secondary battery

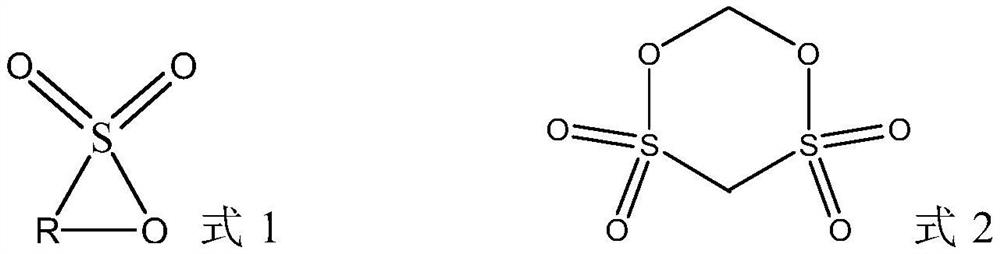

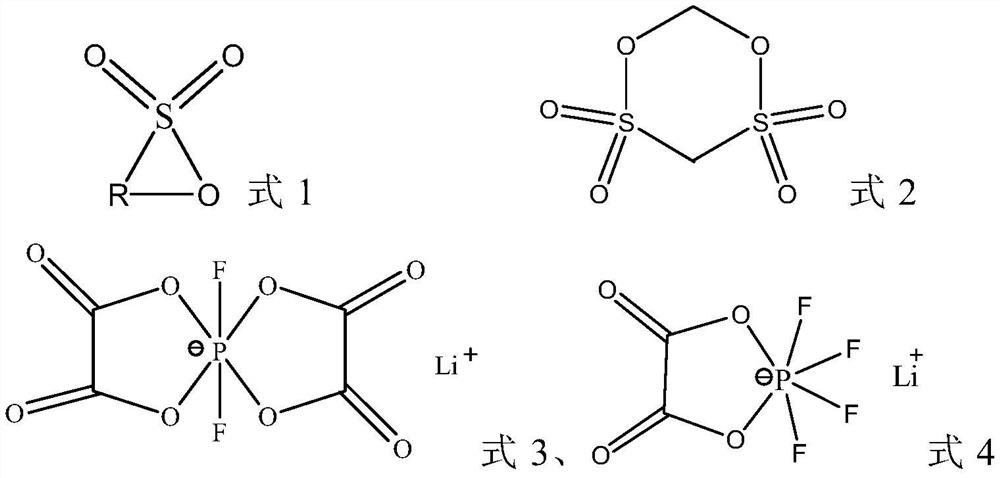

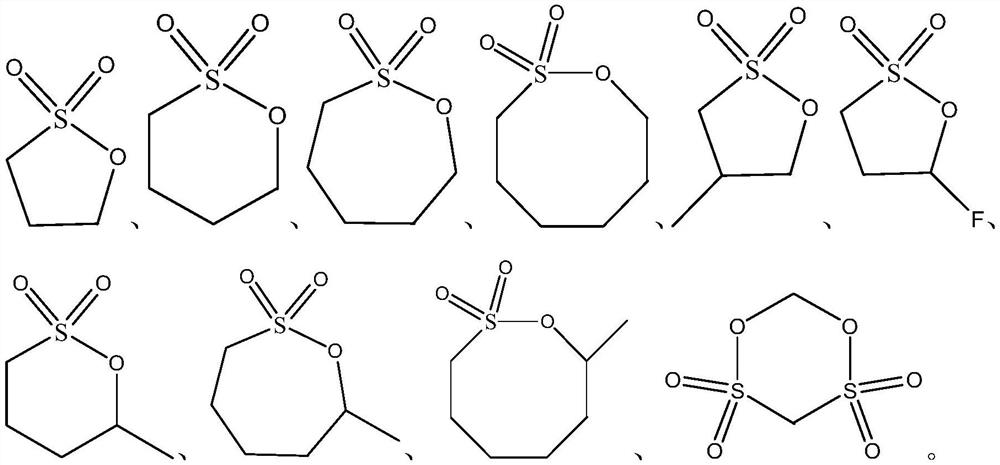

A secondary battery and electrolyte technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve problems that affect the use of lithium-ion batteries, the passivation film is not durable enough, and the acceleration performance and power performance of lithium-ion batteries deteriorate. , to achieve the effect of reducing the effective contact area, inhibiting side reactions, and weakening the oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (1) Preparation of positive pole piece

[0056] Set D50 to 11.4μm and BET to 0.54m 2 / g of positive electrode active material NCM811, conductive agent Super P, and binder polyvinylidene fluoride (PVDF) are mixed according to the mass ratio of 97:1.4:1.6, added to the solvent N-methylpyrrolidone (NMP), and mixed in a vacuum mixer Stir evenly under the action to obtain the positive electrode slurry, wherein the solid content in the positive electrode slurry is 77wt%; the positive electrode slurry is evenly coated on the aluminum foil of the positive electrode current collector and dried at 85°C, cold pressed, edge trimmed, and cut into pieces , slitting to get the initial pole piece.

[0057] An inorganic dielectric layer is deposited on at least one membrane surface of the initial pole piece prepared above by using a plasma-assisted thermal evaporation method. Among them, the heating source is an electron beam, and the heating target is aluminum foil. Under vacuum cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com