Process for producing conjugated diene polymer, conjugated diene polymer, and rubber composition

a technology of conjugated diene and polymer, which is applied in the field of conjugated diene polymer, conjugated diene polymer, and rubber composition, can solve the problems of difficulty in producing a polymer with a sufficiently narrow molecular weight distribution and a sufficiently high cis-1,4-bond content, and achieves simple and inexpensive production of conjugated diene. high cis-bond content and high cis-bond conten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

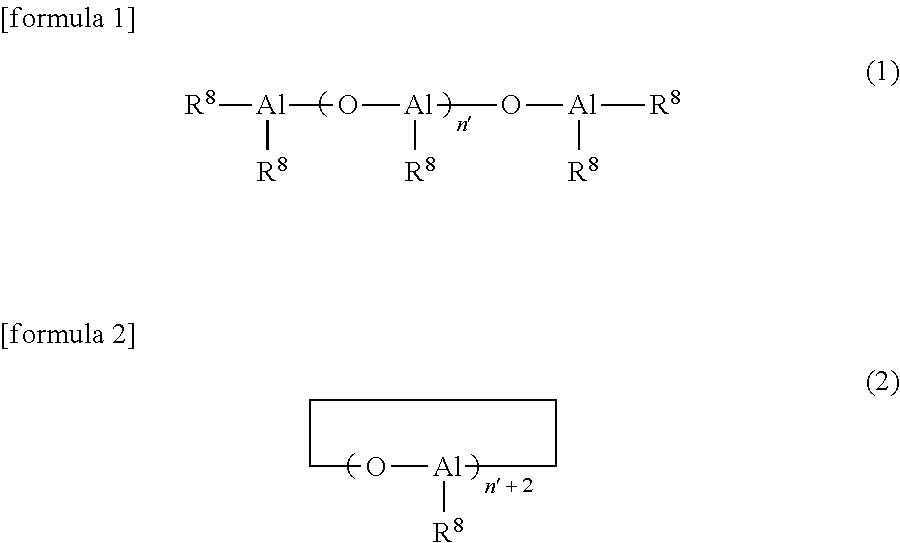

Method used

Image

Examples

example 1

[0082]A 5 L autoclave of which the internal atmosphere was replaced by nitrogen was charged with 2.4 kg of cyclohexane and 300 g of 1,3-butadiene. The autoclave was further charged with a catalyst composition (iodine atom / rare earth element-containing compound (molar ratio)=2.0) obtained by reacting a cyclohexane solution of neodymium versatate (Nd(ver)3) (0.18 mmol), a toluene solution of methyl alumoxane (MAO) (1.8 mmol), hydrogenated diisobutylaluminum (AlBu2H) (5.3 mmol), and a toluene solution of trimethylsilyl iodide (Me3SiI) (0.36 mmol) with 1,3-butadiene in an amount of 5 times the mols of neodymium and aging at 50° C. for 30 minutes, to carry out a polymerization reaction 1,3-butadiene at 30° C. for 2 hours. Then, a methanol solution containing 2,4-di-tert-butyl-p-cresol (1.5 g) was added to terminate the polymerization reaction. The solvent was removed by steam stripping and the residue was dried by a roller at 110° C. to obtain 295 g of polymer. The Mooney viscosity (ML1+...

PUM

| Property | Measurement | Unit |

|---|---|---|

| atomic number | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| atomic number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com