Method for offline analyzing and online scheduling of byproduct gas of metallurgy industry

A technology of off-line analysis of by-product gas, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of difficulty in optimal scheduling of by-product gas, unquantifiable scheduling, poor quantification of balanced scheduling results, etc., to achieve fast and accurate prediction and treatment plan, to achieve energy saving and environmental protection benefits, and to improve the effect of equipment operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

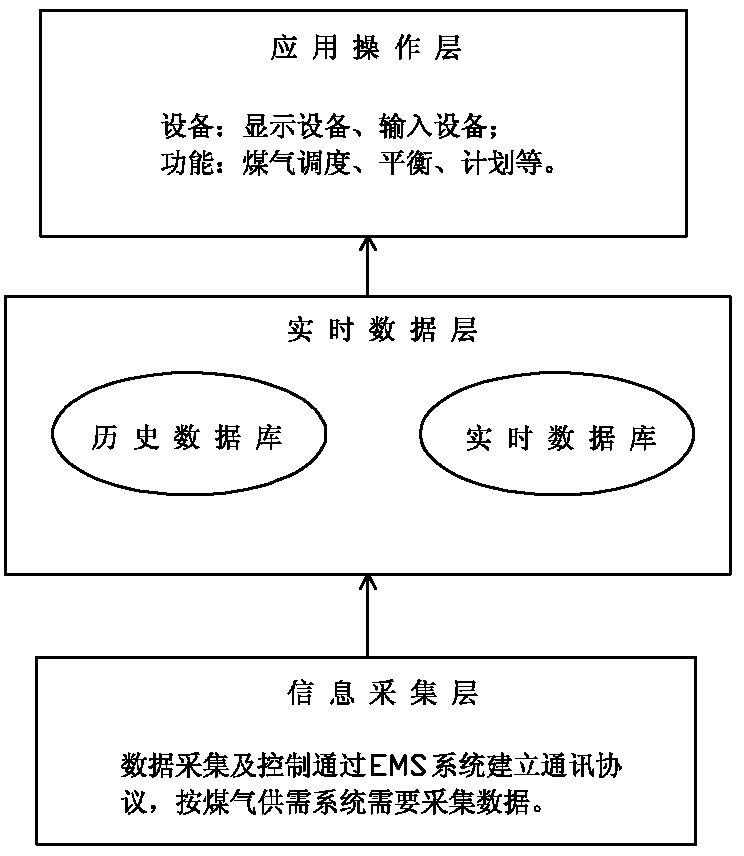

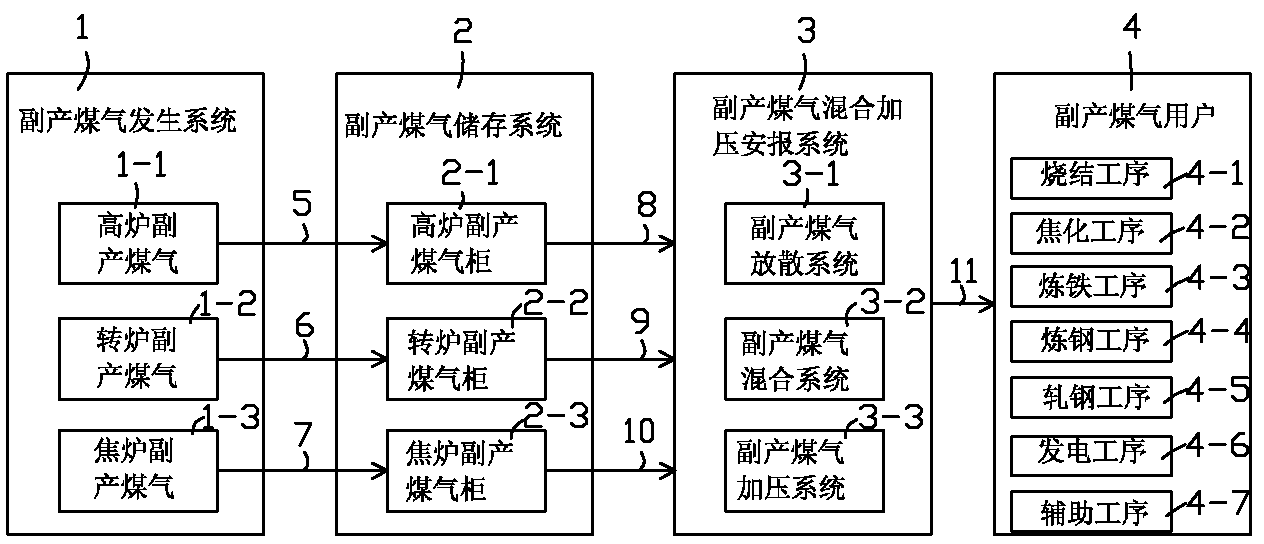

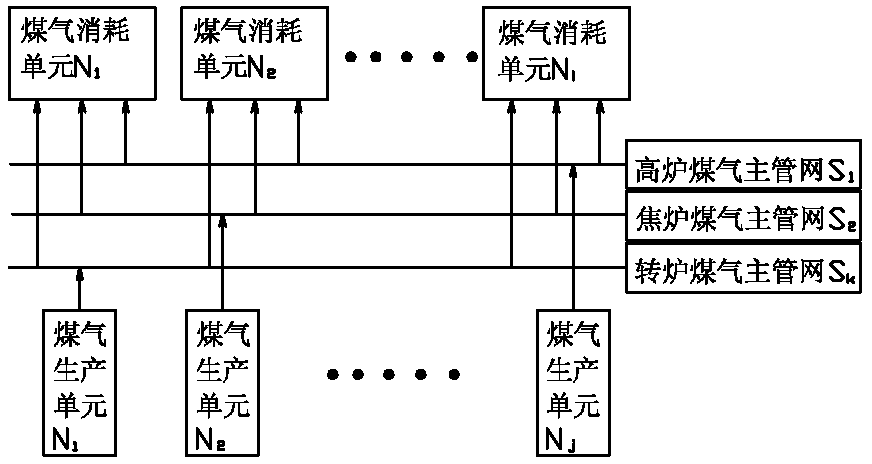

[0045] An online scheduling method for off-line analysis of by-product gas in a metallurgical enterprise, including a by-product gas supply and demand system composed of by-product gas production equipment and gas use equipment, and a metallurgical enterprise by-product gas production and marketing plan management system composed of computer terminals and management servers , the by-product gas production and sales plan management system compiles the by-product gas supply and demand plan report and sends out scheduling production instructions according to the maintenance plan, production plan, by-product gas consumption history and by-product gas supply status of the by-product gas supply and demand system. The gas production equipment provides the required by-product gas resources to the by-product gas use equipment; a data collection server is connected with the by-product gas production and sales plan management system, and the method is further: the data collection server ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com