Fire-retarding and low-temperature resistant polypropylene material, preparation method thereof and use thereof

A polypropylene material, low temperature resistant technology, applied in the field of flame retardant plastics, can solve the problems of changing the comprehensive properties of the material, reducing the tensile elongation of the material, etc., to achieve excellent physical properties, good flame retardant effect, good compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

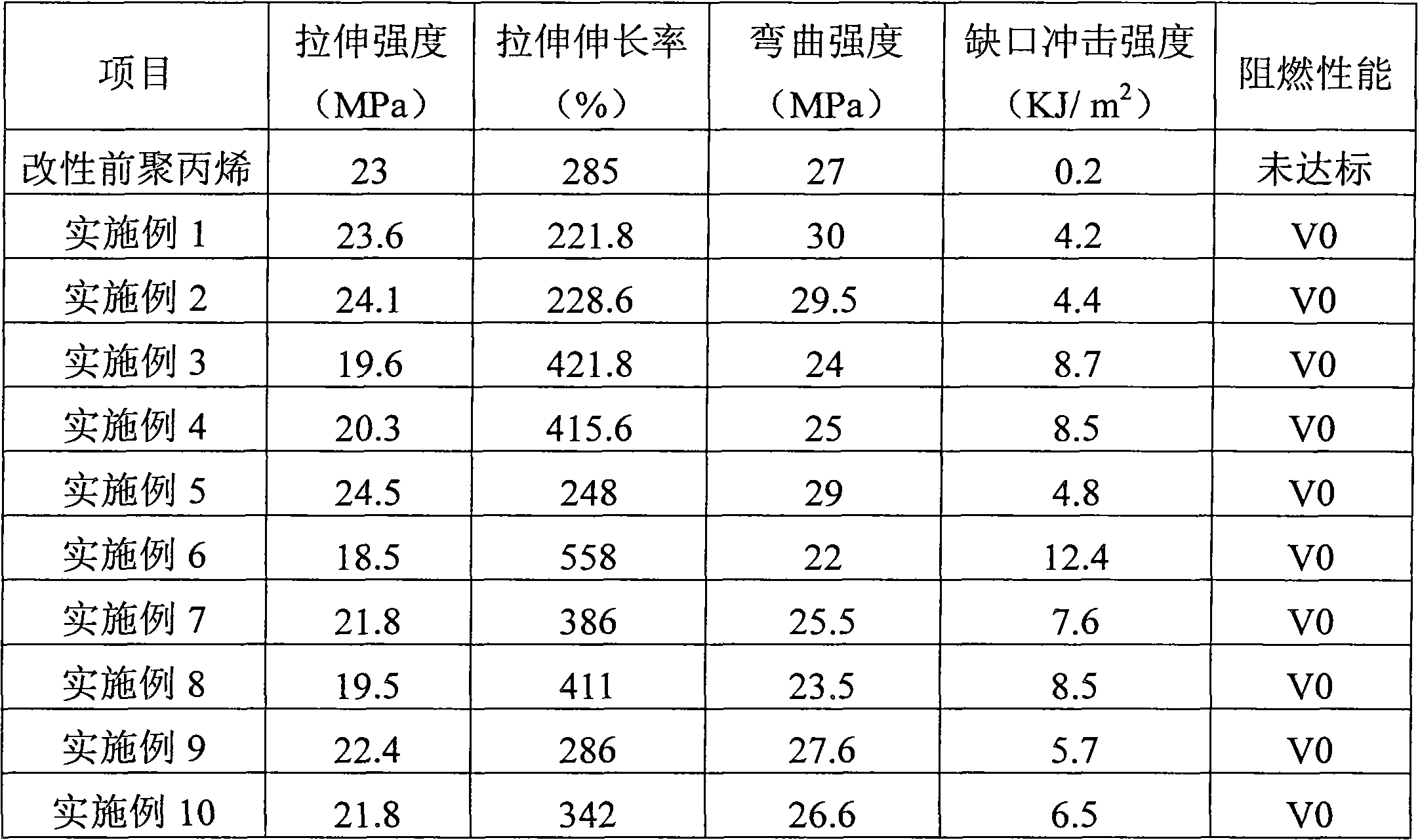

Examples

Embodiment 1

[0029] 75kg of ethylene block copolymerized polypropylene (Korean Hyosung, J740), with a melt index of 25.0g / 10min, 15kg of microencapsulated ammonium polyphosphate (Sean Chemical, FR-CH-3), and 10kg of TPO thermoplastic elastomer (Mitsubishi Chemical, THERMORUN3981B / N), the rubber content is 40% and 0.2kg of 1010 (Swiss Ciba), through a high-speed mixer, high-speed mixing for 30 seconds to make it premixed evenly, and then pass through the double-layer heating zone with multi-stage heating zone Screw extruder, uniformly dispersed, extruded and granulated to produce flame-retardant and low-temperature resistant polypropylene materials. The temperature of the twin-screw extruder is: 160-165°C for the first zone, 165-170°C for the second zone, 170-175°C for the third zone, 175-180°C for the fourth zone, 180-185°C for the fifth zone, 180-185°C for the sixth zone, The seventh zone is 175-180°C, the eighth zone is 170-175°C, the ninth zone is 165-170°C, the tenth zone is 165-170°C,...

Embodiment 2

[0036] Raw materials: 50 kg of block copolymer polypropylene with a melt index of 40.0 g / 10 min, 25 kg of microencapsulated ammonium polyphosphate, 25 kg of TPO thermoplastic elastomer with a rubber content of 50% and 0.5 kg of B215 (Ciba, Switzerland).

[0037] Each raw material model is purchased from the same manufacturer as in Example 1, and the preparation method and testing method are as in Example 1.

Embodiment 3

[0039] Raw materials: 60 kg of block copolymer polypropylene with a melt index of 5.0 g / 10 min, 20 kg of microencapsulated ammonium polyphosphate, 20 kg of TPO thermoplastic elastomer with a rubber content of 25% and 0.3 kg of 168 (Ciba, Switzerland).

[0040] Each raw material model is purchased from the same manufacturer as in Example 1, and the preparation method and testing method are as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com