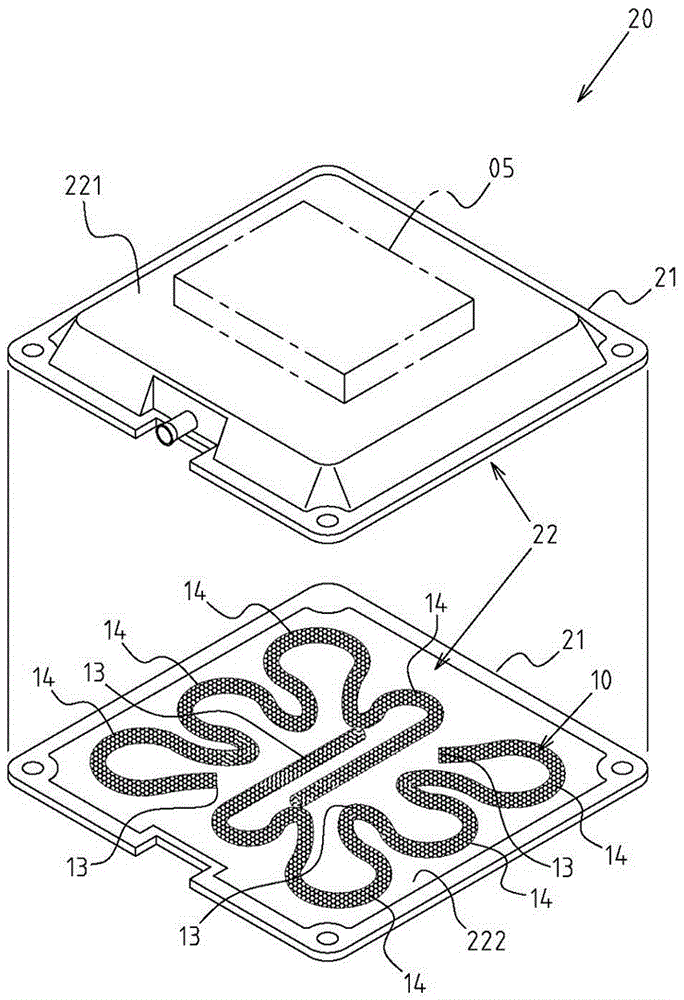

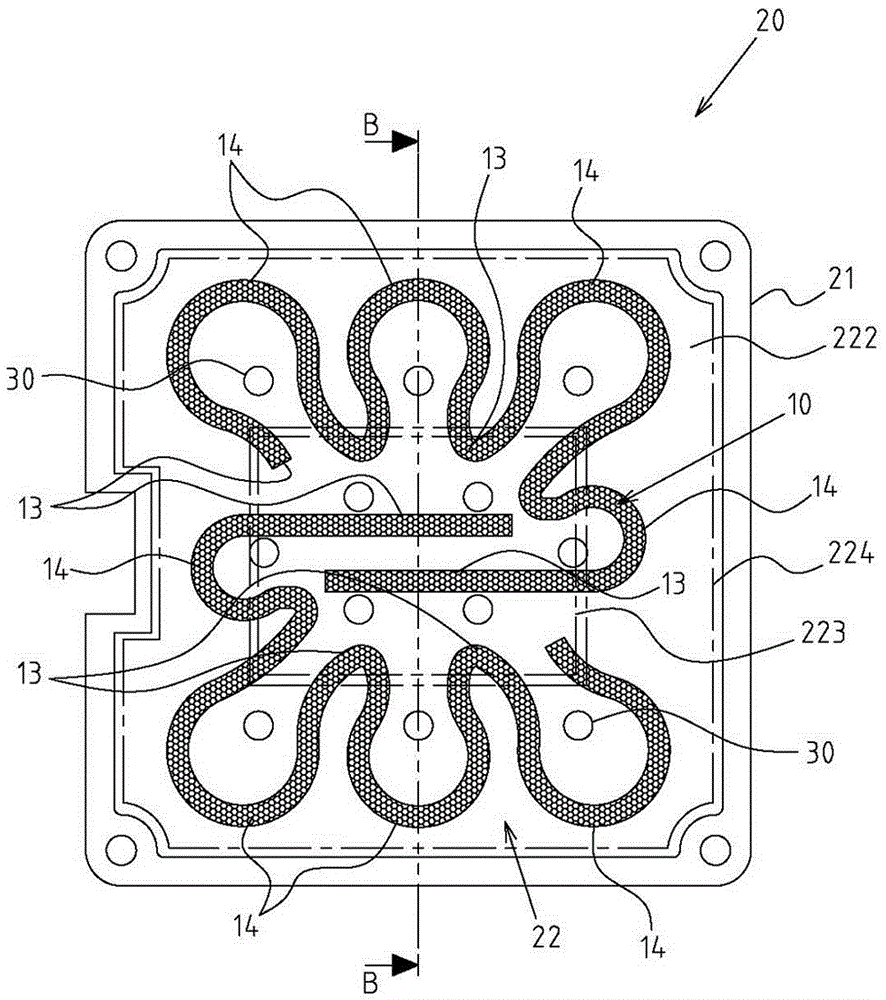

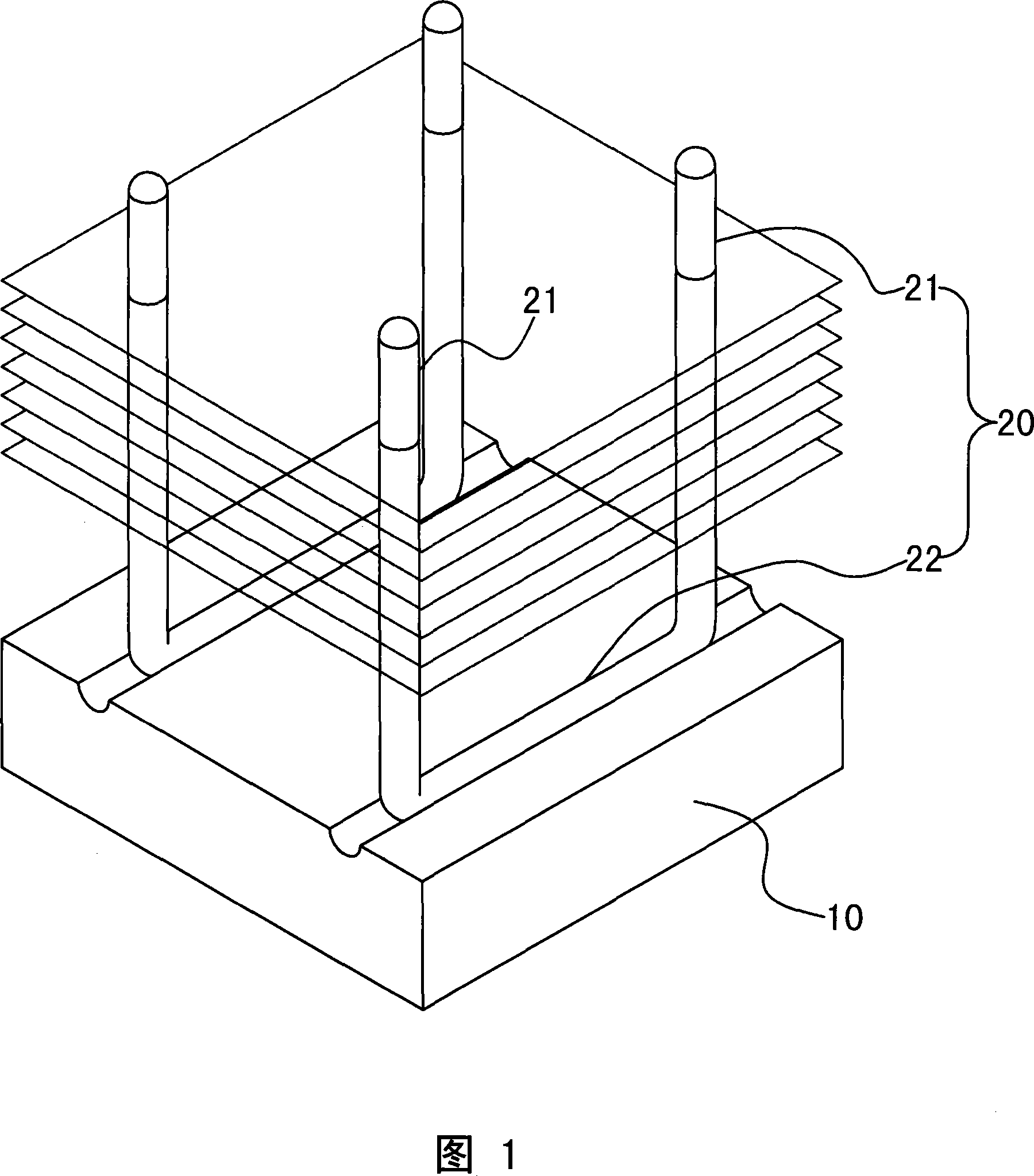

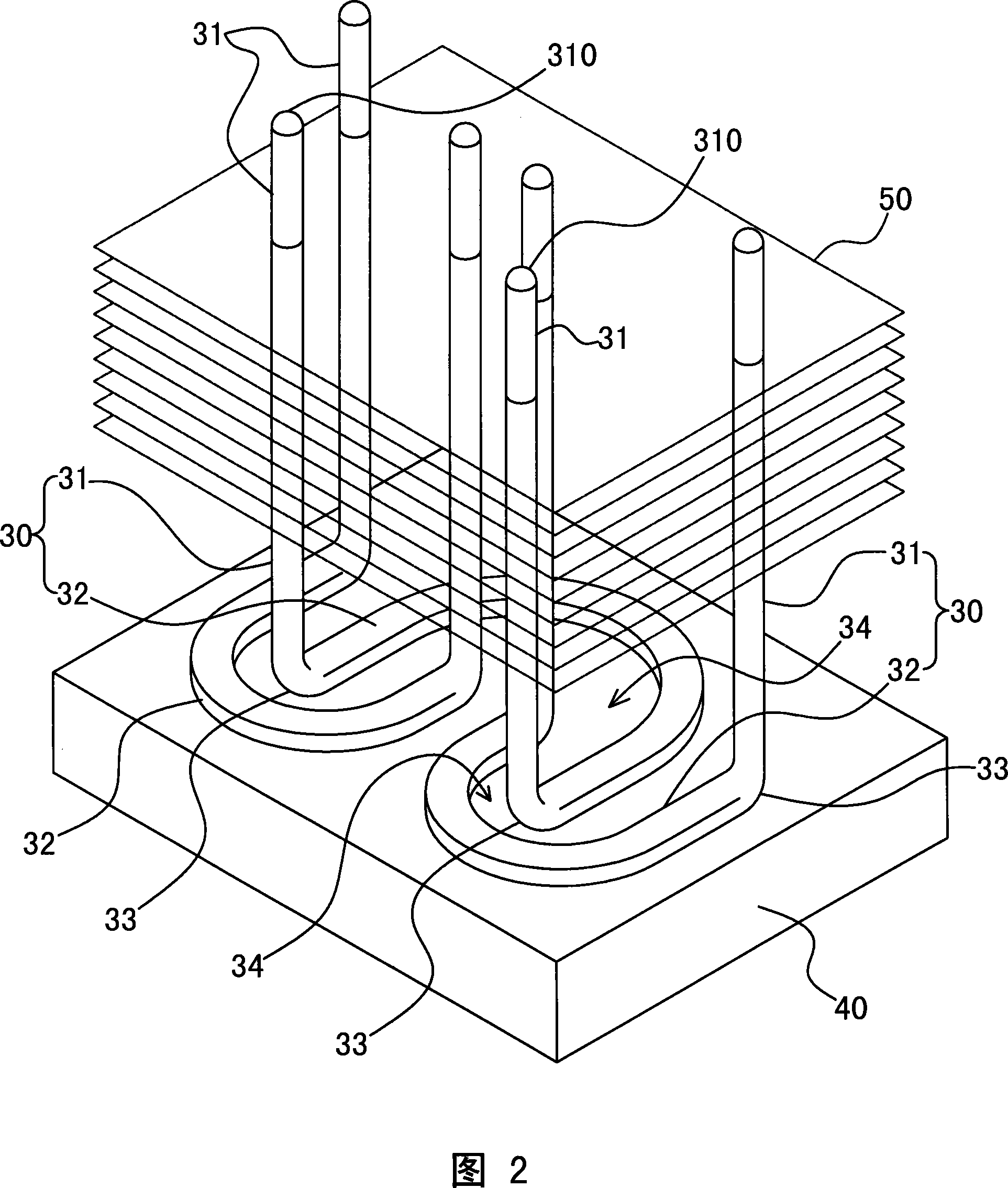

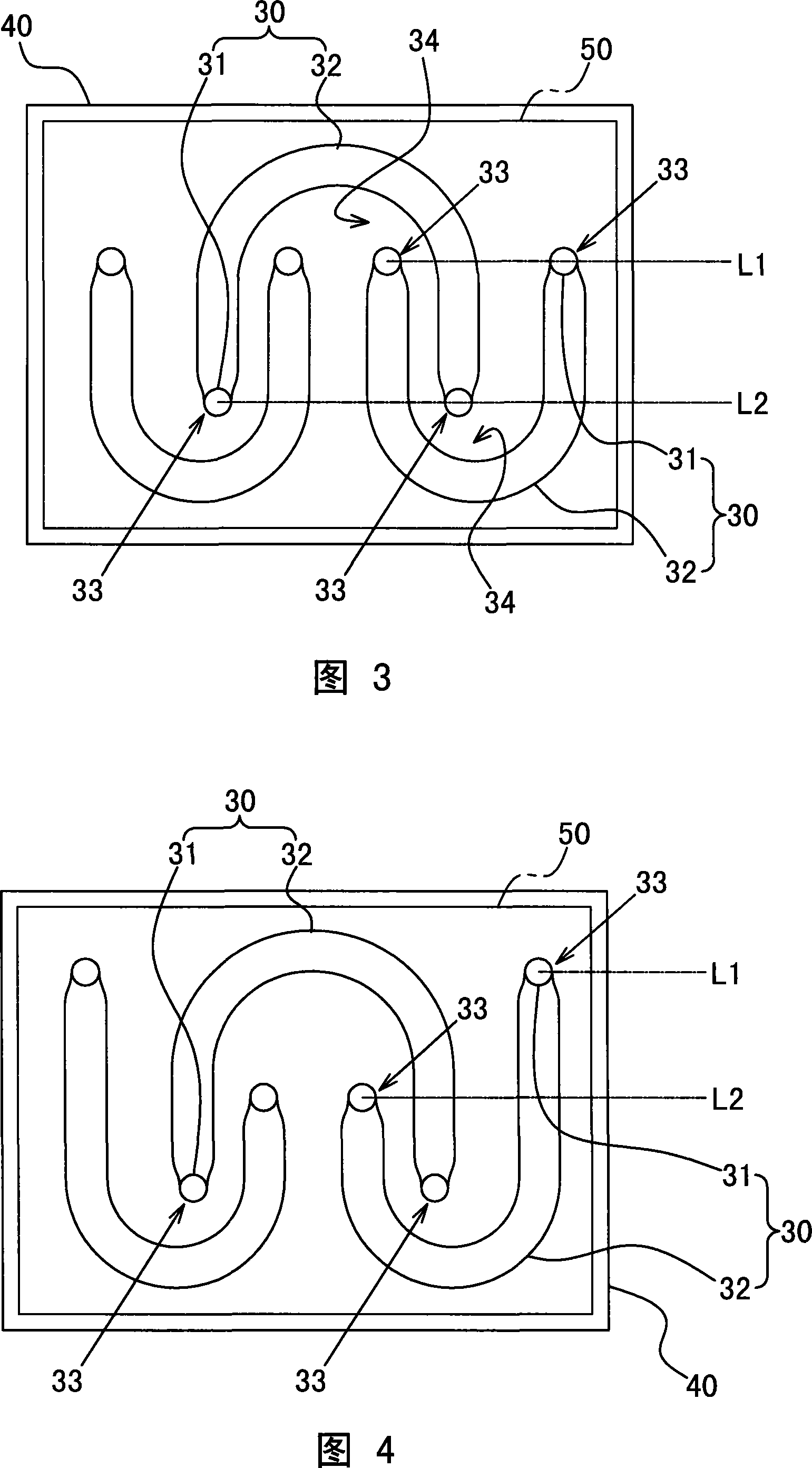

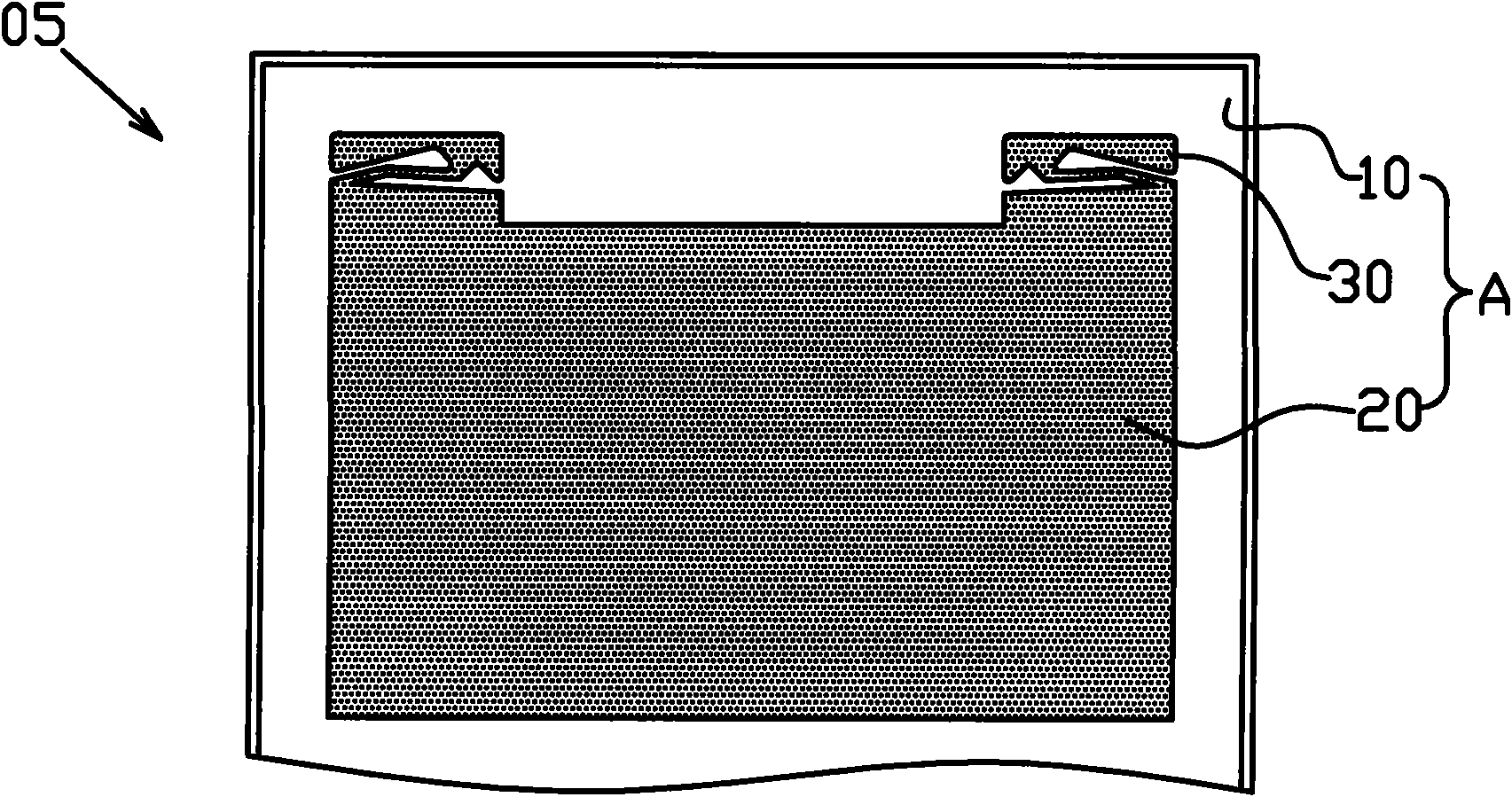

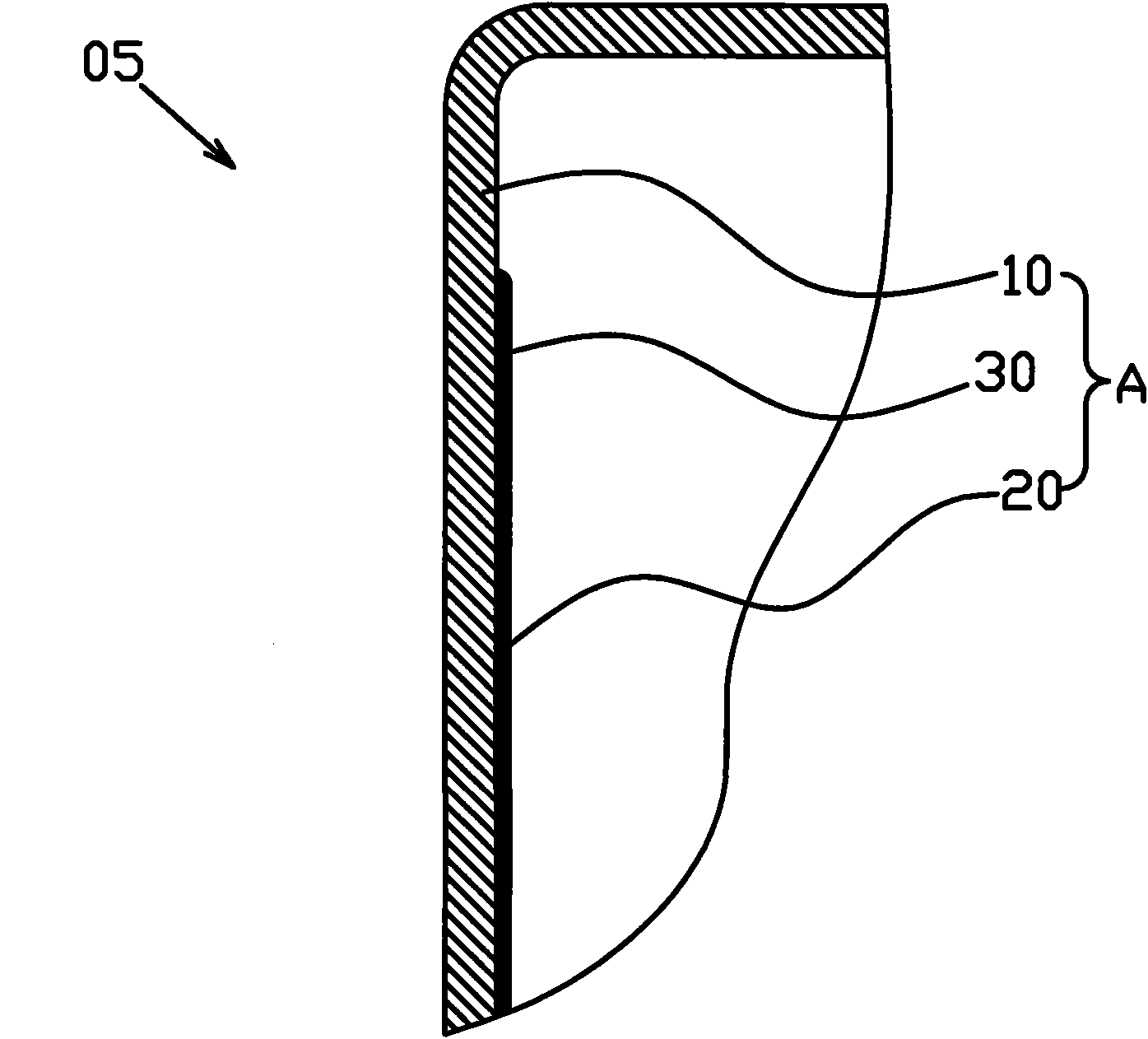

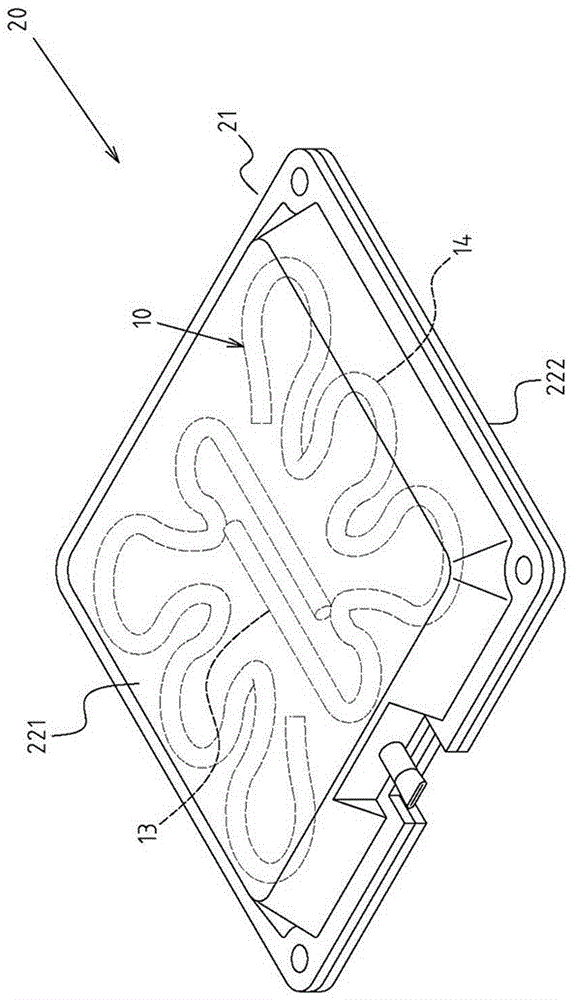

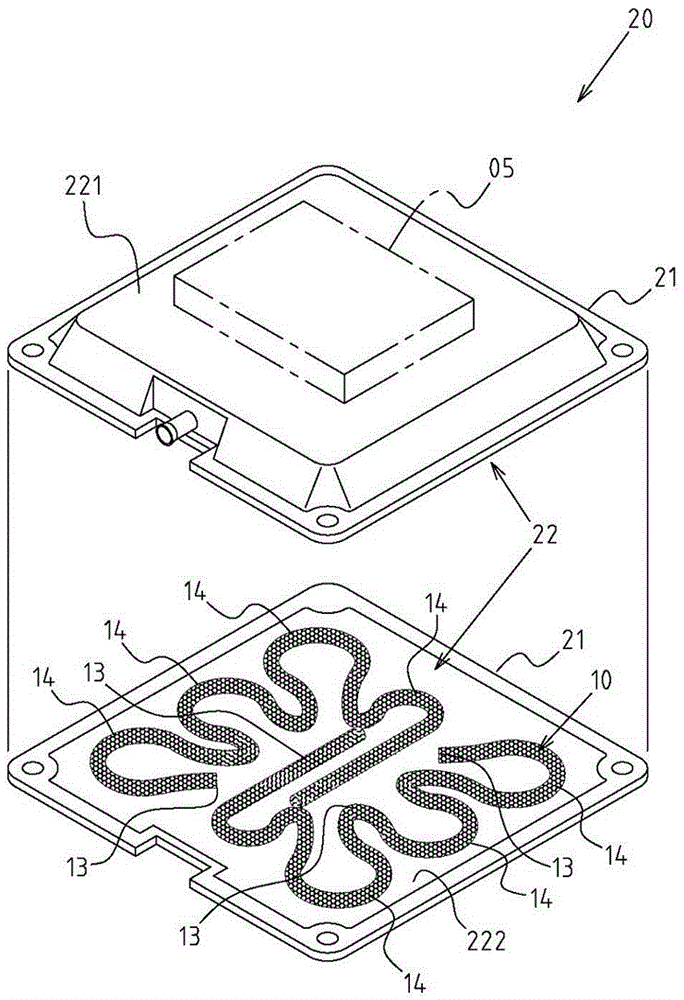

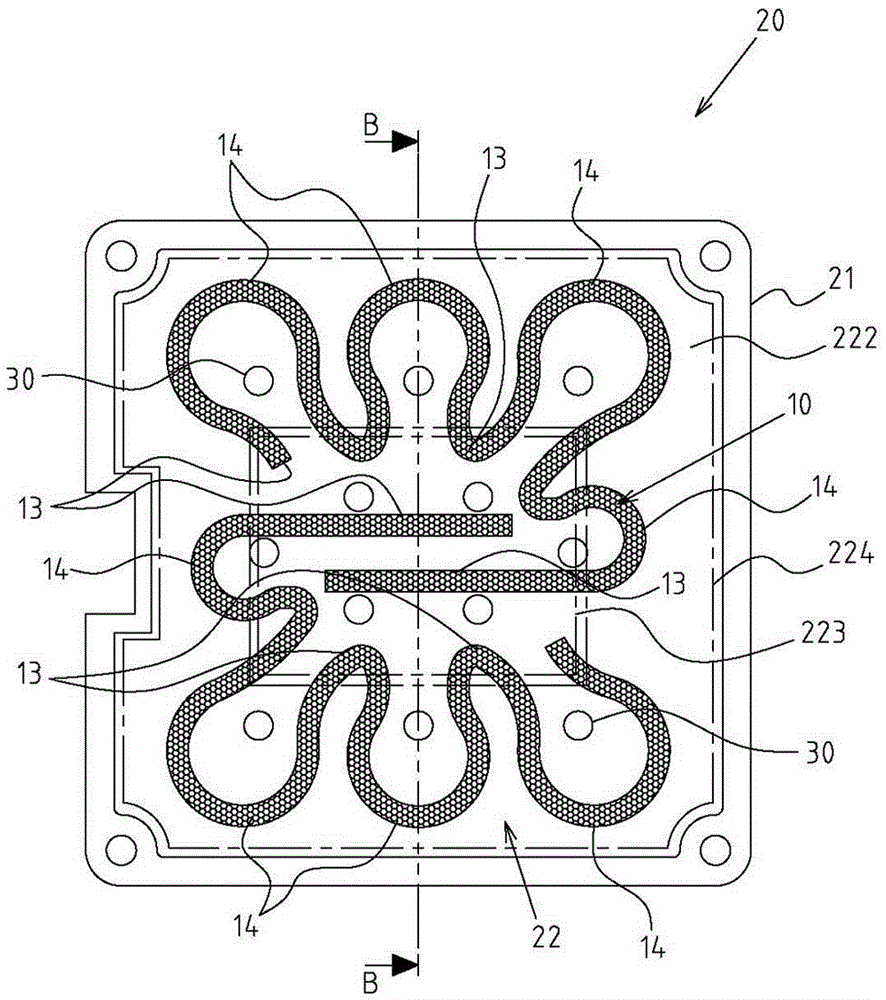

Novel capillary structure configuration structure of soaking plate

InactiveCN106052447AImprove heat transfer efficiencyReduce the number of settingsIndirect heat exchangersHeat conductingEconomic benefits

