Vacuum sealing structure of uniform heat conductor and making method thereof

A vacuum and manufacturing technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of ideal shape influence, complex manufacturing process, easy damage to internal vacuum state and loss of long-term maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

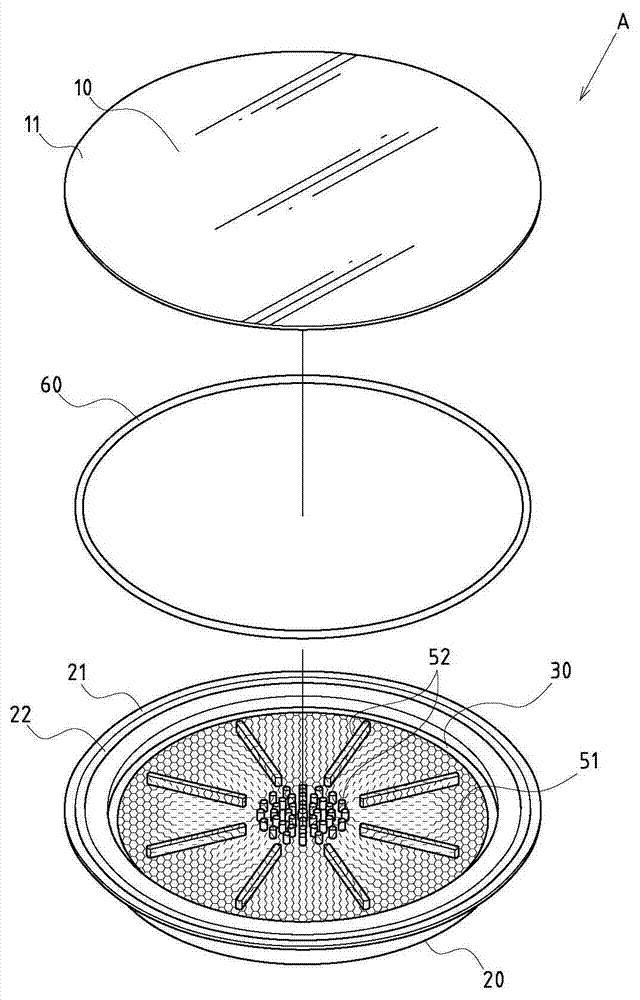

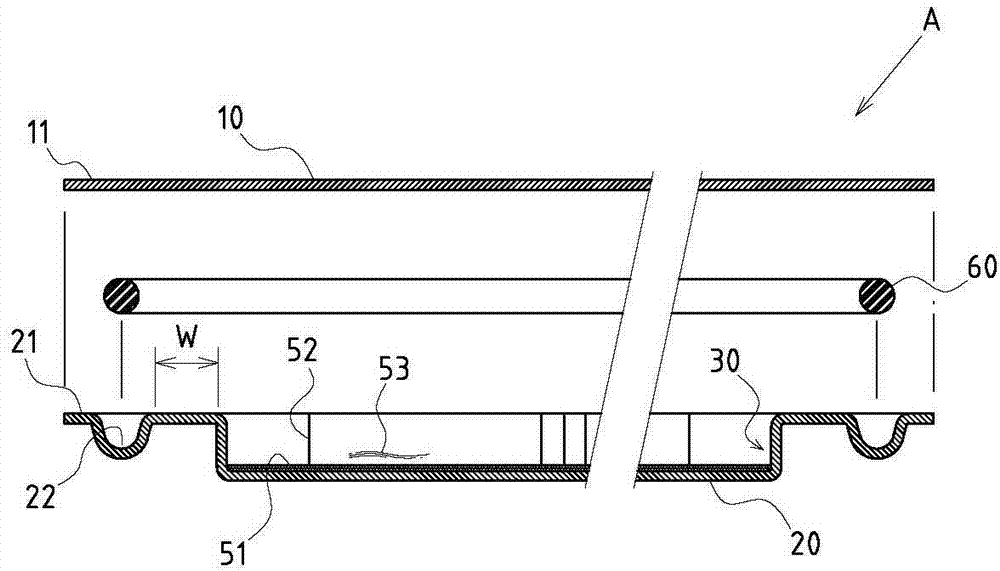

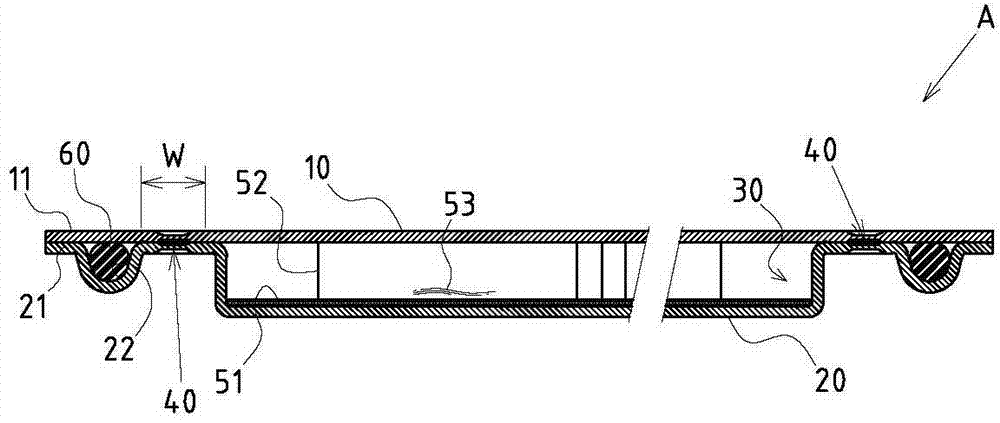

[0042] Example: see Figure 1~4 Shown is the preferred embodiment of the vacuum sealing structure of the uniform temperature heat conduction device of the present invention and its manufacturing method. These embodiments are for illustration purposes only, and are not limited by this structure in the patent application; The heat conduction device A is formed by stacking an upper cover plate 10 and a lower cover plate 20. A vacuum-enclosed hollow chamber 30 is formed inside between the upper cover plate 10 and the lower cover plate 20. The surrounding area of the upper cover plate 10 is There is an upper sealing ring 11 facing horizontally, and a lower sealing ring 21 facing horizontally is arranged around the lower cover plate 20, forming a gap between the upper sealing ring 11 and the lower sealing ring 21. There is a torus-shaped abutment relationship between the upper and lower directions, and has a width for welding (such as image 3 marked by W); and between the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com