Patents

Literature

33results about How to "Reduce oxidation activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medium and low temperature denitration catalyst and preparation method thereof

ActiveCN106492791AReduce oxidation activityHigh activityHeterogenous catalyst chemical elementsDispersed particle separationCeriumStearic acid

The invention provides a medium and low temperature denitration catalyst, and belongs to the technical field of denitration catalysts. The catalyst is prepared from ultrafine titanium dioxide, strontium-doped cerium manganese calcium titanium ore type composite oxides, vanadium pentoxide, tungsten trioxide, molybdenum trioxide and stannic oxide; glass fiber is used as an enhancing agent; carboxymethylcellulose and polyoxyethylene are used as bonding agents; stearic acid is used as a lubricating agent. The invention also relates to a preparation method of the medium and low temperature denitration catalyst. The concrete preparation method comprises the steps of preparation of the strontium-doped cerium manganese calcium titanium ore type composite oxides, preparation of carrier materials, preparation of powder catalysts, extrusion forming of honeycomb-shaped catalysts and post treatment of honeycomb-shaped denitration catalysts. The denitration catalyst prepared by the method has the advantages of high denitration efficiency, good sulfur-resistant and waterproof performance, reliable production process and the like in the wide temperature range from 180 DEG C to 350 DEG C; the requirements of oxynitride removal from industrial smoke gas in industries of coking, petrifaction, furnaces and the like can be met; wide application prospects are realized.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Method for producing semi-graphite prebaked anode

A method of producing prebaking semi-graphite anodes comprises: cracking-screening-blending-pugging-molding-baking. It is characterized in, after the middle forging, the prebaking anode thickener contains( by weight), 20úÑ-50úÑ petrolatum coke, 0úÑ-50úÑ semi-graphite petrolatum coke or graphite petrolatum coke, 0úÑ-40úÑ man-made graphite, 14úÑ-20úÑ coal pitch, 0úÑ-20úÑ stub, ash below 1%; puggingis at 140degree C-180degree C, molding is at 130degree C-150degree C, baking is at 1050degree C-1250degree C. The prebaking semi-graphite anode has a low resistance and a low oxidization activity, excellent performance of resisting heat and shock.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Catalyst for NOx and/or SOx control

InactiveUS20060040823A1High activityIncreased reactionsCatalytic crackingPhysical/chemical process catalystsAlkaline earth metalFlue gas

A catalytic additive for reducing NOx, SOx, and / or precursors thereof in a regenerator flue gas comprises an alkaline earth metal, phosphorous, and at least one transition metal on an alumina-based support.

Owner:ENGELHARD CORP

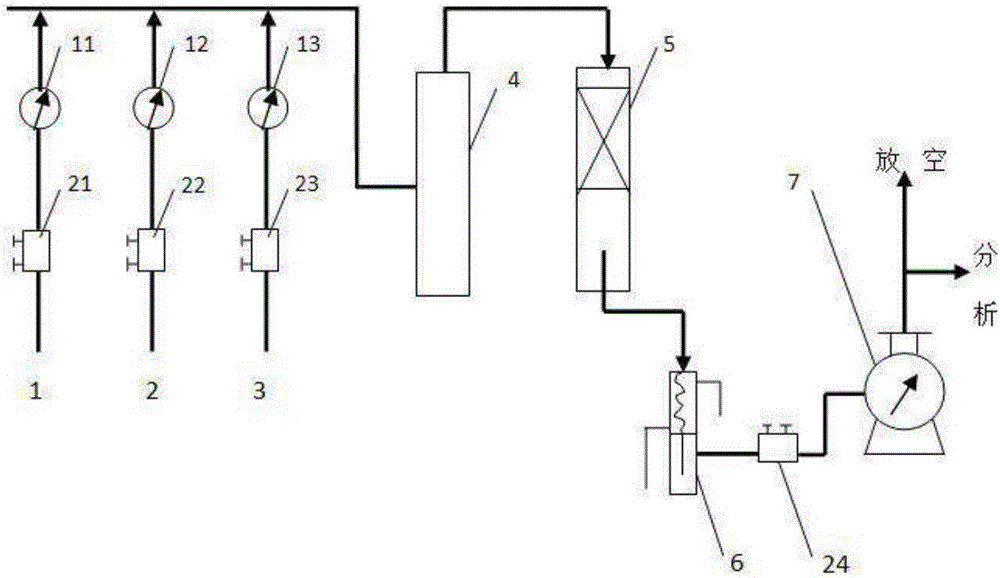

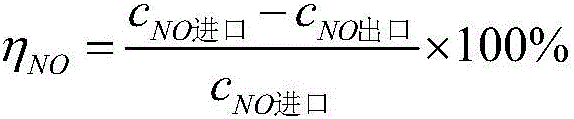

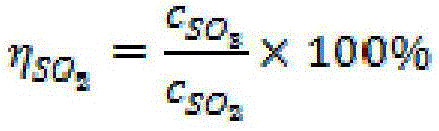

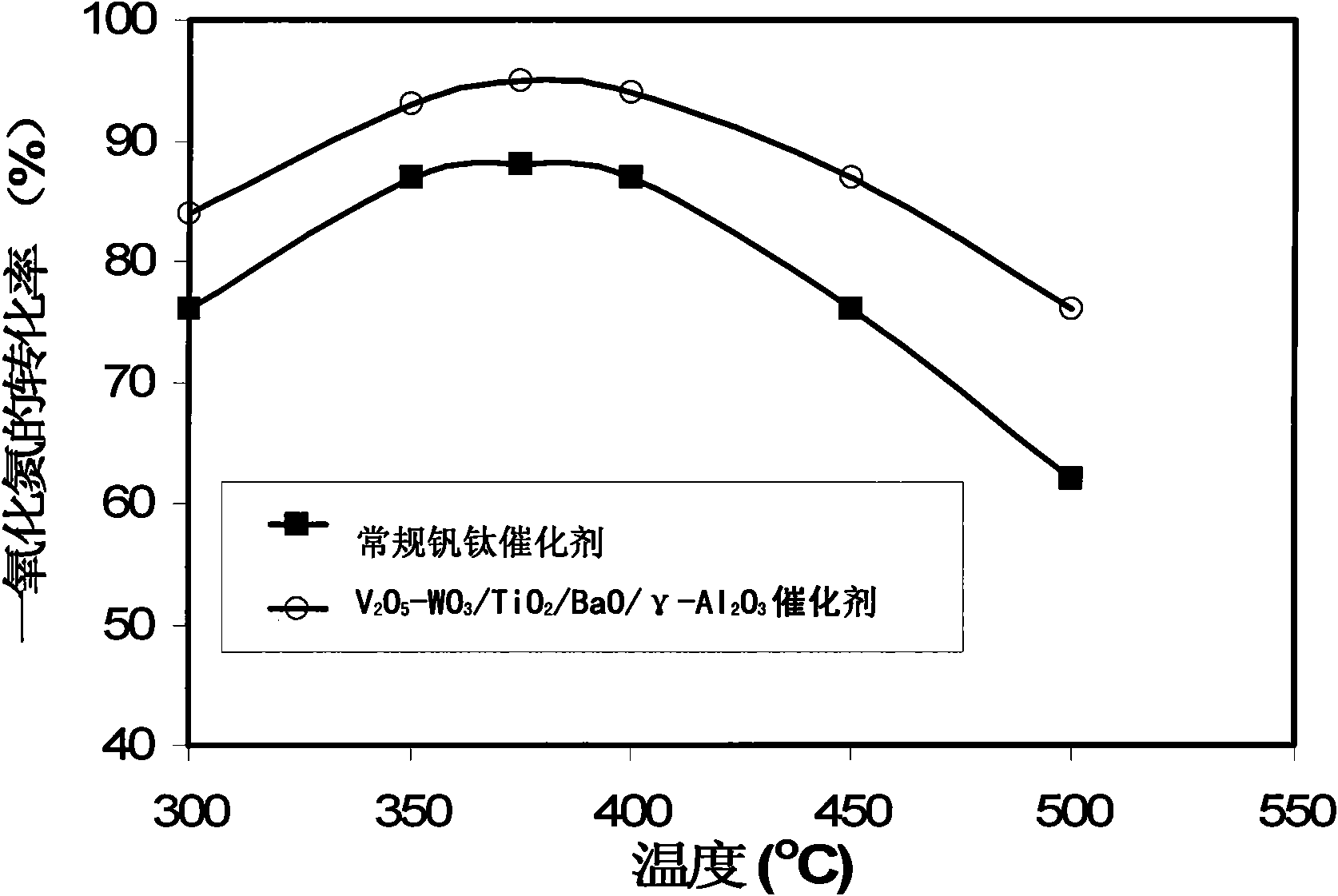

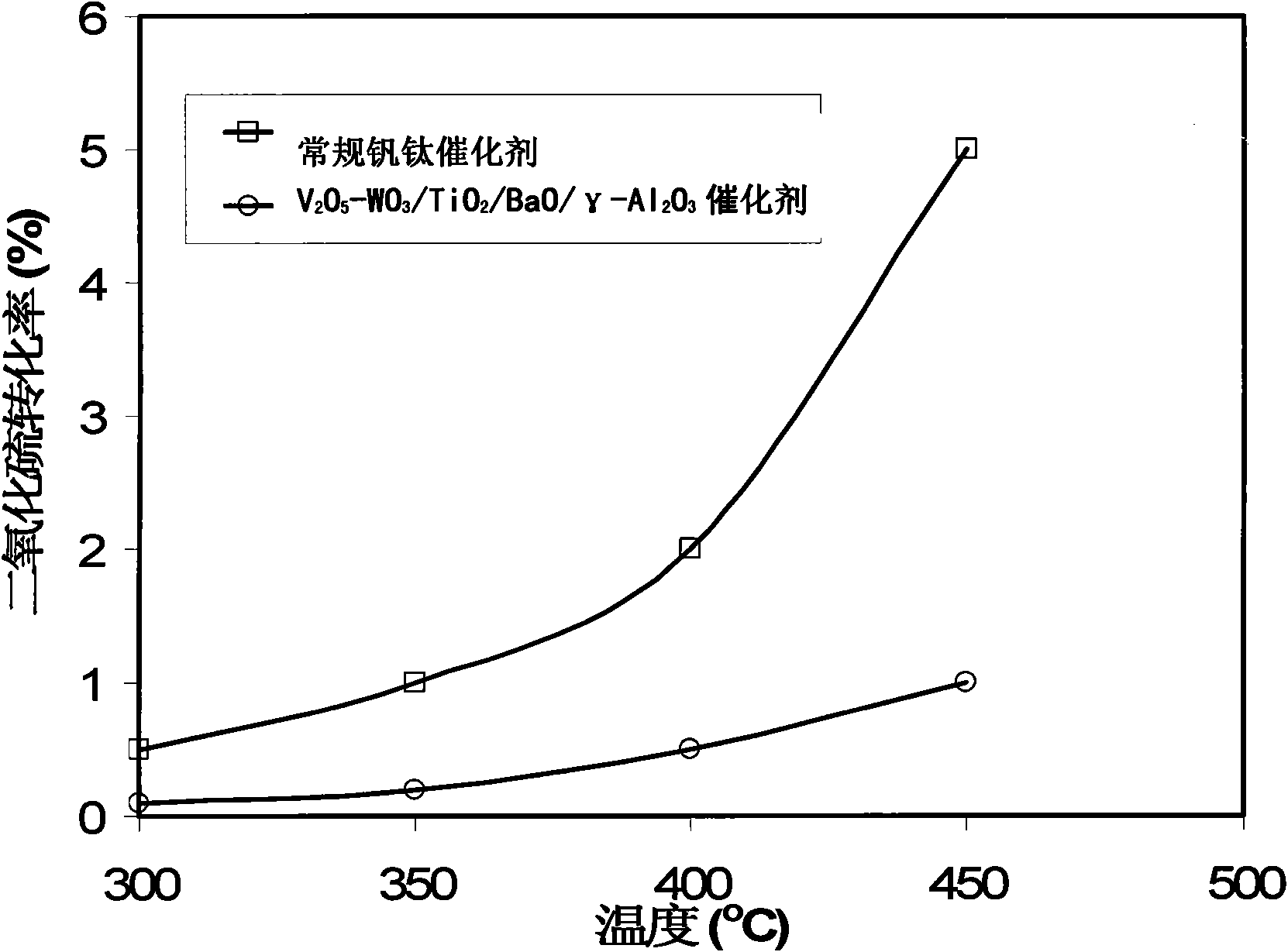

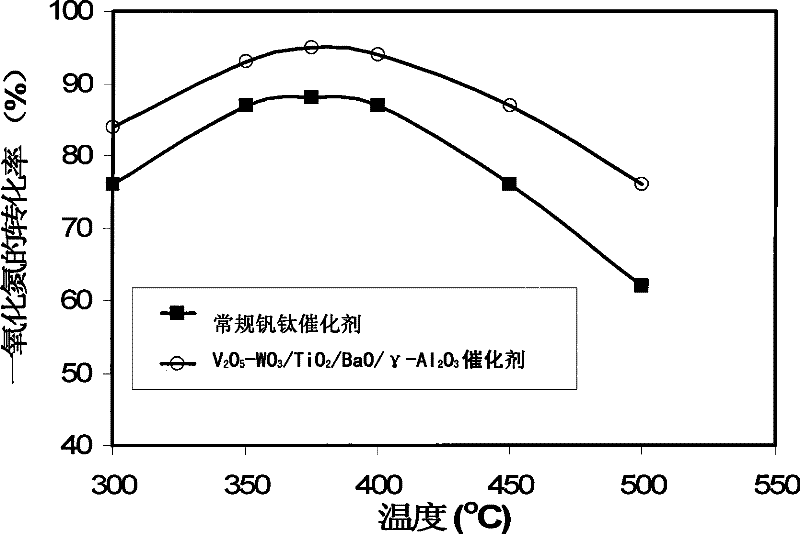

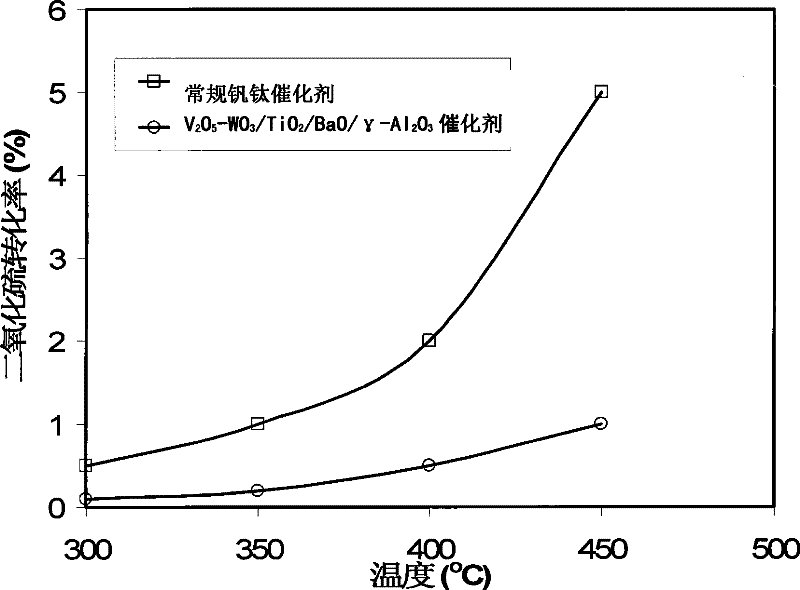

Catalyst used for ammonia selective catalytic reduction of nitrogen oxides to nitrogen gas and preparation method thereof

InactiveCN101554584ALarge specific surface areaLow costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSulfationLow activity

The invention relates to a 'catalyst used for ammonia selective catalytic reduction of nitrogen oxides to nitrogen gas and a preparation method thereof', and belongs to the catalyst technical filed. The catalyst consists of V2O5-WO3 / TiO2 / BaO / gamma-Al2O3. The catalyst takes gamma-Al2O3 as a carrier, which increases specific surface area of the catalyst and lowers the catalyst carrier cost; BaO is added to protect the carrier against sulfation, reduce oxidization activity on sulfur dioxide and prolong service life of the catalyst; and titanium dioxide is highly dispersed on surface of the carrier, thus improving utilization rate of the titanium dioxide. The catalyst is characterized by low cost, high catalytic activity and very low activity to oxidize sulfur dioxide to sulfur trioxide.

