Method of preparing clubbed nano-cellulose

A nanocellulose, rod-shaped technology, applied in fiber raw material processing, textiles and papermaking, etc., can solve the problems of low aspect ratio and limit the application of composite materials, and achieve high aspect ratio, high frequency and power stability, and safe reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

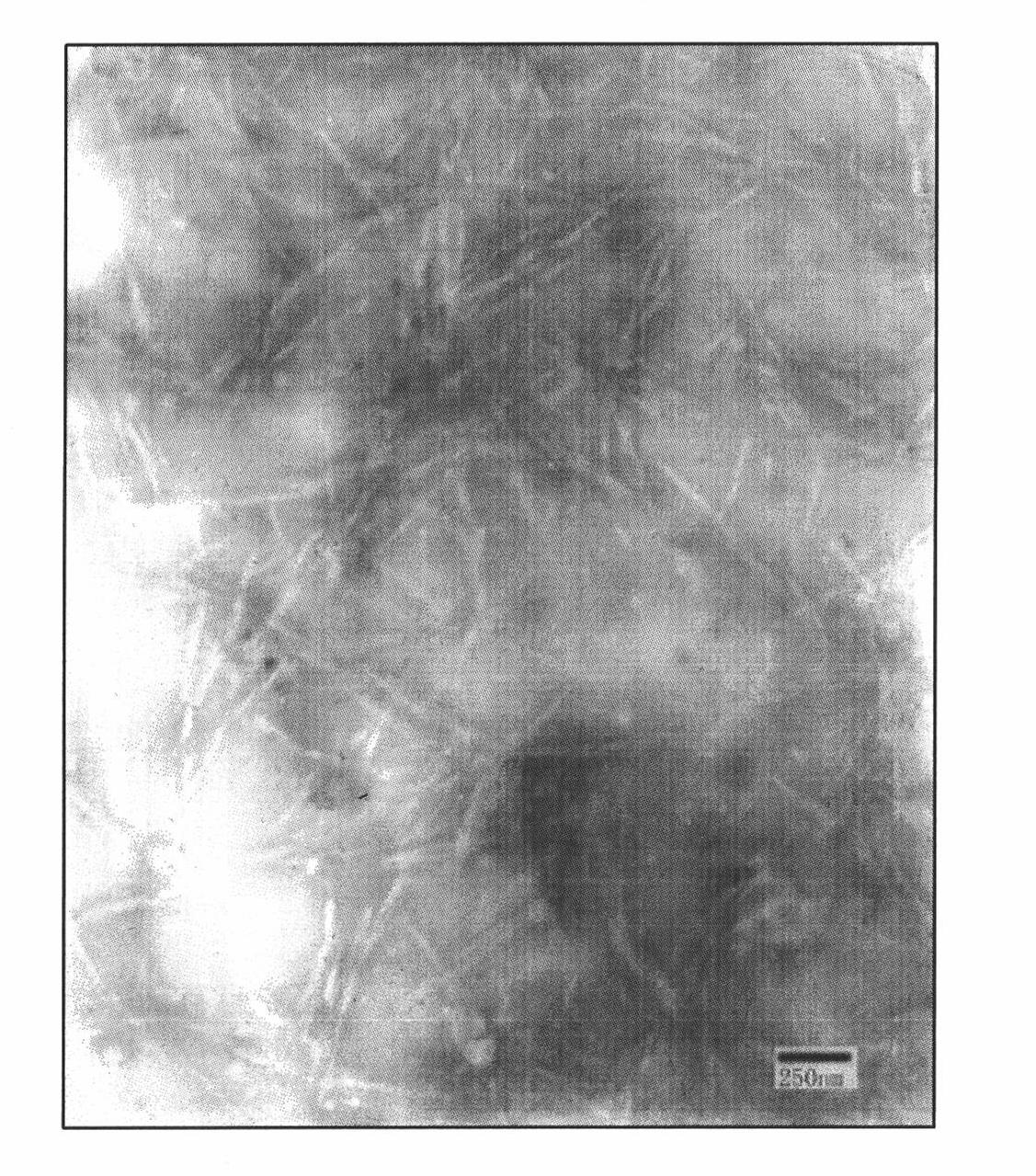

[0022] Disperse 10 grams of cotton fiber in 200 grams of sulfuric acid aqueous solution with a concentration of 60% by mass, and carry out single-mode microwave radiation hydrolysis at a temperature of 45°C. The single-mode microwave radiation power is 100w, and the radiation time is 5 minutes to obtain a hydrolyzed solution Add distilled water to the obtained hydrolyzate to dilute the hydrolyzate to 10 times the volume, then centrifuge the diluted hydrolyzate at 10,000rpm for 3 times; get the precipitate and dialyze for 3 days, and the molecular weight cut-off of the dialysis membrane used After dialysis, it is filtered through a filter membrane with a pore size of 0.45 microns, and the filtrate is dispersed by 200w ultrasonic waves for 35 minutes to obtain a stable rod-shaped nanocellulose suspension, wherein the nanocellulose has a diameter of 5-10 nanometers and a length of 100-300 Nano.

