Method for making organic fertilizer by using packed compost technology

An organic fertilizer and composting technology, which is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of biological organic parts, can solve the problems of high water content in cow dung, affecting the composting process, and anaerobic environment, so as to improve soil fertility and improve Crop yield, effect of improving soil properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

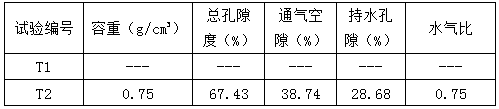

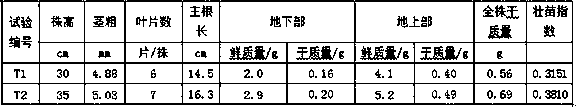

Embodiment 1

[0026] A kind of method that present embodiment utilizes bagged composting technology to manufacture organic fertilizer, comprises the following steps:

[0027] (1) The raw material nitrogen source cow manure (organic matter: 220.87g / kg, total nitrogen 6.76g / kg, total phosphorus 4.44g / kg, total potassium 6.64g / kg, pH value 9.15, EC value 1.50ms / cm) and Carbon source mushroom dregs (organic matter: 491.44g / kg, total nitrogen 13.28g / kg, total phosphorus 8.16g / kg, total potassium 8.45g / kg, pH value 7, EC value 3.47ms / cm) according to the volume ratio of 2:1 The ratio is mixed, and the water content of the mixture is adjusted to 50%;

[0028] (2) Add RW bio-organic fertilizer fermentation agent to the mixture of nitrogen source and carbon source obtained in step (1) at a ratio of 1L / 1.5t and stir evenly to start accumulation and fermentation;

[0029] (3) The compost is subjected to high-temperature aerobic fermentation, and the temperature of the compost is maintained at 50-60°C...

Embodiment 2

[0033] A kind of method that present embodiment utilizes bagged composting technology to manufacture organic fertilizer, comprises the following steps:

[0034] (1) The raw material nitrogen source cow manure (organic matter: 220.87g / kg, total nitrogen 6.76g / kg, total phosphorus 4.44g / kg, total potassium 6.64g / kg, pH value 9.15, EC value 1.50ms / cm) and Carbon source mushroom slag (organic matter: 491.44g / kg, total nitrogen 13.28g / kg, total phosphorus 8.16g / kg, total potassium 8.45g / kg, pH value 7, EC value 3.47ms / cm) according to the volume ratio of 1:1 The ratio is mixed, and the water content of the mixture is adjusted to 55%;

[0035] (2) Add RW decay accelerator to the mixture of nitrogen source and carbon source obtained in step (1) at a ratio of 0.5L / 1t and stir evenly to start accumulation and fermentation;

[0036] (3) The compost is subjected to high-temperature aerobic fermentation, and the temperature of the compost is maintained at 50-60°C for fermentation; when t...

Embodiment 3

[0041] A kind of method that present embodiment utilizes bagged composting technology to manufacture organic fertilizer, comprises the following steps:

[0042] (1) The raw material nitrogen source cow manure (organic matter: 220g / kg, total nitrogen 3g / kg, total phosphorus 0.95g / kg, total potassium 2g / kg, pH value 7.9, EC value 4ms / cm) and carbon source mushroom slag (Organic matter: 491g / kg, total nitrogen 10g / kg, total phosphorus 6.92g / kg, total potassium 8.45g / kg, pH value 6.5, EC value 3.47ms / cm) Mix according to the ratio of volume ratio 1.5:1, adjust the mixture Moisture content to 60%;

[0043] (2) Add VT bacterial agent to the mixture of nitrogen source and carbon source obtained in step (1) at a ratio of 1L / 1t and stir evenly to start accumulation and fermentation;

[0044] (3) The compost is subjected to high-temperature aerobic fermentation, and the temperature of the compost is maintained at 50-60°C for fermentation; when the temperature exceeds 60°C, the compost ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com