Combined Oil Well Casing Gas Recovery Device

A technology of oil well casing and recovery device, which is applied to wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problems of oil well casing gas suffocation, oil well dynamic liquid level drop, production capacity reduction, gas lock, etc. To achieve the effect of eliminating pollution and harm to human beings, increasing efficiency and comprehensive economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

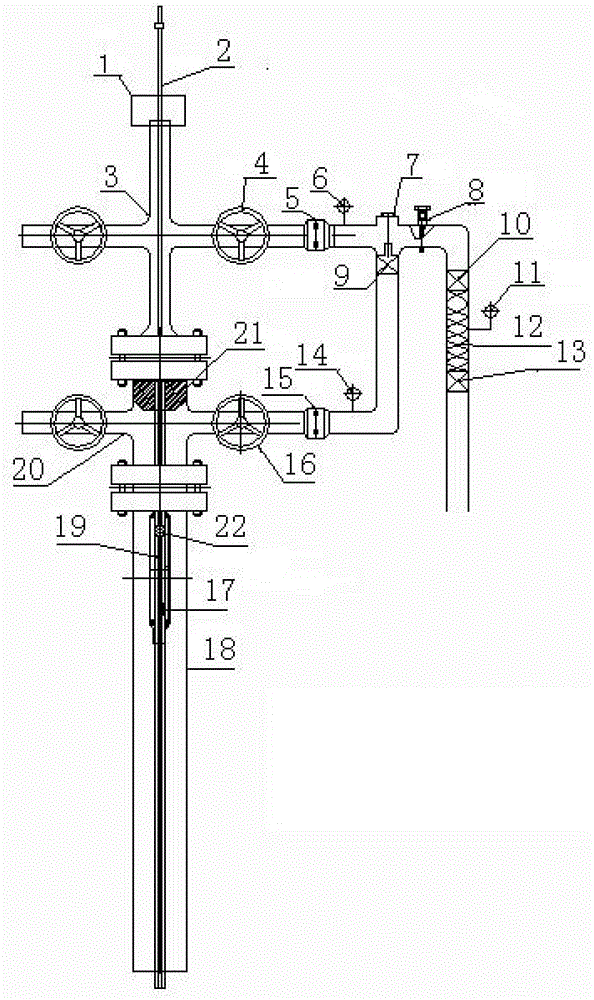

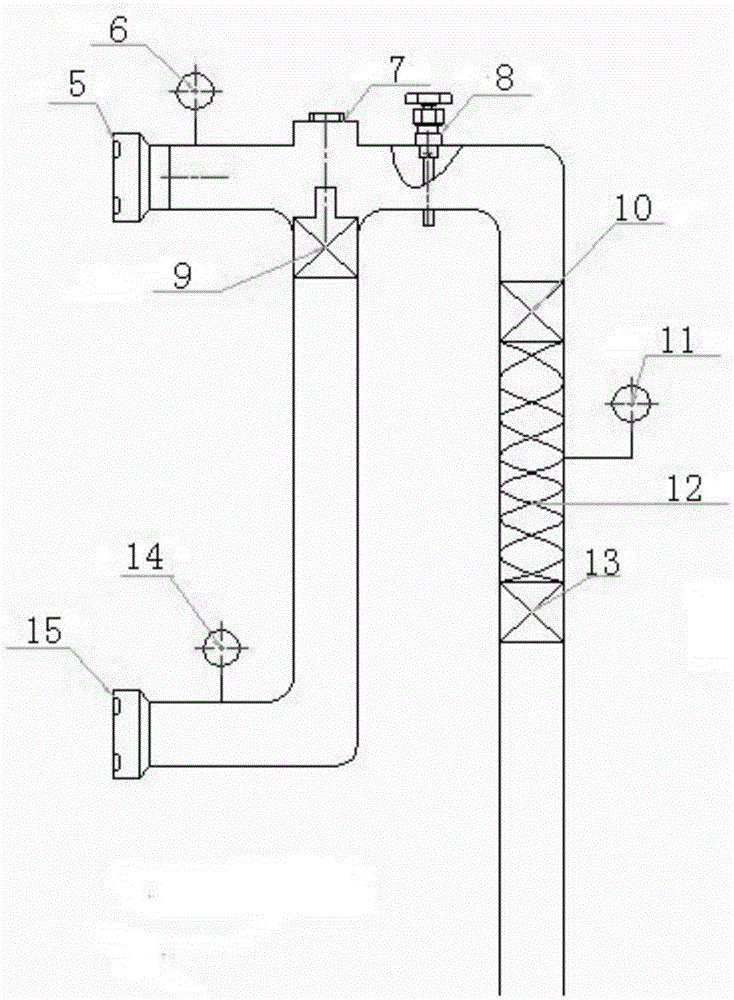

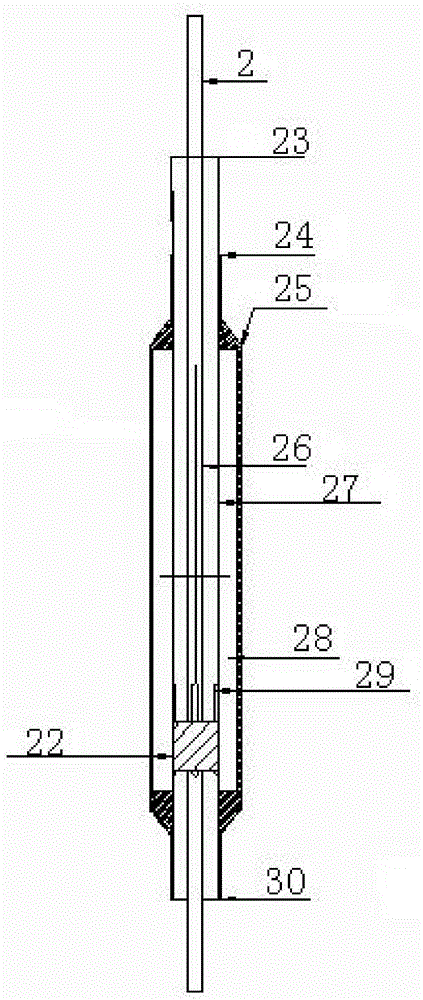

[0016] Structure of the present invention sees figure 1 , The combined oil well casing gas recovery device includes a surface part and an underground part. The ground section is a combined tee assembly, see figure 2 . The underground part is an oil-air mixing pump assembly, see image 3 .

[0017] The ground part is a combined tee assembly. One end of the tee is the A oil nonel joint 5, which is connected to the small cross 3 through the oil pipe gate 4, and the other end of the tee is the B oil nonel joint 15, which is connected with the casing valve 16. The large four-way 20 is connected, and the third end of the three-way is provided with a liquid discharge check valve 10 and a stop valve 13; .

[0018] The underground part is an oil-gas mixing pump assembly. The oil-gas mixing pump assembly includes the mixing pump inner working cylinder 27, the mixing pump outer working cylinder 25, the upper end of the mixing pump outer working cylinder 25 and the tubing hanger in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com