Self-controlled oil well casing gas recovery device

A recovery device and oil well casing technology, which is applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problems of oil well dynamic liquid level drop and production capacity reduction, so as to improve oil well production, eliminate pollution and harm human beings. The effect of harm, synergy and comprehensive economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

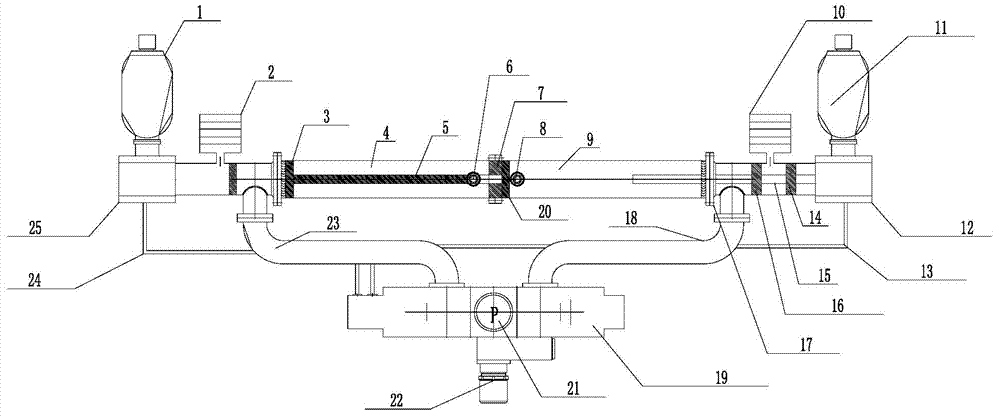

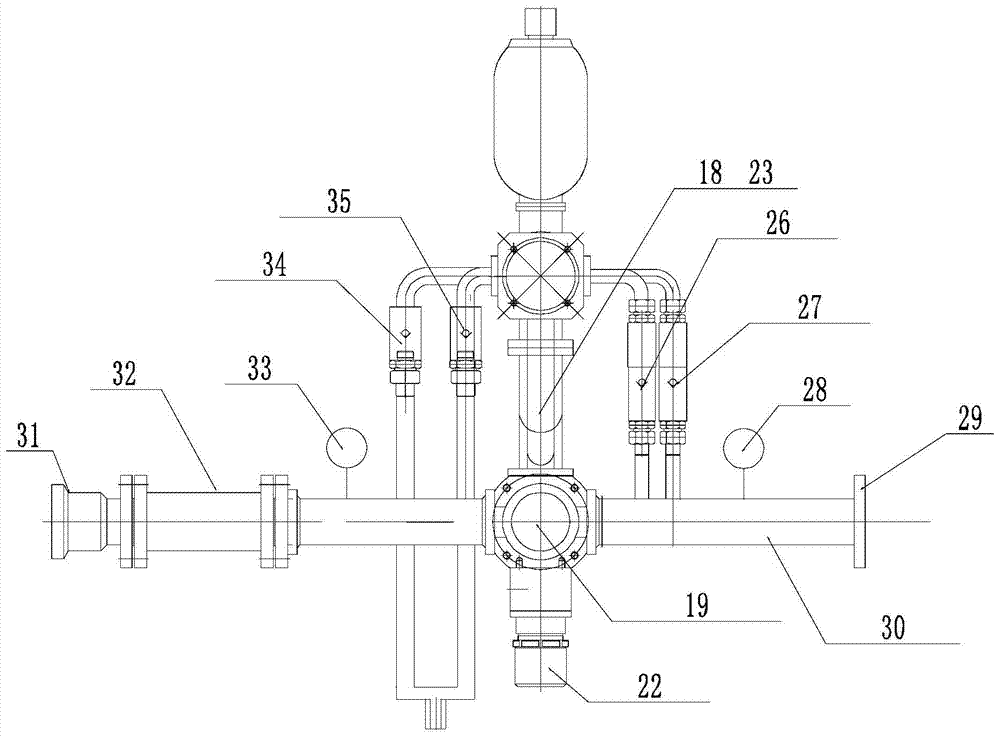

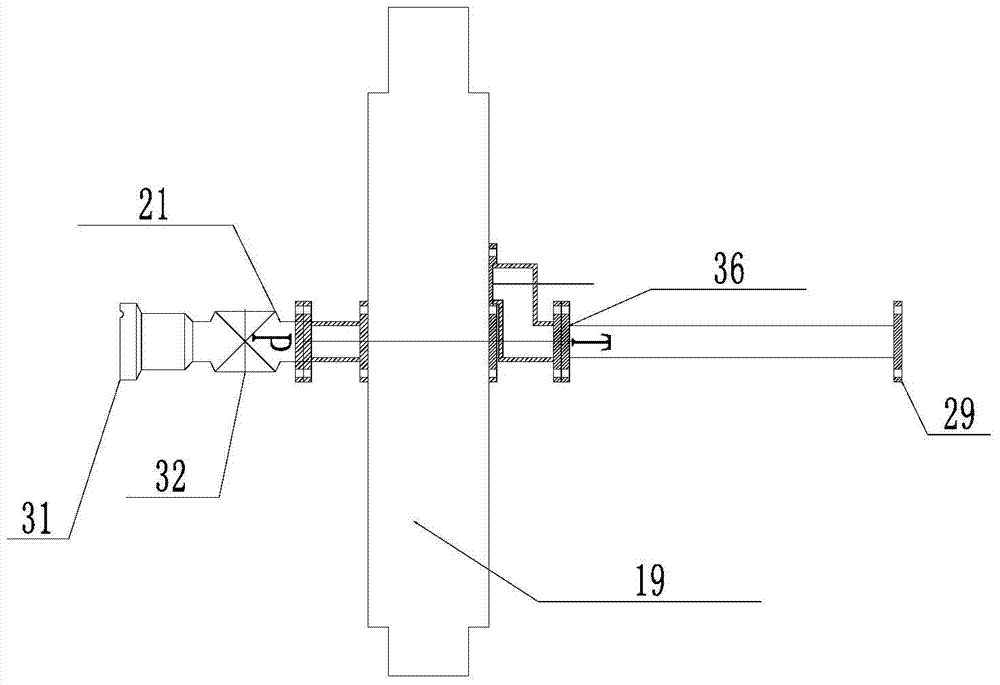

[0017] The specific structure of the present invention is shown in the accompanying drawings. see figure 1 , 2 As shown in the figure, the self-controlled oil well casing gas recovery device includes the first and second hydraulic cylinders 4 and 9 of the two-pole tie-rod piston connected in series, the hydraulic stroke cylinders 25 and 12 with accumulators 1 and 2, and the hydraulic integrated reversing. 19 and hydraulic oil pressure pipes 24 and 13. The first and second hydraulic cylinders 4 and 9 of the two-pole series-connected tie rod piston are in a working state of staggered extraction and discharge. The outside of the first hydraulic cylinder 4 and the second hydraulic cylinder 9 are connected through the cylinder flange 17, and A bridge seal 7 is provided between the first and second hydraulic cylinders. The pistons 3 and 20 of the first hydraulic cylinder 4 and the second hydraulic cylinder 9 are connected in series through the bridge seal 7 through the pull rod 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com