Heat preservation and decoration integrated ecological stone and preparation method thereof

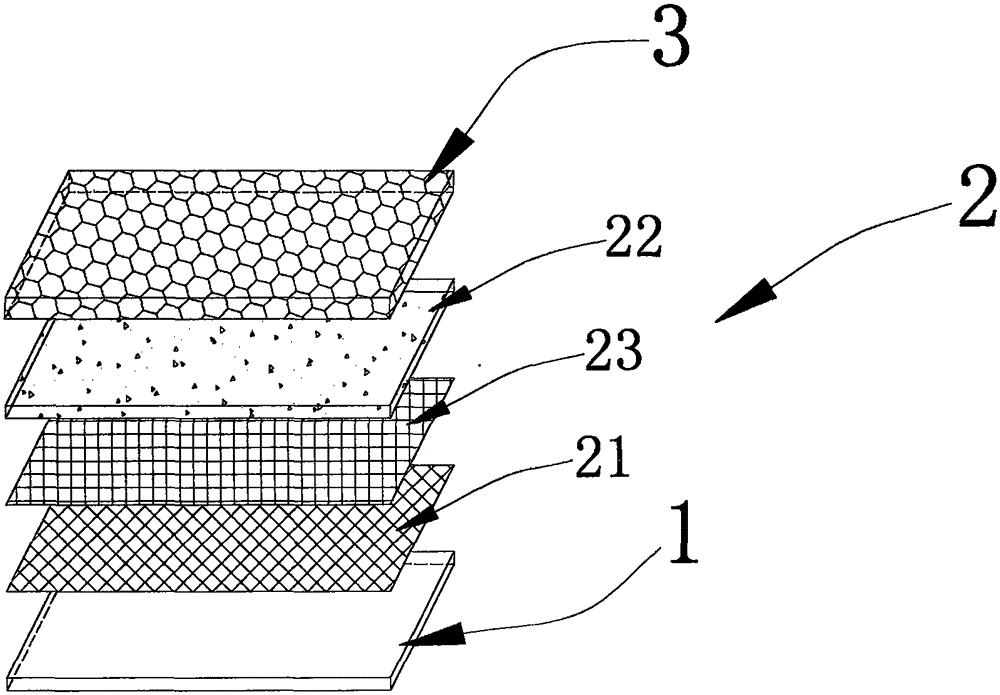

An ecological stone and integrated technology, applied in the direction of chemical instruments and methods, covering/lining, layered products, etc., can solve the problems of cumbersome construction, unable to express the three-dimensional and weight of stone, and complicated construction, so as to reduce construction cost and construction cost. process, improve resource utilization efficiency, and ensure the effect of solid stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0086] 1. Preparation of insulation layer:

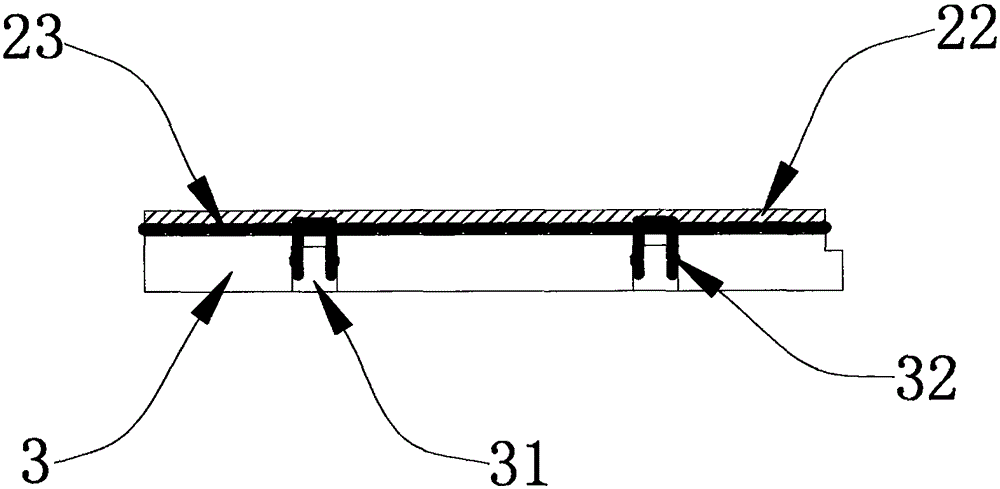

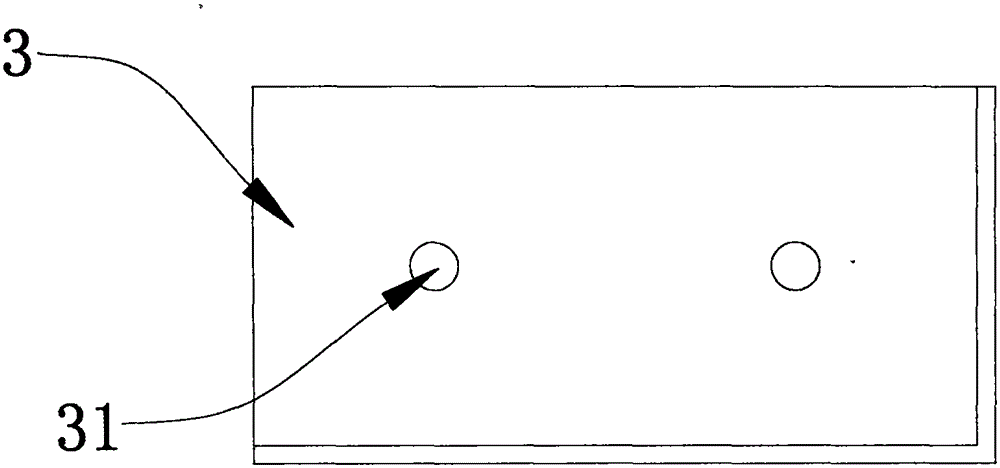

[0087] (1) Groove 10mm*10mm V-shaped groove on the bonding surface of the insulation board and the decorative layer. Two cylindrical grooves with a diameter of 4 cm and a depth of 4 cm are opened on the bonding surface of the insulation board and the decorative exterior wall.

[0088] (2) Fix the hot-dip galvanized wire mesh on the insulation board crosswise with stainless steel buckles, and the stainless steel buckles pass through the other side of the cylindrical deep groove, just passing through the deep groove; Apply polymer cement mortar adhesive evenly on one side.

[0089] 2. Mold preparation:

[0090] Supplied molded with natural stone grain lines and blown clean

[0091] 3. Finishing layer preparation:

[0092] Colored sand, cement, water, functional additives, and pigments are put into a mixer in a certain proportion to mix and stir evenly, and stand in the tank for 1 minute.

[0093] 4. Finished product preparation: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com