Forming method sheet material with hollow sandwich layer and die thereof

A technology for plate forming and forming molds, applied in the direction of molds, ceramic forming machines, manufacturing tools, etc., can solve the problems of bulkiness, high transportation cost and material cost, and difficult to move, so as to achieve flexible manufacturing process, reduce transportation and material costs, The effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the inventive solution, and to make the above-mentioned purpose, features and advantages of the invention more obvious and understandable, the invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

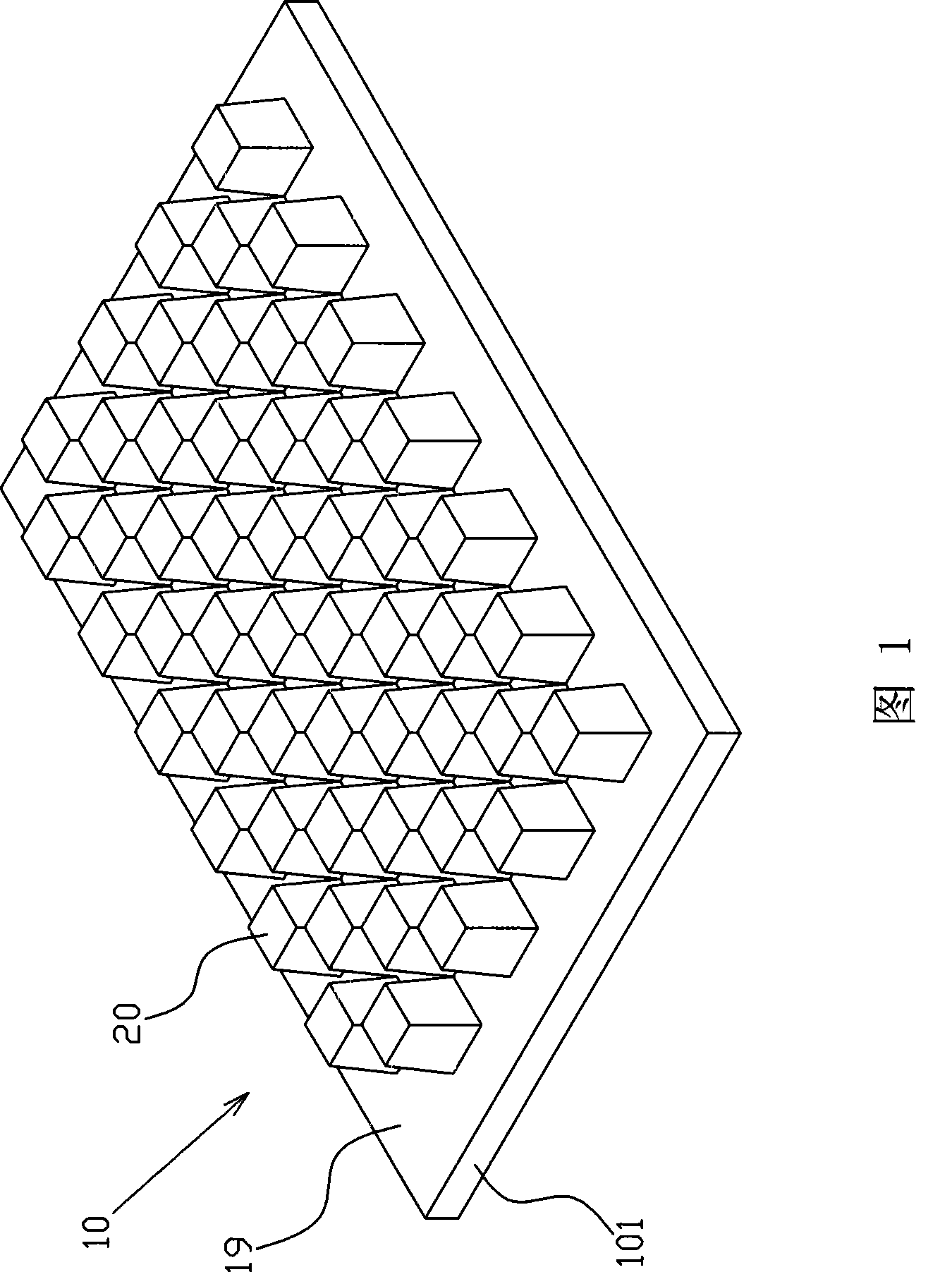

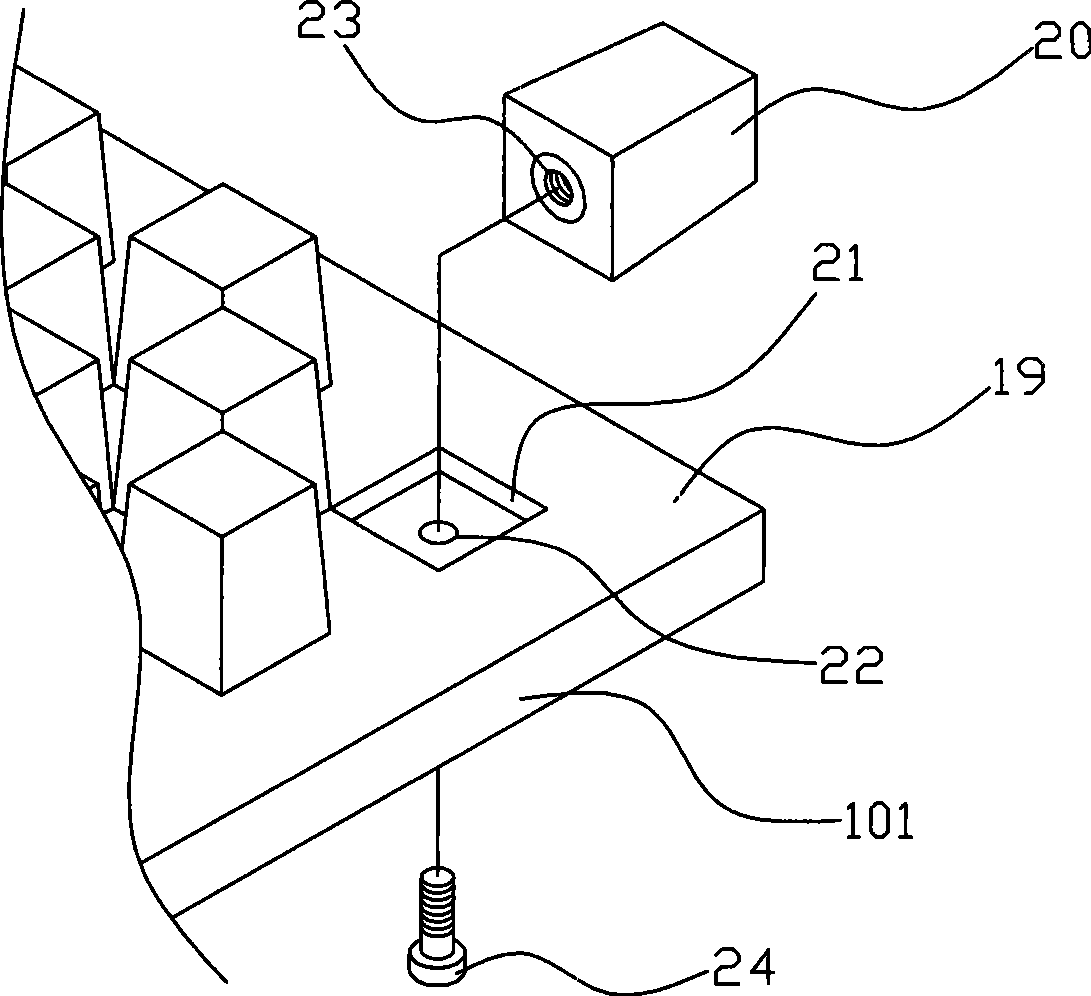

