Method for promoting conversion of alliin in garlic into ajoene

A technology of ajoene and alliin, which is applied in the field of promoting the conversion of alliin into ajoene in garlic, and can solve problems such as difficulty in obtaining ajoene products, low yield of ajoene, and complex enzymatic hydrolysis conditions , to achieve the effect of avoiding the reduction of oxidation activity, strong practical value and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Get the garlic produced in Qixian County, Kaifeng, Henan, peel it, and pulverize it until the particle diameter is 1mm, and take 100g;

[0037] (2) Add 100mL rapeseed oil to the garlic, and stir at a constant speed for 5 minutes to obtain a garlic-vegetable oil mixture;

[0038] (3) Put the mixture in an iron pot, control the temperature at 120°C, and stir fry evenly for 2 minutes;

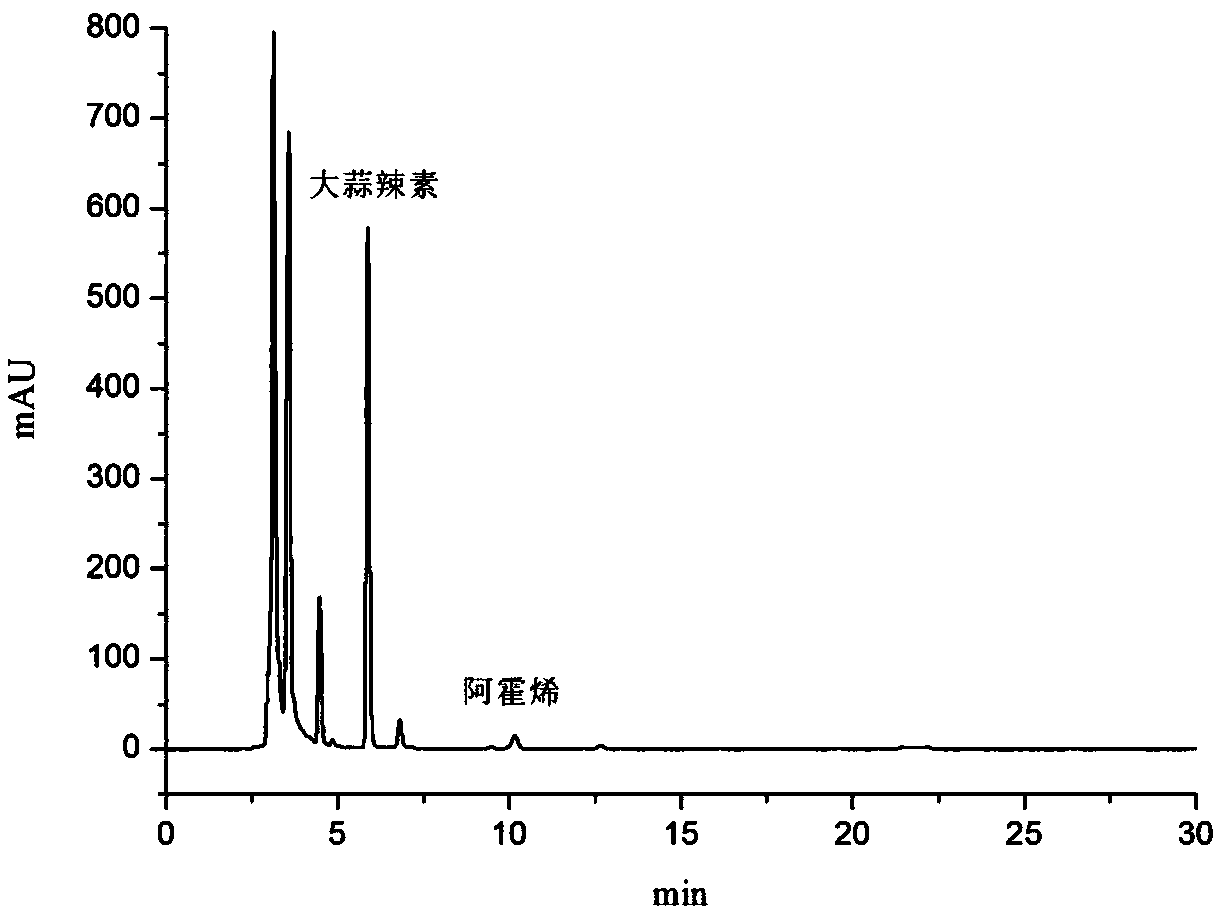

[0039] (4) The stir-fried mixture was centrifuged at 4000 r / min for 5 min to separate and obtain 155 g of garlic grains with increased ajoene content and 41 mL of ajoene-rich vegetable oil. As detected by HPLC, the content of ajoene in the processed garlic grains was 0.01066%, which was 7.69 times of that in untreated garlic; content of 28.60 times.