Owner:无锡科立泰科技有限公司

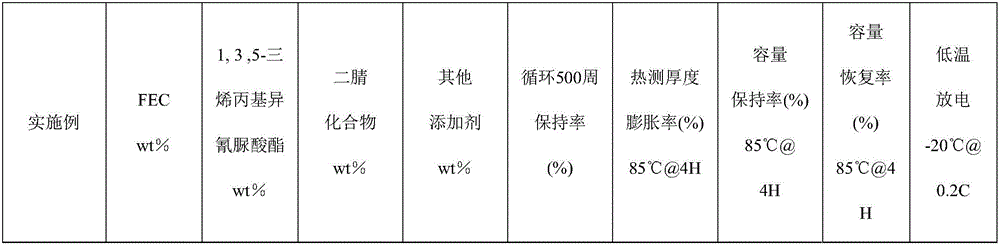

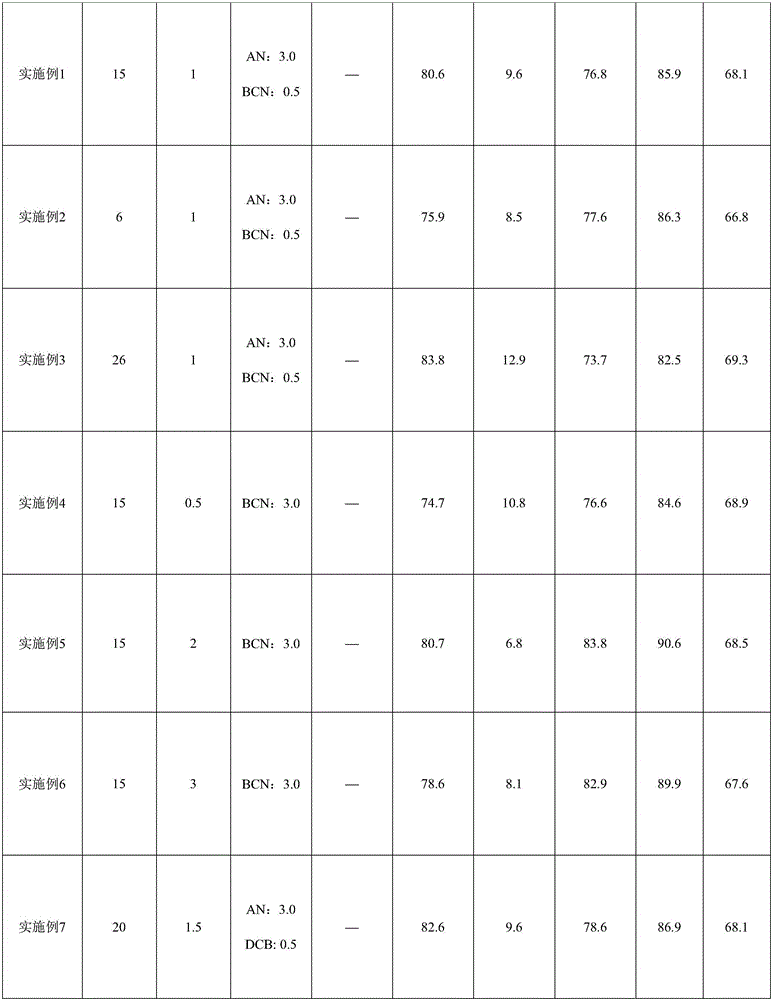

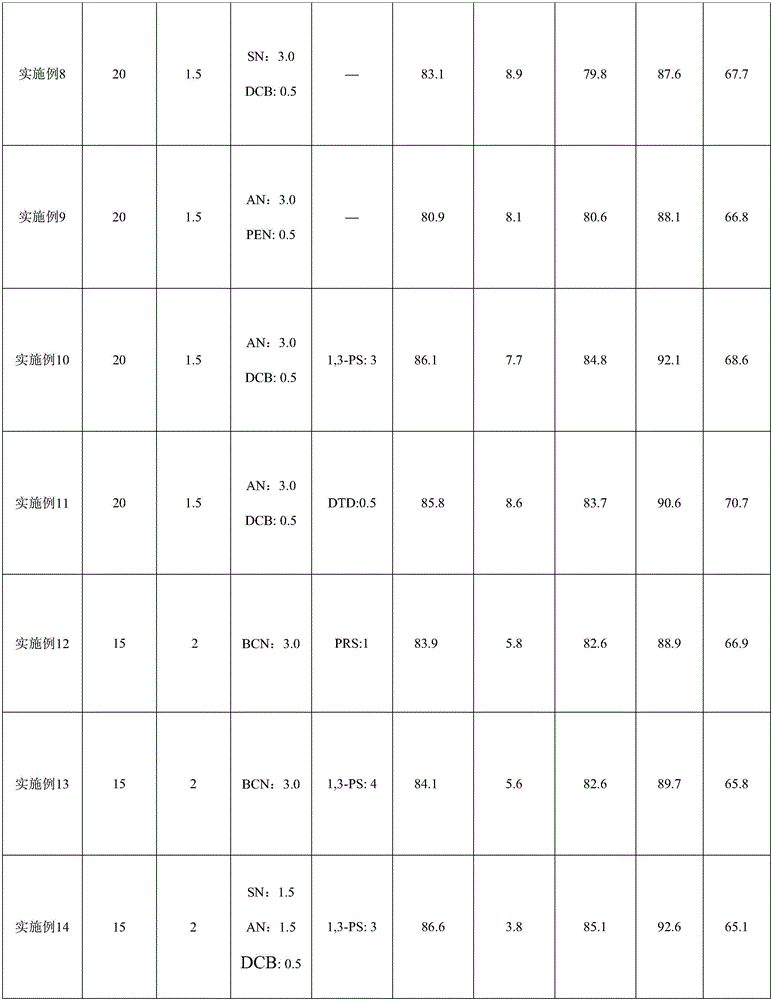

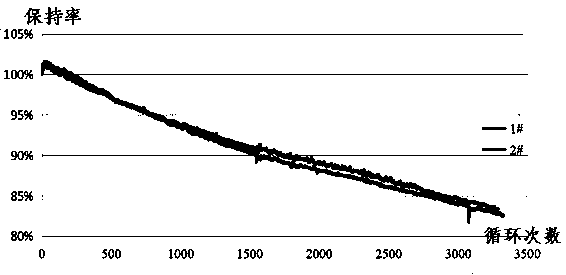

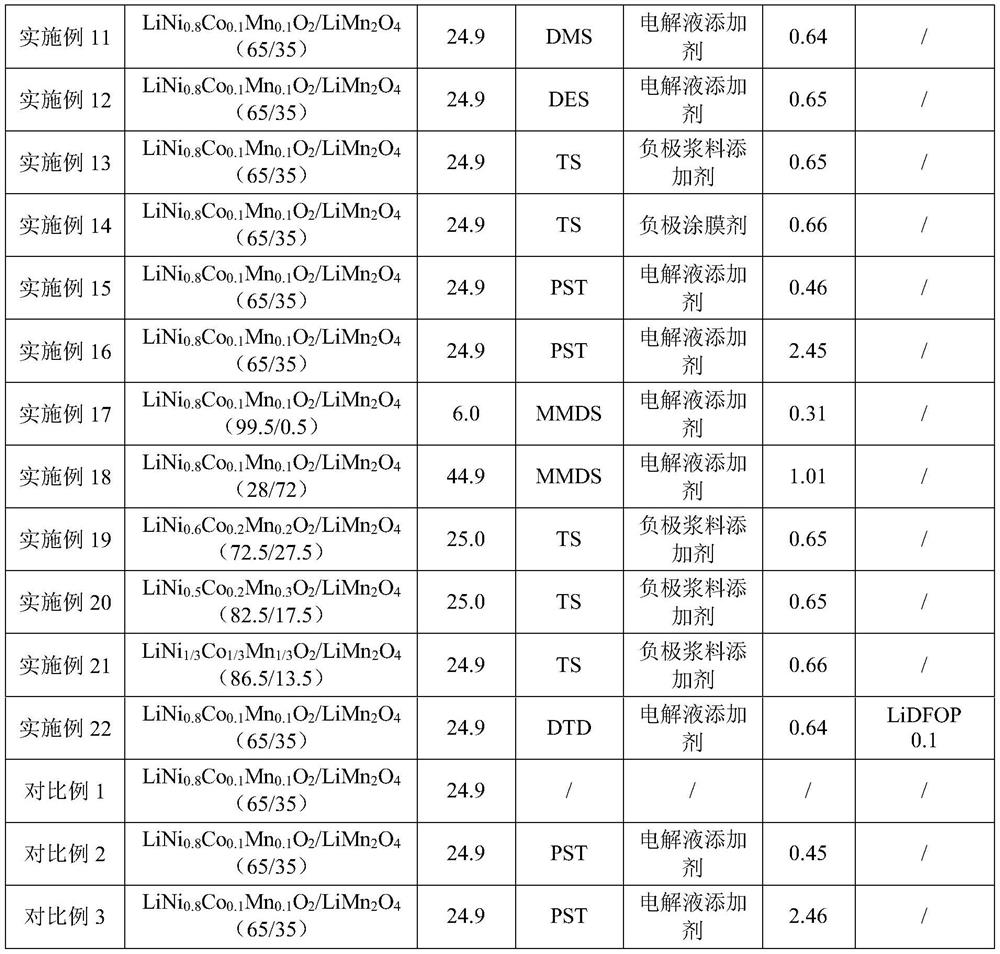

High-voltage lithium battery with silicon-based negative electrode

InactiveCN106654242AImprove cycle performanceImprove cycle lifeCell electrodesSecondary cells servicing/maintenanceHigh temperature storageSilicon oxide

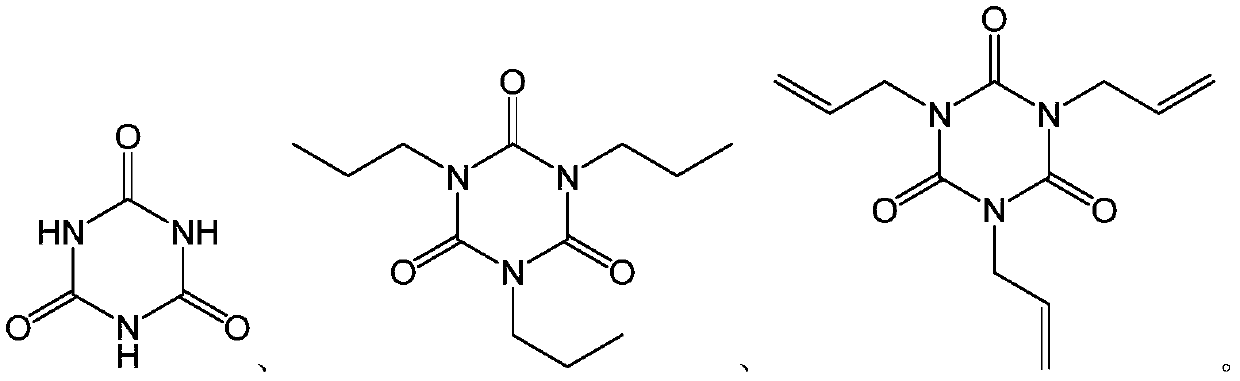

The invention provides a high-voltage lithium secondary battery. The high-voltage lithium secondary battery comprises a negative electrode, a positive electrode, a separator and a non-aqueous electrolyte, wherein the separator and the non-aqueous electrolyte are arranged between the negative electrode and the positive electrode, an active substance of the negative electrode is a lithium transition metal oxide, an active substance of the positive electrode is a mixture containing elemental silicon or silicon oxide, the separator is a polyethylene (PE), polypropylene (PP) or ceramic separator, the non-aqueous electrolyte comprises a non-aqueous organic solvent, a lithium salt and an additive, and the additive comprises fluoroethylene carbonate (FEC), 1,3,5-triallyl isocyanurate and a dinitrile compound. Compared with the prior art, the high-voltage lithium secondary battery has the advantages that by a synergistic effect generated by combined application of the three additives, the physical and chemical structural stability of an electrode surface is improved, so that the high-voltage lithium battery with a silicon-based negative electrode has relatively good high-temperature storage performance and cycle performance.

Owner:GUANGZHOU TINCI MATERIALS TECH

Ternary high-nickel electrolyte and high-nickel anode lithium ion battery containing same

InactiveCN109687010AReduced low temperature performanceGood low temperature performance, lowCell electrodesSecondary cellsHigh temperature storageSlurry

The invention provides ternary high-nickel electrolyte and a high-nickel anode lithium ion battery containing the electrolyte. The ternary high-nickel electrolyte is characterized by comprising, by weight, 13-15% of lithium salt, 80-85% of a non-aqueous organic solvent and 0.1-5% of an additive; wherein the additive comprises vinylene sulfate, vinylene carbonate, succinonitrile, tris (trimethyl silicon-based) phosphorus, lithium bifluroflavin imide and lithium dioxalate borate; the lithium salt is lithium hexafluorophosphate; the non-aqueous organic solvent comprises a cyclic carbonate compound, dimethyl carbonate and ethoxy pentafluoro tripolyphosphate; the high-nickel anode lithium ion battery containing the ternary high-nickel electrolyte adopts anode slurry prepared from high-nickel ternary anode powder, a conductive agent, a functional composite binder, a solvent N-methyl pyrrolidone to prepare the anode membrane, the high-nickel anode lithium ion battery has excellent normal-temperature cycle performance, high-temperature cycle performance and high-temperature storage service life, and can obviously reduce the gas yield in the high-temperature storage process.

