Magnetic-control wheel

A magnetic control wheel and structure technology, applied in the field of magnetic control wheels, can solve the problems of high manufacturing cost, poor movement quality, high transmission resistance, etc., and achieve the effects of reduced defective rate of finished products, low difficulty in mold manufacturing, and accurate positioning points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

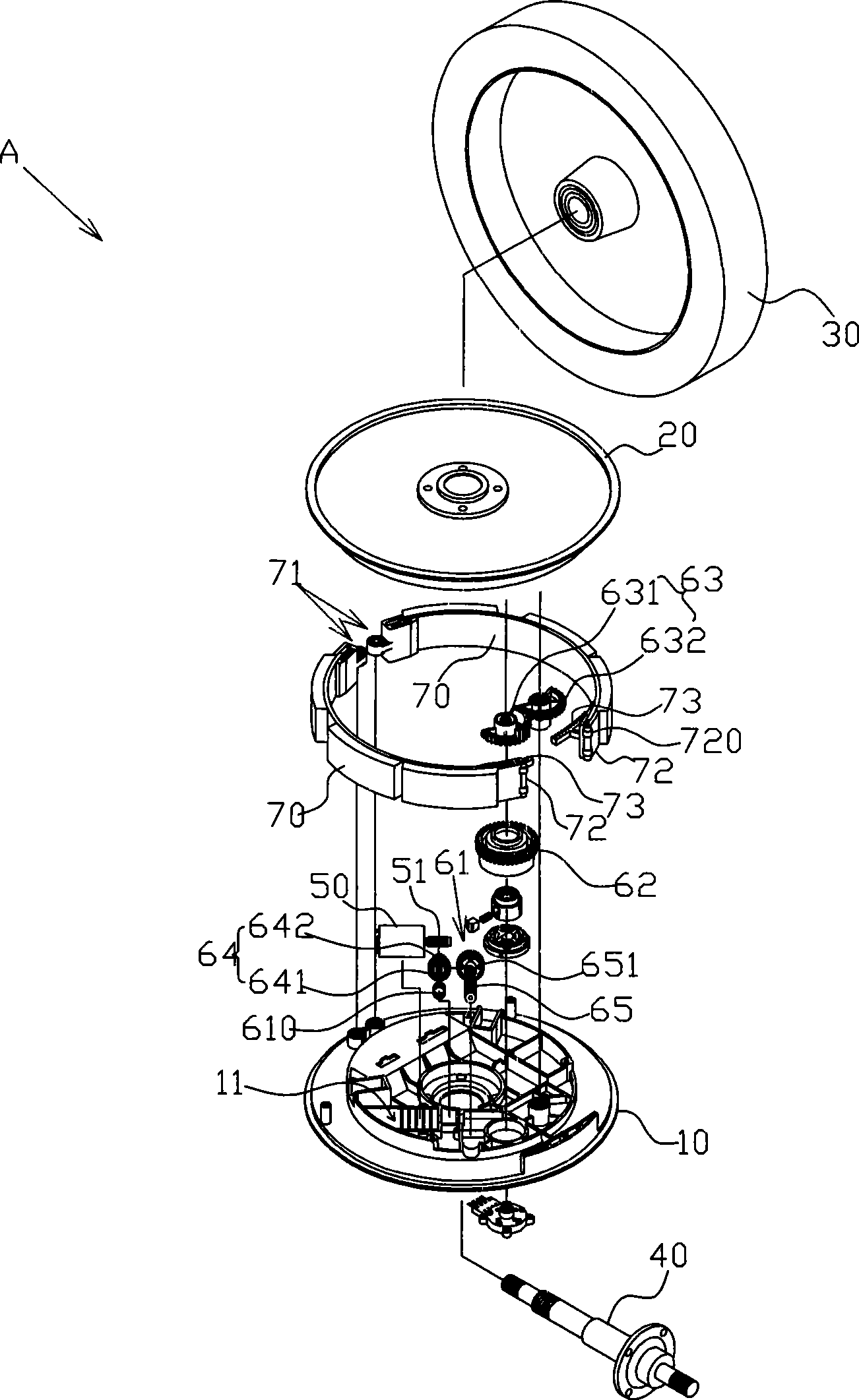

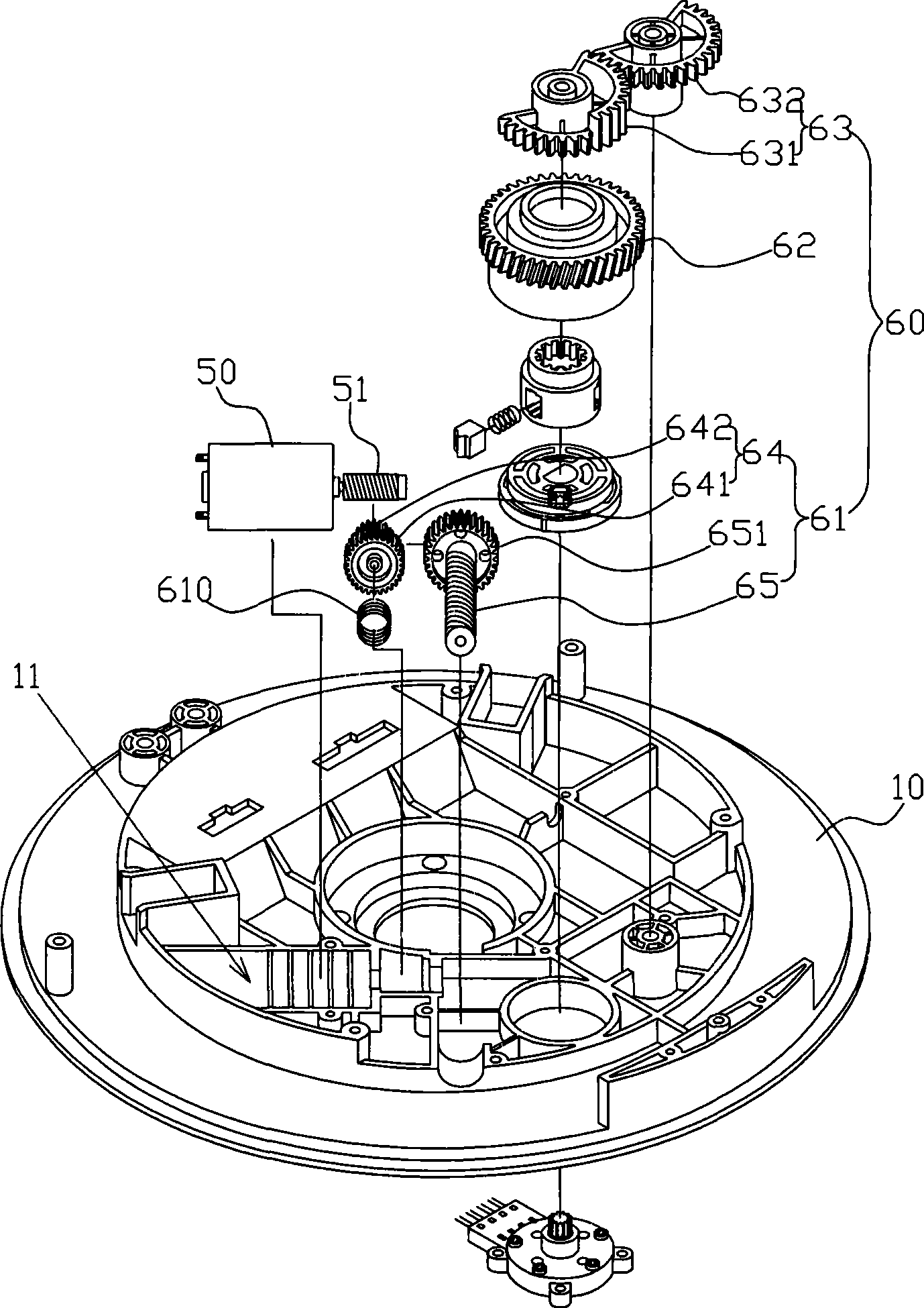

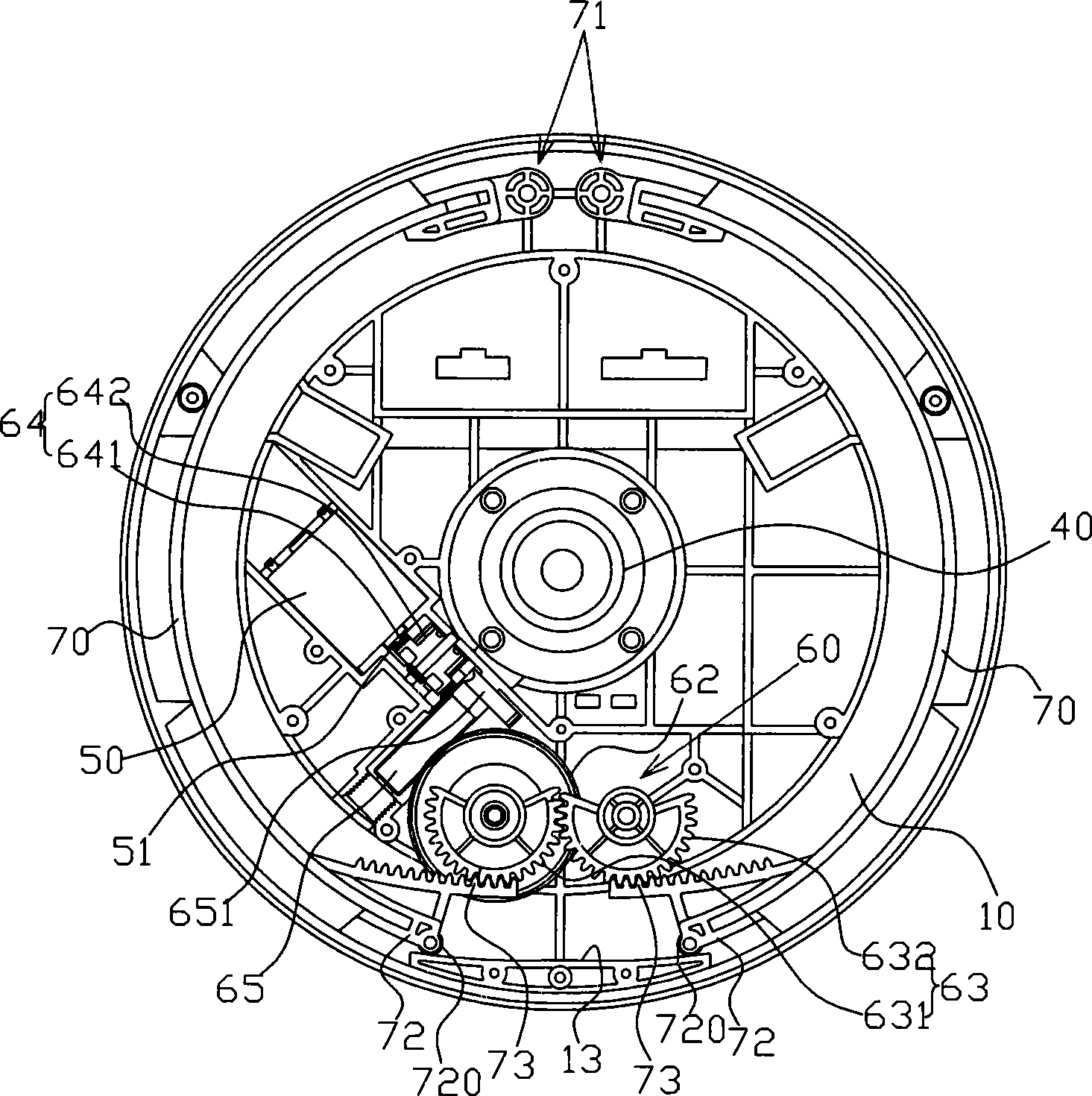

[0030] see Figure 1 ~ Figure 3 As shown, the preferred embodiment of the magnetic control wheel structure of the present invention, the magnetic control wheel A includes a base 10, a cover 20, a flywheel 30, a central shaft 40, a drive motor 50, a transmission gear set 60 And two magnetic control pieces 70; wherein, the pivot portion 71 of the two magnetic control pieces 70 is combined on the seat body 10 to form a swingable displacement at the bottom movable end 72 of the two magnetic force control pieces 70; the seat body 10 is equipped with The space 11 is for the drive motor 50 and the transmission gear set 60 to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com