Anode sizing agent, anode pole piece and lithium ion battery

A technology of positive electrode slurry and positive active material, which is applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of increasing the cost of lithium-ion batteries, poor lithium surface structure in the bulk phase, and failure to achieve performance, and achieve improved storage Life and high-temperature cycle stability, easy industrialization, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

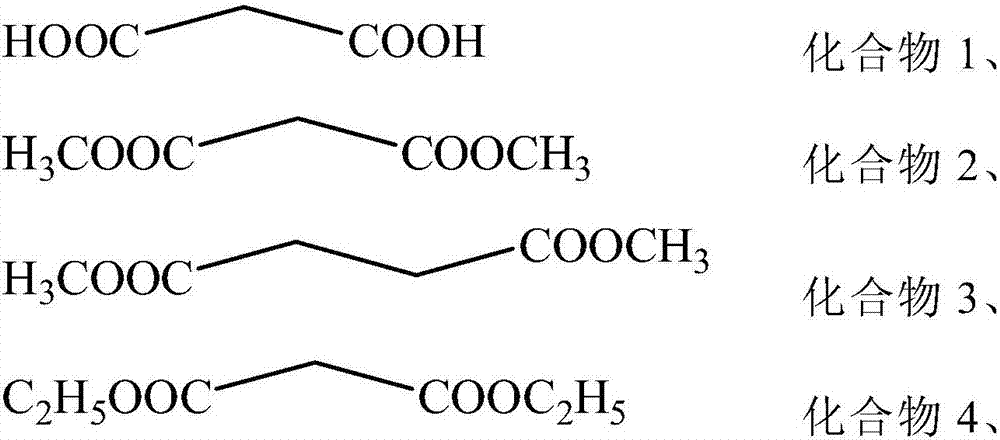

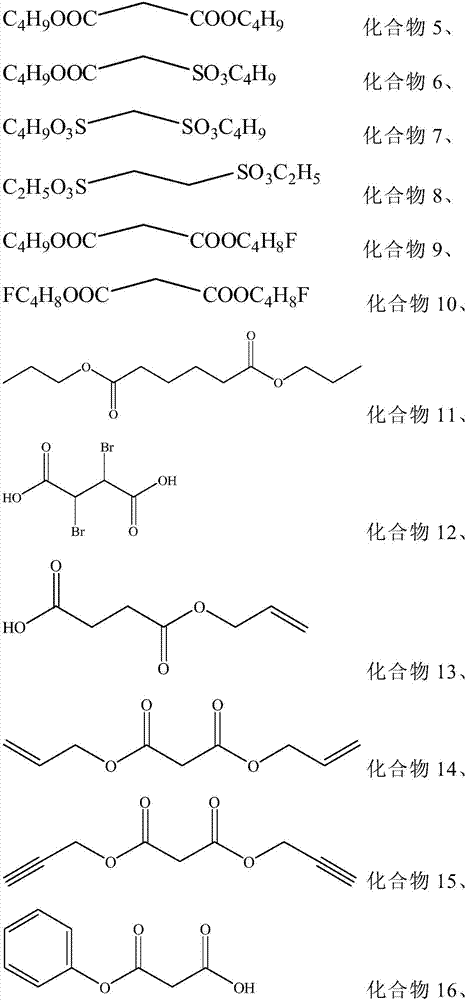

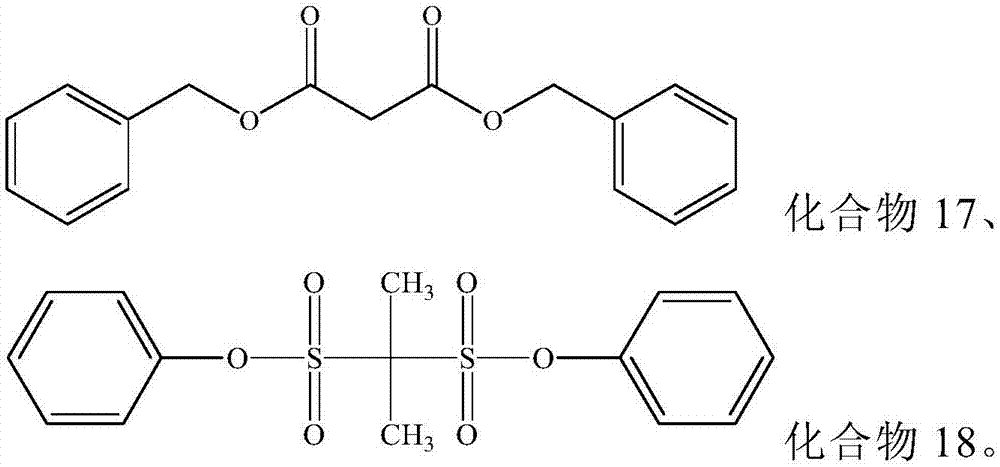

Method used

Image

Examples

Embodiment 1

[0052] The positive electrode active material is lithium nickel cobalt aluminate Li 1.05 Ni 0.80 co 0.15 al 0.05 o 2 (commercialized NCA product, D50=12 μm, pH=11.95), conductive agent is acetylene black (SP) and carbon nanotube (CNT), and bonding agent is polyvinylidene fluoride (PVDF), and the weight ratio of each component is NCA:SP:CNT:PVDF=96:1.5:0.5:2, additive is compound 1, and the quality of additive is 0.3% of the quality of NCA, and solvent is N-methylpyrrolidone (NMP), and solid content is in positive electrode slurry 60%.

[0053] The specific operation is as follows: mix SP and PVDF dry powder, and dry-mix for 10 minutes with the stirring parameters of revolution 20rpm and rotation 1000rpm; add CNT pre-dispersion (solid content is 20%) and 40% volume of NMP, and stir for 10 minutes; add NCA, Pre-kneading and stirring for 90 minutes with 25 rpm of revolution and 2000 rpm of rotation; add the remaining 60% volume of NMP and compound 1, and stir for 30 minutes;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com