The invention discloses a novel capillary structure configuration structure of a soaking plate. A capillary structure is arranged in a hollow groove formed in a shell of the soaking plate; a first side of the capillary structure is contacted with the top wall of the hollow groove; a second side of the capillary structure is contacted with the bottom wall of the hollow groove; and the hollow groove includes a center area and a peripheral area near the periphery of the soaking plate. The novel capillary structure configuration structure is mainly characterized in that the capillary structure is set as a continuous bend extending shape; and the extending distribution range of the capillary structure covers the center area and the peripheral area of the hollow groove, so that a structural form of the capillary structure including a center heat conducting part corresponding to the center area and a peripheral cooling part corresponding to the peripheral area is formed, and the better industrial economic benefits of greatly improving the heat transfer benefit and the practical advancement of the quality of the soaking plate and reducing the manufacturing cost can be achieved.

Owner:SUZHOU FORCECON ELECTRIC

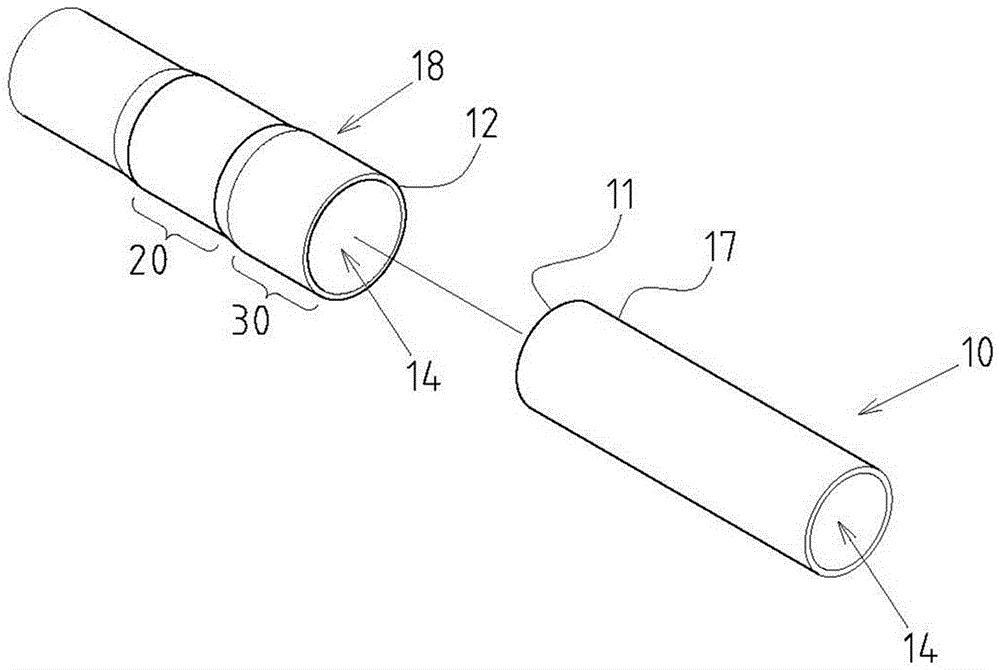

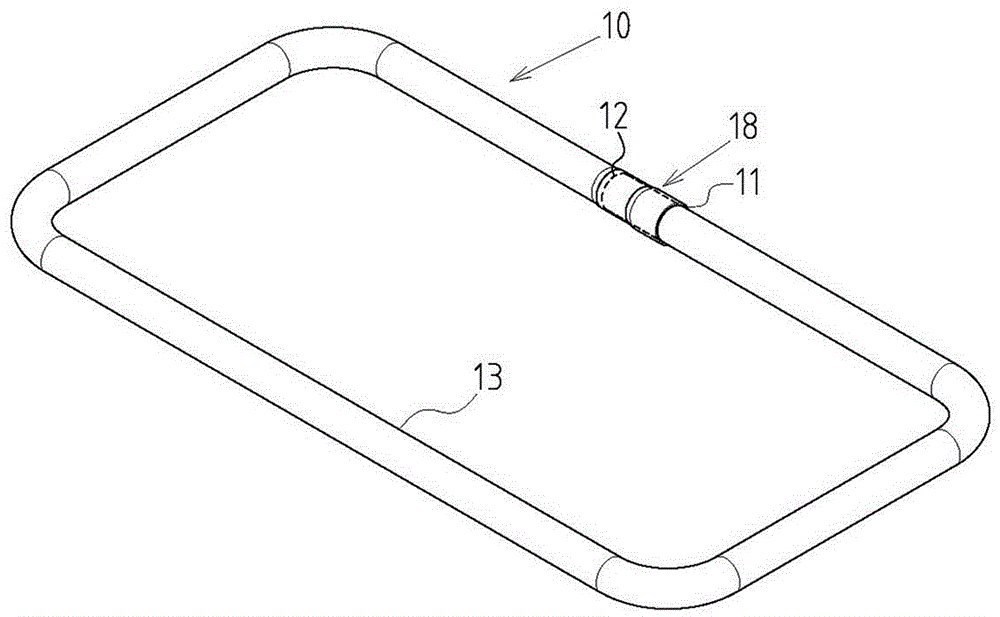

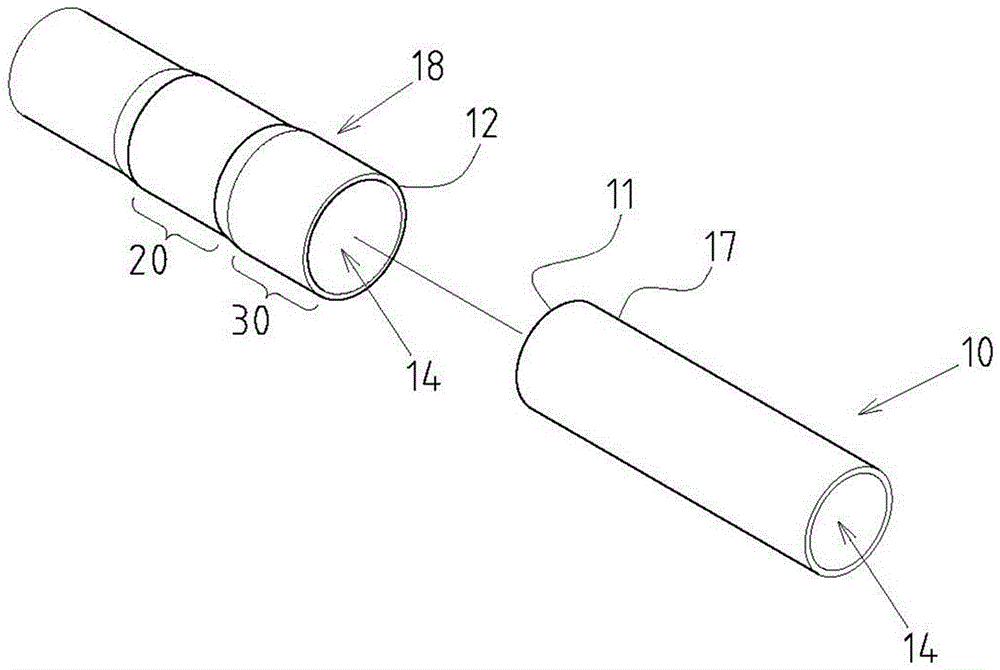

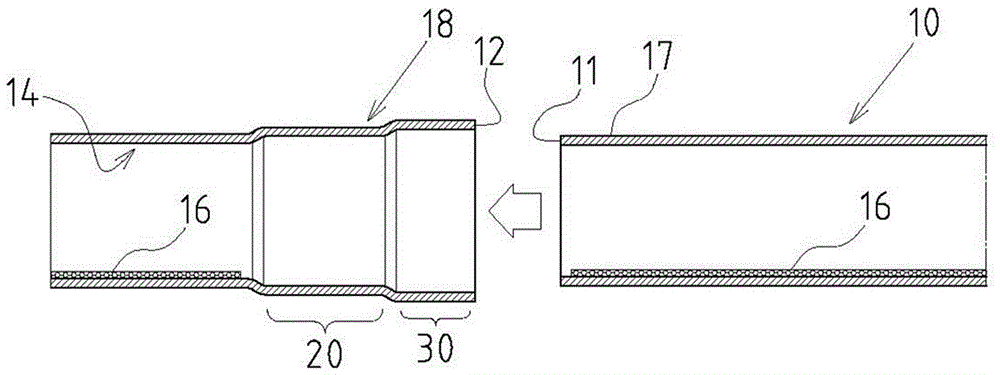

Pipe-end butt joint type loop heat pipe and forming method thereof

InactiveCN106247833AReduce manufacturing costImprove cooling effectIndirect heat exchangersManufactured formButt joint

