Slurry long-distance hydraulic conveying and solid-liquid separation device and separation process

A technology of hydraulic transportation and solid-liquid separation, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of waste of coal slime, inability to realize long-distance transport of coal slime for reuse of circulating water, and affecting the working environment of workers , to achieve the effect of flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

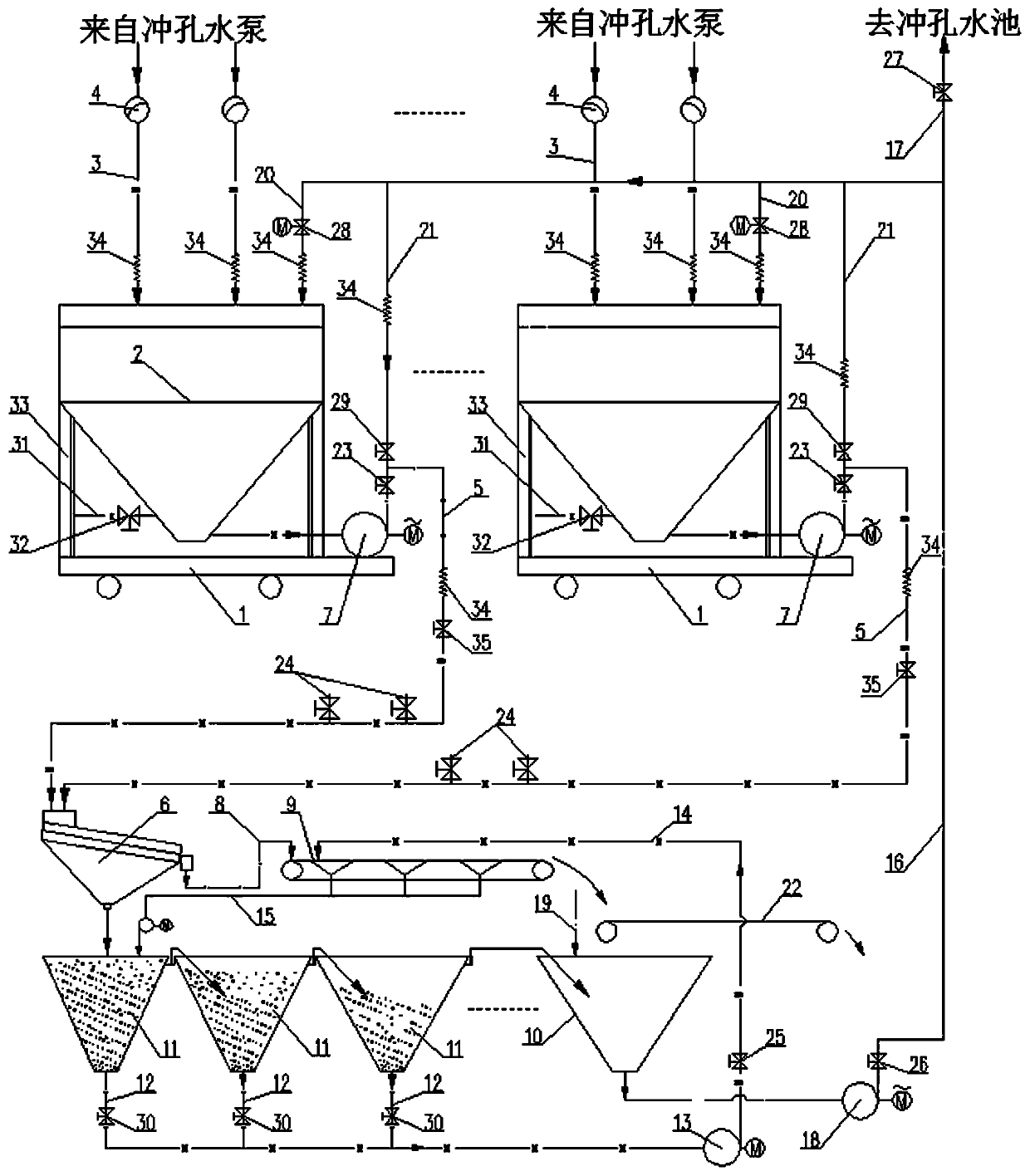

[0031] Such as figure 1 As shown, a slurry long-distance hydraulic transportation and solid-liquid separation device includes a plurality of identical collection and transportation units, the collection and transportation unit includes a mobile trolley 1, and the mobile trolley 1 is fixed with a collection bucket 2 with an open top, and a collection bucket 2 The top end is respectively communicated with a plurality of corresponding gas drainage holes 4 above the collection barrel 2 through a plurality of perforated slime water pipes 3 and a plurality of inverted cone-shaped slime water collection funnels, and the bottom of the collection barrel 2 is connected to the collection barrel 2 to inflate gas. The inflatable part includes a high-pressure air pipe 31, and the high-pressure air pipe 31 is provided with a manual high-pressure air valve 32, the high-pressure air pipe 31 is connected with the compressed air storage tank, and the bottom ends of each collection barrel 2 respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com