Self-controlled oil well casing gas recycling device

A technology of recovery device and oil well casing, applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problems of high installation cost, difficult maintenance, top-over of pumping units, etc., to prevent pollution and prevent pollution. Human harm, synergistic effect of comprehensive economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

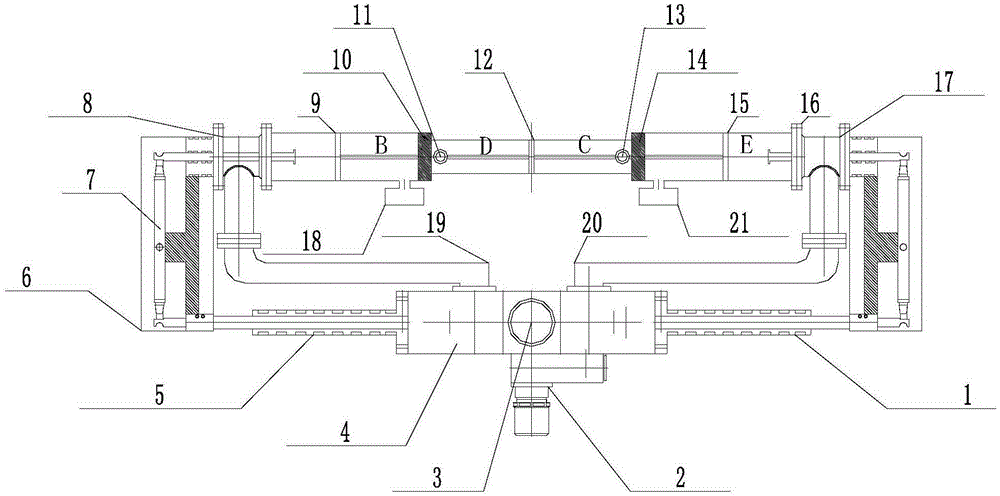

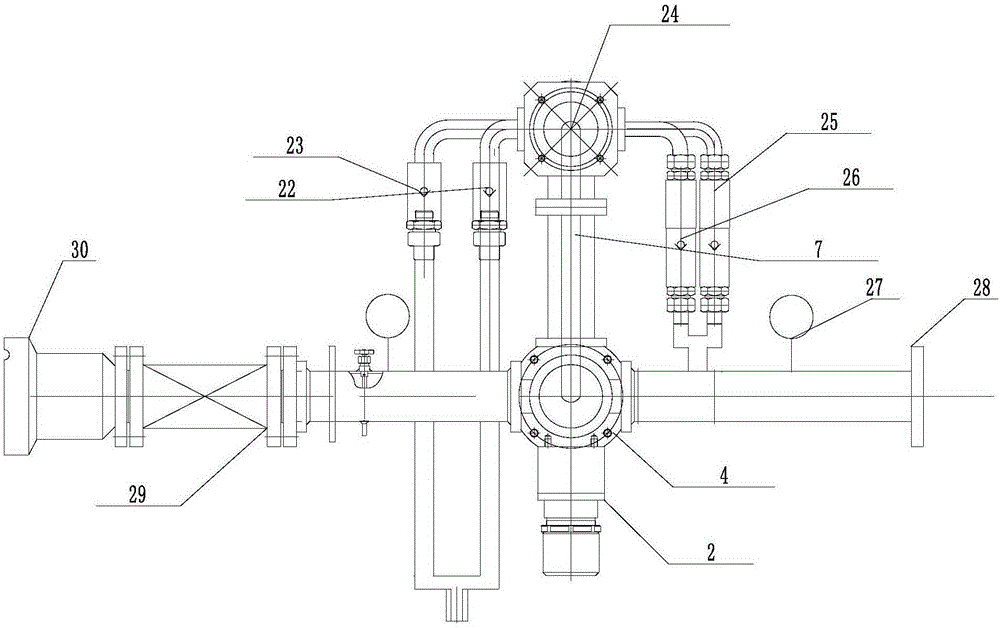

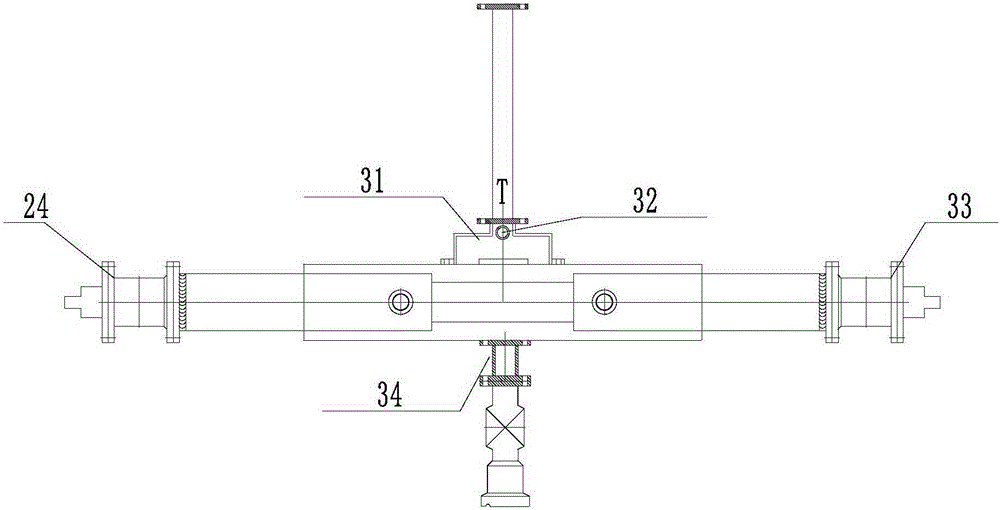

[0025] Concrete structure and working principle of the present invention refer to figure 1 , 2 , 3, 4 shown. In the present invention, the series-connected piston rod hydraulic cylinder is a working mode of staggered front and back, and reciprocating pumping. The outside of the hydraulic cylinder is connected by a cylinder flange 16, and the inner cylinder is guided by a bridge seal 10. The sleeves are connected, and the piston 9, piston 12, and piston 15 between the cylinders are connected in series through the bridge seal guide sleeve through the pull rod, and a liquid inlet tee is installed at the front and rear ends of the hydraulic cylinder. , that is, the left liquid inlet tee 8, the right liquid inlet tee 17, a stroke push rod sealer 24 is respectively provided on the left and right sides of the liquid inlet tee, and a push rod is respectively provided at the front and rear ends of the stroke push rod sealer 24 The reversing rocker arm frame 7 is provided with A and B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com