The invention provides a pipe-end butt joint type loop heat pipe and a forming method thereof. The pipe-end butt joint type loop heat pipe mainly comprises components in a structural plane as follows: a hollow pipe body, an inserting joint part, a sleeve joint part, a tight fit zone and a loose fit zone, wherein the hollow pipe body comprises two pipe ends and a loop zone, and loop channel space in the loop zone is in a vacuum closed state and accommodates a working solution; the inserting joint part is arranged at one pipe end of the hollow pipe body; the sleeve joint part is arranged at the other end of the hollow pipe body, and is assembled on the periphery of the inserting joint part in a sleeving manner; the tight fit zone is arranged in one local zone at the inserting and sleeving part of the inserting joint part and the sleeve joint part, and a tight insertion airtight state is formed between the inserting joint part and the sleeve joint part through the tight fit zone; the loose fit zone is arranged in the other local zone at the inserting and sleeving part of the inserting joint part and the sleeve joint part, and a gap is formed between the inserting joint part and the sleeve joint part through the loose fit zone. According to the pipe-end butt joint type loop heat pipe and the forming method thereof, the loop heat pipe can realize practical progress that components and manufacturing forming steps are greatly simplified, the manufacturing cost is greatly reduced and better heat dissipation efficiency is kept, and has better industrial economic benefits.

Owner:SUZHOU FORCECON ELECTRIC

Heat pipe structure of radiator

InactiveCN101146433AAssembly volume is smallIncrease the heating areaSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat spreader

A heat tube structure of a heat dissipater is disclosed, which includes two vertically extended heat dissipating sections, and a heat receiving section positioned between bottom ends of the two heat dissipating sections, wherein the heat receiving section is against a heat guide base seat, and connecting part of the heat receiving section and the two heat dissipating sections form a bending part. A relative better embodiment is mainly characterized in that the heat receiving section is set into a bending state, and heat receiving sections of adjacent heat tubes form relative version distribution, i.e. heat receiving section bending part of one heat tube is aligned to a concave space of another heat tube. Therefore, a largest heat receiving area can be obtained with a smallest heat tube assembling volume to realize practical improvement such as greatly improved heat dissipating function and reduced manufacture cost, thus achieving higher industrial economic benefits.

Owner:SUZHOU FORCECON ELECTRIC

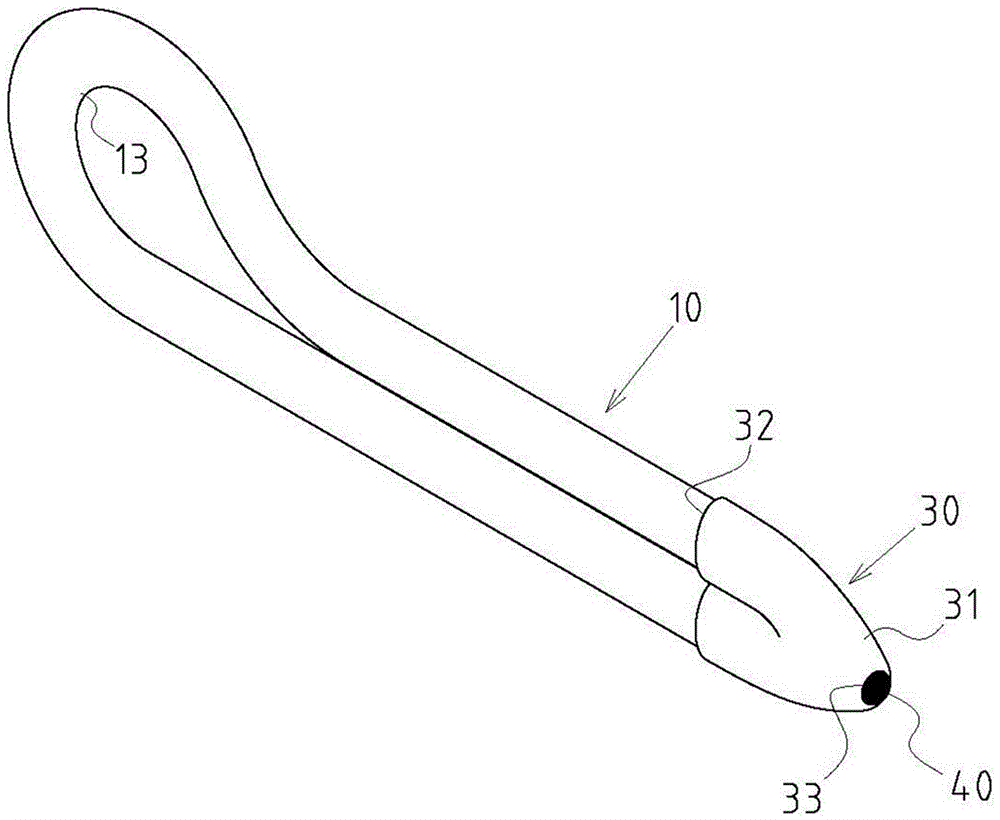

End butt joint type loop heat pipe

InactiveCN106091771ASimple and fast manufacturing and processingReduce manufacturing costIndirect heat exchangersManufacturing cost reductionMicro-loop heat pipe

The invention provides an end butt joint type loop heat pipe which is mainly being characterized by comprising a loop pipe body, an inserting and sleeving type butt joint part, an inserting gap and a degassing pipe. The outside of the loop pipe body is bent into a hollow square shape, and the loop pipe body comprises a first pipe end, a second pipe end and a loop section. The inserting and sleeving type butt joint part is formed in the manner that the first pipe end and the second pipe end of the loop pipe body serve as an inner pipe and an outer pipe to be inserted and sleeved oppositely in a sealed manner, and any one of the first pipe end and the second pipe end is arranged in the manner that the pipe diameter is enlarged, and provided with a pipe enlarging part. The inserting gap is formed at the position of the radial local part between the first pipe end and the second pipe end, and penetrates the outside of the inserting and sleeving type butt joint part and a loop flow pass space in the loop pipe body. The degassing pipe is inserted into the inserting gap in a close fit manner to serve as a vacuumizing and working solution pouring channel, and the outer end of the degassing pipe extends out of the inserting and sleeving type butt joint part and is provided with a closed part. The structure of the loop heat pipe can achieve practical progress of member simplification, easier and faster manufacturing, machining and forming and substantial manufacturing cost reduction, and achieve better industrial economy benefits.

