Method for preparing anti-breakage gum for wall

A technology of anti-fracture and wall, applied in the direction of adhesive, film/sheet adhesive, adhesive type, etc., can solve the problems of material waste, economic loss, easy to fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

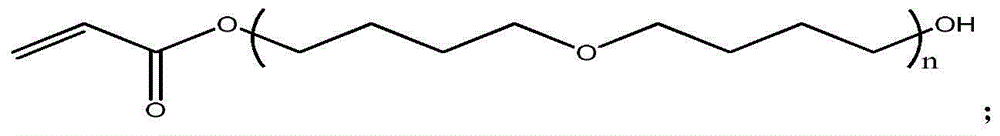

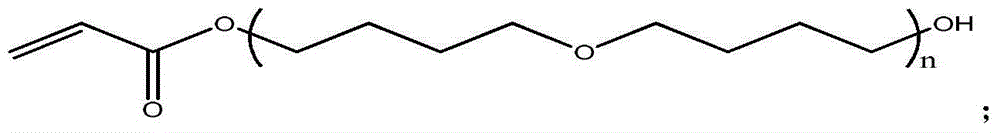

[0032] A method for preparing an anti-fracture adhesive for walls, comprising coating an ink-absorbing coating with a thickness of 20mm on the coated paper layer and coating an anti-break acrylate pressure-sensitive adhesive layer on the release layer, and after drying, The anti-fracture adhesive for walls is compounded by dry compounding process. The coating and drying process is to coat the base material with anti-break acrylate pressure-sensitive adhesive for walls, and then carry out through box oven type drying and heating equipment. Drying treatment, the drying tunnel type drying equipment is divided into 8 drying areas from the entrance to the exit; the coating amount is 60g / m 2 ; The temperature range and air volume range of the drying process are controlled at: 30 °C, the air volume is 1m / s, and the anti-breaking acrylic pressure-sensitive adhesive used in the anti-breaking acrylic pressure-sensitive adhesive layer is the anti-breaking acrylic pressure-sensitive adhesi...

Embodiment 2

[0045] A method for preparing an anti-fracture adhesive for walls, comprising coating an ink-absorbing coating with a thickness of 20mm on double-adhesive paper and coating an anti-break acrylate pressure-sensitive adhesive layer on a release layer, after drying, The anti-fracture adhesive for walls is compounded by dry compounding process. The coating and drying process is to coat the base material with anti-break acrylate pressure-sensitive adhesive for walls, and then carry out through box oven type drying and heating equipment. Drying treatment, the drying tunnel type drying equipment is divided into 8 drying areas from the entrance to the exit; the coating amount is 80g / m 2 The temperature range and air volume range of the drying process are controlled at: 130°C, the air volume is 30m / s, and the anti-break acrylic pressure-sensitive adhesive used in the anti-break acrylic pressure-sensitive adhesive layer is the anti-break acrylic pressure-sensitive adhesive for walls, mai...

Embodiment 3

[0058] A method for preparing an anti-fracture adhesive for walls, comprising coating an ink-absorbing coating with a thickness of 80mm on a synthetic paper layer and coating an anti-break acrylate pressure-sensitive adhesive layer on a release layer, after drying, The anti-fracture adhesive for walls is compounded by dry compounding process. The coating and drying process is to coat the base material with anti-break acrylate pressure-sensitive adhesive for walls, and then carry out through box oven type drying and heating equipment. Drying treatment, the drying tunnel type drying equipment is divided into 8 drying areas from the entrance to the exit; the coating amount is 70g / m 2 ; The temperature range and air volume range of the drying process are controlled at: 50°C, the air volume is 15m / s, and the anti-breaking acrylic pressure-sensitive adhesive used in the anti-breaking acrylic pressure-sensitive adhesive layer is the anti-breaking acrylic pressure-sensitive adhesive fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com