Owner:湖北诺邦科技股份有限公司

Method of regenerating used catalyst

ActiveUS20100093517A1Increases Hg oxidation activityOxidation rate is lowGas treatmentOther chemical processesHeteropoly acidPhosphate ion

[Problem] Provided is a method for regenerating a catalyst, the method decreasing the SO2 oxidation rate, which has been increased by Fe and V compounds, of a spent denitration catalyst to an extremely low level, and improves the oxidation activity of the catalyst for metal mercury by the regeneration treatment.[Solving Means] A method for regenerating a catalyst, including steps of immersing a spent denitration catalyst composed mainly of titanium oxide in (a) a mixed aqueous solution containing phosphate ions and oxo-acid ions of one or more elements selected from vanadium (V), molybdenum (Mo), and tungsten (W), (b) a heteropoly acid compound aqueous solution containing phosphorus and one or more elements selected from V, M, and W, or (c) a mixed aqueous solution containing a phosphate compound and a vanadyl compound, and then drying the catalyst.

Owner:MITSUBISHI POWER LTD

Prebaked anode for electrolytic aluminum

The invention relates to a prebaked anode for electrolytic aluminum. The prebaked anode is prepared from calcined petroleum coke, secondary coke and modified coal tar pitch in percentage by weight: 50percent to 65 percent of the calcined petroleum coke, 30 percent to 35 percent of the secondary coke and 15 percent to 20 percent of the modified coal tar pitch, wherein based on particle size distribution, the calcined petroleum coke comprises the following components in percentage by weight: 25 percent to 30 percent of granulated materials with phi being greater than 3mm and less than or equalto 7mm, 45 percent to 50 percent of granulated materials with phi being more than or equal to 0.075mm and less than or equal to 3mm and 25 percent to 30 percent of powder with phi being less than or equal to 0.075mm; and the calcined petroleum coke can be replaced by pitch coke, or the calcined petroleum coke can be replaced by a mixture of the pitch coke and the calcined petroleum coke. Materialsare mixed according to the proportion, and the prebaked anode is manufactured by adopting a conventional process. The prebaked anode produced by adopting the conventional process disclosed by the invention has the advantages of being lower in resistivity, higher in volume density and mechanical performance and low in anode consumption, so that reduction on the production cost of primary aluminumcan be facilitated.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Preparation method of catalytic cracking flue gas desulfurization agent

ActiveCN104475077AHigh reactivityHigh desulfurization activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWork in processPorous channel

The invention provides a preparation method of a catalytic cracking flue gas desulfurization agent. The preparation method provided by the invention comprises the following steps: dipping cerium ion active components on a granular carrier under a certain condition, adding alumina sol and / or silica sol, drying, and roasting to obtain a semi-finished product, wherein the active components can be better dispersed on the carrier; simultaneously, more acid centres can be formed in the carrier; and the reaction activity is increased; and then, dipping magnesium ion active components on the semi-finished product, drying, and roasting to obtain the desulfurization agent. According to the invention, the cerium ion active components are dipped at first; the magnesium ion active components are dipped after alumina sol and / or silica sol are / is added; therefore, the cerium active components are sufficiently dispersed in an aluminium oxide porous channel; the magnesium active components form a clad layer outside the cerium active components; in the event of desulfurizing, desulfurization reaction is carried out in different levels; the desulfurization activity is higher; the transfer rate of SOx in flue gas is high; and the desulfurization agent is long in service life.

Owner:SHENYANG SANJUKAITE CATALYST

Oil resistant, high and low temperature resistant ethylene propylene diene monomer rubber/polyurethane rubber cable material

InactiveCN105111591AReduce oxidation activityImprove heat resistanceRubber insulatorsPolymer scienceEPDM rubber

The invention discloses an oil resistant, high and low temperature resistant ethylene propylene diene monomer / polyurethane rubber bable material. The raw material comprises the following components: ethylene propylene diene monomer rubber, polyurethane rubber, ethylene acrylate, EPDM rubber grafted with maleic anhydride, carbon black, pottery clay, coumarone resin, zinc oxide, stearate, magnesia, zinc methacrylate, benzoyl peroxide, trimerization thiocyanate, trimethylol propane trimethacrylate, accelerator M, accelerant DZ, antioxidant, dihydroxy higher alcohol, diethylene glycol dibenzoate, epoxidized soybean oil and N-(morpholine thiosulfate) phthalimide. The oil resistant, high and low temperature resistant ethylene propylene diene monomer / polyurethane rubber bable material disclosed by the invention is high in mechanical strength, excellent in oil resistance, high in temperature resistance and cold tolerance; and the cable made from the material is long in service life, so that the cost can be reduced.

Owner:繁昌县菲德通讯材料设计有限公司

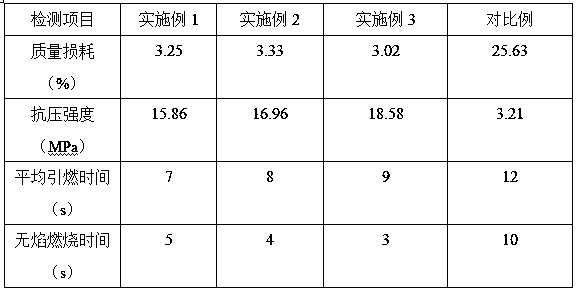

Preparation method of fire prevention and extinguishing material for coal mine

The invention relates to a preparation method of a fire preventing and extinguishing material for a coal mine and belongs to the technical field of flame-retardant materials. The prepared fire preventing and extinguishing material for the coal mine is water absorption gel, a large amount of condensed water and a small amount of immobile water exist in the water absorption gel, and 2-3 water molecular layers with the thickness of 0.5-0.6 nm are formed on the surfaces of molecules through hydrophilic hydration; the first layer is hydrated water formed by polar ion groups and water molecules through coordination bonds or hydrogen bonds; the second layer is a combined water layer formed by water molecules and hydrated water through hydrogen bonds; the gel absorbs water mainly through the interaction between internal three-dimensional space networks, a large amount of free water is absorbed and stored in grids, and the larger the pore diameter of the gel three-dimensional space networks is,the higher the water absorption rate is; the water absorption gel covering the surface of the coal body reduces the probability of contact between a coal body and oxygen, blocks an air leakage channel, reduces the oxygen concentration, absorbs heat for cooling and reduces the oxidation activity of the coal, so that the prepared fire preventing and extinguishing material for the coal mine is highin fire extinguishing efficiency and high in speed.

Owner:李宏伟

Catalyst For NOx And/Or SOx Control

InactiveUS20080227625A1High activityIncreased reactionsCatalytic crackingOther chemical processesAlkaline earth metalFlue gas

A catalytic additive for reducing NOx, SOx, and / or precursors thereof in a regenerator flue gas comprises an alkaline earth metal, phosphorous, and at least one transition metal on an alumina-based support.

Owner:STOCKWELL DAVID M

Fish meal additive

InactiveCN104186980APrevent oxidationReduce oxidation activityAnimal feeding stuffButylated hydroxytolueneToluene

The invention provides a fish meal additive, belongs to the field of additives, and solves the problems that fat is easy to rancidify and protein is easy to corrupt and mildew in fish meal of feeds in the prior art. The fish meal additive comprises the following components in parts by weight: 0.2-0.6 part of butylated hydroxytoluene, 0.2-0.6 part of tert-butyl hydroquinone, 2-4 parts of malic acid, 1-2 parts of citric acid, 1-2 parts of silica bauxite, 2-5 parts of zeolite and 0.05-0.1 part of yeast. According to the fish meal additive, by selecting varieties and contents of materials, the possibilities of rancidity of the fat and corruption and mildewing of the protein are reduced, so that the preservation time of the fish meal is prolonged, and the application security of the fish meal in the feeds is improved.