Owner:SUZHOU FORCECON ELECTRIC

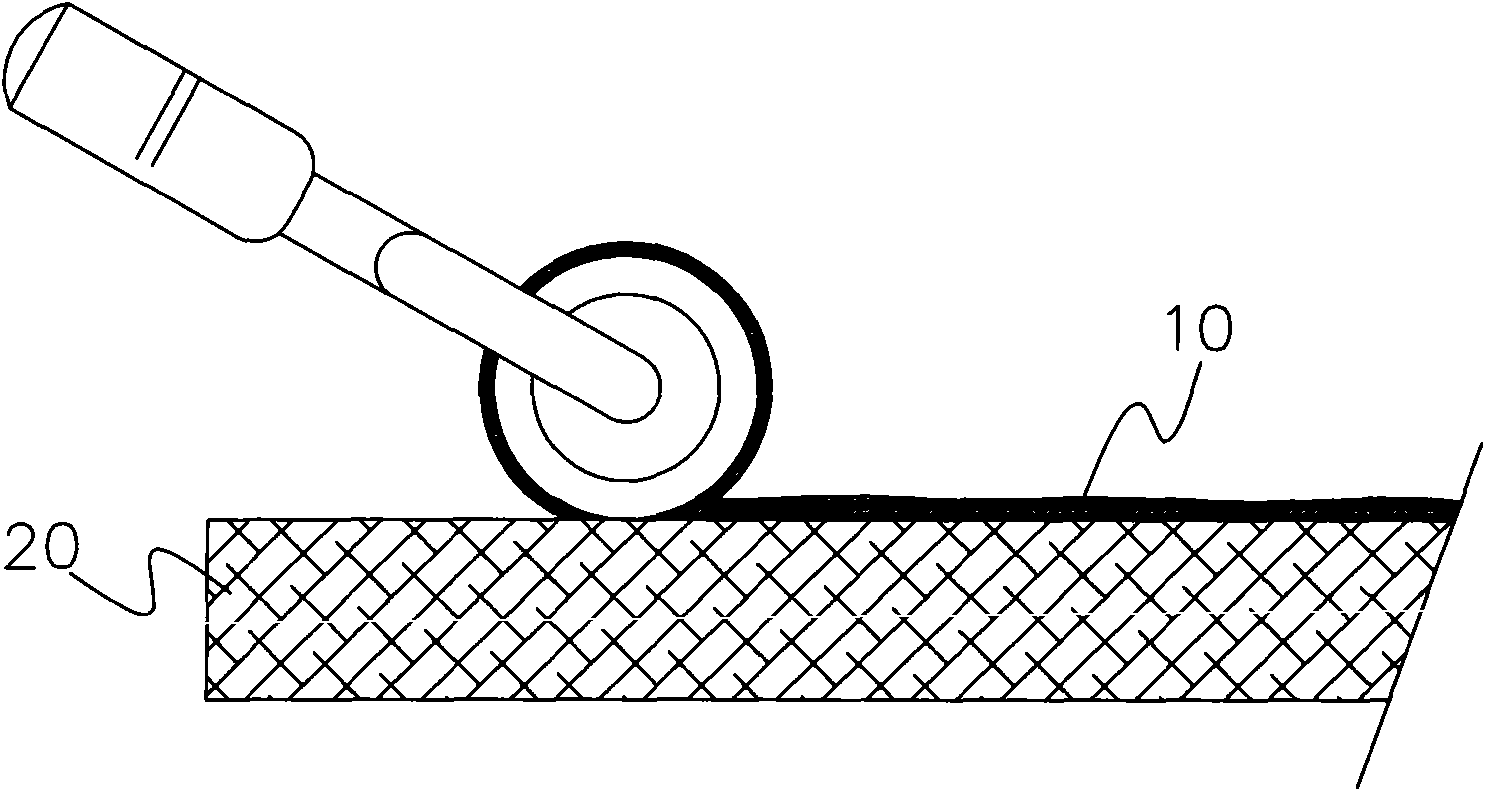

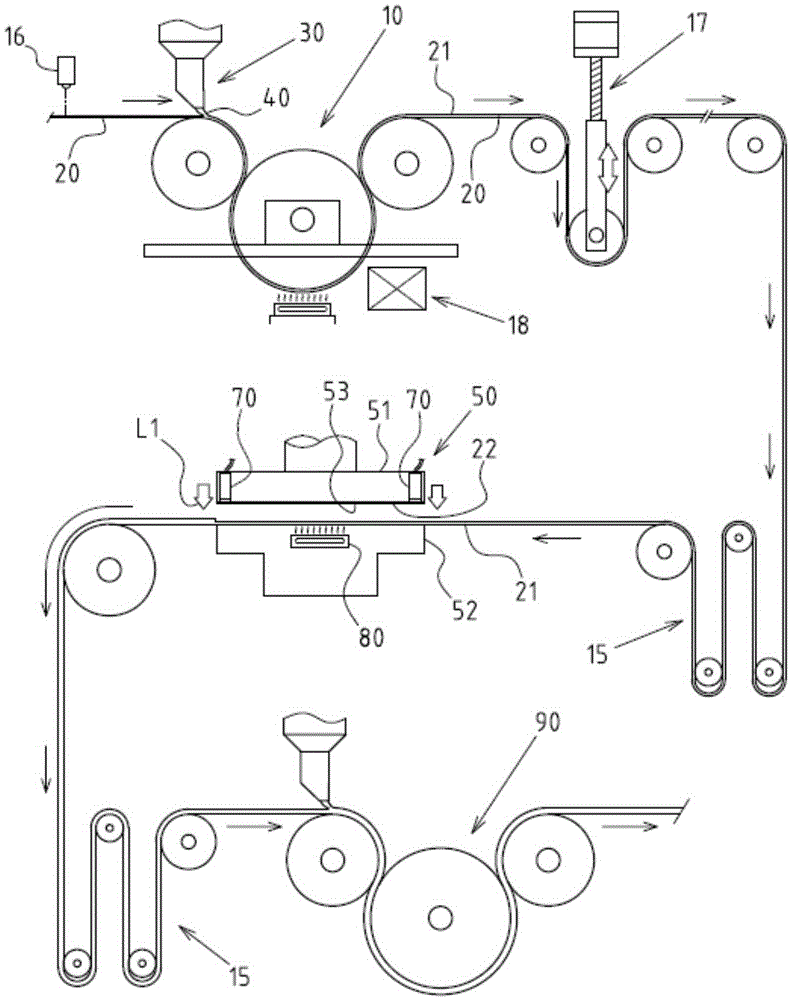

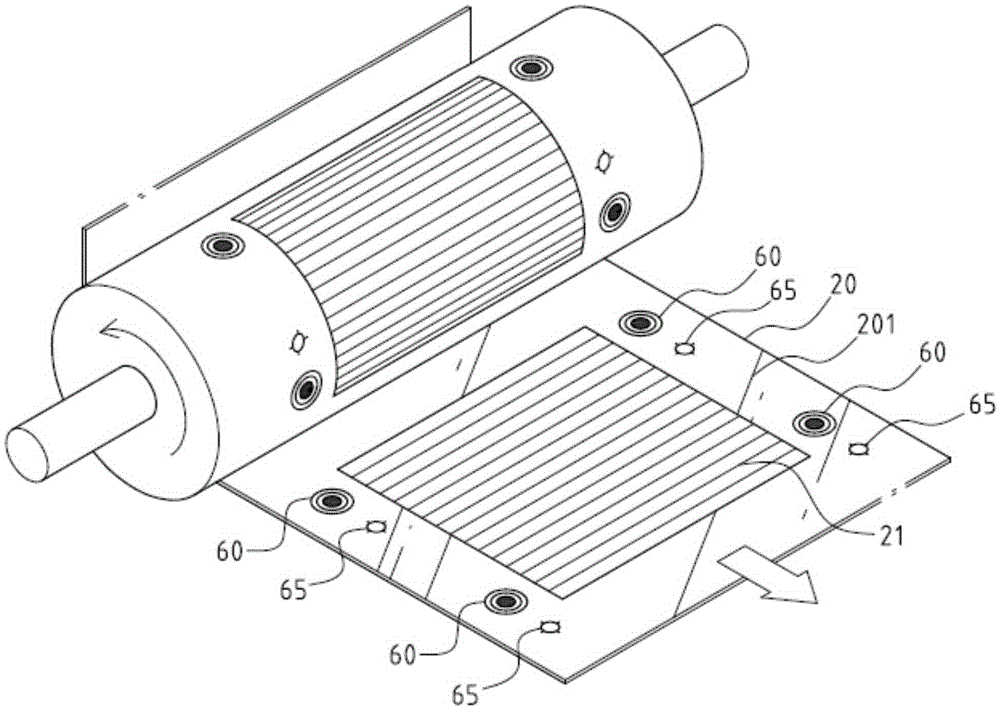

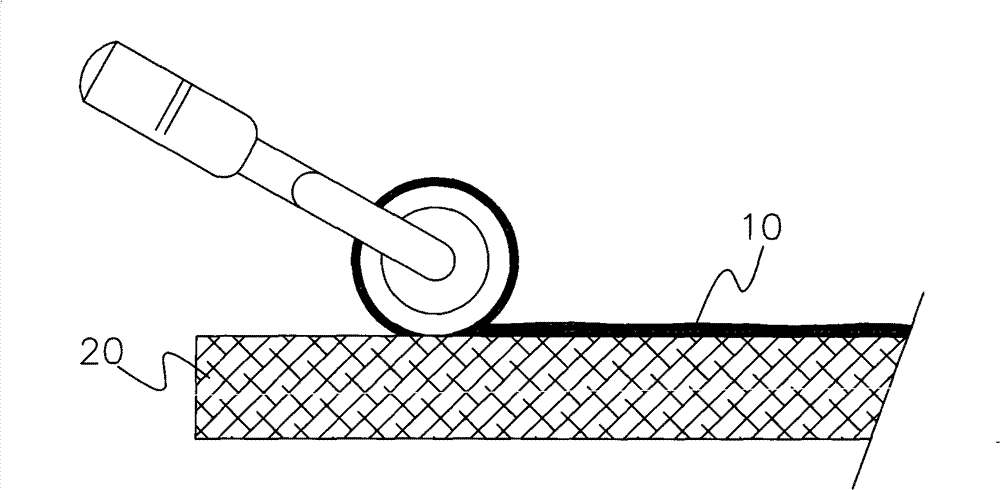

Forming mechanism of single-sheet double-sided coated optical film

ActiveCN104417013BHigh precisionImprove practical progressControlling laminationLaminationEngineeringSingle chip

The invention discloses a shaping mechanism for a single-chip double-face coating-type optical film, wherein the shaping mechanism comprises a first roller group, a press fit shaping unit, a positioning mark, and a positioning sensor. The first roller group comprises a first glue applicator; the press fit shaping unit is arranged behind the first roller group and comprises a press fit base and a bearing platform both which are arranged at an interval from top to bottom; the bearing platform is used for an optical film base material to pass through and bearing the optical film base material, the press fit base can generate a press fit action towards the bearing platform; the press fit face of the press fit base is provided with a second optical layer which aligns at the first optical layer of the first surface; the positioning mark is formed on the first surface of the optical film base material and at the specified interval of the first optical layer; the positioning sensor is arranged on at least one part of the press fit base of the press fit shaping unit and at the specified interval of the second optical layer so that the set positioning mark of the optical film base material is detected to obtain the precision position and time point for performing the press fit action by the press fit base, thus two optical layers precisely aligned can be formed on two opposite surfaces of the single optical film base material.

