Magnetic connector

A magnetic suction connector technology, which is applied in the direction of connecting and connecting parts of the device, and a device for joining/disconnecting connected parts, etc., can solve the problem that the long iron rod and the circuit board are not easy to weld, etc., to reduce the assembly volume, The effect of improving the magnetic attraction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical content and detailed description of the present invention will be described below with the accompanying drawings, but the attached drawings are only for illustration purposes and are not intended to limit the present invention.

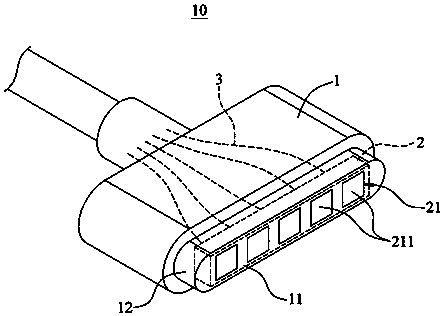

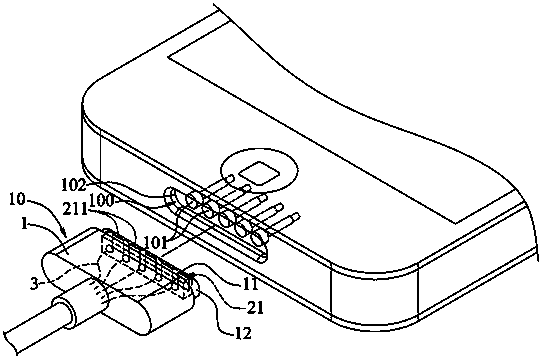

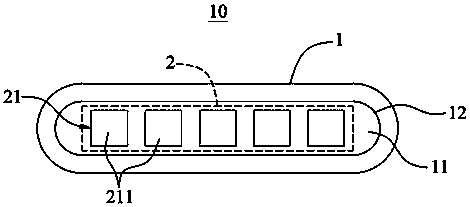

[0037] Please refer to Figure 1 to Figure 5 As shown, it is the first embodiment of the magnetic suction connector of the present invention. The present invention provides a magnetic suction connector 10, the magnetic suction connector 10 is used to connect the magnetic suction socket 100, the magnetic suction The socket 100 has more than two magnetic terminals 101 and a socket 102. The magnetic terminals 101 are exposed in the socket 102. The magnetic connector 10 mainly includes an insulating body 1, a circuit board 2, two or more magnetic gold fingers 21 and Two or more cables3.

[0038] The insulating body 1 has a plug-in portion 11; the details are as follows, the insulating body 1 extends with a bump 12, the plug-in portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com