Magnetic attracting positioning type rotary platform

A rotating platform and positioning technology, which is applied in the direction of workbench, large fixed members, metal processing machinery parts, etc., can solve the problems of expensive setup cost, complicated servo motor structure, and difficulty in achieving high-precision positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

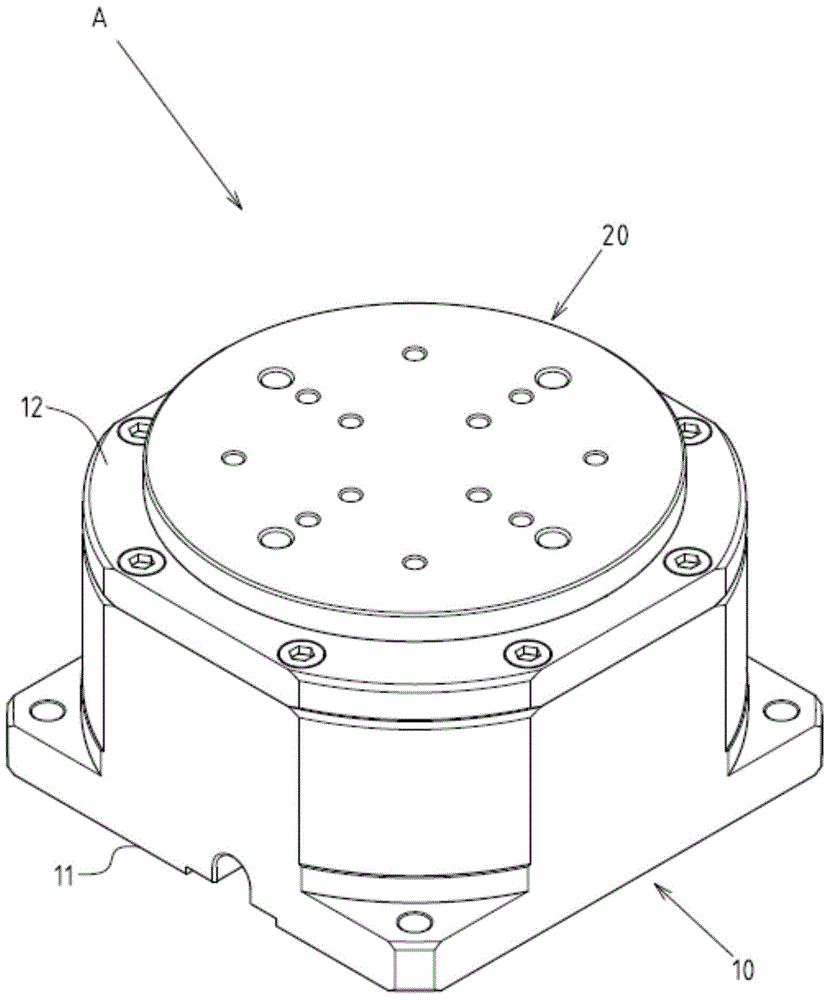

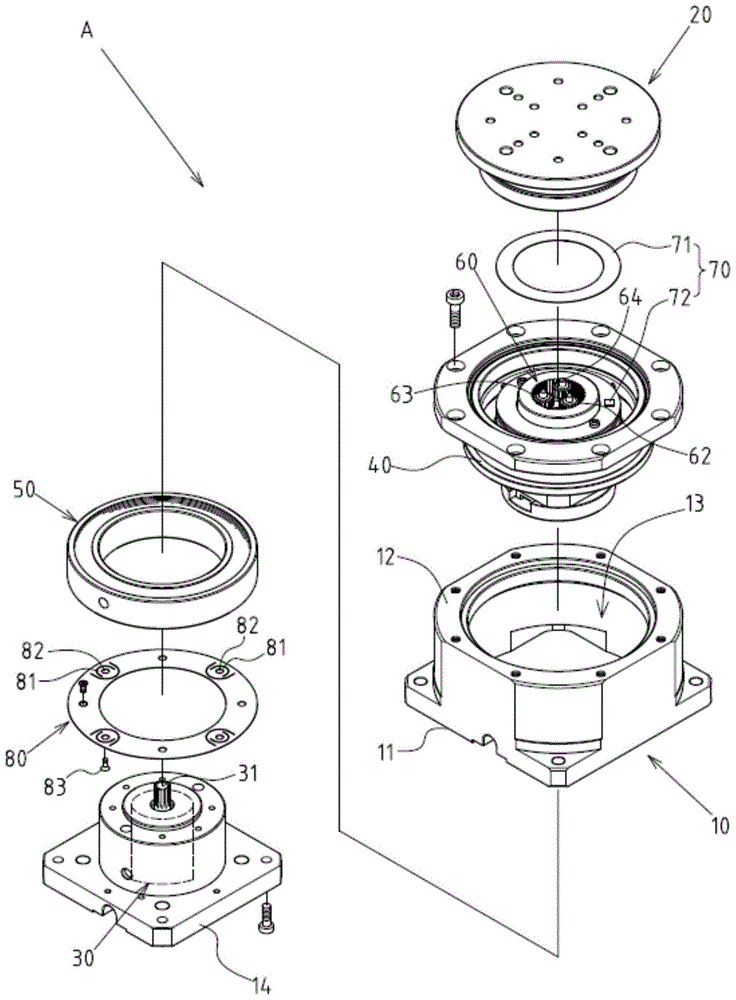

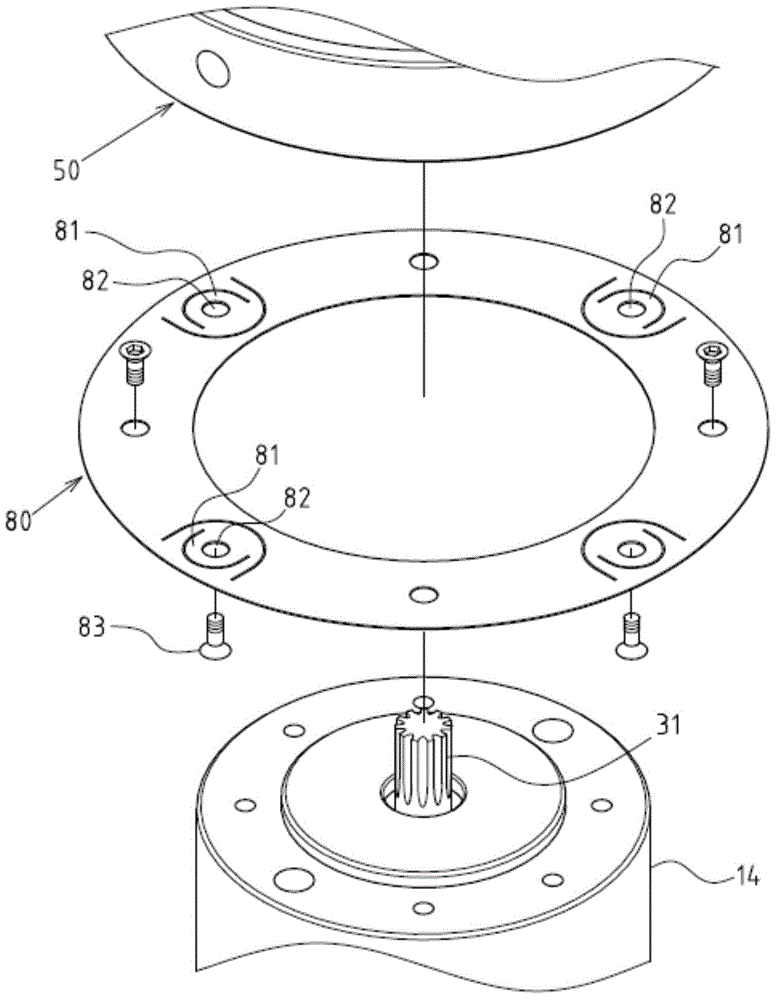

[0016] Such as figure 1 , 2 , 3, and 4 show preferred embodiments of the magnetic suction positioning rotary platform of the present invention, but these embodiments are only for illustration purposes, and are not limited by this structure in patent applications; the magnetic suction positioning type The rotating platform A includes the following components: a base 10, which is in the shape of a hollow seat, and includes a placement portion 11, a top 12, and a hollow accommodation portion 13, and the bottom end of the hollow accommodation portion 13 has a mounting seat 14 ; a rotating disk 20, which is pivotally assembled on the top 12 of the base 10 through a bearing 21, and is in a horizontally rotatable state; Inside the seat 14, a driving shaft 31 protrudes upward toward the center of the bottom of the rotating disk 20 at the top of the actuating device 30; And protrude downwards into the hollow housing portion 13 of the base 10, and be located at the peripheral interval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com