Embodiment 2

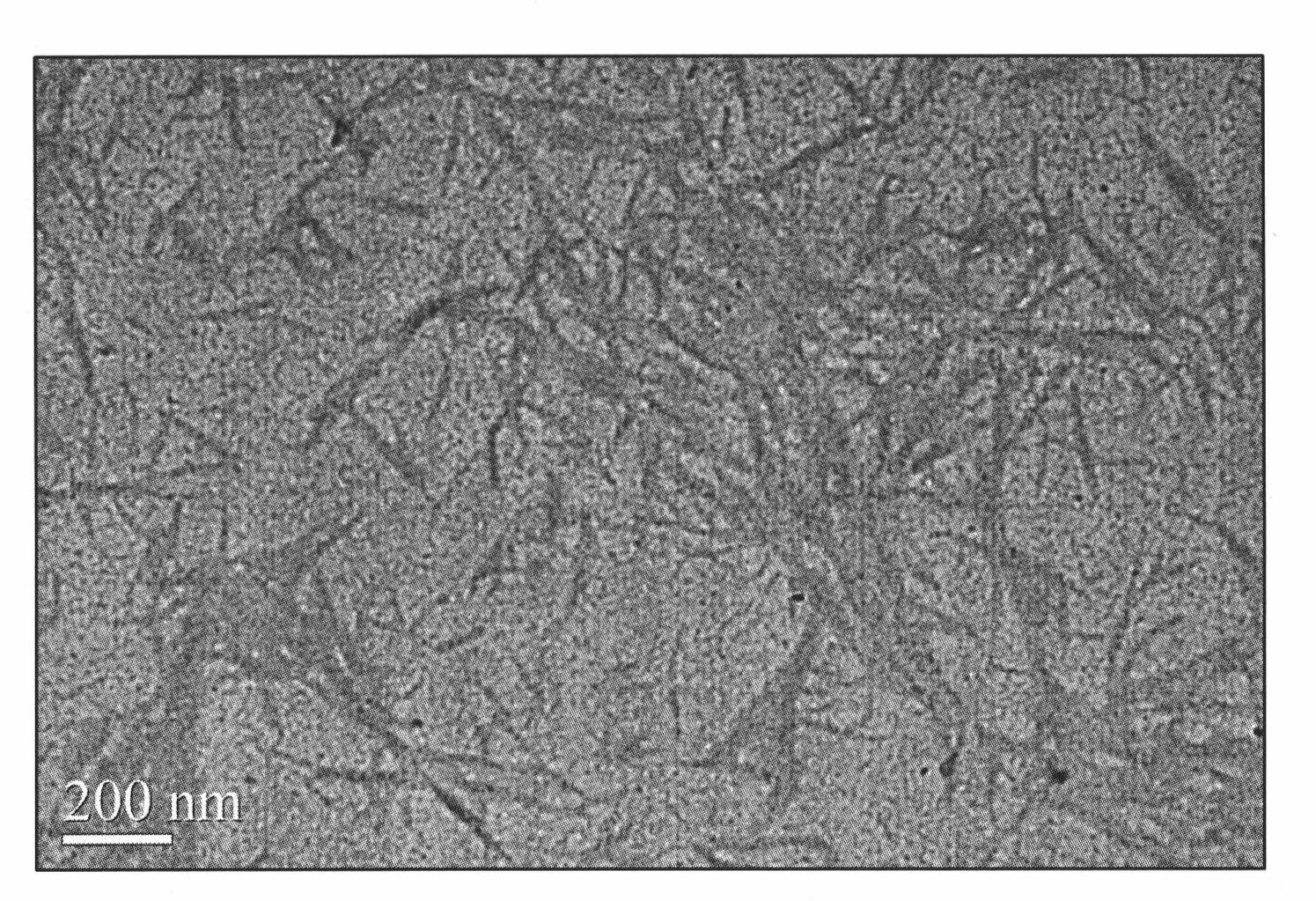

[0024] Disperse 10 grams of wood pulp fibers in 150 grams of sulfuric acid aqueous solution with a mass concentration of 50%, and carry out single-mode microwave radiation hydrolysis at a temperature of 50°C. The single-mode microwave radiation power is 10w, and the radiation time is 60 minutes. The obtained hydrolysis Distilled water was added to the solution to dilute the hydrolyzate to 10 times the volume, and then the diluted hydrolyzate was centrifuged at 12000rpm for 5 times, and the precipitate was dialyzed for 3 days. The molecular weight cut-off of the dialysis membrane used was 12000; after dialysis Filtrate with a filter membrane with a pore size of 0.45 microns, and the filtrate is dispersed by 200w ultrasonic waves for 30 minutes to obtain a stable rod-shaped nanocellulose suspension, wherein the nanocellulose has a diameter of 5-20 nanometers and a length of 100-300 nanometers.

