Pneumatic tool motor with built-in beating mechanism

A technology of pneumatic tools and motors, applied in the field of partial structure of pneumatic tools, can solve the problems of heavy feeling, laborious use, and inconformity with industrial economic benefits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

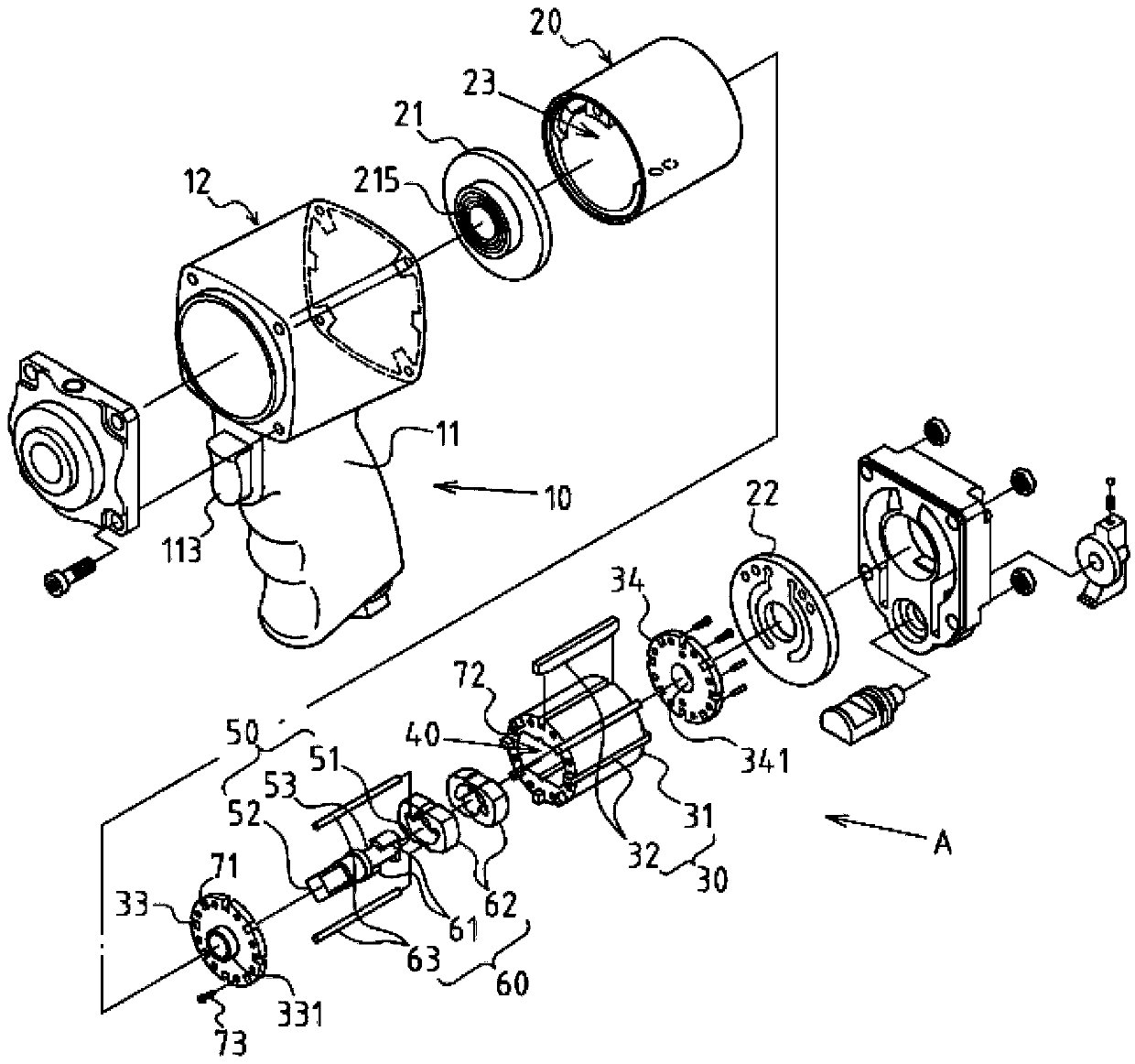

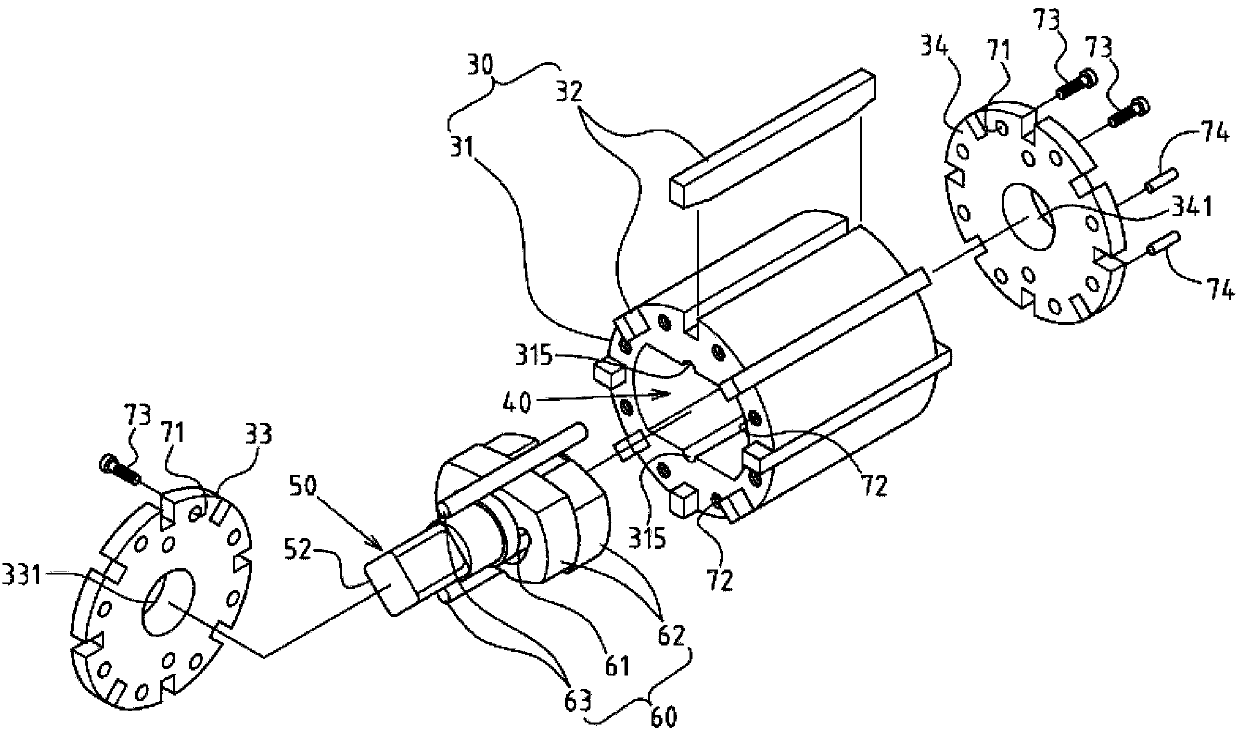

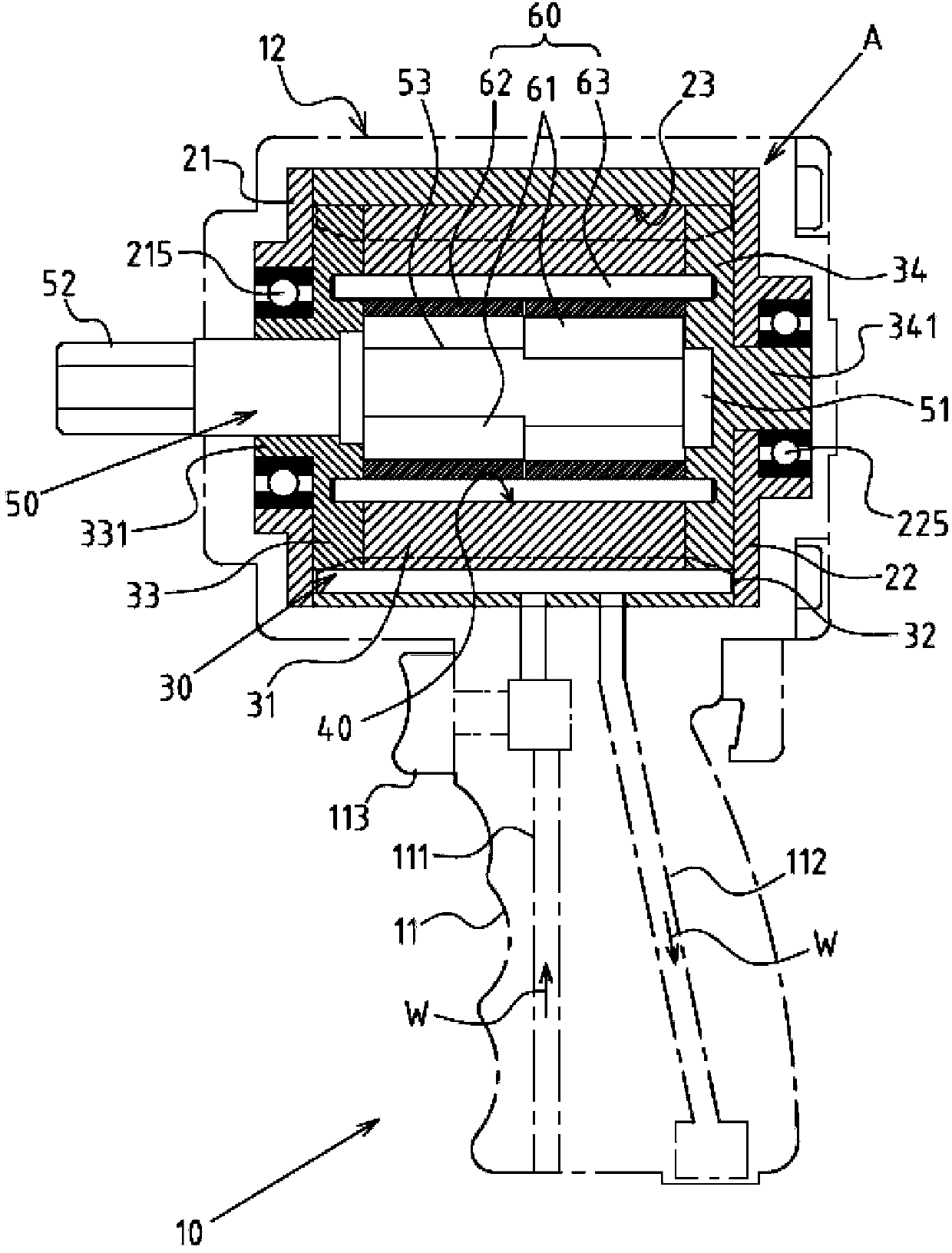

[0023] see figure 1 , 2 , 3, 4, the air tool motor A with a built-in striking mechanism of the present invention is located inside the body 12 formed by one end of the handle 11 (the top end in this embodiment) of an air tool 10, the handle 11 is detailed as image 3 As shown, it mainly includes an air intake channel 111, an exhaust channel 112 and a switch 113 to control the opening and closing of the air intake channel 111; the air tool motor A then includes the following components:

[0024] A cylinder block 20 is in the form of a hollow shell. The cylinder block 20 includes a front end wall 21, a rear end wall 22 and a cylinder chamber 23 that is cylindrical inside. The front end wall 21 is provided with a front end bearing 215, The rear end wall 22 is provided with a rear end bearing 225;

[0025] A rotor set 30 is rotatably accommodated in the cylinder chamber 23 of the cylinder block 20. The rotor set 30 includes a rotating drum 31 and at least two telescopic vanes 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com