Owner:ARLUMI MACHINE

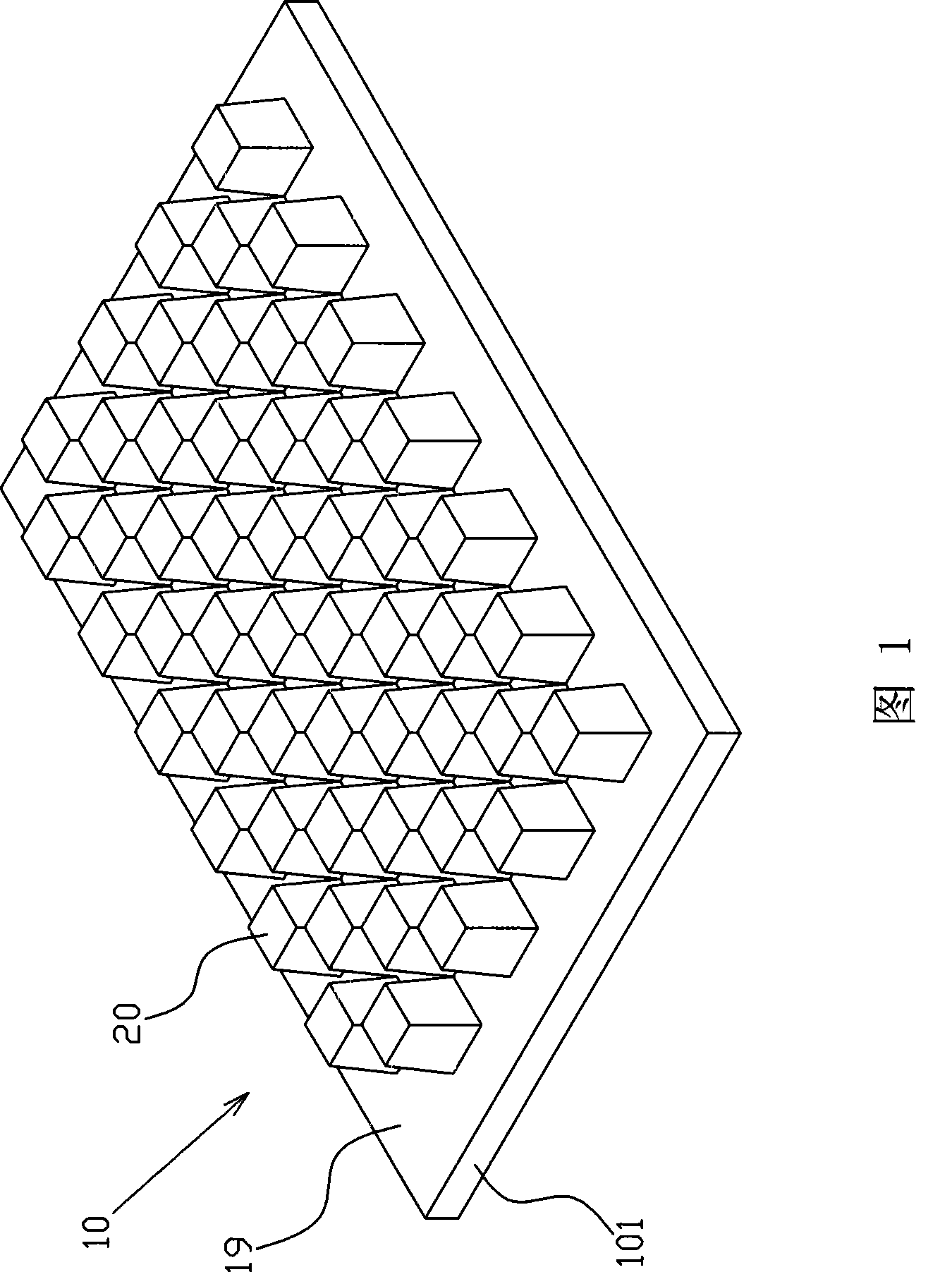

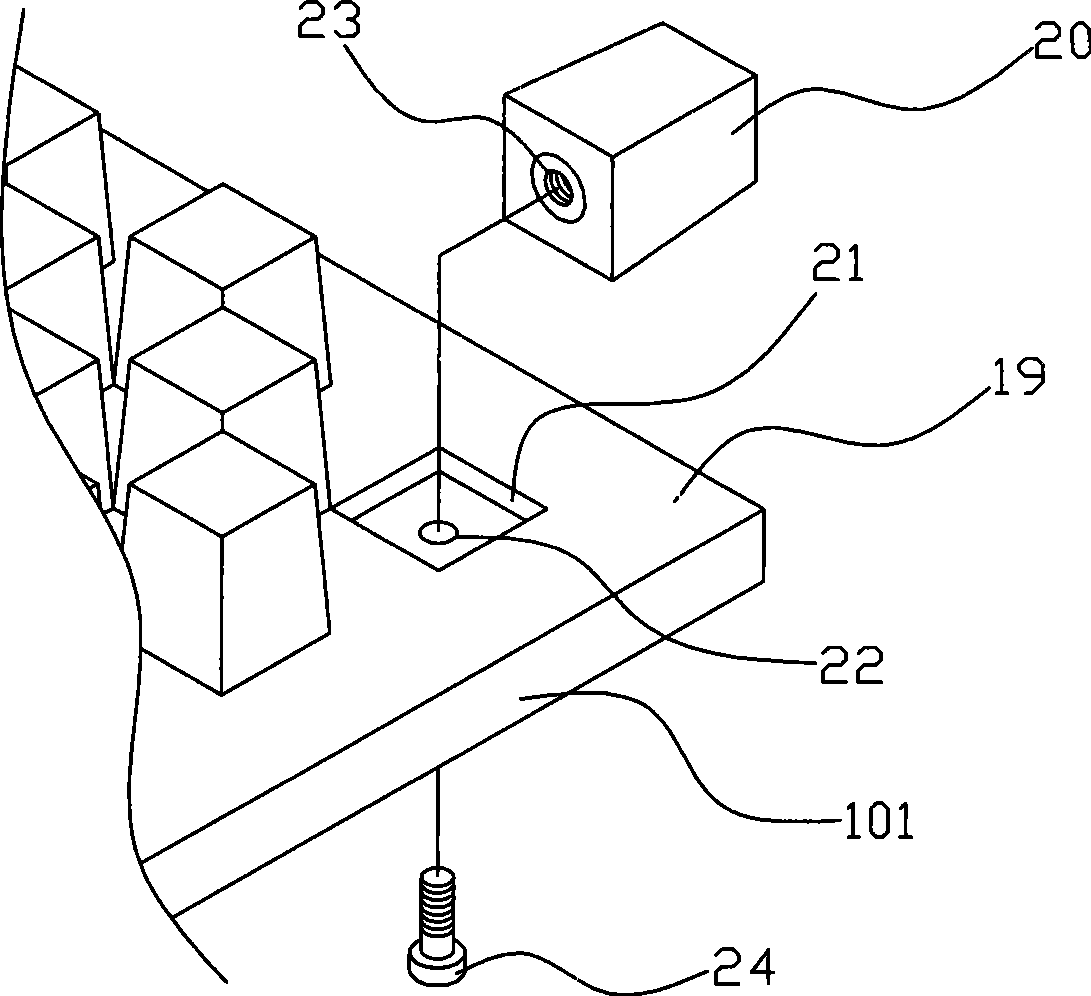

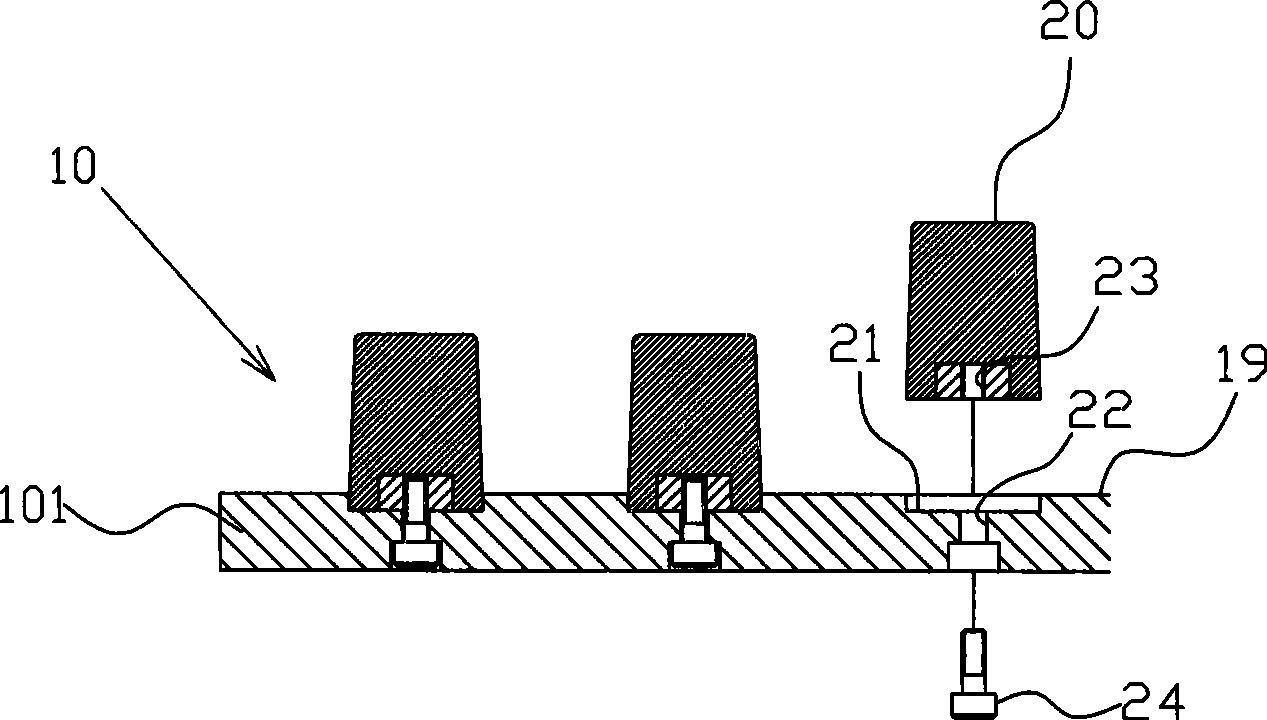

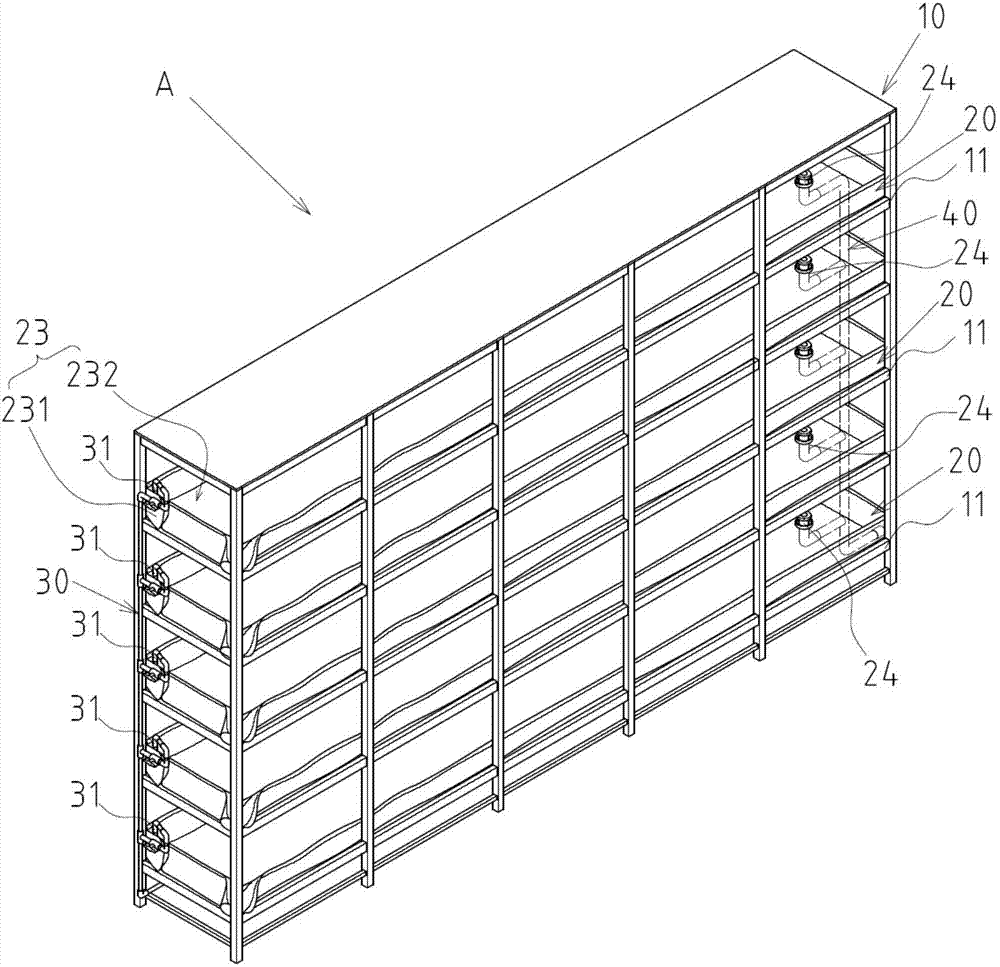

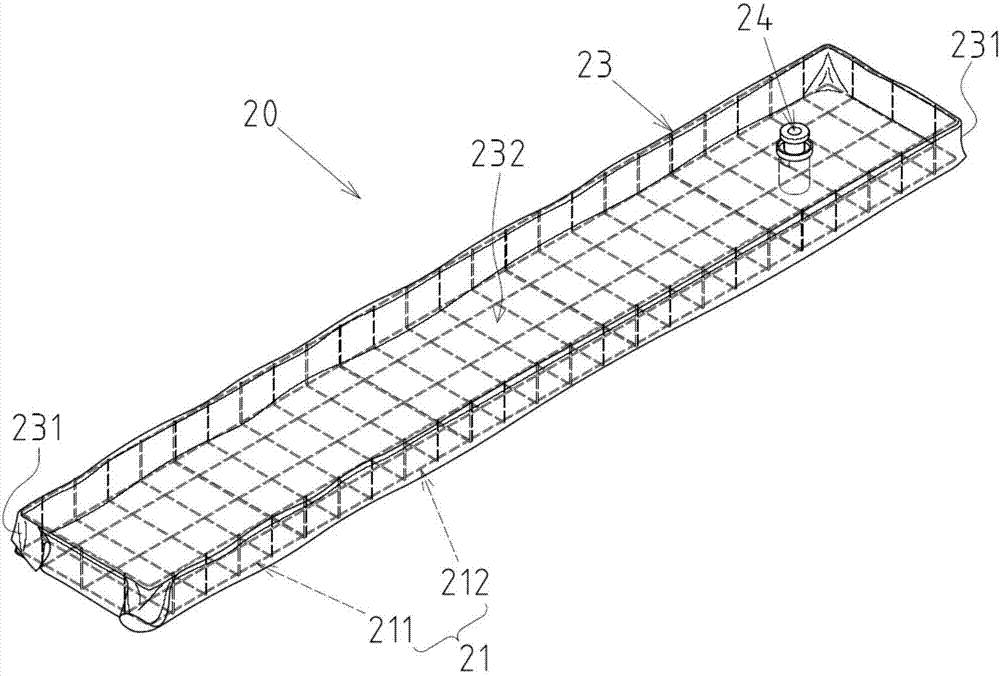

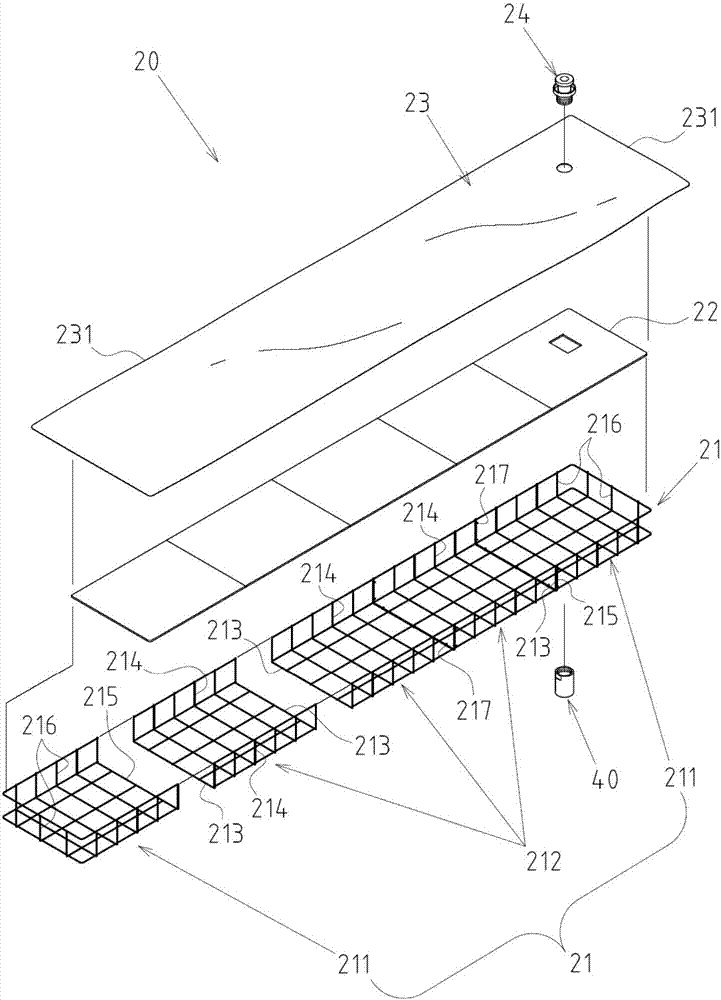

Planting device and combined containing grooves thereof

InactiveCN107197769AEasy to cleanQuick clean upAgriculture gas emission reductionCultivating equipmentsEngineeringCotton material

The invention discloses a planting device and combined containing grooves thereof. The planting device mainly comprises a frame body with a layer frame, the combined containing grooves arranged on the layer frame of the frame body, a water supply pipeline arranged and positioned on the frame body, and a drainage pipeline. Each combined containing groove comprises a frame formed by combining an end unit frame body and a middle unit frame body, a base plat arranged in the frame and a light shading waterproof fabric laid on the base plate, the peripheral region of the waterproof fabric stretches upwards in a curved mode along the middle section vertical side frame and the end vertical side frame of the frame to form a containing groove, the containing groove is provided with a water drainage portion, the water supply pipeline is provided with a water outlet end stretching into the containing groove of the combined containing groove, and the drainage pipeline is connected with water drainage portions of the combined containing grooves. Accordingly, the combined containing grooves are convenient to clean and small in storage and transfer size.