Embodiment 3

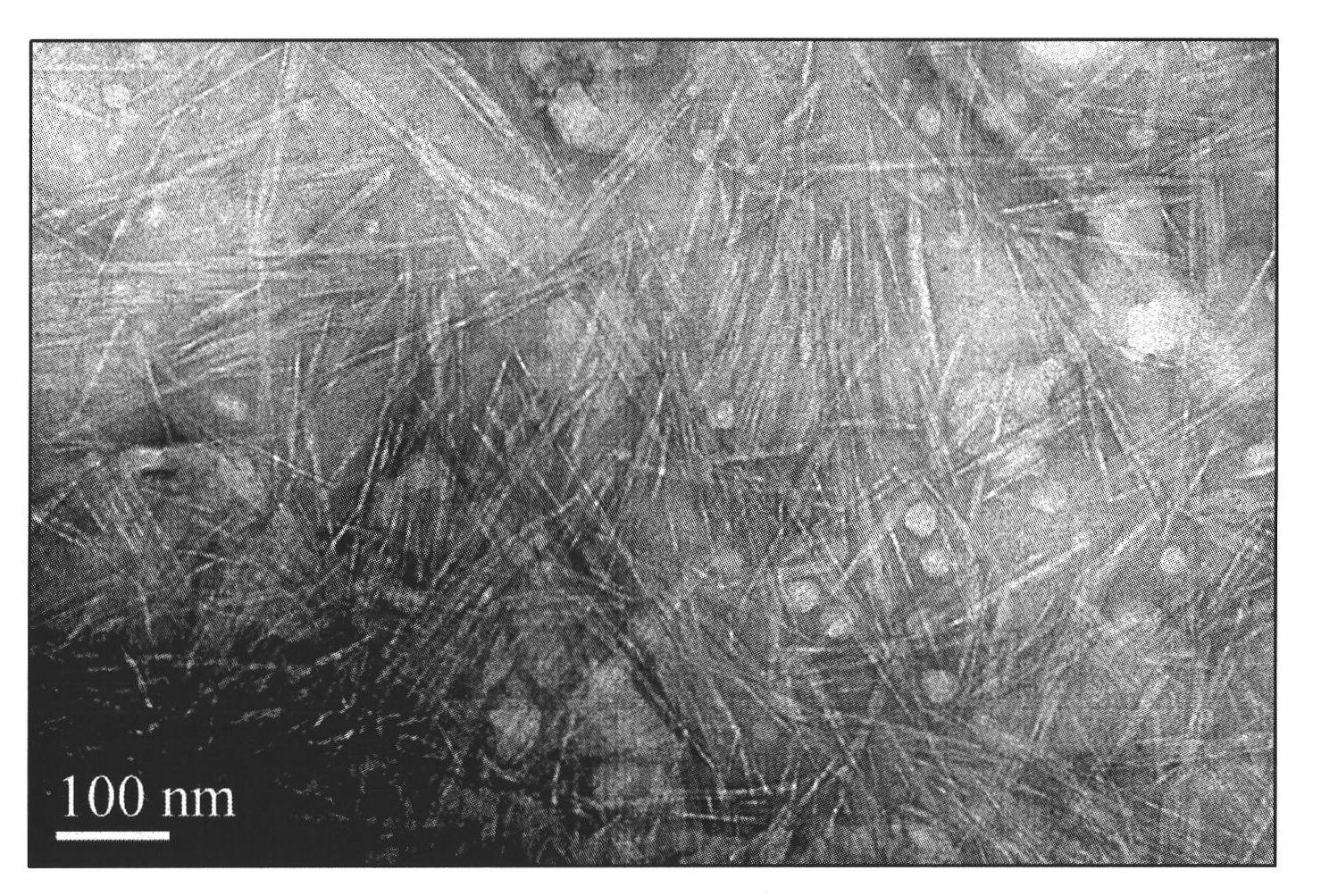

[0026] Disperse 10 grams of microcrystalline cellulose in 100 grams of sulfuric acid aqueous solution with a mass concentration of 65%, and carry out single-mode microwave radiation hydrolysis at a temperature of 40 ° C. The single-mode microwave radiation power is 20w, and the radiation time is 20 minutes; the obtained Distilled water was added to the hydrolyzate to dilute the hydrolyzate to 10 times the volume. The diluted hydrolyzate was centrifuged 4 times at 11,000 rpm, and the precipitate was dialyzed for 3 days. The molecular weight cut-off of the dialysis membrane used was 14,000; Filtrate through a 0.45 micron filter membrane, and the filtrate is dispersed by 200w ultrasonic waves for 25 minutes to obtain a stable rod-shaped nanocellulose suspension, wherein the nanocellulose has a diameter of 10-20 nanometers and a length of 100-300 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com