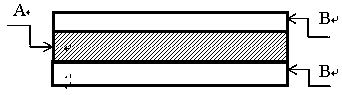

Easy-to-pull removable double-sided adhesive tape of TPU base material

A substrate and removal technology, applied in the direction of adhesives, natural rubber adhesives, adhesive types, etc., can solve the problems of low bonding strength, incomplete removal, and insufficient adhesion of tapes, and achieve stretching High elongation, convenient after-sales maintenance, and improved viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

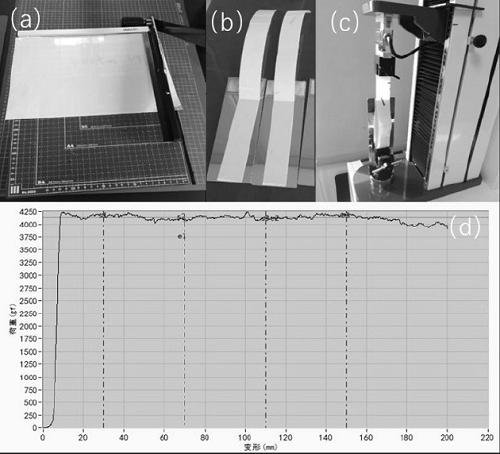

[0025] The rubber-type glue used to prepare the TPU easy-to-pull removable tape contains the following raw materials in parts by weight: 150 parts of styrene-butadiene rubber, 130 parts of Ganzhou Taipu Chemical T115 terpene resin, 270 parts of toluene, 0.6 part of adhesion promoter ADDID900, color 7 parts of slurry; first dissolve the tackifying resin with toluene, then add styrene-butadiene rubber, adhesion promoter, and color paste in turn, and get the glue after stirring evenly; adjust the coating thickness, and apply the glue on the release paper or release paper On the molded film, drying, and bonding the TPU substrate to obtain a TPU substrate with a thickness of 120 μm and a removable double-sided adhesive tape. During the test of the obtained tape on the SUS steel plate, when the peeling force reached 4022 gf / inch, there was no separation and residual glue on the tape, which reflected the excellent adhesion between the TPU substrate and the tape.

[0026] When the TPU...

example 2

[0028] The rubber-type glue used to prepare the TPU easy-to-pull removable tape contains the following raw materials in parts by weight: 120 parts of styrene-butadiene rubber, 130 parts of Arakawa chemical GB125 rosin resin, 300 parts of toluene, 4 parts of adhesion promoter ADDID901, and 8 parts of color paste ;Use toluene to dissolve the tackifying resin first, then add styrene-butadiene rubber, adhesion promoter, and color paste in turn, and mix well to obtain glue; adjust the coating thickness, and coat the glue on the release paper or film , dried, and bonded to the TPU substrate to obtain a TPU substrate with a thickness of 150 μm and a removable double-sided adhesive tape. During the test of the obtained tape on the SUS steel plate, when the peeling force reached 4114 gf / inch, no separation and residual glue was found in the tape, which reflected the excellent adhesion between the TPU substrate and the tape.

[0029] When the TPU base material is easy to pull and remove...

example 3

[0031] The rubber-type glue for preparing the TPU easy-to-pull removable adhesive tape includes the following raw materials in parts by weight: 100 parts of synthetic natural rubber, 120 parts of Arakawa chemical GB125 rosin resin, 300 parts of toluene, 3 parts of adhesion promoter ADDID901, and 8 parts of color paste ;Use toluene to dissolve the tackifying resin first, then add natural synthetic rubber, adhesion promoter, and color paste in turn, and mix well to obtain glue; adjust the coating thickness, and apply the glue on the release paper or release film , dried, and bonded to the TPU substrate to obtain a TPU substrate with a thickness of 200 μm and a removable double-sided adhesive tape. During the test of the obtained tape on the SUS steel plate, when the peeling force reached 4231 gf / inch, there was no separation and residual glue on the tape, which reflected the excellent adhesion between the TPU substrate and the tape.

[0032] When the TPU base material is easy to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com