Owner:SHENTER ENTERPRISE

Magnetic-control wheel

InactiveCN101450247BReduce manufacturing difficultyReduce defective rateMuscle exercising devicesMagnetic tension forceSports facility

The invention discloses a magnetic control wheel configuration for solving problem of high cost, poor action quality and high transfer resistance of the magnetic control wheel driving gear mechanism by using oblique cone mating surface shape; the magnetic control wheel includes a base body, a cover body, a flying wheel, a center axis, a driven motor, a transfer gear group and two magnetism control pieces; the transfer gear group includes a speed change turning group, an interlock piece and a rear gear; a setting axial direction of the interlock piece and the rear gear is same with the magnetic control center axis; a gear row set by two magnetism control pieces mesh transmit with the rear gear together, a spur gear meshing shape is in between the rear gear and the gear row set by the magnetic control piece; a spring component is top braced between one axial end of the speed change turning group of the transfer gear group and one resistance piece of the base body containing space mutually. The magnetic control wheel configuration can be used in sports facility configuration.

Owner:HER YUAN CHYUN

Vacuum sealing structure of uniform temperature heat conduction device and its manufacturing method

InactiveCN104121798BSimplify the manufacturing processReduce manufacturing costIndirect heat exchangersManufacturing cost reductionHeat conducting

Owner:SUZHOU FORCECON ELECTRIC

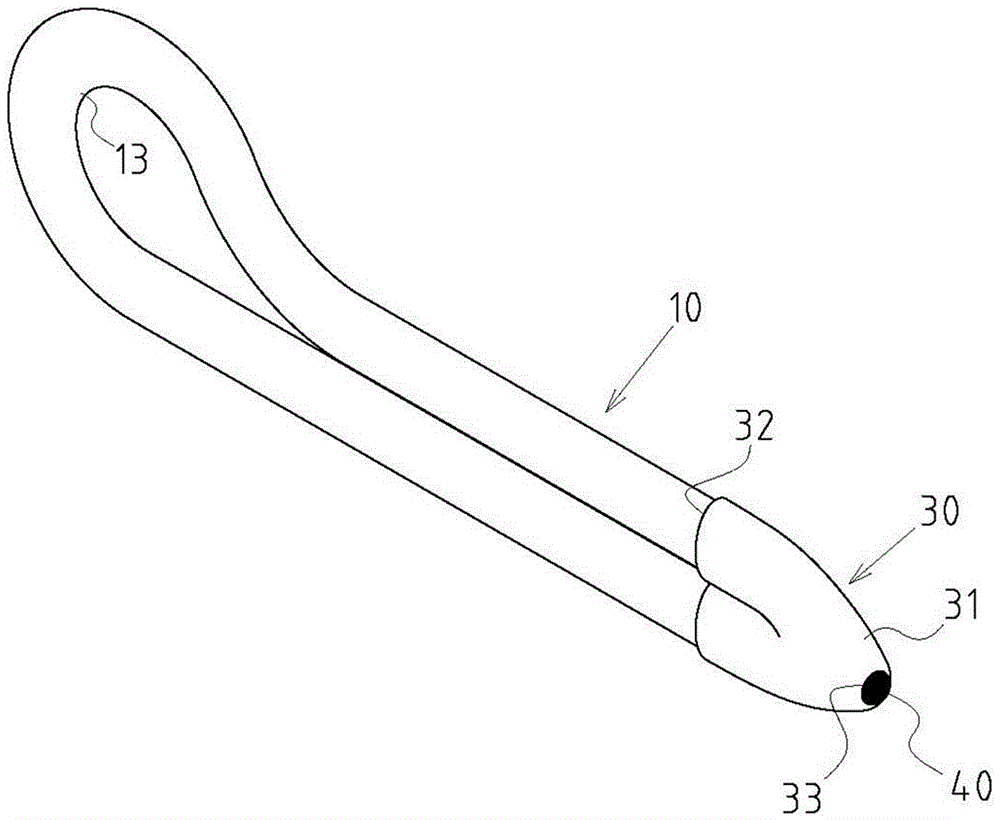

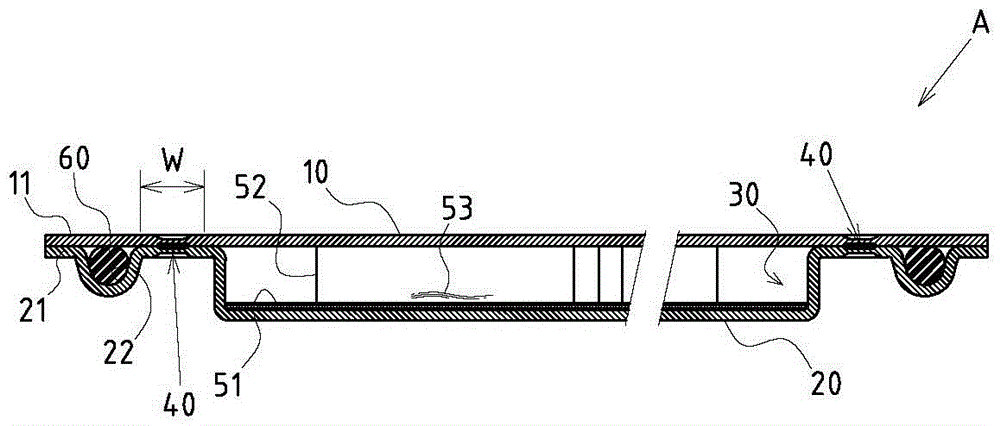

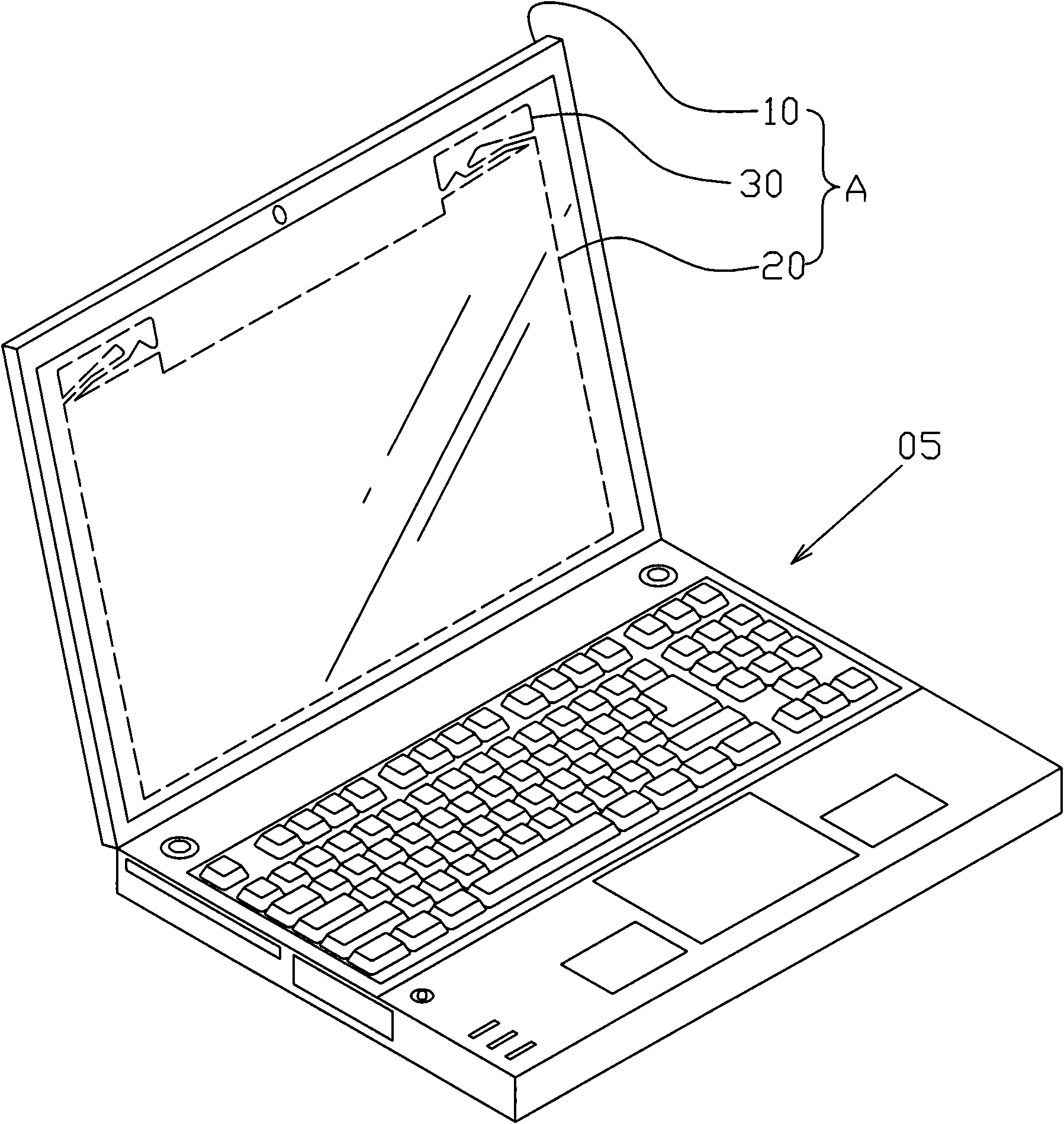

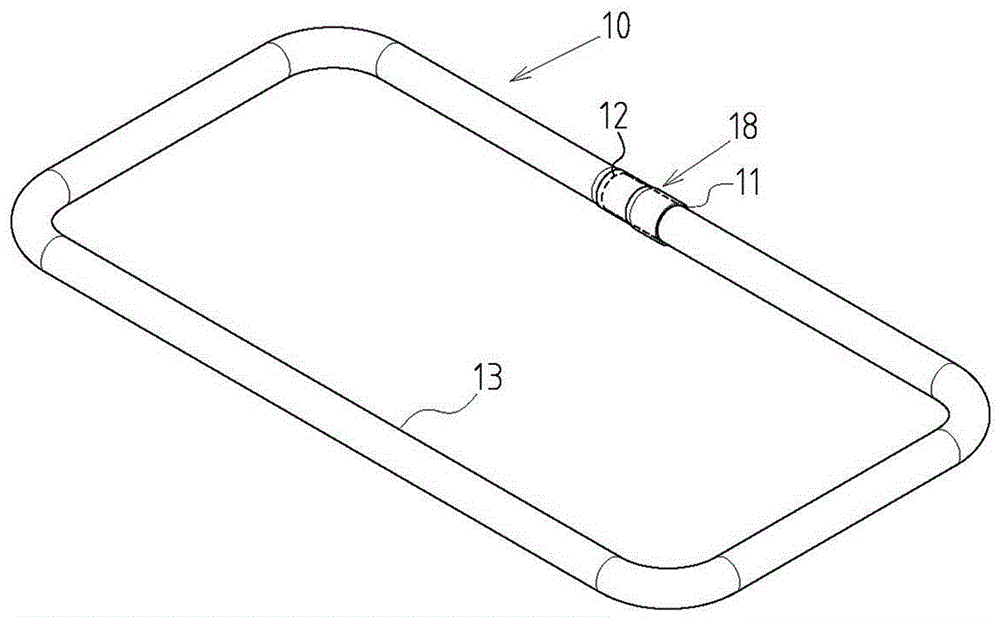

Membrane device with electromagnetic interference resisting and signal receiving and transmitting functions and molding method

InactiveCN101790301ASimplify the signal transceiver assembly processProgressiveMagnetic/electric field screeningElectrical apparatus contructional detailsSurface modeEconomic benefits

The invention discloses a membrane device with electromagnetic interference resisting and signal receiving and transmitting functions and a molding method. The membrane device comprises a substrate material, a conductive thin layer, and a signal receiving and transmitting part, wherein the conductive thin layer is integrally attached to a position on which the substrate is arranged and is in the form of a thin layer. The method comprises the following steps of: selecting the substrate material; selecting a signal receiving and transmitting mode and a conductive metal surface mode according to a required working frequency band; and forming the signal receiving and transmitting part in the form of the thin layer and the conductive thin layer on a region in which the substrate is arranged by means of attachment. Therefore, the conductive thin layer with signal receiving and transmitting and shielding effects can be formed on the substrate by attachment means such as film coating and spraying, the assembling procedure of a signal receiving and transmitting device of an electronic device can be simplified greatly, the production efficiency is enhanced, the cost is saved, and the advancement of the shielding effect and excellent industrial economic benefit are achieved. The invention can be suitable for various occasions and situations which need the membrane device with the electromagnetic interference resisting and signal receiving and transmitting functions and the molding method.