Owner:巨星农牧有限公司

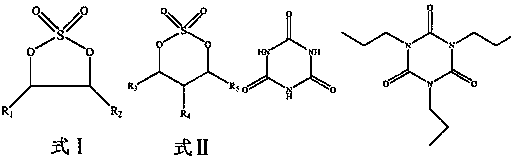

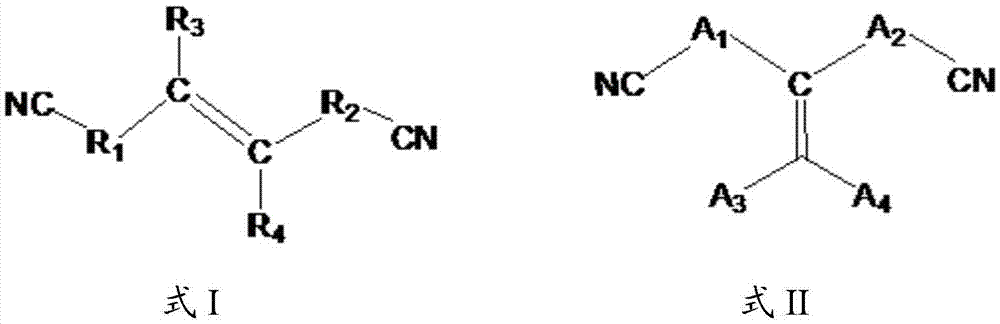

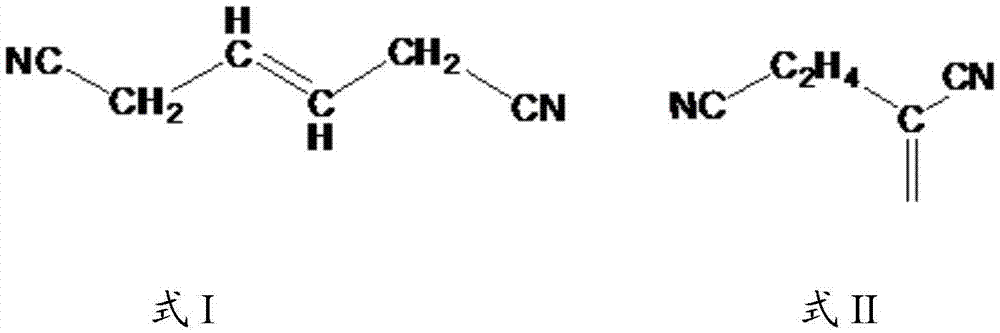

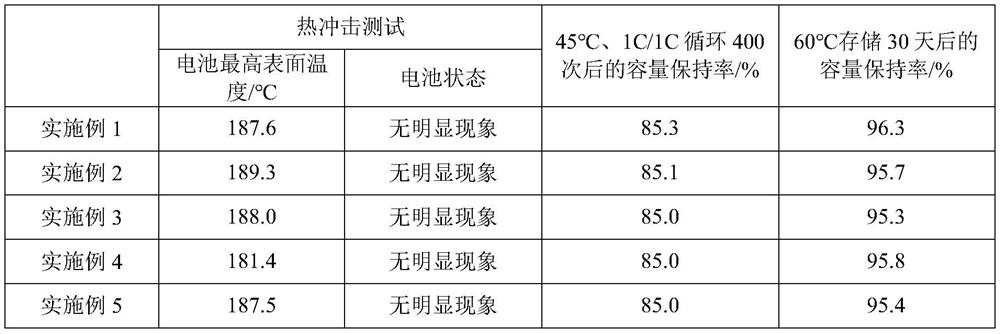

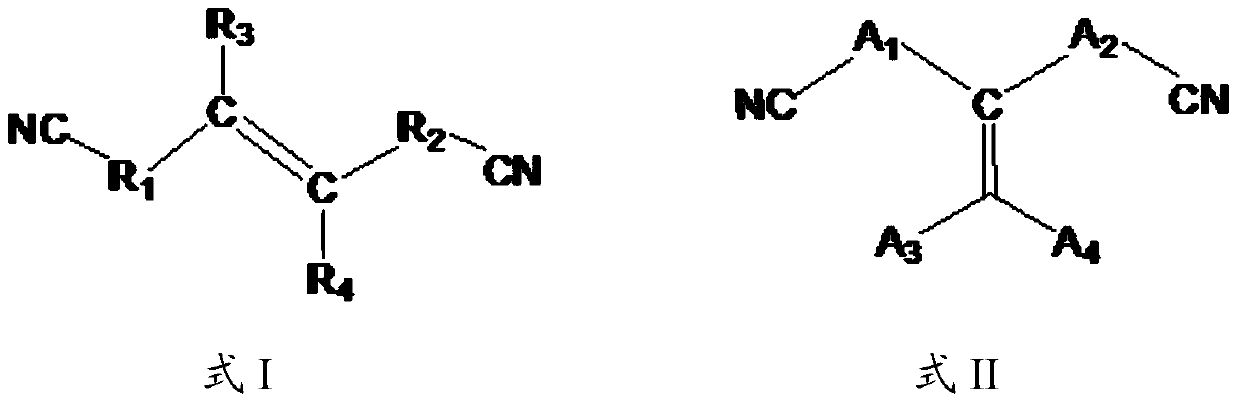

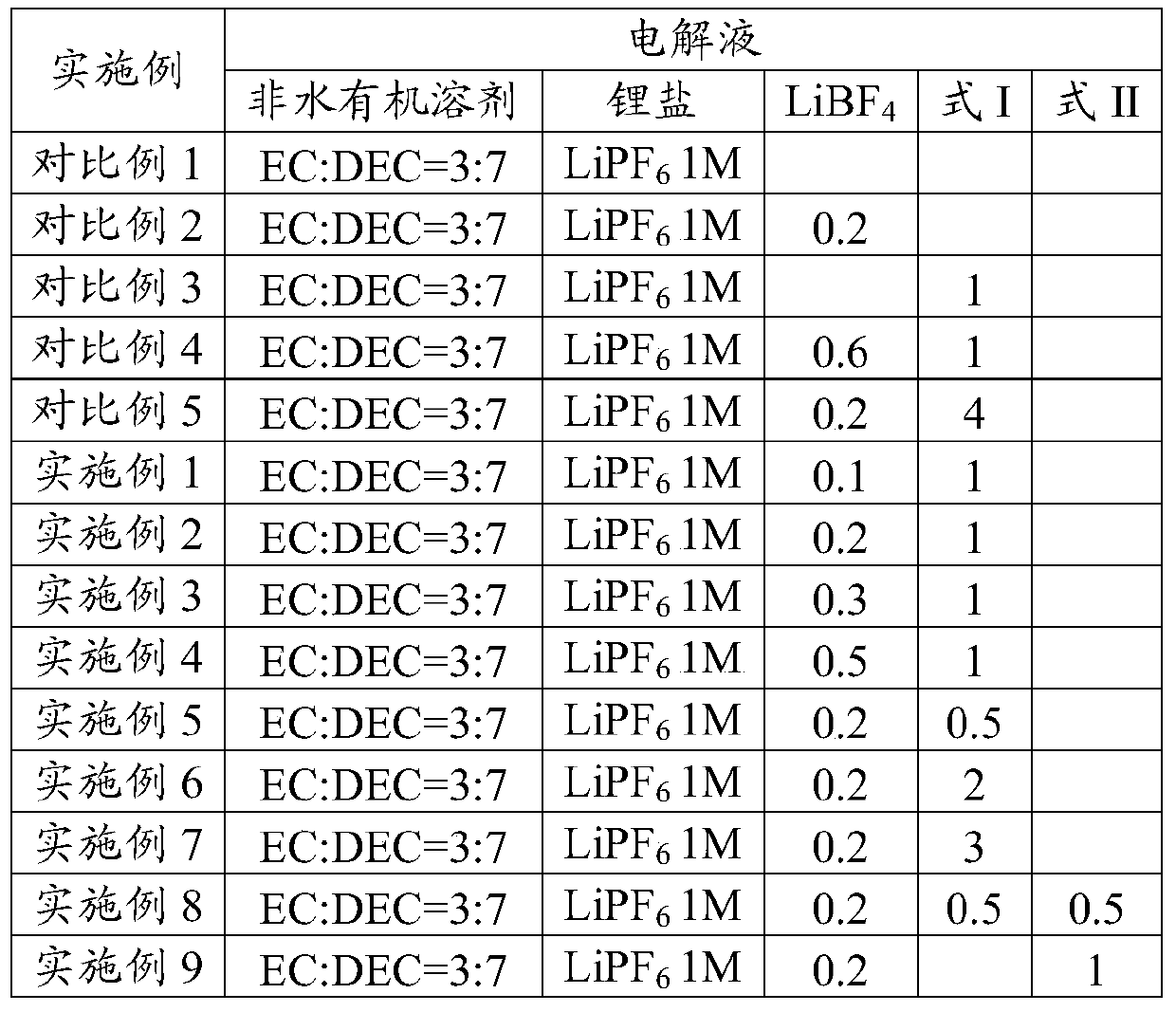

Lithium ion battery and non-aqueous electrolyte thereof

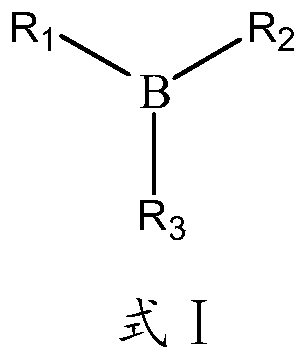

ActiveCN106941191AImproved high temperature storage performance and intermittent cycle capacity retentionImprove stabilitySecondary cellsLithium tetrafluoroboratePhenyl group

The invention discloses a non-aqueous electrolyte. The non-aqueous electrolyte comprises a non-aqueous organic solvent, a lithium salt and an additive, and the additive comprises lithium tetrafluoroborate and at least one of unsaturated bond-containing dinitrile compounds of formula I and formula II. In the formula I and the formula II, R1, R2, A1 and A2 are independently selected from one or more of C0-C5 aliphatic alkyl groups; and R3, R4, A3 and A4 are independently selected from one or more of the hydrogen atom, the fluorine atom , the chlorine atom, an alkyl group and a phenyl group. Additionally, the invention also discloses a lithium ion battery containing the non-aqueous electrolyte.

Owner:NINGDE AMPEREX TECH

Treatment method of smelted neodymium-iron-boron alloy sheet

ActiveCN111681868AImprove discharge efficiencyReduce oxidation activityMagnetic materialsProcess efficiency improvementAlloyMixed gas

The invention discloses a treatment method of a smelted neodymium-iron-boron alloy sheet. The method comprises the steps that a smelted neodymium-iron-boron alloy sheet is placed in hydrogen-argon mixed gas; the temperature of the smelted neodymium-iron-boron alloy sheet is 400 to 550 DEG C; and in the hydrogen-argon mixed gas, the volume ratio of hydrogen is 5% to 80%. According to the treatmentmethod for the smelted neodymium-iron-boron alloy sheet, the discharging efficiency of the alloy sheet can be effectively improved, and the hydrogen decrepitation process time is shortened; and the alloy sheet is not easy to oxidize in air.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

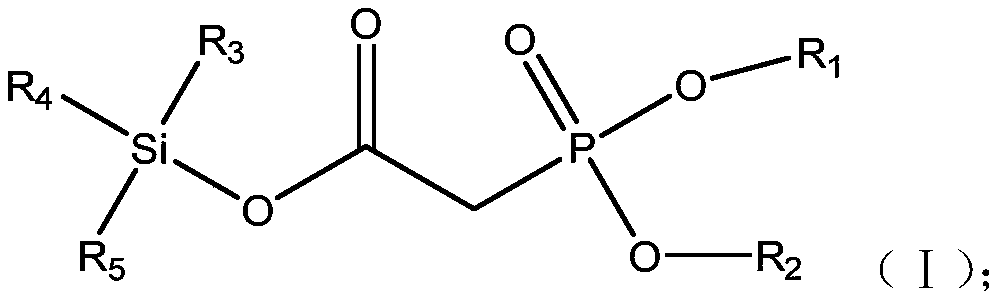

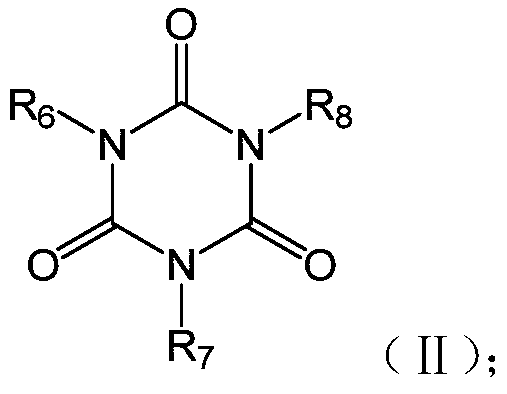

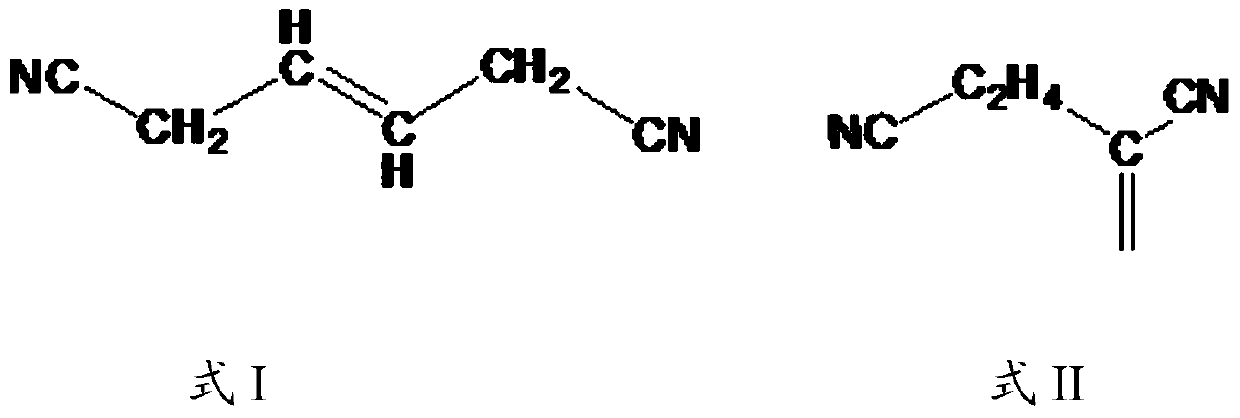

Electrolyte for lithium ion battery and lithium ion battery comprising same

InactiveCN110957532AHigh capacity retentionReduce dissolutionSecondary cellsOrganic electrolytesElectrolytic agentOrganic solvent

The invention provides an electrolyte for a lithium ion battery and a lithium ion battery comprising the same. The electrolyte for the lithium ion battery comprises an organic solvent, a lithium salt,a first additive and a second additive, wherein the first additive and the second additive respectively have structural formulas as shown in formulas (I) and (II). The oxidation potential of the first additive is lower than that of the organic solvent, a compact solid electrolyte phase interface film can be preferentially formed on the surface of the positive electrode through oxidative polymerization, oxygenolysis gas production is reduced, and consumption of active substances is reduced. Nitrogen atoms of the second additive can be effectively complexed with transition metal atoms with highvalence, and the interface impedance of the positive electrode is reduced to facilitate migration of lithium ions on the positive electrode interface, effectively reduce the oxidation activity of a positive electrode material to the electrolyte, especially the oxidation of the electrolyte under a high-temperature condition, further inhibit reduction and dissolution of transition metals caused bythe change of the structure of the positive electrode material, and improve the high-temperature performance of the lithium ion battery.

