End butt joint type loop heat pipe

A docking and looping technology, applied in the field of heat pipes, can solve the problems of difficult manufacturing, processing and forming, inconsistent with industrial economic benefits, and reduced heat dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

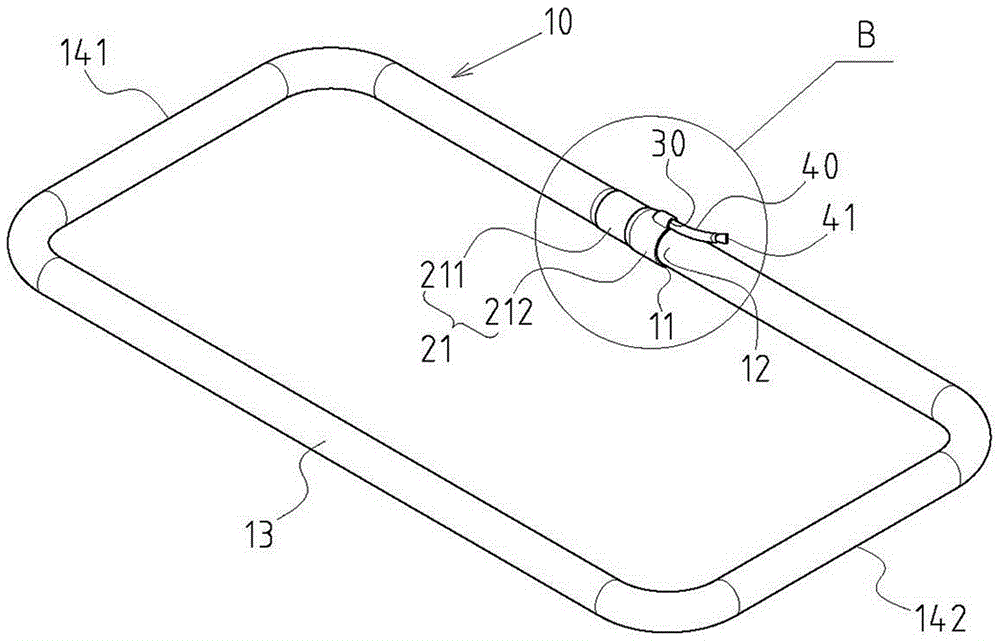

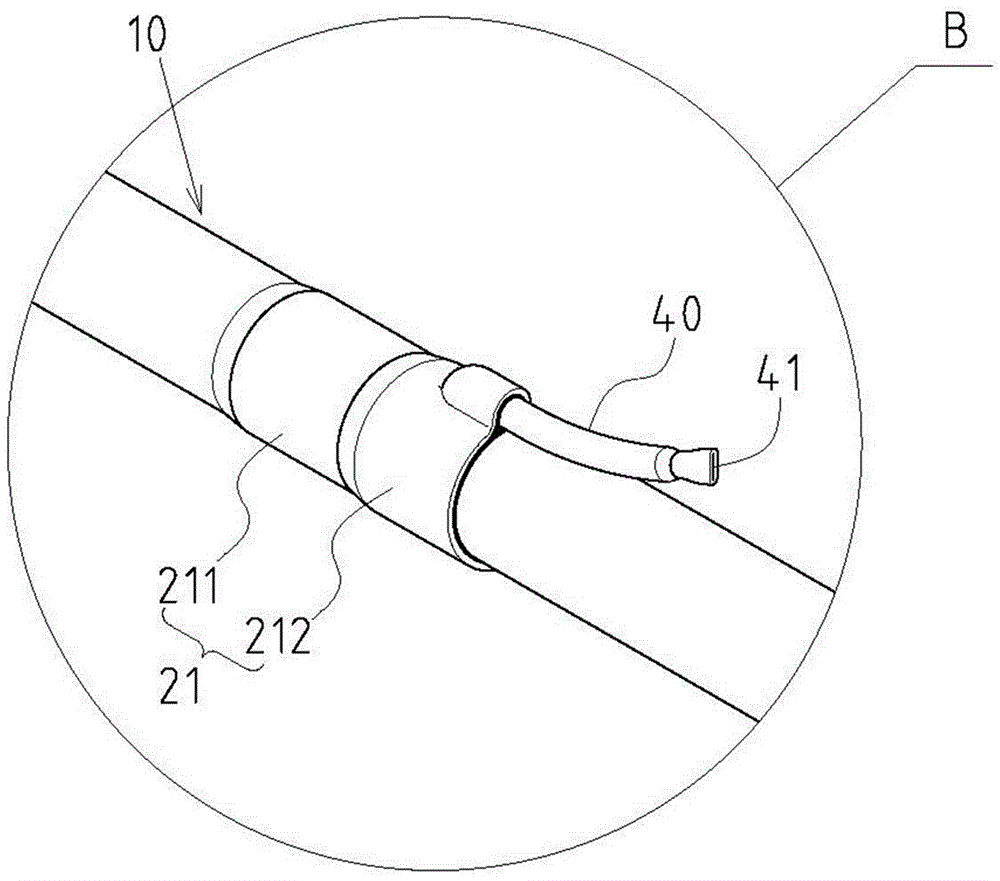

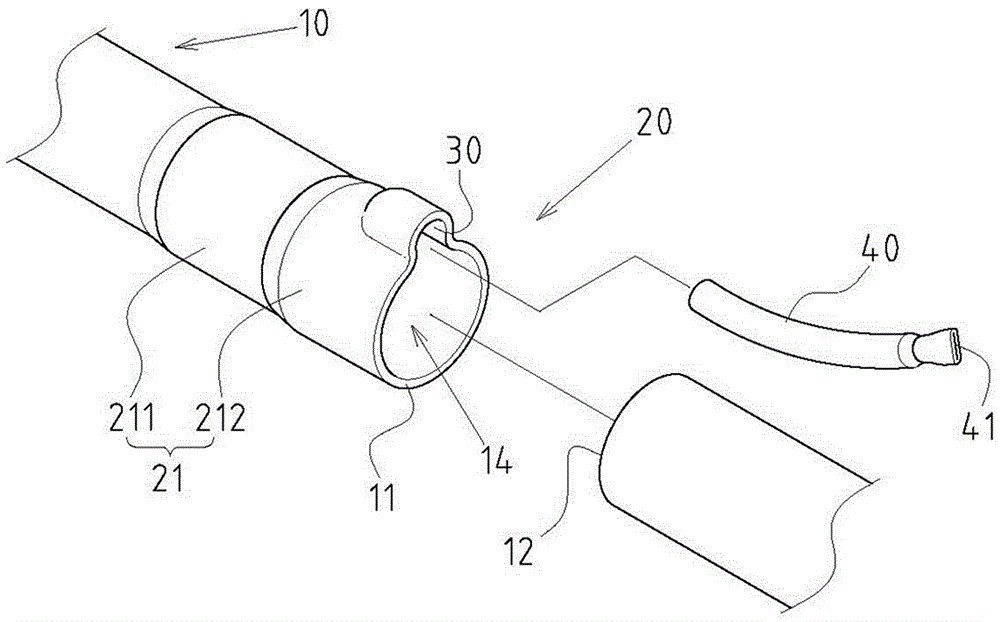

[0025] Example: see Figure 1~4 Shown is the preferred embodiment of the end-butt loop heat pipe of the present invention, but these embodiments are for illustration purposes only, and are not limited by this structure in patent application.

[0026] The end-butt loop type heat pipe includes the following components: a loop-type tube body 10, which is formed by a hollow tube body, and its exterior is bent into a folded shape to include a first tube end 11, a second tube end 12 and a loop-type segment 13 between the first pipe end 11 and the second pipe end 12, the inside of the loop-type pipe body 10 forms a loop-type flow passage space 14, and the loop-type flow passage space 14 includes an evaporating section 141 and a condensing section 142. The loop-type flow channel space 14 is in a vacuum-enclosed state and accommodates a working fluid 143, and a capillary section is provided between the evaporating section 141 and the condensing section 142. Tissue 144 (it can be a met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com