Dust-proof cover device

A dust-proof cover and base technology, which is applied in the direction of optics, instruments, camera bodies, etc., can solve the problems of space occupation, inconvenient assembly, and many components of the dust-proof cover device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The aforementioned and other technical contents, features and functions of the dustproof cover device of the present invention will be clearly understood in the following detailed description of preferred embodiments with reference to the drawings.

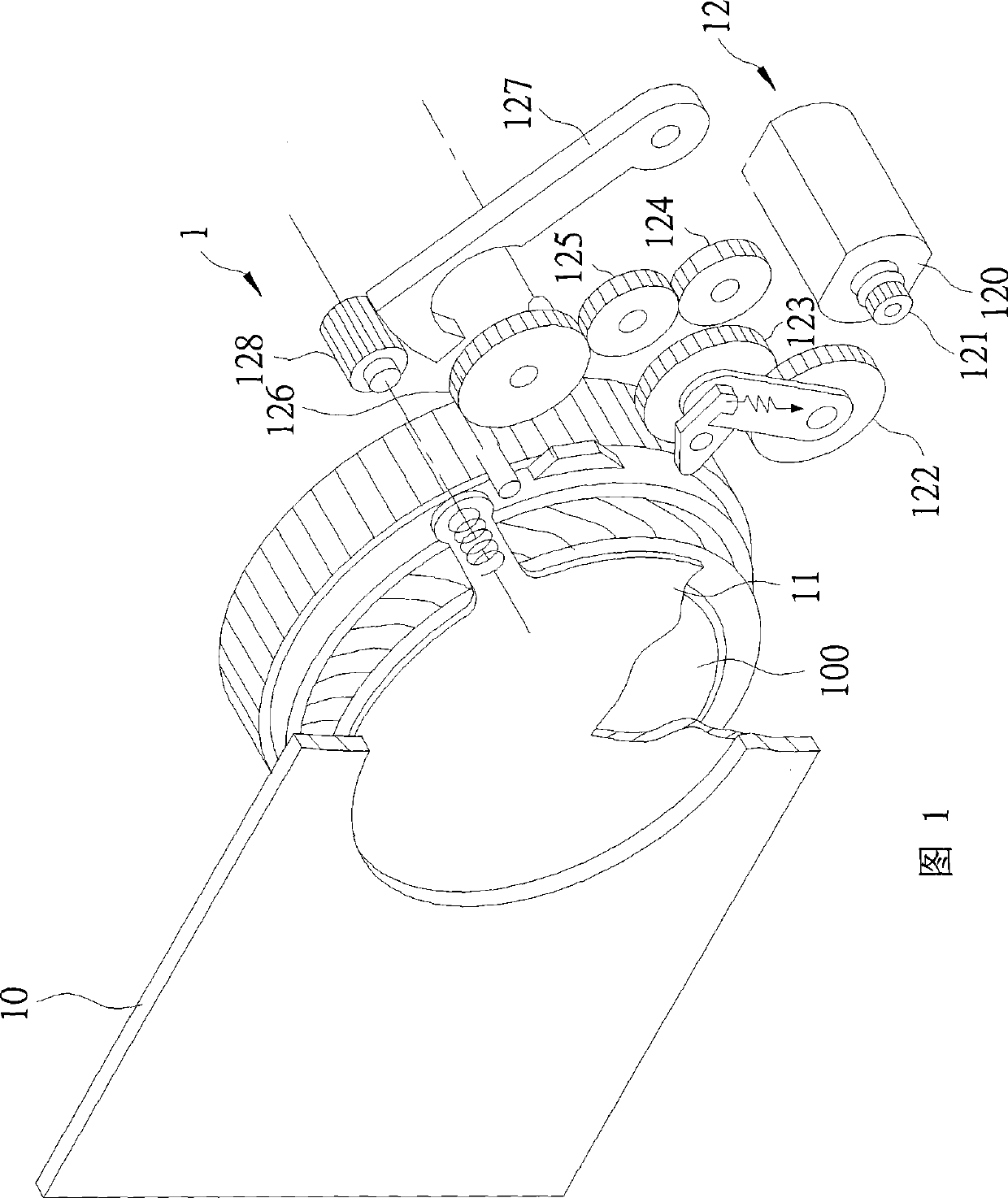

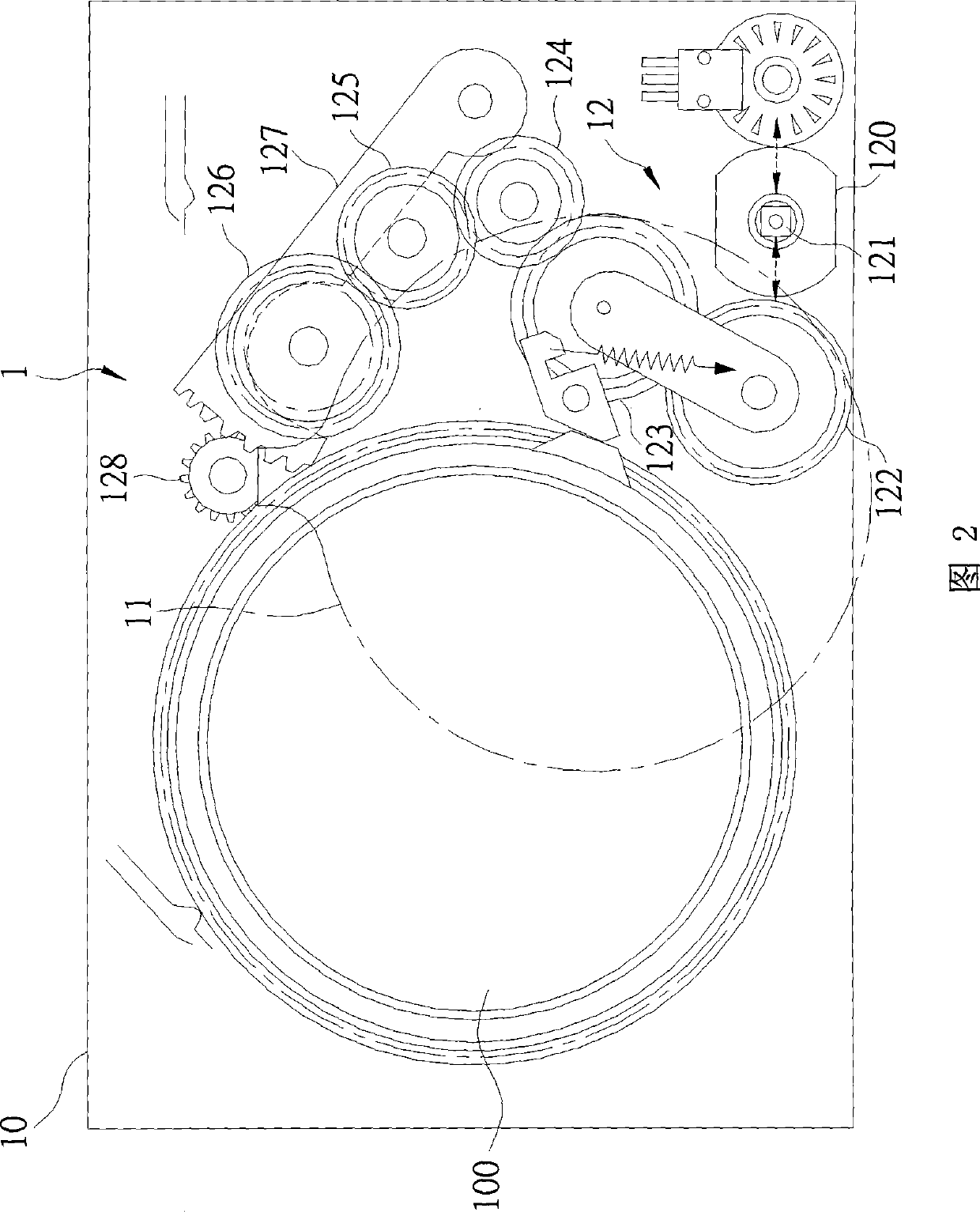

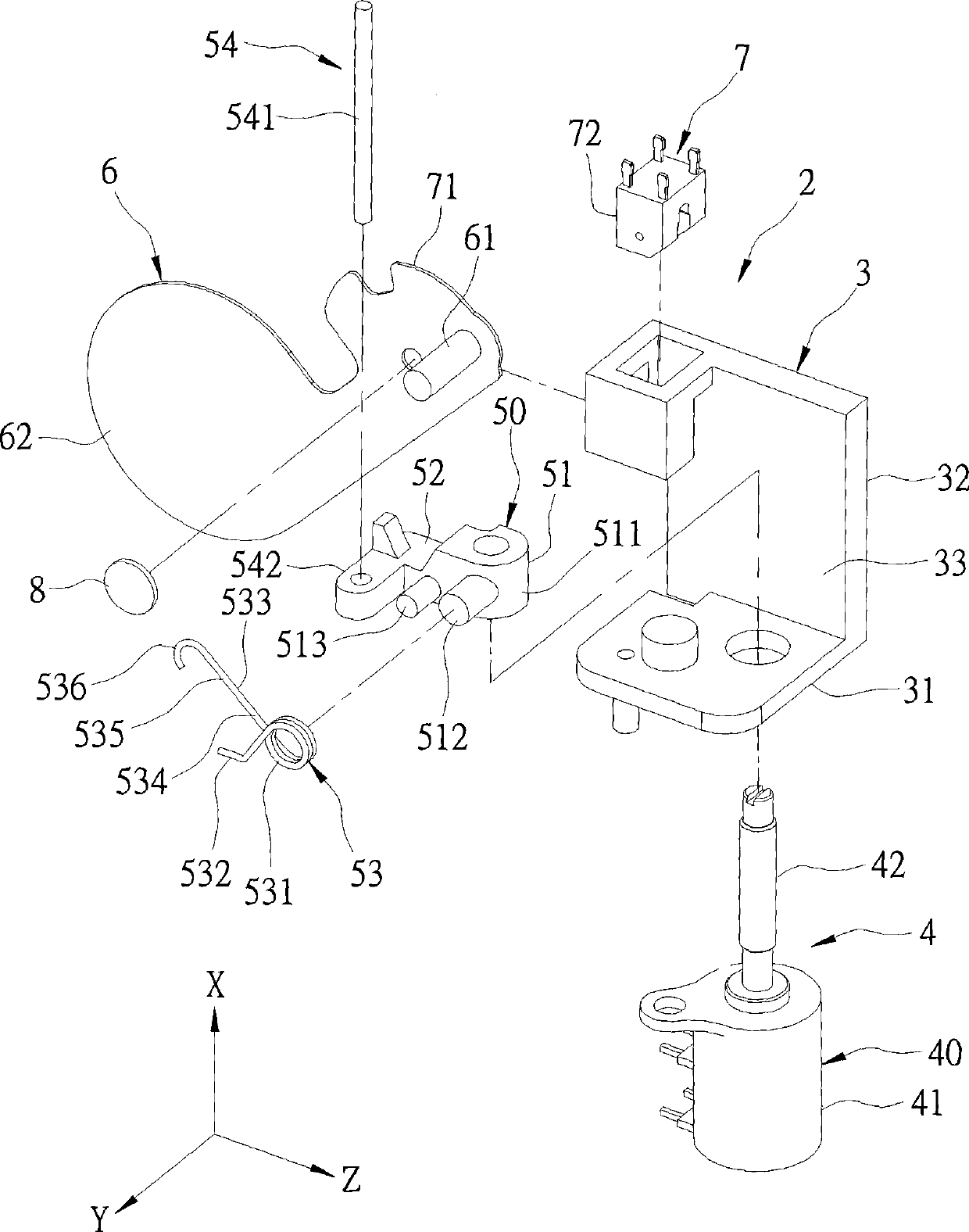

[0018] refer to image 3 and Figure 4 , are the three-dimensional exploded view and the three-dimensional assembly view of the present invention respectively, the preferred embodiment of the dust cover device 2 of the present invention includes a base 3, a drive mechanism 4 mounted on the base 3, connected by the drive mechanism 4 A moving dust cover 6, and a position sensing unit 7 respectively provided on the base 3 and the dust cover 6 correspondingly.

[0019] The base 3 includes a base wall 31 , and a side wall 32 extending from the base wall 31 along a first direction X and cooperating with the base wall 31 to define a receiving space 33 .

[0020] The driving mechanism 4 includes a power unit 40 and a transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com