Owner:HIGHPOWER TECH HUIZHOU

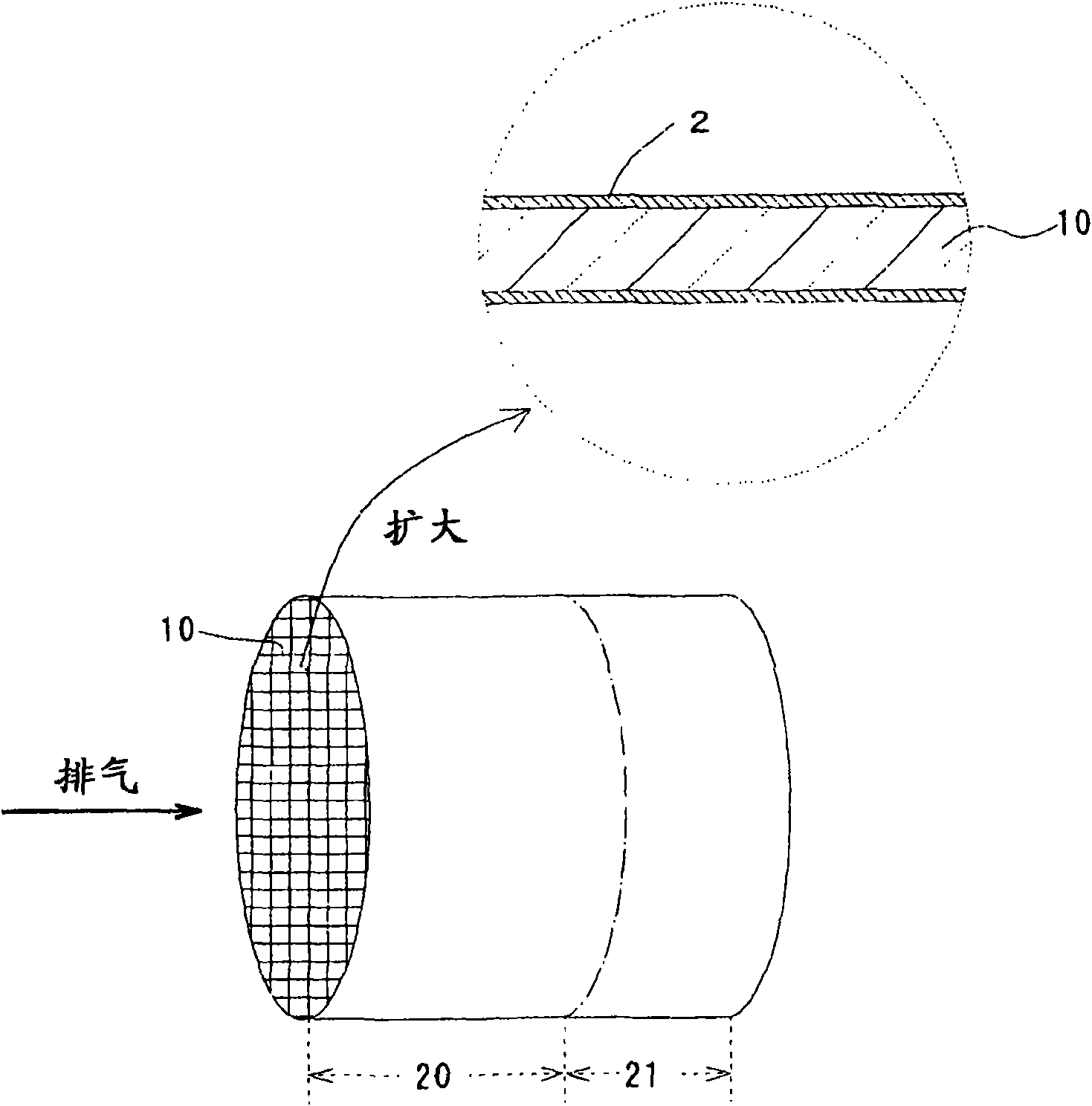

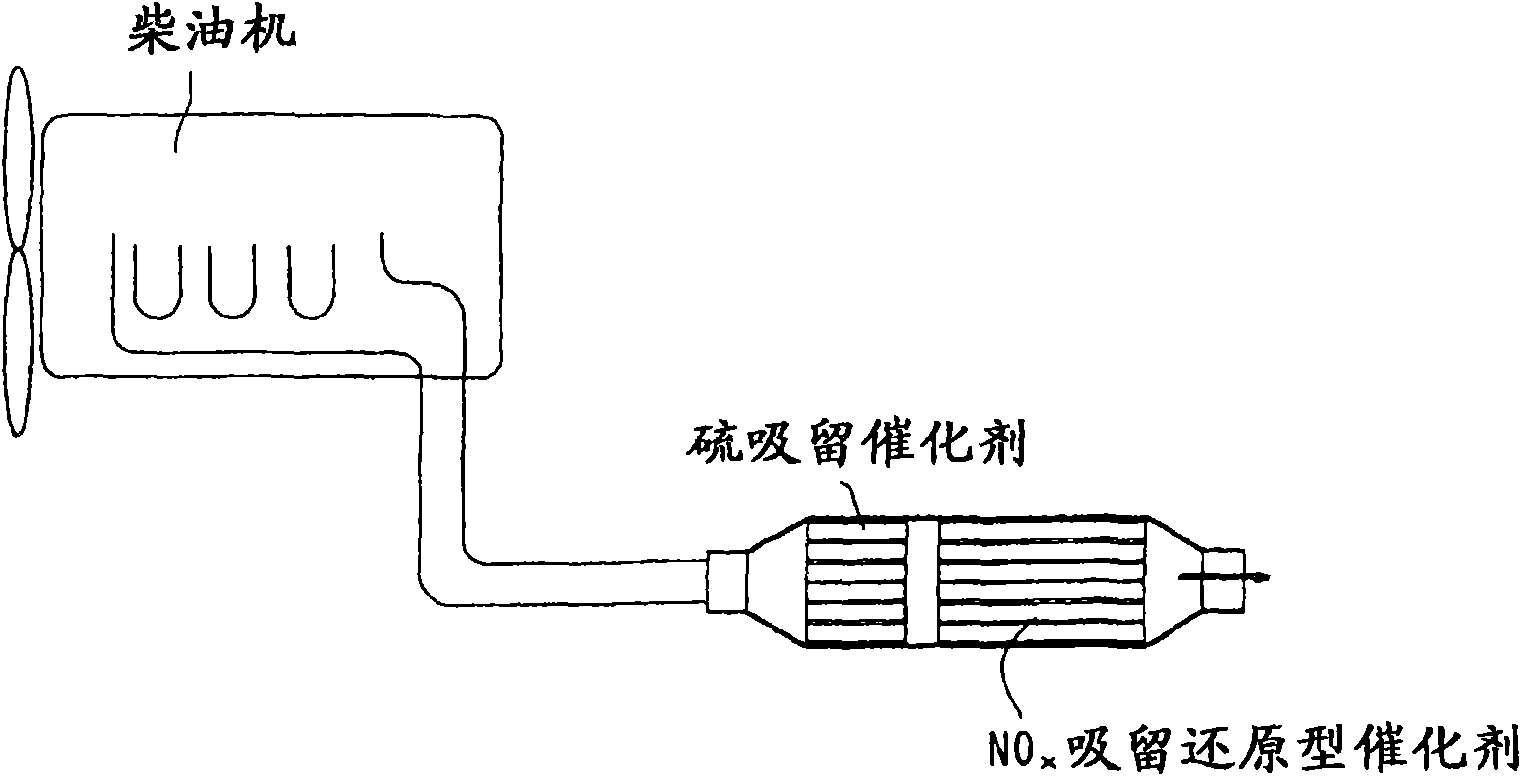

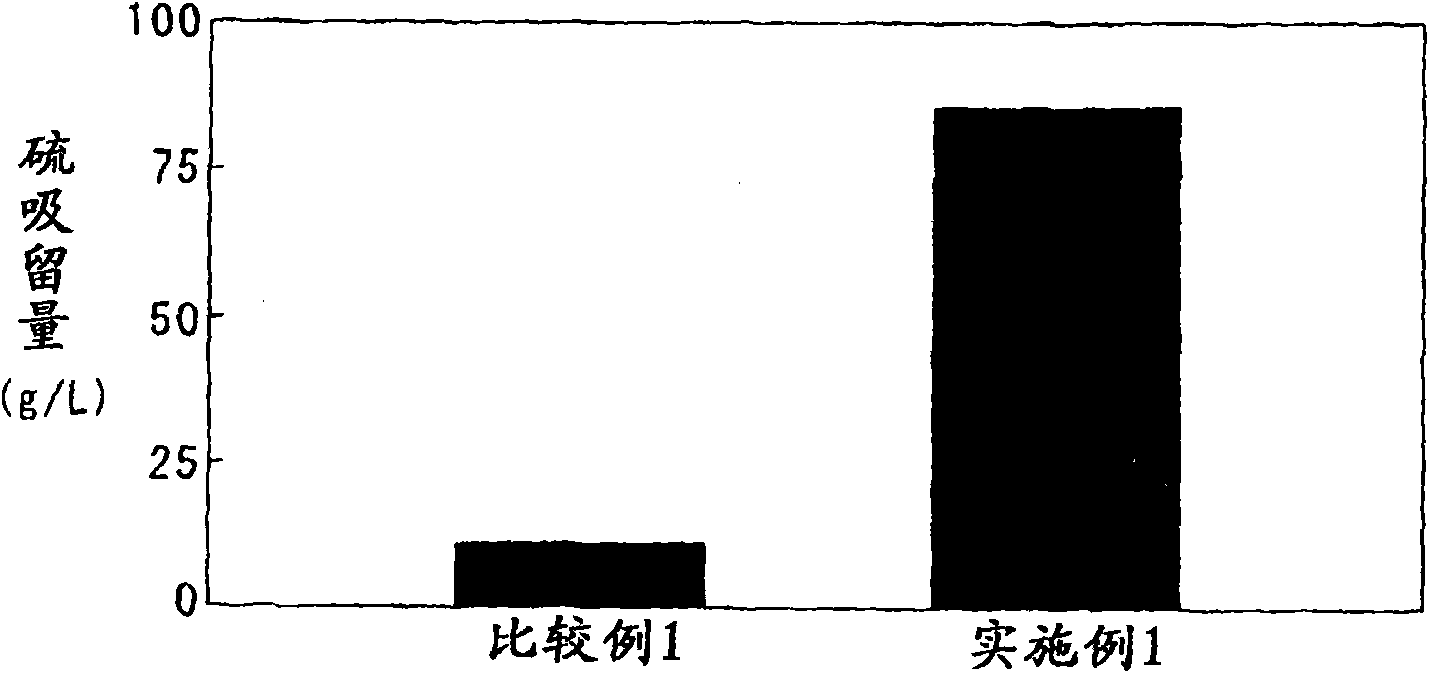

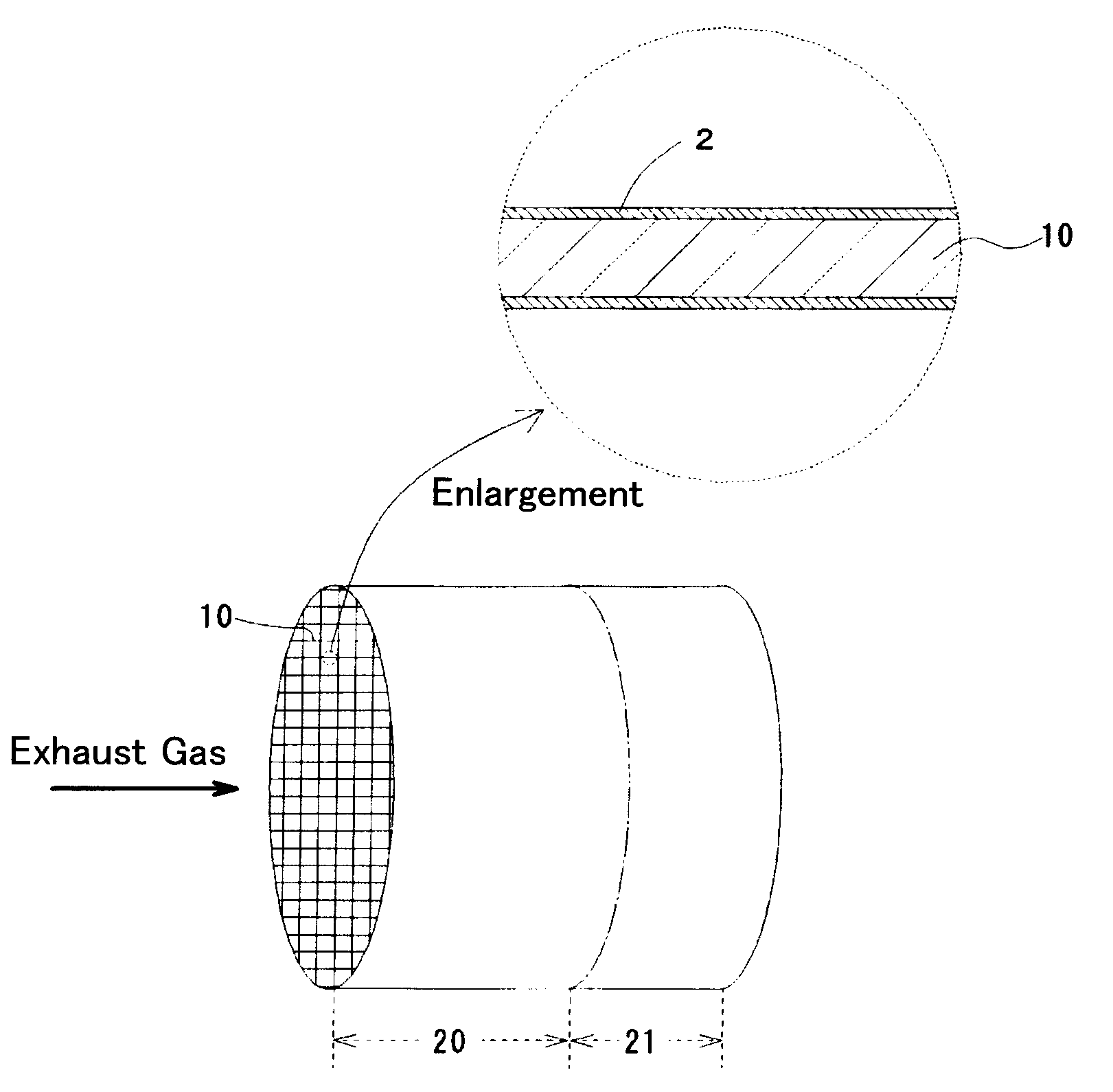

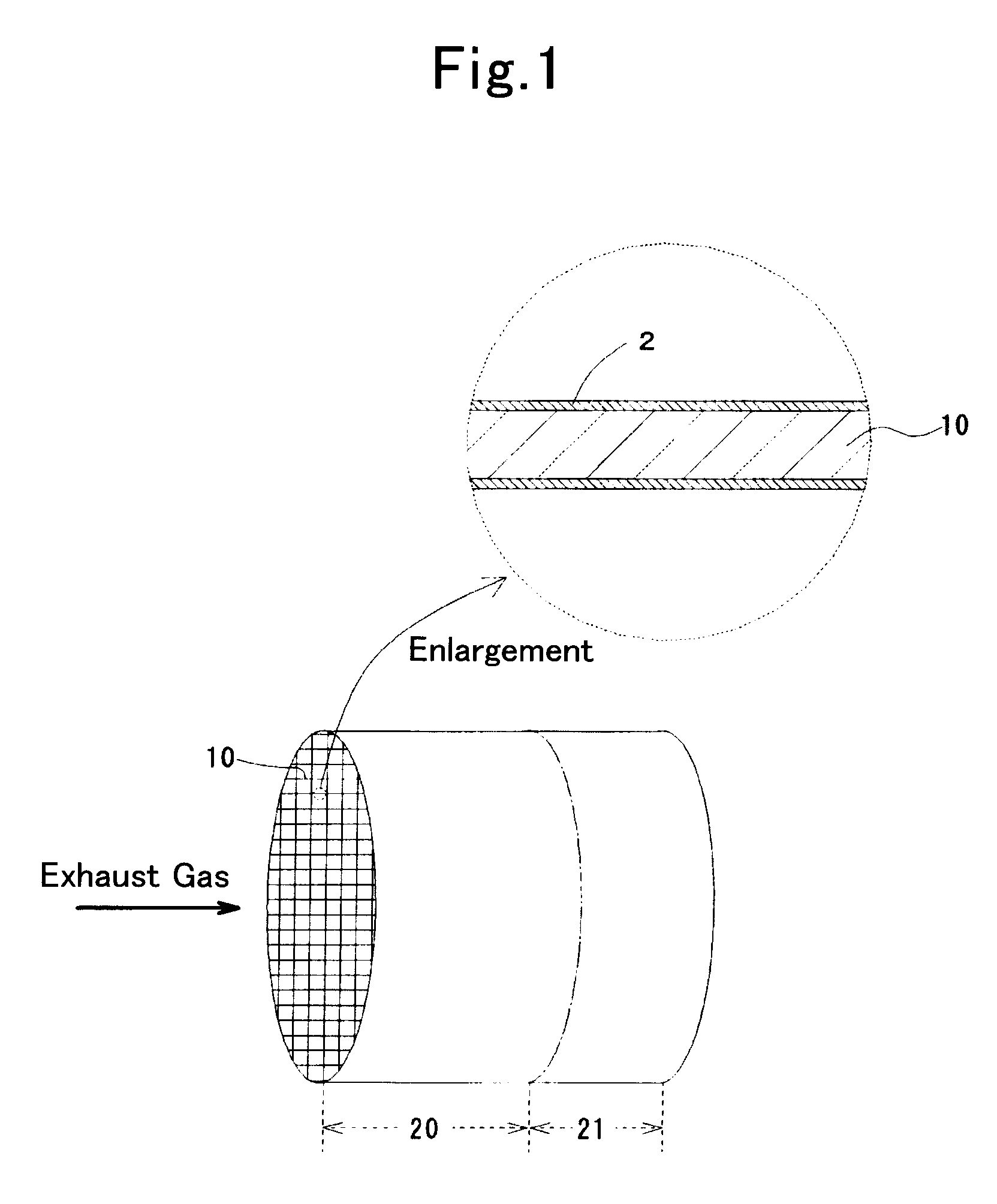

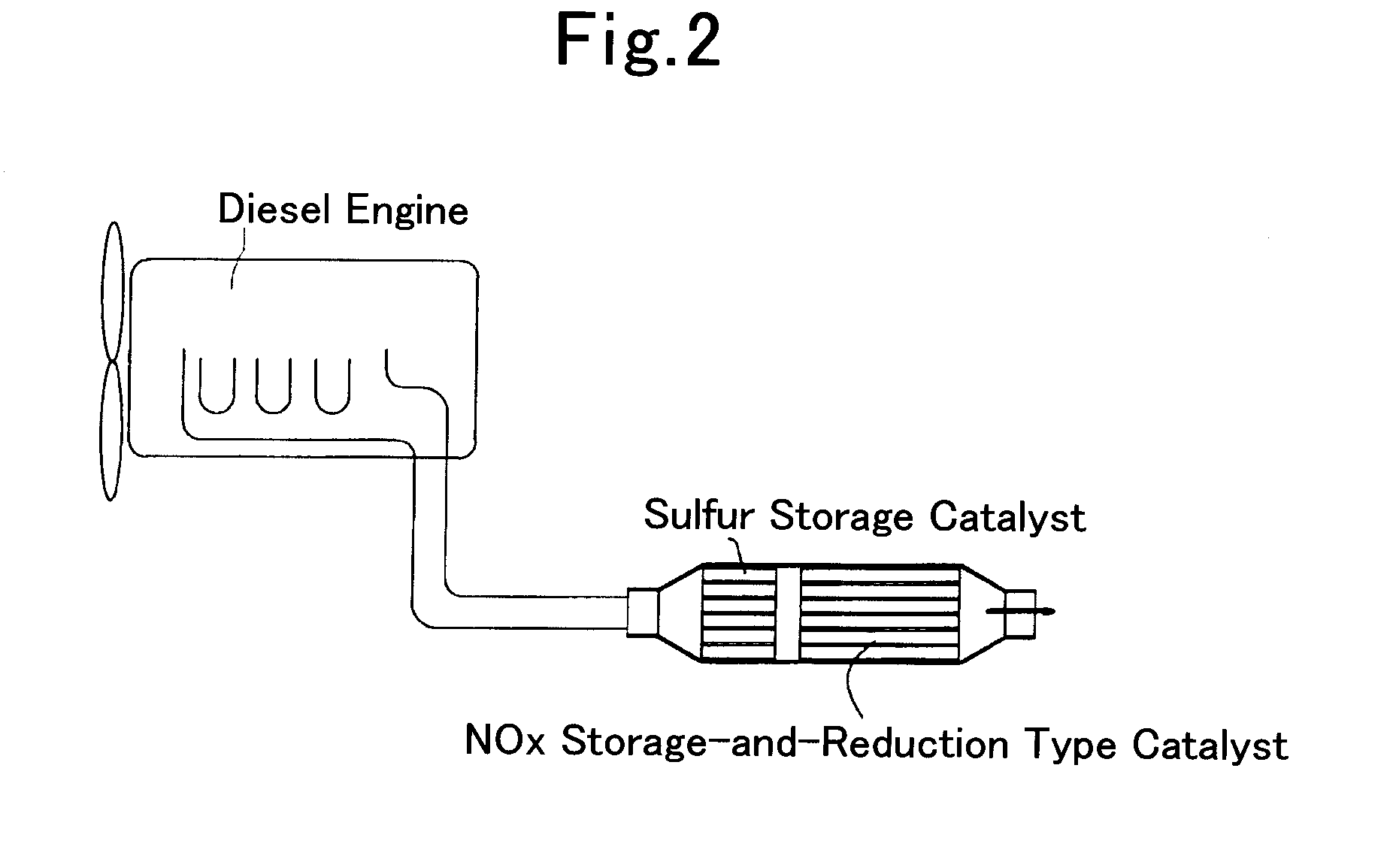

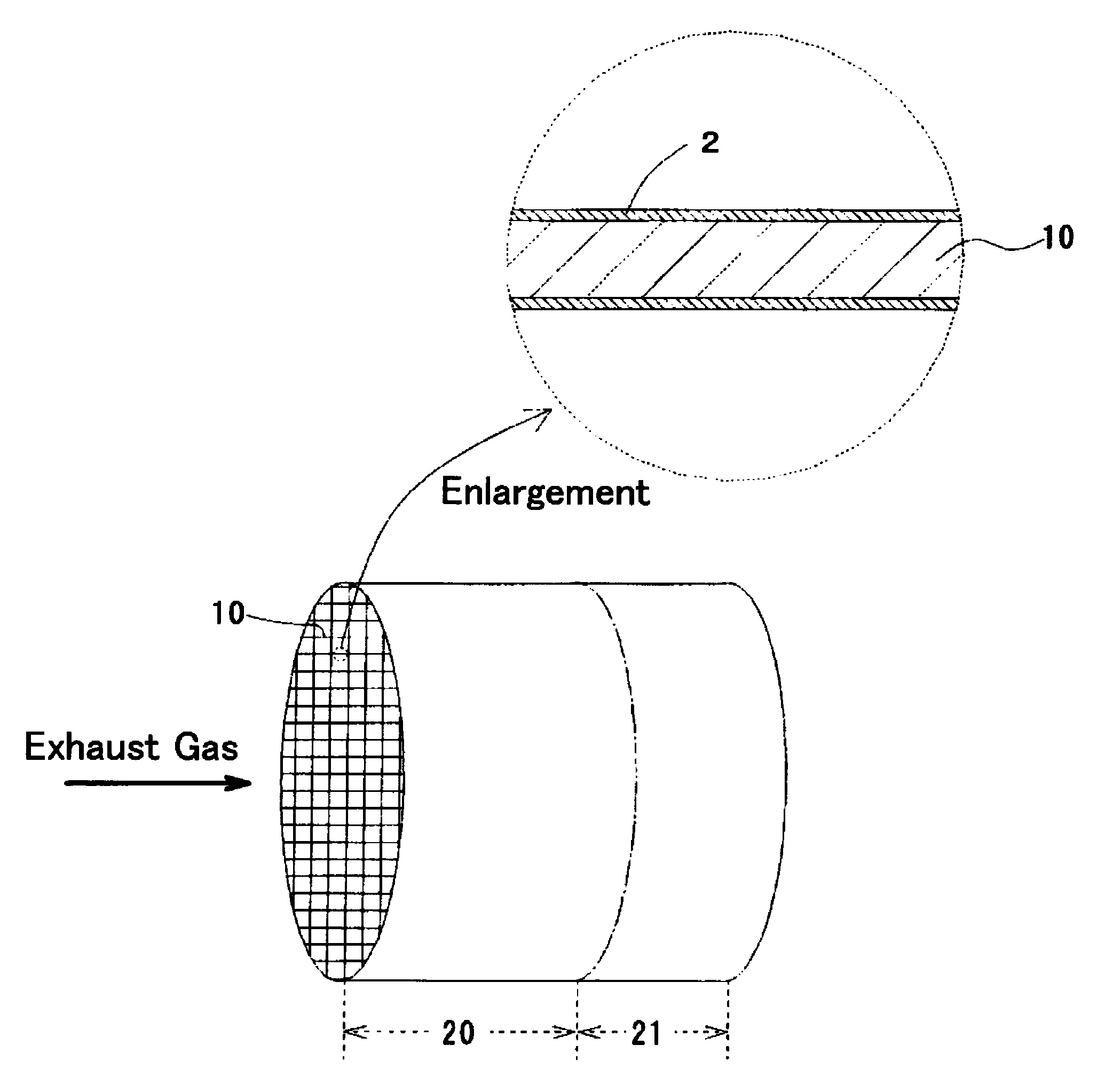

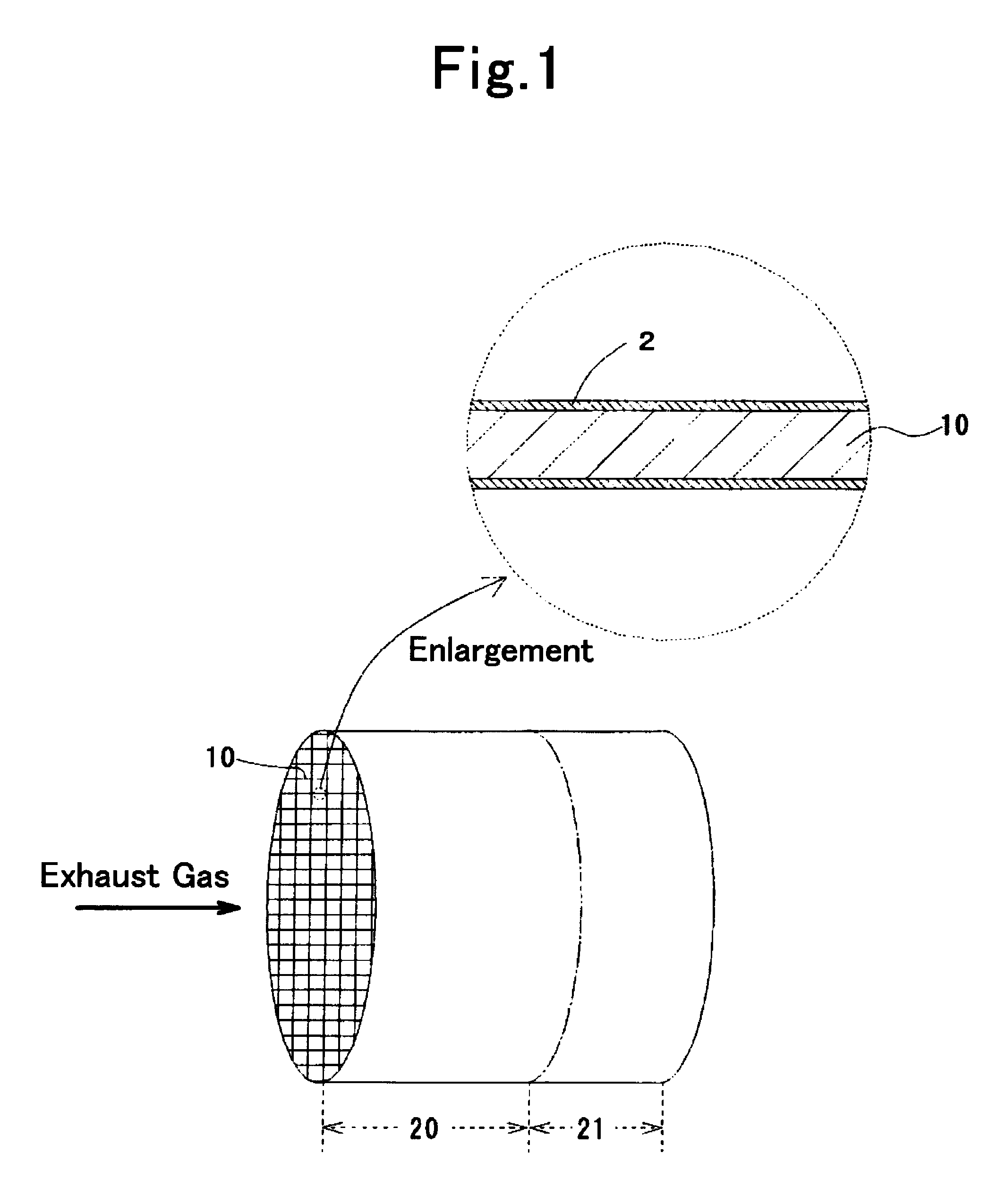

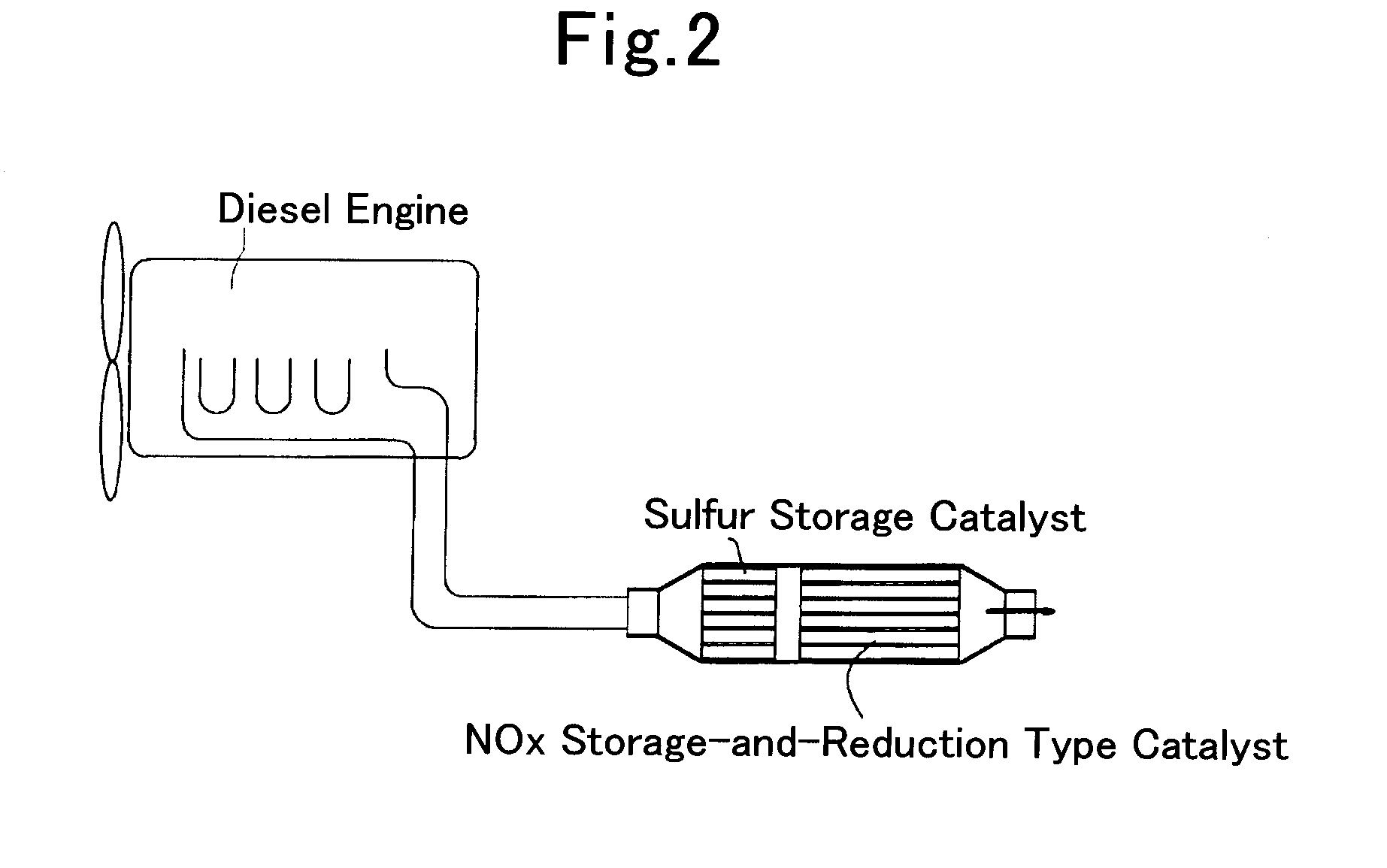

Sulfur occlusion catalyst

InactiveCN101663091AReduce oxidation activityAvoid poisoningGas treatmentExhaust apparatusSulfurPotassium

A noble metal was deposited at least on an upstream-side catalyst part (20), and an SOx-occluding material reducing noble-metal activity, such as magnesium or potassium, was deposited on a downstream-side catalyst layer (21). Since the noble metal deposited on the upstream-side catalyst part (20) is inhibited from decreasing in oxidation activity, SO2 is efficiently oxidized to SOx. This SOx is occluded and held by the SOx-occluding material deposited on the downstream-side catalyst layer (21). Consequently, this catalyst has improved SOx-occluding performance and further has excellent durability.

Owner:TOYOTA JIDOSHA KK

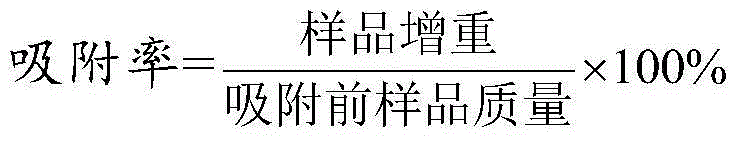

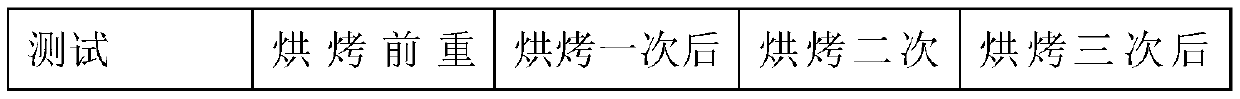