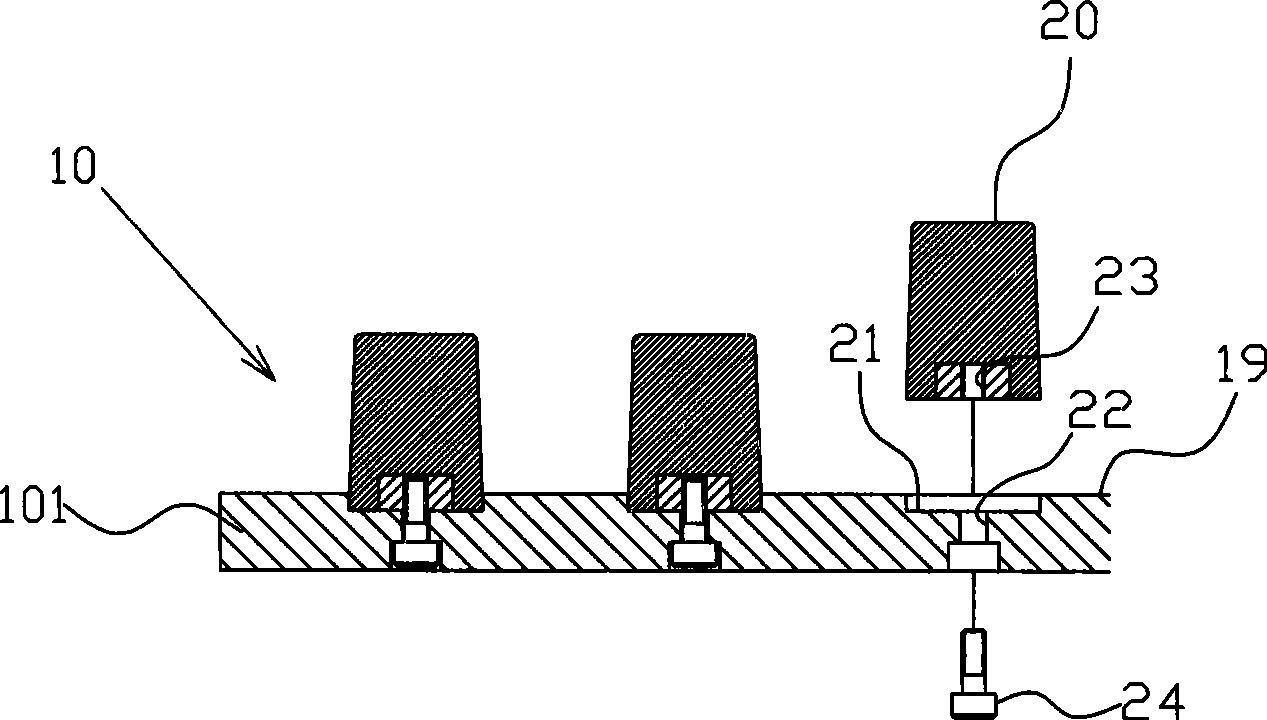

[0032] Figure 1, figure 2 As shown, the embodiment of the forming method of the sheet material A having a hollow core layer in the present invention includes: first setting up a forming mold 10 with a concave-convex shape on the surface, the forming mold 10 has a base plate 101, and the base plate 101 has Predetermined length, width and thickness shape, and then form at least one molding surface 19, and the molding surface 19 has a concave-convex shape;

[0033] The specific form of the concavo-convex portion of the molding surface 19 can be arranged on the molding surface 19 at intervals with convex cylinders 20 arranged in dislocations, and the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com