Sulfur occlusion catalyst

A catalyst and oxide technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve problems such as difficulty in preventing sulfur poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

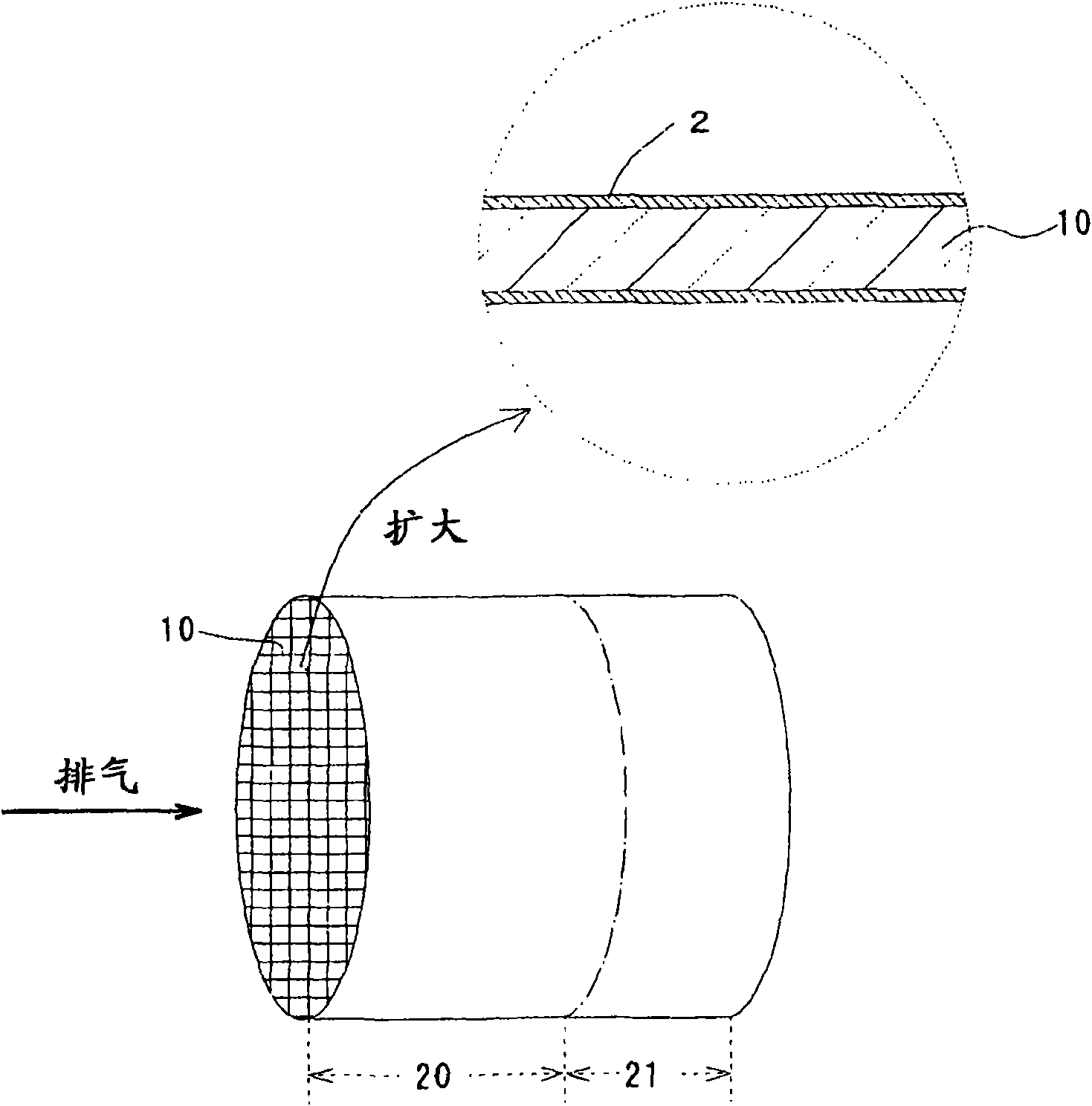

[0044] figure 1 A sulfur storage catalyst according to an example of the present invention is shown. The sulfur storage catalyst comprises a straight-line honeycomb-shaped support substrate 1 having many unit channels with quadrilateral cross-sections, and a catalyst coating 2 formed on the surface of its cell partition walls 10 . On the exhaust gas upstream side of the catalyst coating layer 2, an upstream side catalyst portion 20 carrying Ba and Pt is formed, and a downstream side catalyst portion 21 carrying Mg, Ba, and Pt is formed on the downstream side thereof. The downstream side catalyst portion 21 is formed within a range of 3 / 10 of the entire length of the carrier substrate 1 from the exhaust side end surface of the carrier substrate 1 .