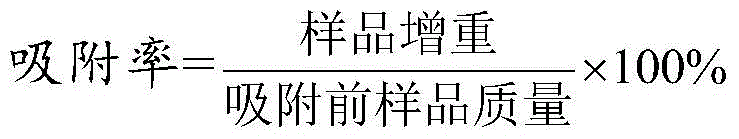

Battery slurry solid content test device and test method

InactiveCN109856005AReduce oxidation activityStrong high temperature resistanceWeighing by removing componentPresent methodAdditive ingredient

The invention discloses a battery slurry solid content test device and test method. The device is specifically a concave type tray. The concave type tray comprises a tray bottom and an external rim. The concave type tray is made of a composite material. The specific raw materials for preparing the composite material comprise the following ingredients: C: 0.03-0.06%, Si: 0.6 -0.8%, Mn: 2-2.1%, Cr:19.0-22.0%, Ni: 9-11. 5%, N: 1.0-1.2%, and the balance being Fe. Compared with the prior art, the device has the following advantages: 1) the design of the concave type tray structure effectively ensures storage stability of the slurry to be tested in the taking and putting, testing and transporting process, and reduces splashing; 2) the test device prepared through the composite material is low in oxidation activity, is high in high-temperature tolerance and can maintain constant weight before or after baking, thereby reducing errors caused by the device itself of the test method; and 3) thetest method is simple, and the device is low in cost.

