Heat pipe structure of radiator

A radiator and heat pipe technology, applied in the field of innovative design, can solve problems such as low heat dissipation gain, inconsistent industrial economic benefits, and difficulty in achieving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

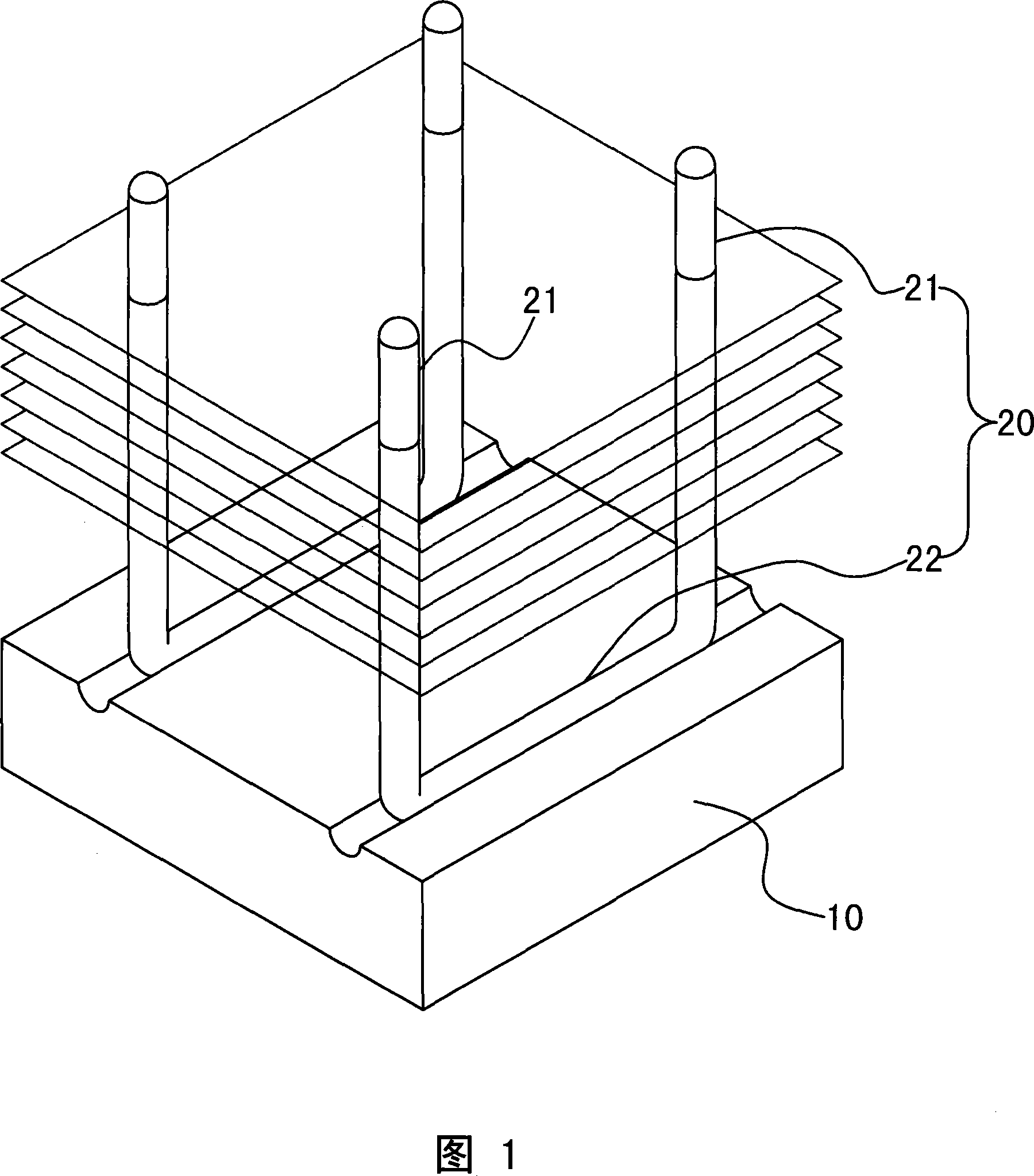

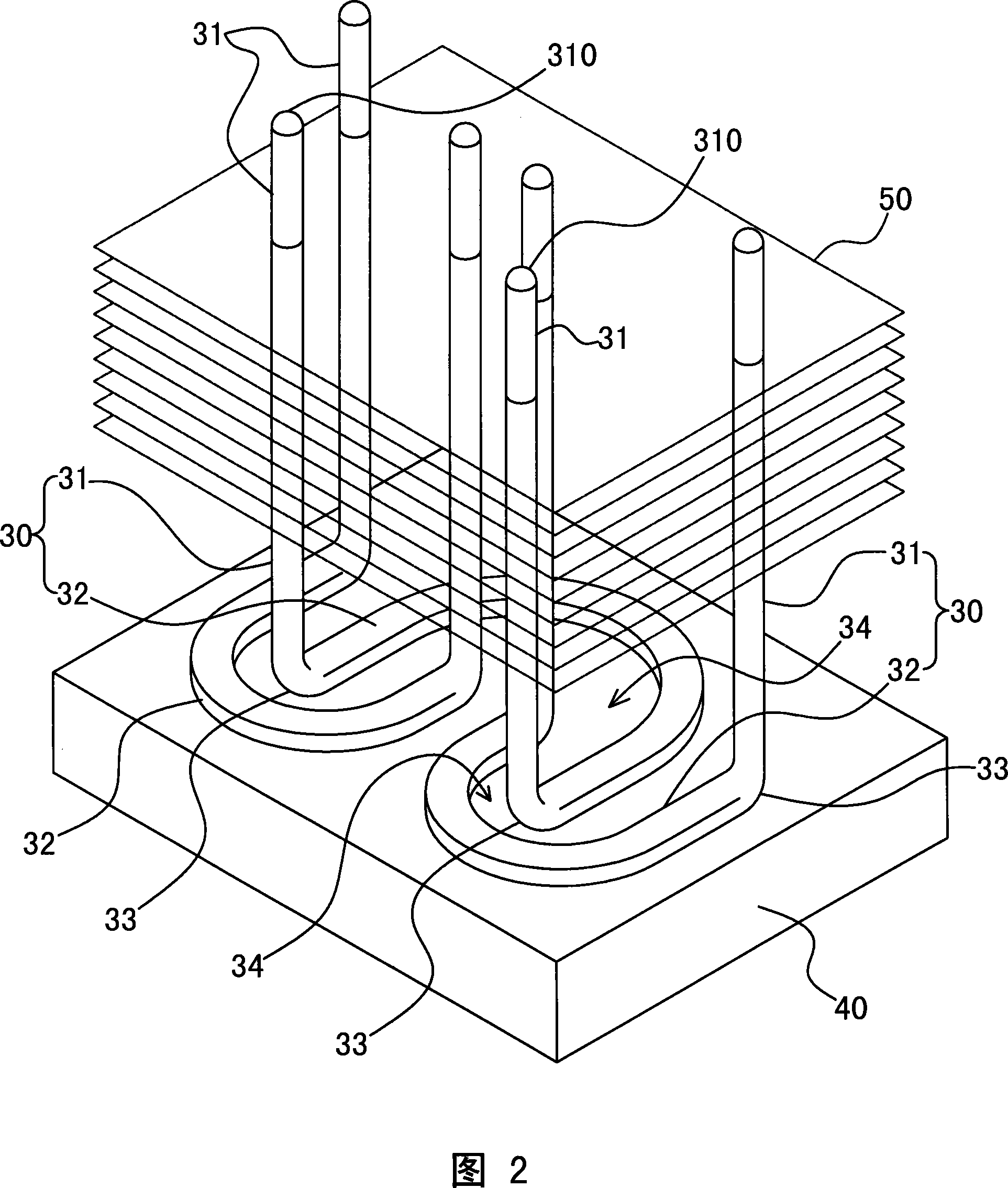

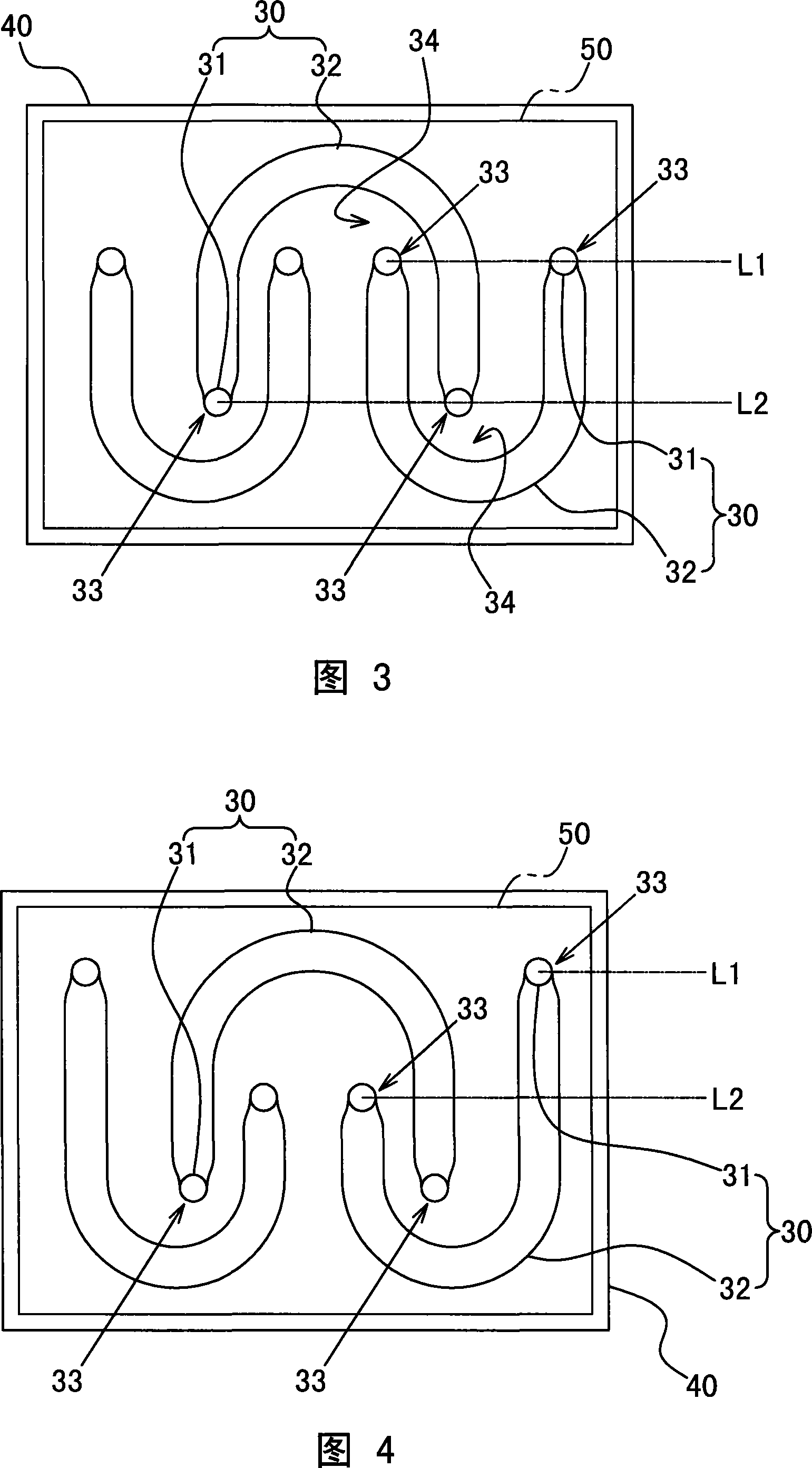

[0025] As shown in Figures 1 to 3, it is a preferred embodiment of the heat pipe structure of the radiator of the present invention; more than 30 heat pipes are arranged at intervals on a heat conduction base 40, and include two vertically upwardly protruding heat dissipation sections 31 , and the heat-receiving section 32 between the bottom ends of the two heat-dissipating sections 31, the heat-receiving section 32 rests on the heat-conducting base 40, and the junction of the heat-receiving section 32 and the two heat-dissipating sections 31 forms two turning parts 33, and the The heat dissipation section 31 is also provided with a predetermined number of heat dissipation fins 50;

[0026] The features of the present invention include: the heating section 32 is arranged in a curved shape to form a concave space 34, and the heating sections 32 of the adjacent heat pipes 30 are in a relative dislocation relationship, that is, the heating of a heat pipe 30 The turning portion 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com