Novel capillary structure configuration structure of soaking plate

A vapor chamber and capillary technology, applied in the field of innovative design of capillary configuration structure, can solve the problems of efficiency and quality impact, multiple costs and man-hours, and the difficulty of further improving heat conduction benefits, so as to improve heat conduction benefits and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

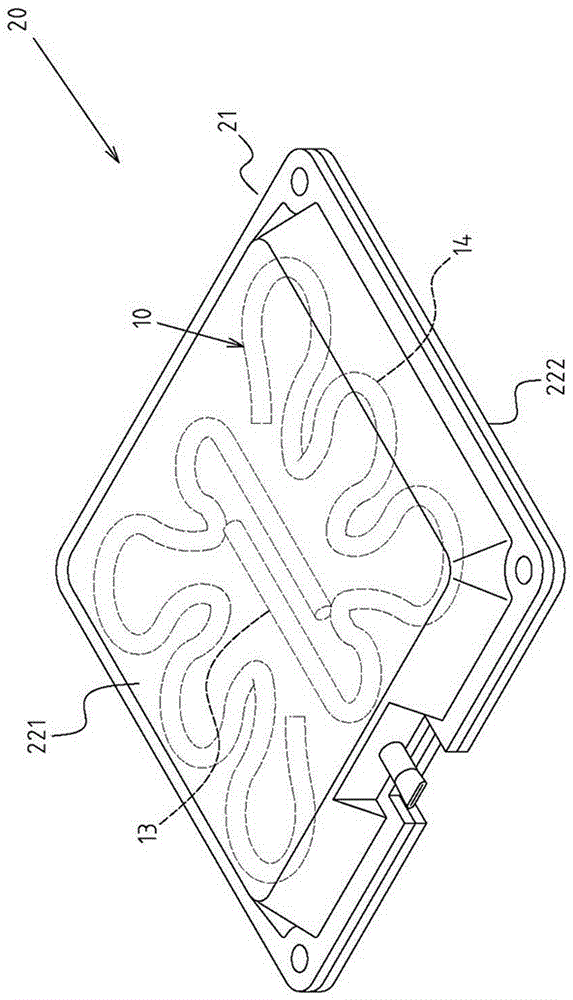

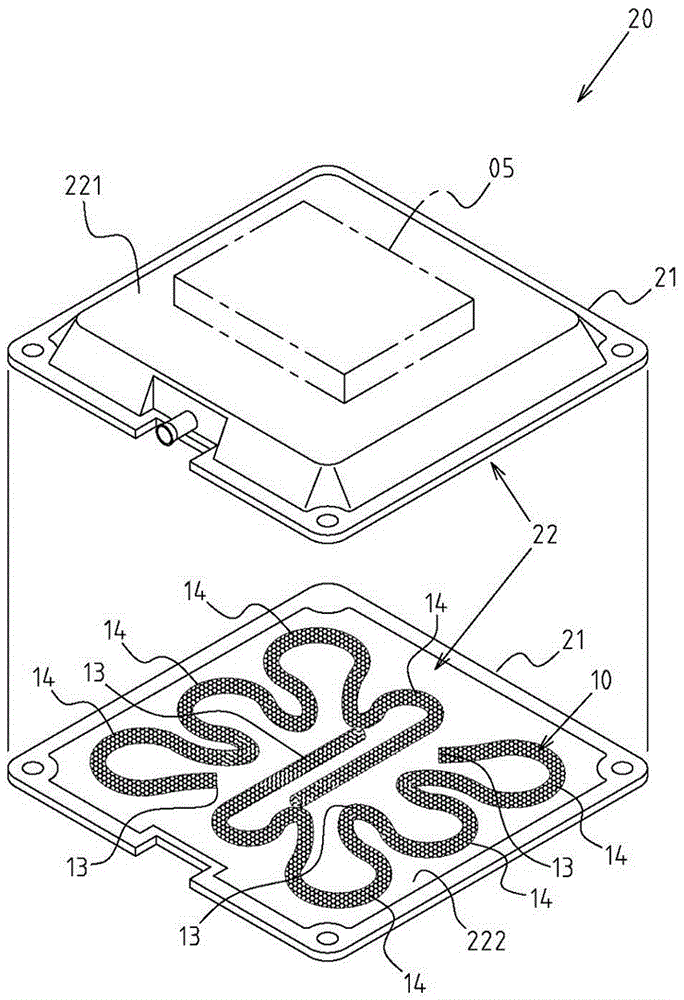

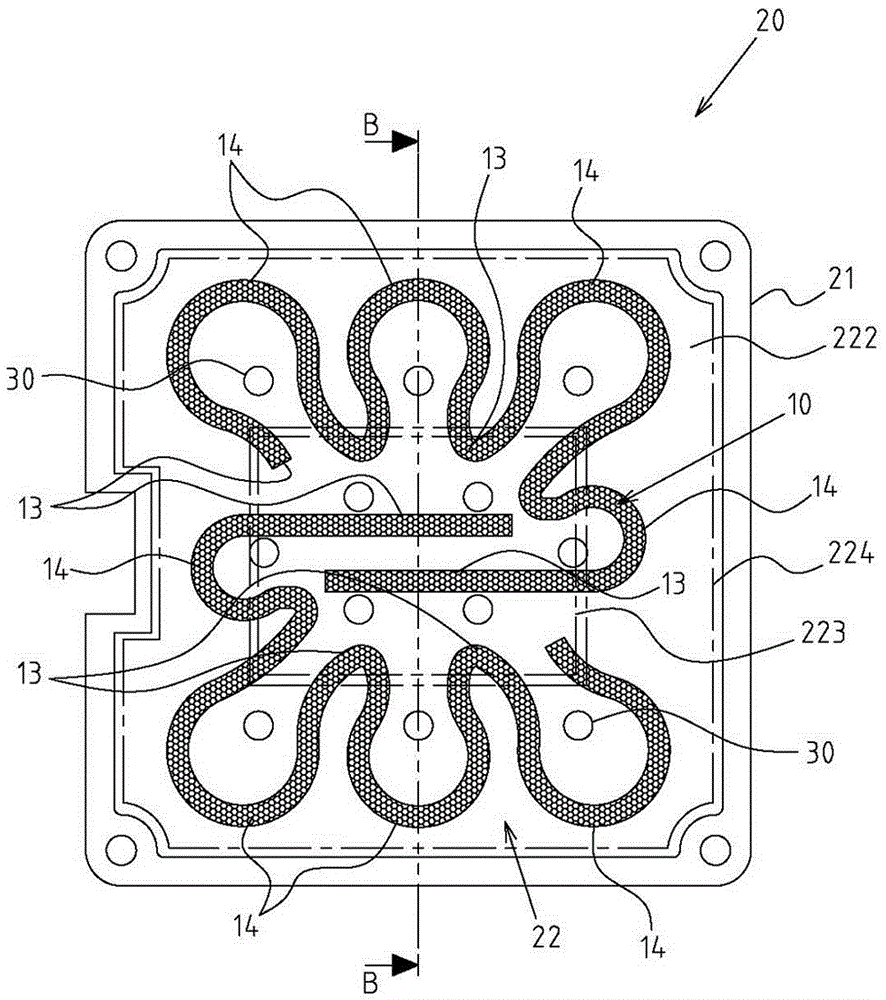

[0027] Example: see Figure 1~4 As shown, it is a preferred embodiment of the new capillary configuration structure and configuration method of the vapor chamber of the present invention, but these embodiments are only for illustration purposes, and are not limited by this structure in patent applications;

[0028] The capillary tissue 10 is arranged in a hollow chamber 22 provided in the housing 21 of a vapor chamber 20, and the first side 11 of the capillary tissue 10 is in contact with the top wall 221 of the hollow chamber 22, the The second side 12 of the capillary tissue 10 is then in contact with the bottom wall 222 of the hollow chamber 22; image 3 As shown, the hollow chamber 22 includes a central region 223 and a peripheral region 224 adjacent to the periphery of the vapor chamber 20; and wherein:

[0029] The capillary tissue 10 is set in a continuously curved and extended form, and the extended distribution range of the capillary tissue 10 covers the central area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com