Owner:ETRUST POWER ETP GRP LTD

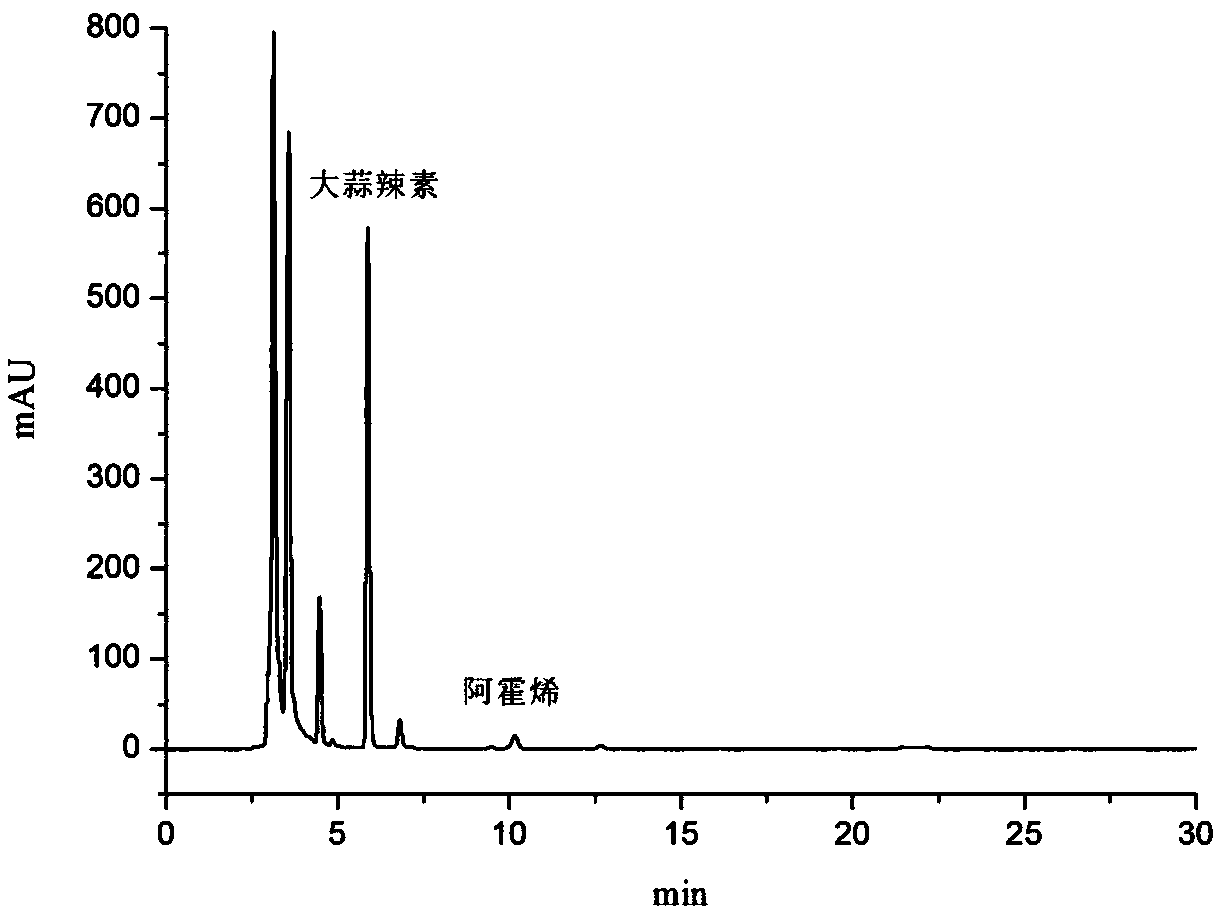

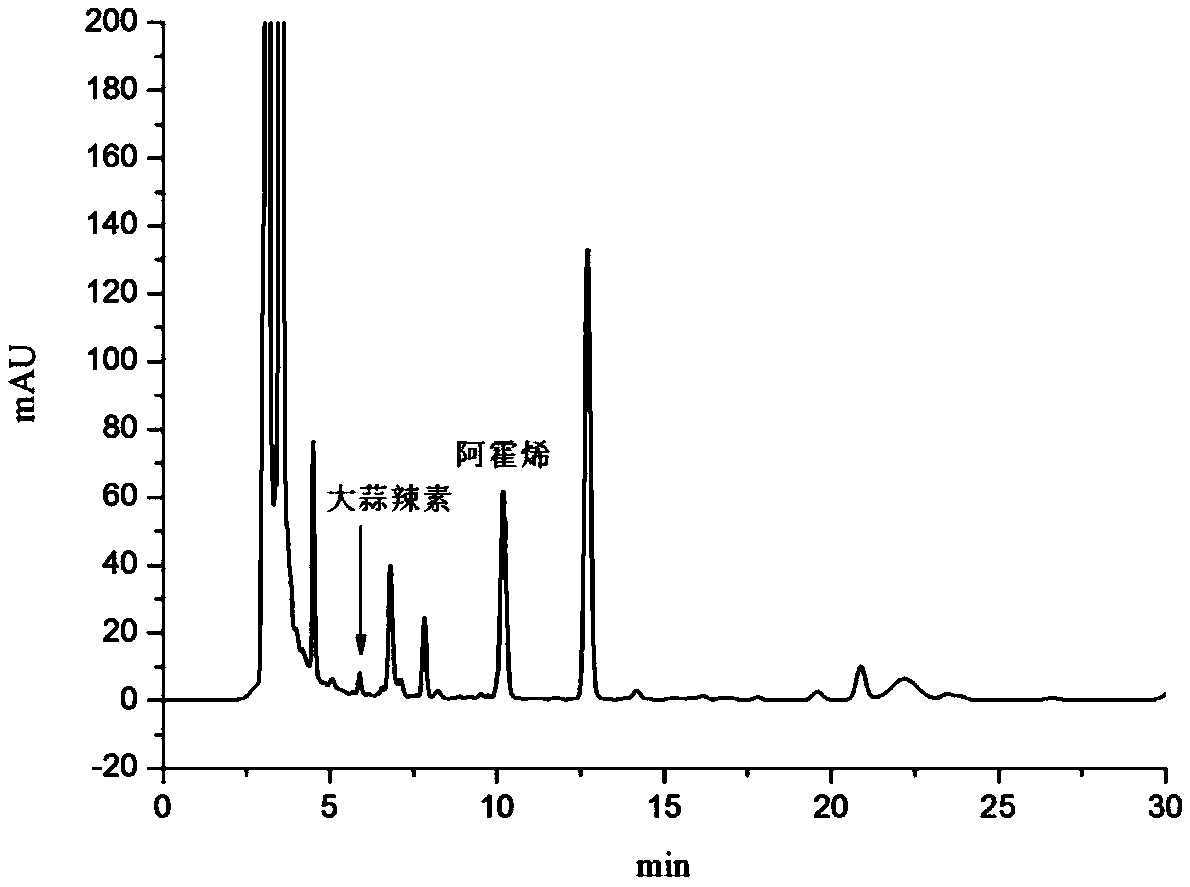

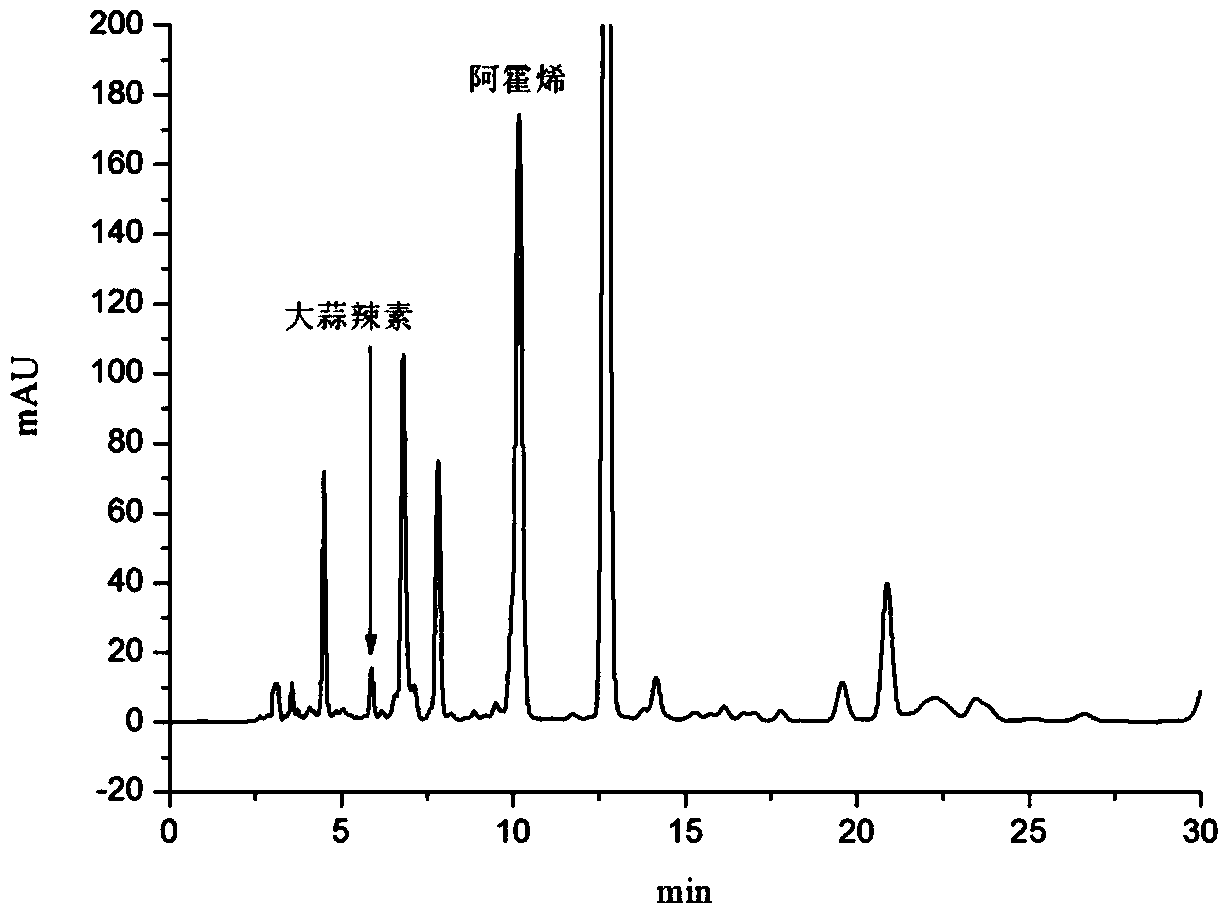

Method for promoting conversion of alliin in garlic into ajoene

InactiveCN108783298AReduce oxidation activityIncrease contentFermentationEdible oils/fatsVegetable oilHigh heat

The invention discloses a method for promoting conversion of alliin in garlic into ajoene. The method comprises the following steps of (1) crushing garlic so as to obtain garlic granules; (2) adding vegetable oil to the garlic granules, and performing uniform stirring so as to obtain a garlic-vegetable oil mixture; (3) placing the mixture in an iron pan, and performing stir-frying at high temperature; and (4) filtering the stir-fried mixture so as to obtain garlic granules of which the ajoene content is increased and a vegetable oil product which is rich in ajoene. The method disclosed by theinvention has the advantages that the technology is simple, and the stability is good; the crushed garlic and an appropriate amount of vegetable oil are mixed, the alliin is converted into the ajoenethrough catalysis under the high temperature condition, the content of the ajoene in the treated garlic granules is increased by 4 times or above, and the content of the ajoene in oil is 20 times or above of that of untreated garlic.

Owner:深圳市阿霍烯生物科技有限公司

Sulfur storage catalyst

ActiveUS20100137132A1Low oxidize activityHigh storage capabilityGas treatmentOther chemical processesChemistryStorage material

Owner:TOYOTA JIDOSHA KK

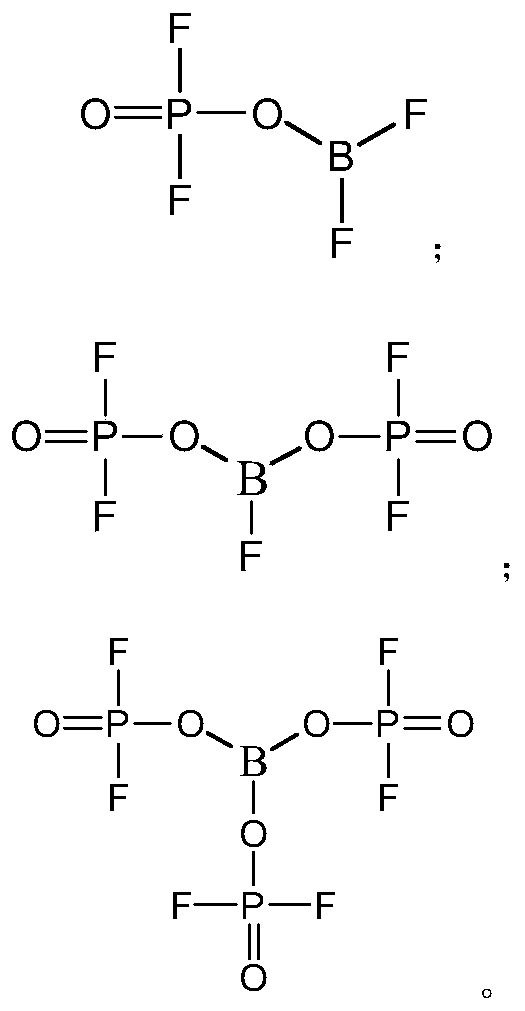

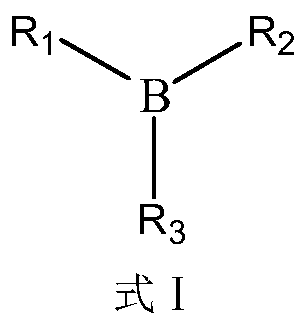

Multifunctional high-voltage lithium ion battery electrolyte and high-voltage lithium ion battery

InactiveCN110890590AImprove high temperature performanceImprove cycle performanceSecondary cells servicing/maintenanceElectrolytic agentOrganic solvent

The invention belongs to the technical field of lithium ion batteries. The multifunctional high-voltage lithium ion battery electrolyte comprises a lithium salt, a non-aqueous organic solvent and an additive, the additive comprises a difluorophosphoryl boron-accommodating compound, three substituent groups of the difluorophosphoryl boron-accommodating compound are respectively difluorophosphoryl-PO2F2 or-F, and at least one of the substituent groups is difluorophosphoryl. Compared with the prior art, the electrolyte disclosed by the invention not only can improve the high-temperature performance of the lithium ion battery under high voltage, but also greatly improves the cycle performance and the low-temperature performance of the battery. Meanwhile, the special additive also has a certaineffect of removing water and acid. In addition, the invention also provides a high-voltage lithium ion battery using the electrolyte.

