High-voltage lithium battery with silicon-based negative electrode

A silicon-based negative electrode, high-voltage technology, used in battery electrodes, secondary batteries, and secondary battery repair/maintenance, etc., to achieve good cycle life and good cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. For the preparation method of the high-voltage lithium-ion battery in this embodiment, the coating area density is determined according to the battery model (PL454261), design capacity, and positive and negative electrode material gram capacity. The positive electrode active material was purchased from Peking University Xianxing 4.4V lithium cobalt oxide material; the negative electrode active material was purchased from the silicon-based negative electrode produced by Shenzhen Beiterui (the silicon content in the silicon-based negative electrode material accounts for 1% to 15%).

[0038] The positive electrode preparation steps, negative electrode preparation steps, electrolyte preparation steps, diaphragm preparation steps and battery assembly steps are described as follows:

[0039] The preparation step of the positive electrode is: mix high-voltage positive electrode active material lithium cobaltate, conductive carbon black and binder polyvinylidene fluoride at a...

Embodiment 2~15

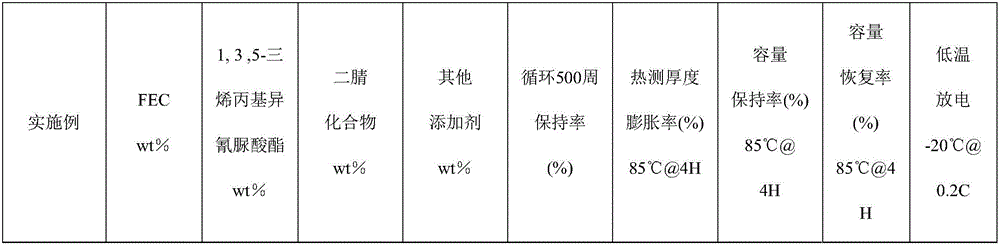

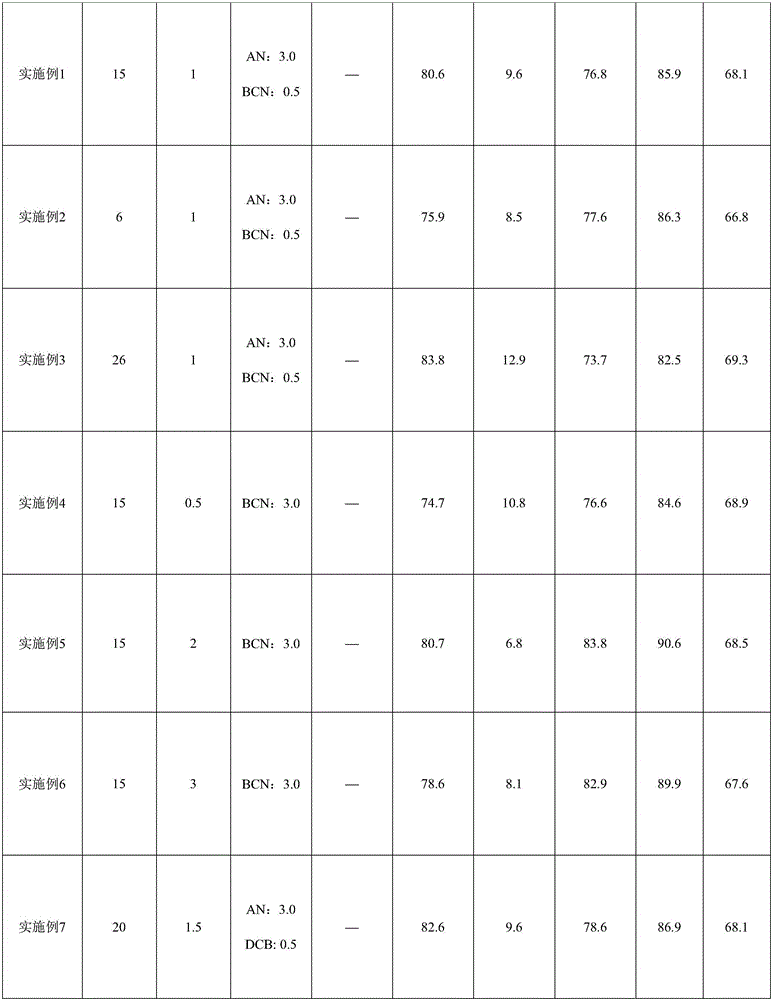

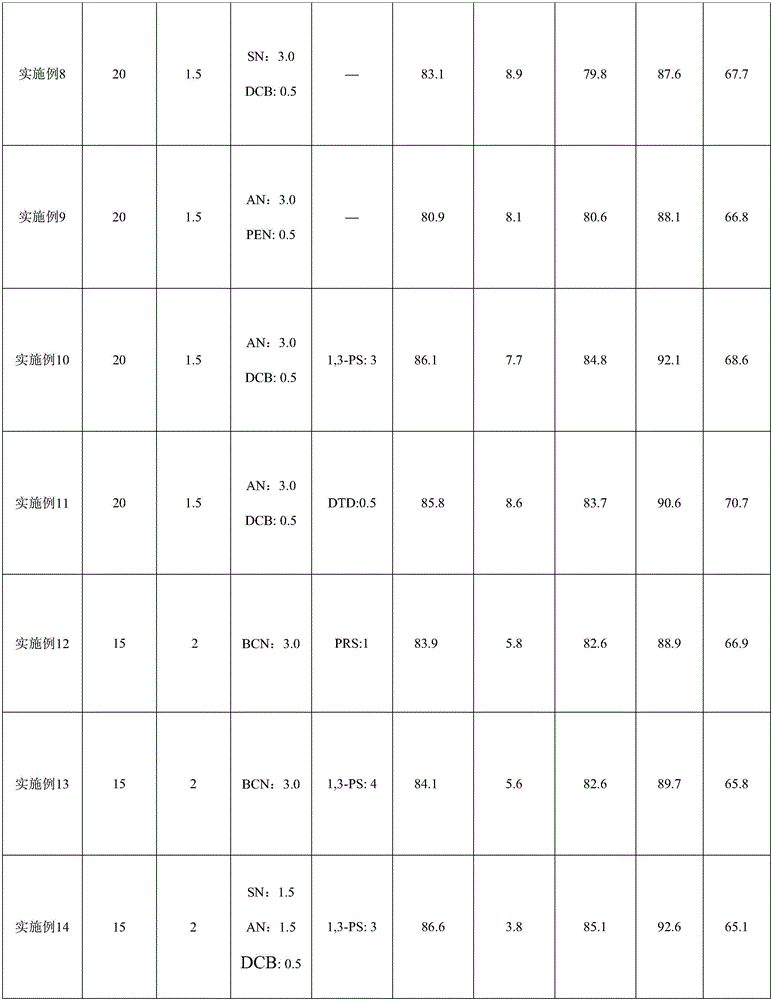

[0053] Examples 2-15 are the same as Example 1 except that the composition and content of additives (based on the total weight of the electrolyte) are added as shown in Table 1. In the table, 1,3-PS is 1,3-propane sultone, PRS is propenyl-1,3-sultone, AN is adiponitrile, SN is succinonitrile, DTD is vinyl sulfate, DCB 3-hexenedinitrile, BCN is 1,2-bis(2-cyanoethoxy)ethane, and PEN is 1,3-benzenediacetonitrile.

[0054]

[0055]

[0056]

[0057]

[0058] Examples 1 to 15 adopting the technical solution of the present application have better normal-temperature cycle performance, high-temperature storage and low-temperature discharge performance. The batteries using the electrolyte solutions of Comparative Examples 1 to 6 cannot simultaneously take into account high and low temperature and cycle performance, and the overall performance is poor.

[0059] Embodiment 1 is with comparative example 1, comparative example 2 and comparative example 3; Embodiment 14 is comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com