Air tool motor with built-in striking mechanism

A technology of pneumatic tools and motors, applied in the field of local structure of pneumatic tools, can solve the problems of greatly increased cost, increased heavy feeling, laborious use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

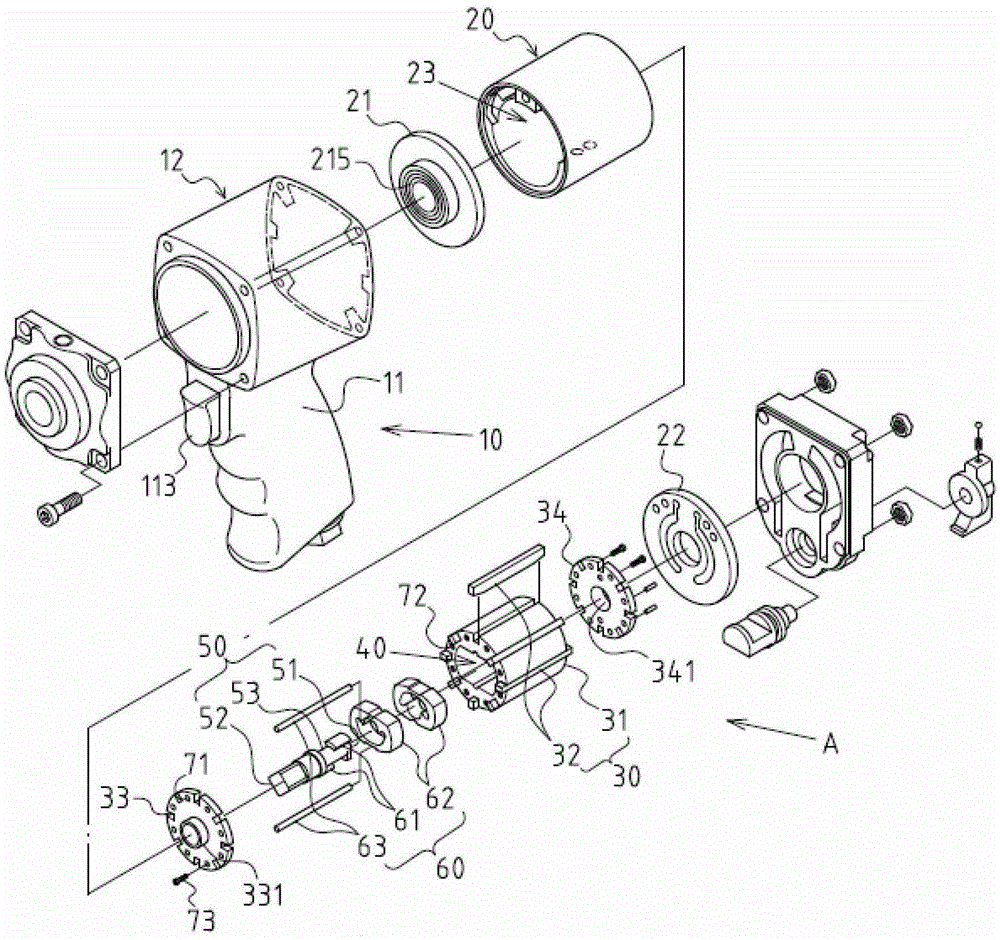

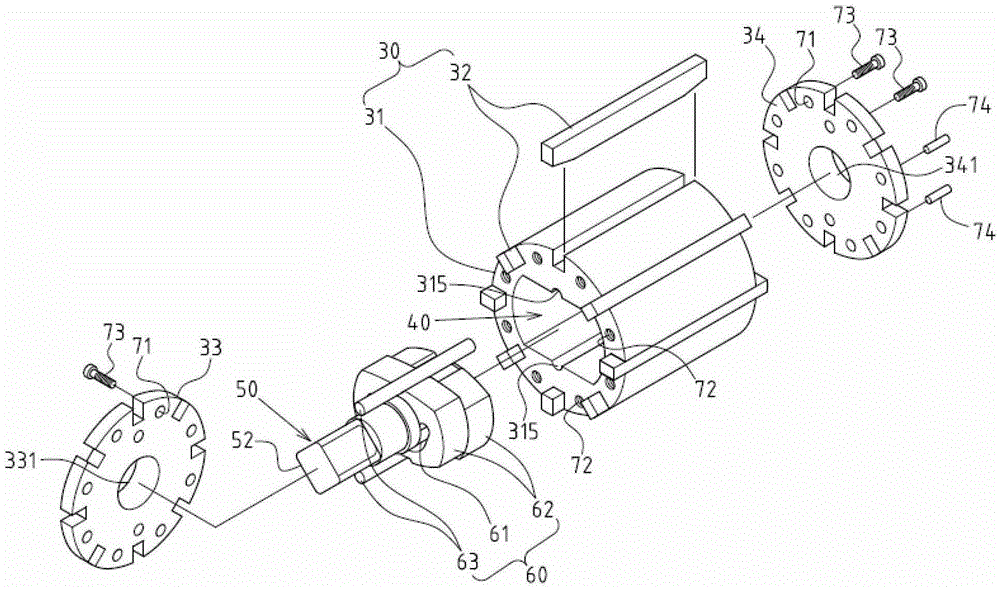

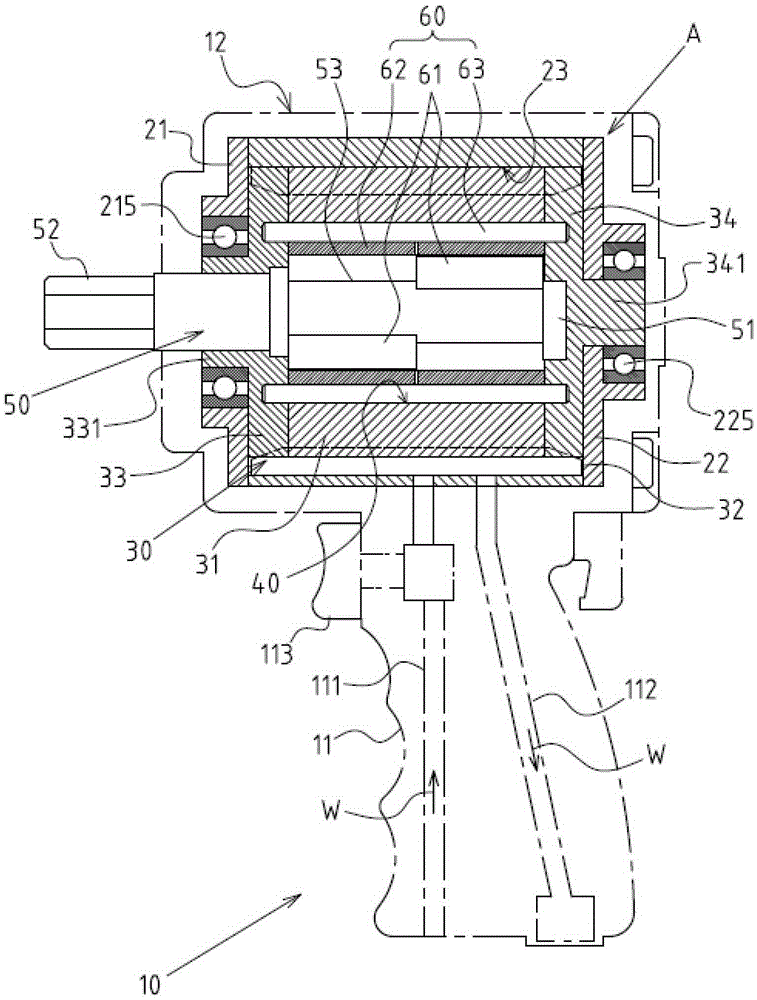

[0023] See figure 1 , 2 , 3, 4, the pneumatic tool motor A with a built-in striking mechanism of the present invention is arranged inside the body 12 formed by one end of the grip 11 (the top end in this embodiment) of a pneumatic tool 10. The grip 11 is detailed as image 3 As shown, it mainly includes an intake passage 111, an exhaust passage 112, and a switch 113 to control the opening and closing state of the intake passage 111; the pneumatic tool motor A includes the following components:

[0024] A cylinder block 20 is in the form of a hollow shell. The cylinder block 20 includes a front end wall 21, a rear end wall 22, and a cylinder chamber 23 inside which is cylindrical. The front end wall 21 is provided with a front end bearing 215, The rear end wall 22 is provided with a rear end bearing 225;

[0025] A rotor group 30 is housed in the cylinder chamber 23 of the cylinder block 20 in a rotatable state. The rotor group 30 includes a rotating drum 31 and at least two telescop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com