Owner:PARAGON TECH

Capillary structure configuration structure for soaking plate

InactiveCN106091768AImprove heat transfer efficiencyReduce the number of settingsIndirect heat exchangersEconomic benefitsBiomedical engineering

The invention provides a capillary structure configuration structure for a soaking plate. Each capillary structure is arranged in a hollow chamber in a shell of the soaking plate. The first side of each capillary structure is in contact with the top wall of the hollow chamber. The second side of each capillary structure is in contact with the bottom wall of the hollow chamber. Each hollow chamber comprises a center region and a periphery region close to the periphery of the soaking plate. Each capillary structure is mainly characterized in that the capillary structure is set to be in the continuous bending and extending state, and a center region and the periphery region of the hollow chamber are contained in the extending distribution range of the capillary structure. Each formed capillary structure is in the structure form containing a center heat conduction portion corresponding to the center region and peripheral heat dissipation portions corresponding to the periphery region. In this way, the good industrial economic benefits that heat conduction benefits of the soaking plate can be increased greatly, the progressiveness and practically of the quality of the soaking plate can be improved greatly, and the manufacturing cost is lowered are achieved.

Owner:SUZHOU FORCECON ELECTRIC

LED cooling module structure

InactiveCN102412365BFast conductionAlso has circuit insulationSemiconductor devicesFiberHeat conducting

The invention provides a heat-conducting substrate and a radiating module structure of an LED (light-emitting diode). The heat-conducting substrate comprises a composite-material heat-conducting substrate formed by combination of a plurality of heat-conducting lines or fibers and an insulating material; the heat-conducting lines or fibers are distributed at intervals, penetrate through the front surface and the back surface of the composite-material heat-conducting substrate and are separated by the insulating material; electrode welding pads are combined on the front surface of the composite-material heat-conducting substrate so as to form electric connection with electrode pins of an LED member, and heat-conducting welding pads are also combined on the front surface of the composite-material heat-conducting substrate so as to form heat-conducting contact with heat-sink parts of an LED component of the LED member; and insulating layers corresponding to the electrode welding pads are combined on the back surface of the composite-material heat-conducting substrate. In the invention, the characteristics with high heat conductivity in the thickness direction but insulation in the plane direction can be achieved by a simple structure, so that the heat can be quickly conducted to a radiating member. The invention can be used for high-brightness LED illuminating products.

Owner:HO CHENG INDUSTRIAL CO LTD

Cold and heat balanced ceramic valve

ActiveCN103047446BReduce manufacturing costPractical progressMultiple way valvesMetallurgyEconomic benefits

The invention discloses a cold and hot balancing ceramic valve which is characterized in that under the condition that the outer diameter and height of a valve casing and a high-leg base meet the existing system specification condition of a ceramic valve product, a water inlet pipe accommodating groove is arranged at the bottom ends of a cold water hole and a hot water hole of the high-leg base and used for arranging a combined water inlet pipe group arranged in inclined mode. The combined water inlet pipe group is formed by a cold water pipe body and a hot water pipe body. Adjacent sides of the hot water pipe body and the cold water pipe body are opposite and combined to form a balancing valve accommodating space inside the adjacent sides, and the balancing valve accommodating space is used for accommodating a cold and hot balancing valve construction member. A cold and hot balancing ceramic valve structure capable of being applied to the existing system ceramic valve specification generally is provided, manufacture cost of the cold and hot balancing ceramic valve is greatly reduced, a cold and hot balancing function is achieved, practicality advancement and better industrial economic benefit are achieved.

Owner:童炳荣

Pipe end butt joint type loop type heat pipe

InactiveCN106052442AReduce manufacturing costImprove cooling effectIndirect heat exchangersButt jointEconomic benefits

A pipe end butt joint type loop type heat pipe mainly comprises a hollow pipe body, an inserting connection part, a sleeved connection part, a close fit area segment and a loose fit area segment, wherein the hollow pipe body comprises two pipe ends and a loop type area segment, and a loop type runner space in the hollow pipe body is in a vacuum closed state and contains work liquid; the inserting connection part is arranged at one pipe end of the hollow pipe body; the sleeved connection part is arranged at the other pipe end of the hollow pipe body, and the sleeved connection part is used for being assembled on the periphery of the inserting connection part in a sleeving manner; the close fit area segment is arranged on one local area segment of the portion where the inserting connection part and the sleeved connection part are inserted and sleeved, and the inserting connection part and the sleeved connection part are in a closely-inserted gastight state through the close fit area segment; and the loose fit area segment is arranged on the other local area segment of the portion where the inserting connection part and the sleeved connection part are inserted and sleeved, and a gap is formed between the inserting connection part and the sleeved connection part through the loose fit area segment. The loop type heat pipe can achieve the practical progress that a component is formed, the manufacturing and forming steps are substantially simplified, the manufacturing cost is substantially reduced and good cooling performance is maintained, and good industry economic benefits.

Owner:SUZHOU FORCECON ELECTRIC

Air tool motor with built-in striking mechanism

InactiveCN104175269BReduced axial length volumeQuick and easy lock removalPower driven toolsRotary piston enginesEconomic benefitsPneumatic tool

The invention discloses a pneumatic tool motor with a built-in beating mechanism. The pneumatic tool motor comprises an air cylinder body, a rotor group and an output shaft rod, wherein the rotor group comprises a drum and a telescopic blade, and the output shaft rod can be driven by the drum; an inner containing chamber is formed in the inner part of the drum of the rotor group; the output shaft rod is provided with a beating action zone which is positioned in the inner containing chamber; the inner containing chamber is internally provided with the built-in beating mechanism, and the built-in beating mechanism comprises a beating convex block which is arranged in the beating action zone in a bulged way, a movable beating hammer which is arranged at the periphery of the beating convex block in a sleeving way and a supporting post which is axially located on the drum. According to the pneumatic tool motor with the built-in beating mechanism, disclosed by the invention, the axial length and the volume of the pneumatic tool motor can be substantially reduced, and the advantage and advancement that the use is more labor-saving and more convenient can be achieved; the built-in beating mechanism of the pneumatic tool motor has the advantages that the rotor group can be directly driven, a twisting force can be increased immediately, and the disassembling and the locking of components are quick and convenient, and thus the pneumatic tool motor has the advantages that the multi-aspect cost can be substantially reduced, and the better industrial economic benefit can be obtained.

Owner:陈秀如 +1

Method for forming loop type heat pipe with pipe ends in butt joint

InactiveCN106066132ASimplified manufacturing stepsReduce manufacturing costIndirect heat exchangersButt jointEngineering

The invention discloses a method for forming a loop type heat pipe with the pipe ends in butt joint. The method mainly comprises the step that a hollow pipe body is taken, wherein the hollow pipe body comprises the two pipe ends, a loop type segment, an insertion portion, a sleeving portion, a tight-fit segment and a loose-fit segment, and a loop type runner space inside the hollow pipe body is in a vacuum closed state and contains a working solution; the insertion portion is arranged at one of the pipe ends of the hollow pipe body; the sleeving portion is arranged at the other pipe end of the hollow pipe body, and the sleeving portion is used for being assembled to the outer circumference of the insertion portion in a sleeving manner; the tight-fit segment is arranged at one local segment of an insertion and sleeving part between the insertion portion and the sleeving portion, and through the tight-fit segment, the insertion portion and the sleeving portion are mutually in the tight-insertion airtight state; and the loose-fit segment is arranged at the other local segment of the insertion and sleeving part between the insertion portion and the sleeving portion, and through the loose-fit segment, a gap is formed between the insertion portion and the sleeving portion. By means of the method for forming the loop type heat pipe with the pipe ends in butt joint, the loop type heat pipe can achieve the practical and advancement performance that constituent components and production formation steps are substantially simplified, manufacturing cost is substantially lowered, and good heat dissipation efficiency is maintained; and good industrial economic benefits are achieved.

Owner:SUZHOU FORCECON ELECTRIC

Environmental-protection and multiple-effect powder composite and production method thereof

InactiveCN101805152BGood physical propertiesThe industry has good economic benefitsSolid waste managementSlurryPolyresin

Owner:王武添 +7

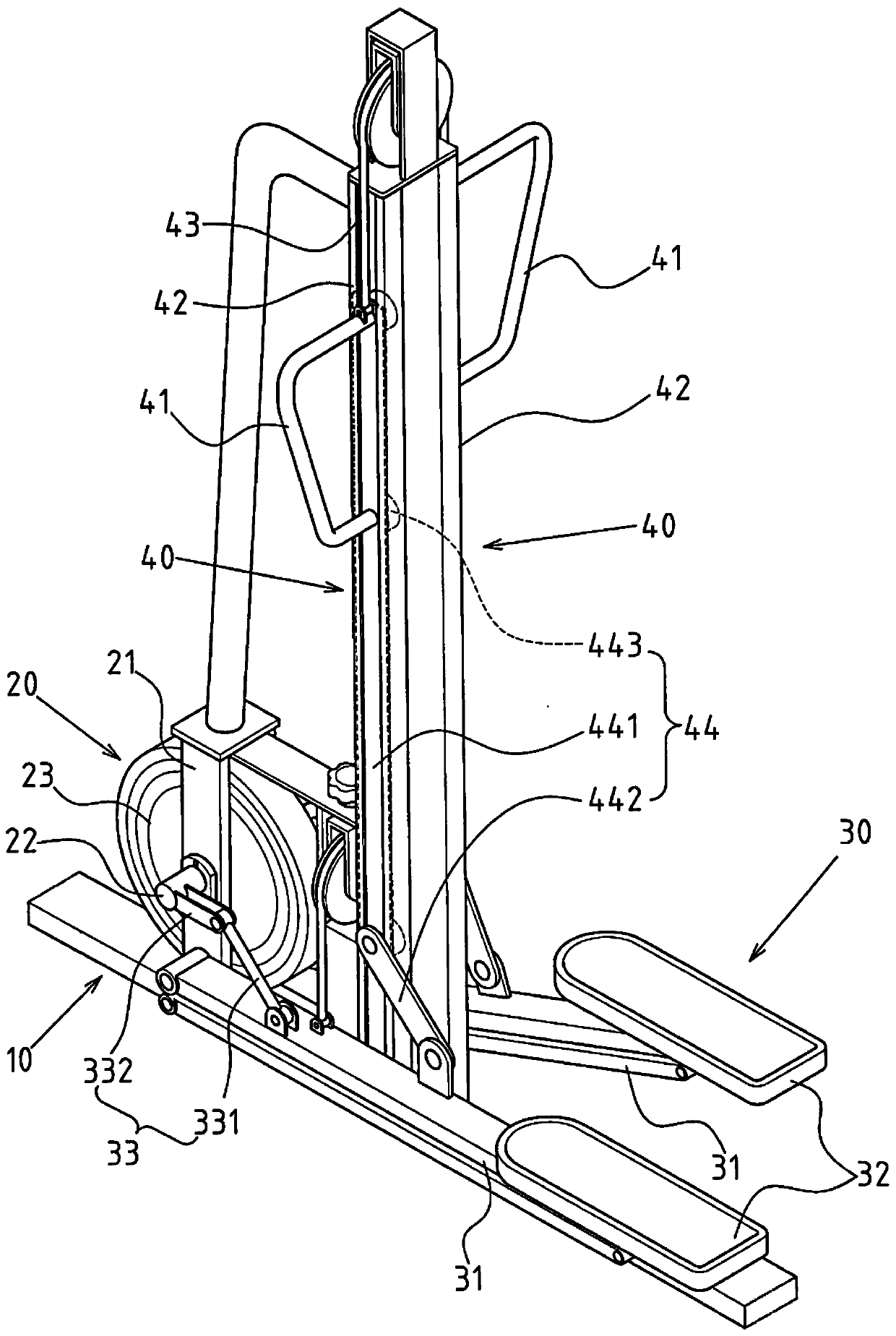

climbing machine

The invention discloses a rock climbing machine, which mainly comprises a base which is flatly placed on the supporting surface and a damping device which is arranged on the base, wherein a pedaling structure and two rock climbing simulators which are oppositely fixedly arranged on the base are each arranged at two sides of the damping device; the two rock climbing simulators are arranged at two sides of the damping device, wherein a holding device is slidingly arranged on each rock climbing simulator; and each holding device is connected to the pedaling structure at the corresponding side. The two pedaling structures, when alternately offering a pedaling function, can be linked to the corresponding holding devices so as to do reciprocating moving up and down; therefore, a function of simulating rock climbing actions is offered.

Owner:叶永松

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com