LED cooling module structure

A heat dissipation module and LED component technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of high cost, poor thermal conductivity of the overall composite substrate, poor mechanical shock resistance, etc., and achieve the best industrial economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

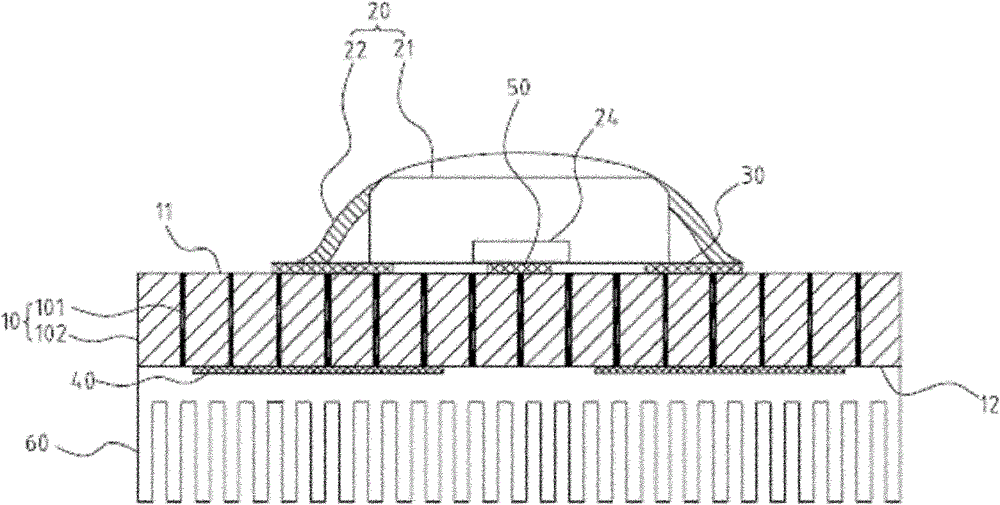

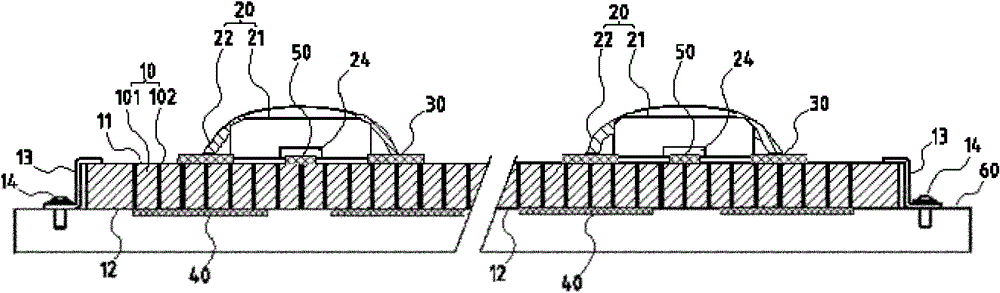

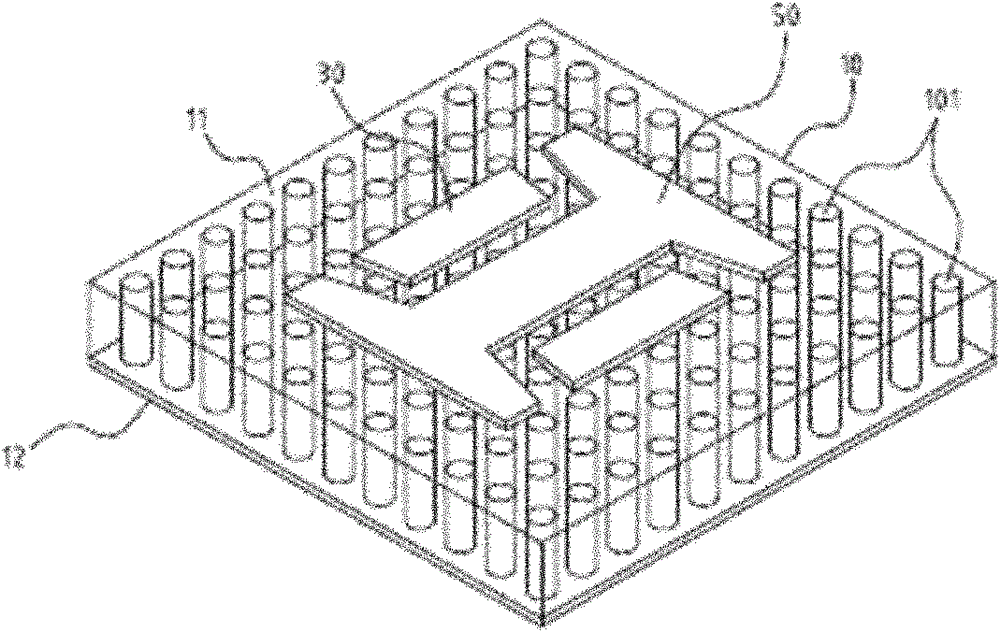

[0018] Figure 1 to Figure 3 Shown is a preferred embodiment of the heat dissipation module structure of the LED of the present invention, but this embodiment is only for illustration, and the scope of patent protection is not limited by this structure; the heat dissipation module structure of the LED (light emitting diode) includes:

[0019] A composite heat conduction substrate 10 is a plate-shaped body formed by combining a plurality of heat conduction wires 101 and insulating material 102, which has a front surface 11 and a back surface 12, wherein the heat conduction wires 101 are spaced apart from each other, and the conduction wires The heating wire 101 runs through the front side 11 and the back side 12, and the heating wires 101 are separated by an insulating material 102;

[0020] At least one LED component 20 is combined with the front surface 11 of the composite heat-conducting substrate 10, and the LED component 20 includes an LED component 21 and an electrode pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com