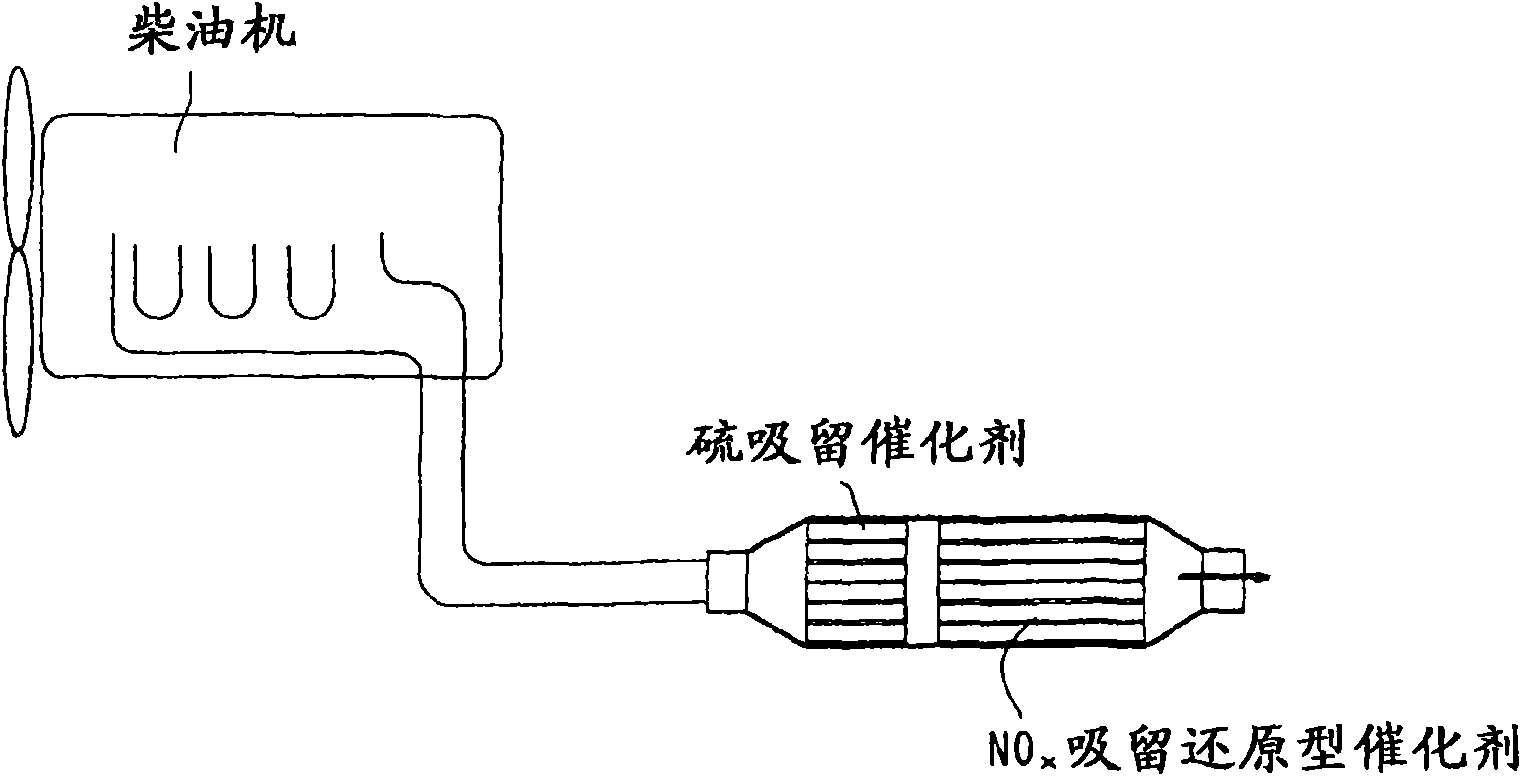

[0045] Such as figure 2 As shown, the sulfur storage catalyst is configured in the exhaust system of the diesel engine x It is used on the exhaust gas upstream side of the occlusion reduction catalyst.

[0046] Hereinafter, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com