Parallel arrangement connection portion and end cover sealing structure for loop type heat pipe

A closed structure and group connection technology, which is applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of reduced heat dissipation efficiency, complex structure composition, mutual obstruction of flow directions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

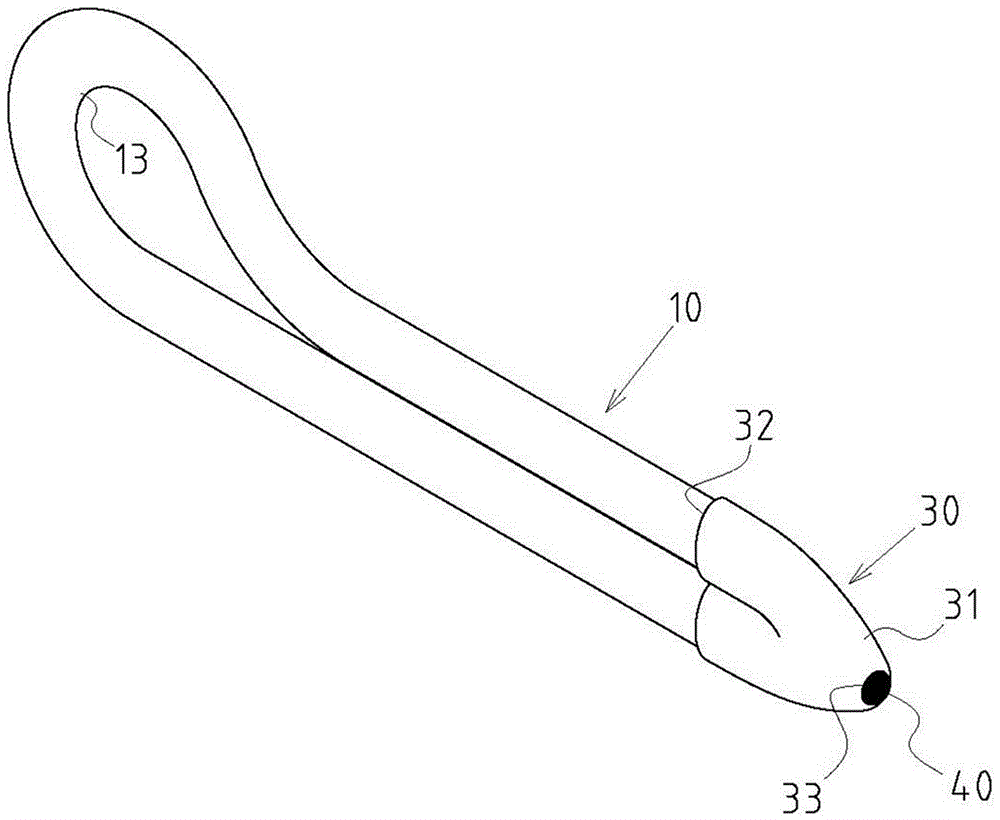

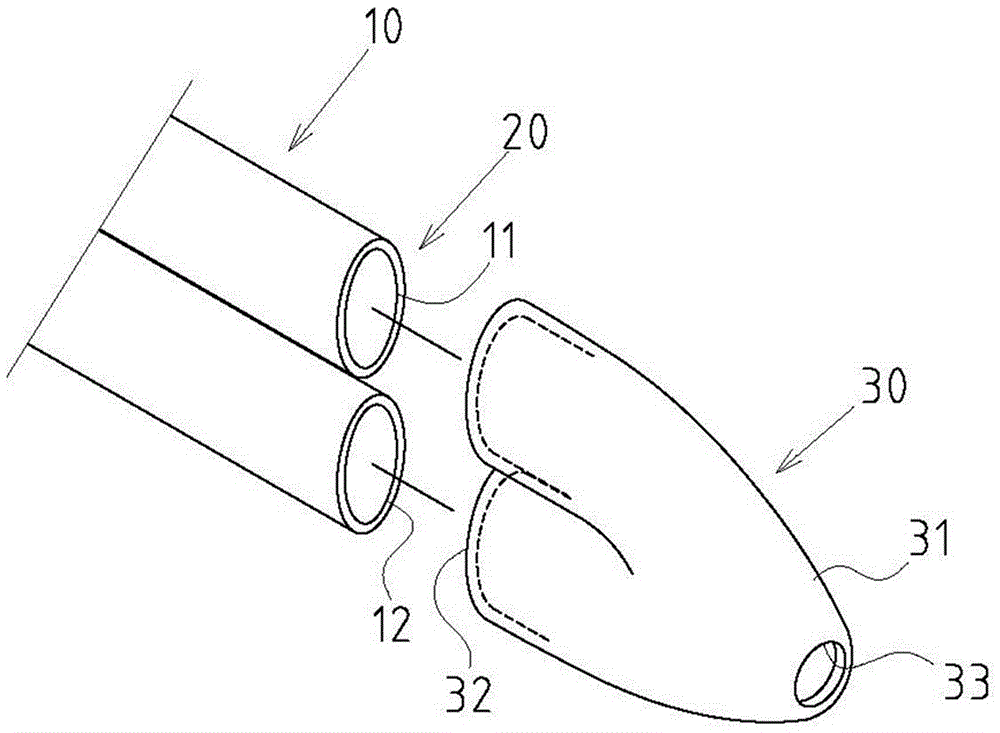

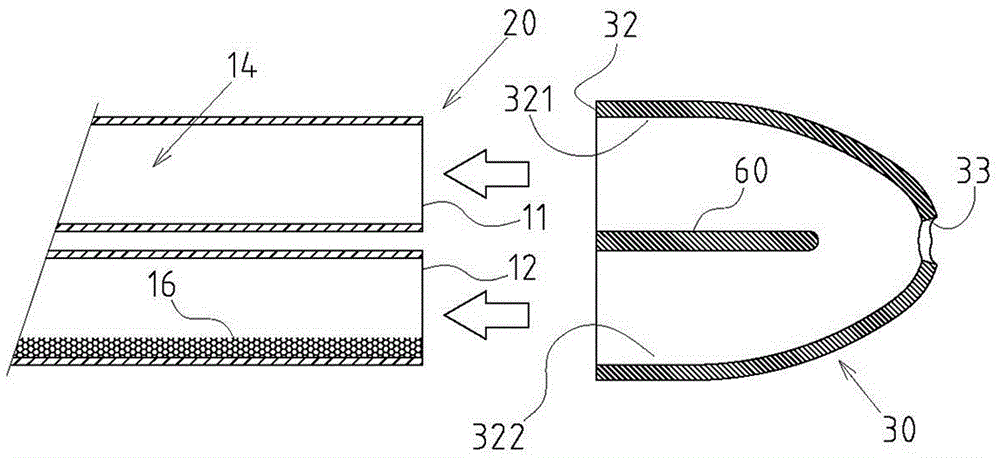

[0027] Example: see Figure 1~5 Shown is a preferred embodiment of the end cap closure structure of the parallel connection part of the loop heat pipe of the present invention, but these embodiments are for illustration purposes only, and are not limited by this structure in the patent application.

[0028] The closure structure of the end cover of the parallel connection part of the loop type heat pipe includes the following components:

[0029] A hollow tube body 10 is bent into a folded shape and includes two tube ports 11, 12 and a loop-type section 13 between the two tube ports 11, 12, and the hollow tube body 10 has a flow channel inside Space 14, the channel space 14 includes an evaporation section 141 and a condensation section 142 (only marked in Figure 5 ) and accommodate a working fluid 15; and at least the evaporating section 141 is provided with a capillary 16; a group of connecting parts 20, the two tube ports 11, 12 passing through the hollow tube body 10 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com