Owner:东莞维科电池有限公司

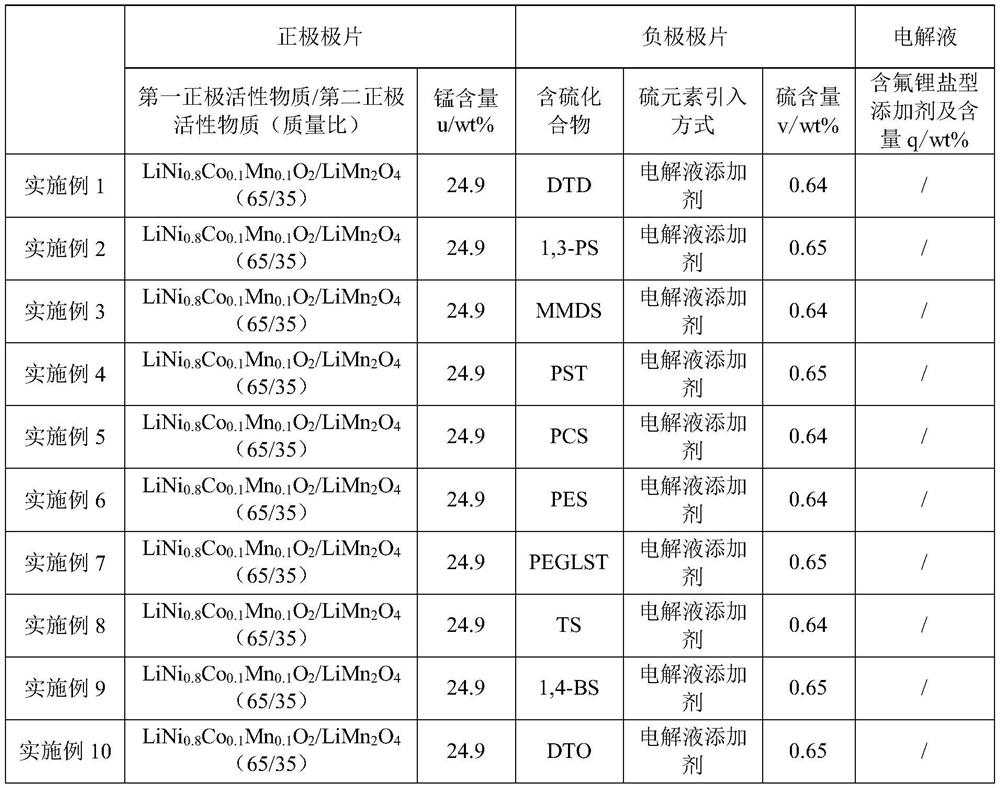

Lithium-ion secondary battery

ActiveCN110265632BImprove structural stabilityReduce the risk of loss of controlSolid electrolytesFinal product manufactureElectrolytic agentPhysical chemistry

The invention discloses a lithium ion secondary battery. The lithium ion secondary battery includes a positive pole piece, a negative pole piece, a separator and an electrolyte solution, the positive pole piece includes a positive active material layer, and the negative pole piece includes a negative active material layer. Wherein, the positive electrode active material of the positive electrode active material layer includes a lithium manganese-based positive electrode active material; the negative electrode active material layer and / or the electrolyte include a sulfur-containing compound, so that the sulfur-containing compound is in the negative electrode The active material layer forms a solid electrolyte interface film containing sulfur elements, and the mass percentage v of the sulfur element in the negative electrode active material layer containing the interface film is equal to the mass percentage u of the manganese element in the positive electrode active material. Satisfy: v=0.018u+ω, wherein, the units of u and v are both wt%, and ω is 0.01-2. The lithium ion secondary battery of the present invention can take into account high safety performance, cycle performance and storage performance at the same time.

Owner:CONTEMPORARY AMPEREX TECH CO

Lithium-ion battery and its non-aqueous electrolyte

ActiveCN106941191BInhibit oxidative decompositionReduce electrochemical activitySecondary cellsElectrolytic agentAqueous electrolyte

The invention discloses a non-aqueous electrolyte. The non-aqueous electrolyte comprises a non-aqueous organic solvent, a lithium salt and an additive, and the additive comprises lithium tetrafluoroborate and at least one of unsaturated bond-containing dinitrile compounds of formula I and formula II. In the formula I and the formula II, R1, R2, A1 and A2 are independently selected from one or more of C0-C5 aliphatic alkyl groups; and R3, R4, A3 and A4 are independently selected from one or more of the hydrogen atom, the fluorine atom , the chlorine atom, an alkyl group and a phenyl group. Additionally, the invention also discloses a lithium ion battery containing the non-aqueous electrolyte.

Owner:NINGDE AMPEREX TECH

Catalyst used for ammonia selective catalytic reduction of nitrogen oxides to nitrogen gas and preparation method thereof

InactiveCN101554584BLarge specific surface areaLow costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSulfationLow activity

The invention relates to a 'catalyst used for ammonia selective catalytic reduction of nitrogen oxides to nitrogen gas and a preparation method thereof', and belongs to the catalyst technical filed. The catalyst consists of V2O5-WO3 / TiO2 / BaO / gamma-Al2O3. The catalyst takes gamma-Al2O3 as a carrier, which increases specific surface area of the catalyst and lowers the catalyst carrier cost; BaO is added to protect the carrier against sulfation, reduce oxidization activity on sulfur dioxide and prolong service life of the catalyst; and titanium dioxide is highly dispersed on surface of the carrier, thus improving utilization rate of the titanium dioxide. The catalyst is characterized by low cost, high catalytic activity and very low activity to oxidize sulfur dioxide to sulfur trioxide.

Owner:无锡科立泰科技有限公司

Sulfur storage catalyst

ActiveUS8084389B2Reduce oxidation activityLowering of oxidizing activity is suppressedGas treatmentOther chemical processesSulfurStorage material

A noble metal is supported on an upstream-side catalytic portion 20 at least, and an SOx storage material, such as Mg and K that lower the noble metal's activities, is supported on a downstream-side catalytic portion 21. The noble metal being supported on the upstream-side catalytic portion 20 oxidizes SO2 efficiently to turn it into SOx, because the lowering of oxidizing activities is suppressed. These SOx are retained by means of storage in the SOx storage material being loaded on the downstream-side catalytic portion 21. Therefore, the SOx storing performance improves, and it is good in terms of durability as well.

Owner:TOYOTA JIDOSHA KK

Additive for improving pig feed safety

InactiveCN104206839AReduce oxidation activityReduce the likelihood of corruptionAnimal feeding stuffProteinZeolite

The invention provides an additive for improving pig feed safety, belongs to the field of pig feed additives, and aims to solve the problems that fat in fish meal in pig feed is easy to rancidify, proteins in the fish meal in the pig feed are easy to decay and mildew, and the like. The additive for improving pig feed safety comprises the following components in parts by weight: 2-4 parts of malic acid; 1-2 parts of succinic acid; 0.2-0.8 part of citric acid; 0.1-0.5 part of tartaric acid; 1-2 parts of bentonite; 2-5 parts of zeolite; 0.3-0.8 part of saccharomycetes and 0.3-0.8 part of lactic acid bacteria. The additive for improving pig feed safety is selective in the type and the content of the materials, and by reducing the possibility of fat rancidity and protein decay and mildewing of the fish meal, the feed safety of the pig feed is improved.

Owner:巨星农牧有限公司

A prebaked anode for electrolytic aluminum

The invention relates to a prebaked anode for electrolytic aluminum, the composition of the prebaked anode is calcined petroleum coke, secondary coke and modified coal tar pitch, and the composition of the calcined petroleum coke, secondary coke and modified coal tar pitch The weight percentage content is: calcined petroleum coke 50~65%, secondary coke 30~35%, modified coal tar pitch 15~20%, among which calcined petroleum coke according to the weight percentage of particle size distribution: 3mm

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Preparation (sic nw )/(zrc matrix-coating integration) method for modifying c/c composites

The present invention relates to a preparation (SiC NW ) / (ZrC matrix-coating integration) modification method of C / C composite material, by pre-preparing SiC nanowire skeleton, so that ZrC ceramic doped matrix can be prepared by PIP method and ZrC(SiC) can be formed on the surface of the matrix Ceramic coating. The method can make the ZrC (SiC) ceramic coating and the doped substrate integrally formed, which can not only effectively block the erosion of the substrate by oxygen atmosphere and high-speed particles, but also reduce the oxidation activity of the substrate. The mismatch of thermal expansion coefficients improves the long-term ablation resistance of C / C composites as a whole from the inside to the outside. The invention has simple operation, low preparation temperature, little damage to the matrix and low cost, can provide certain theoretical and experimental assistance for the application of the C / C composite material in a high temperature ablation environment, and has good economic and social benefits.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A kind of preparation method of catalytic cracking flue gas desulfurization auxiliary agent

ActiveCN104475077BExtended service lifeGood dispersionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentFlue gas

Owner:SHENYANG SANJUKAITE CATALYST

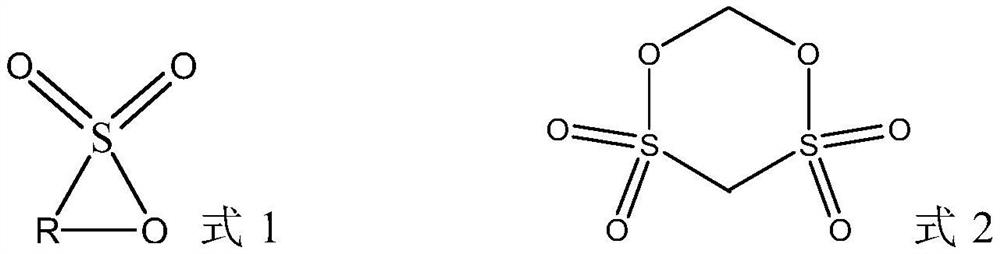

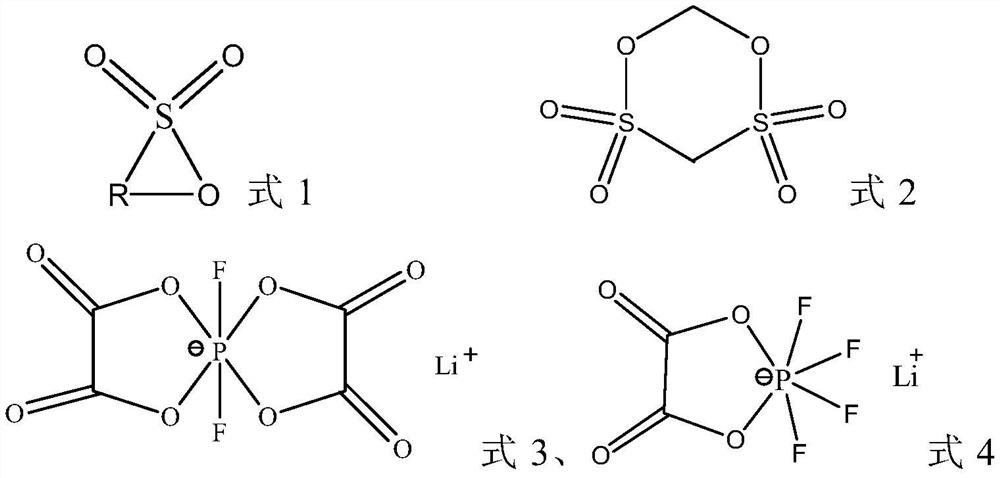

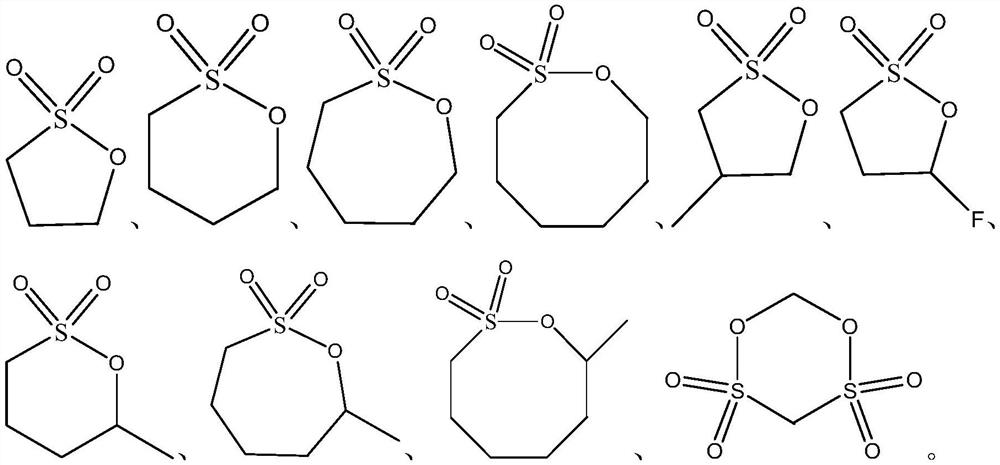

secondary battery

ActiveCN110660962BExtended storage lifeReduce roughnessCell electrodesSecondary cellsElectrolytic agentInternal resistance

The invention provides a secondary battery, and the secondary battery comprises a positive electrode piece, a negative electrode piece, an isolating membrane and an electrolyte; the positive electrodepiece comprises a positive current collector and a positive diaphragm which is arranged on the surface of the positive current collector and contains a positive active material. The electrolyte comprises an additive A and an additive B, wherein the additive A is selected from one or more of cyclic sultone compounds shown in a formula 1 and a formula 2, and the additive B is selected from one or two of lithium difluoro bis (oxalato) phosphate and lithium tetrafluoro (oxalato) phosphate. An inorganic dielectric layer is arranged on the surface, far away from the positive electrode current collector, of the positive electrode diaphragm, wherein the inorganic dielectric layer is made of an inorganic dielectric material, and the thickness T1 of the inorganic dielectric layer ranges from 0.05 micrometer to 1 micrometer. According to the invention, the gas production rate of the battery can be reduced, the increase of direct-current internal resistance in battery circulation and storage processes is significantly inhibited, and the battery is ensured to have good power performance and service life.

Owner:CONTEMPORARY AMPEREX TECH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com