[0040] Table 1 Example 1 HPLC detection result

[0041]

[0042]

Embodiment 2

[0044] (1) Get Shandong Jinxiang to produce garlic, peel, pulverizer is pulverized to particle diameter and is 0.1mm, takes by weighing 100g;

[0045] (2) Add 25mL sunflower oil to the garlic, and stir at a constant speed for 10 minutes to obtain a garlic-vegetable oil mixture;

[0046] (3) Put the mixture in an iron pot, control the temperature at 80°C, and stir fry evenly for 5 minutes;

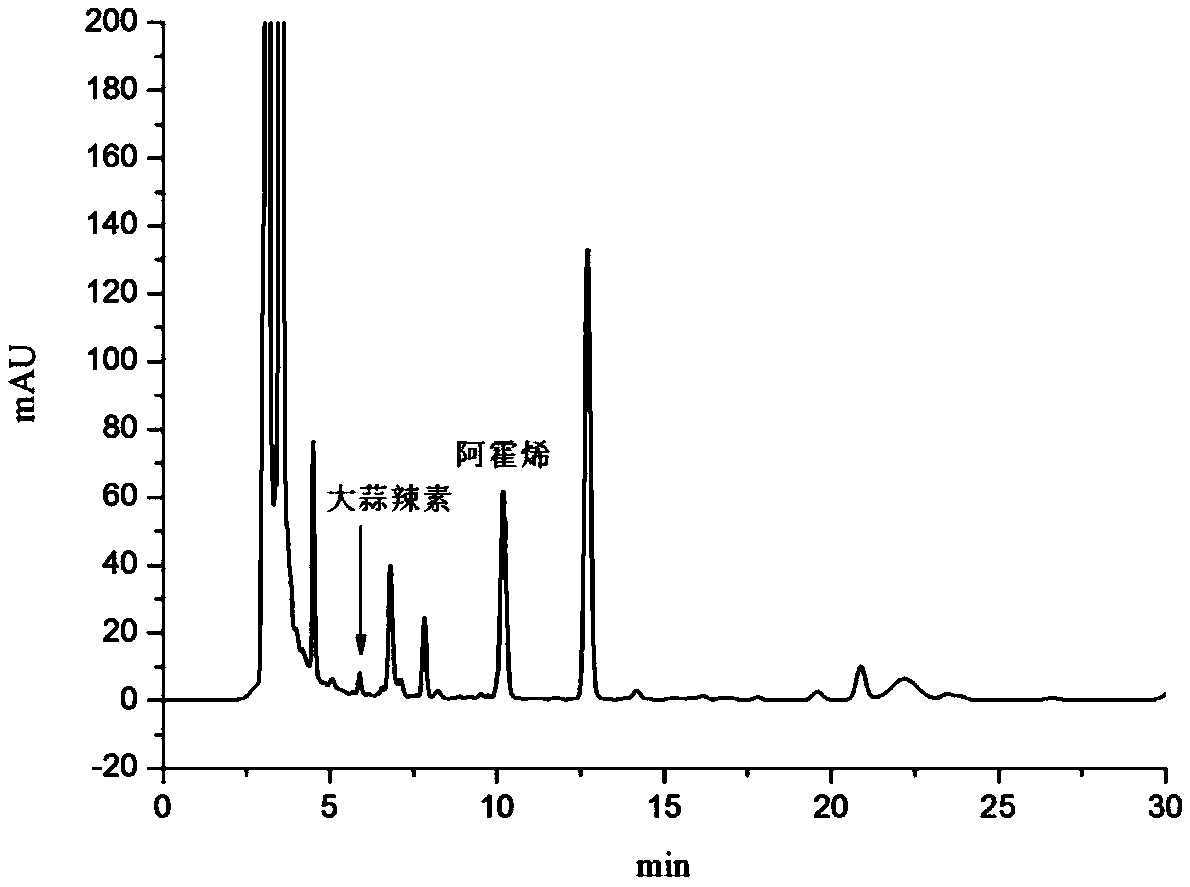

[0047] (4) The stir-fried mixture was centrifuged at 4000 r / min for 10 min to separate and obtain 110 g of garlic grains with increased ajoene content and 13 mL of ajoene-rich vegetable oil. As detected by HPLC, the ajoene content in the treated garlic grains was 0.008087%, which was 4.16 times that of the untreated garlic; the ajoene content in the vegetable oil was 0.05216%, which was 0.05216% of the ajoene content in the untreated garlic. 26.84 times of content.

[0048] Table 2 Example 2 HPLC detection result

[0049]

Embodiment 3

[0051] (1) Get the garlic produced in Xuzhou, Jiangsu, peel it, grind it to a particle diameter of 5mm, and weigh 100g;

[0052] (2) Add 200 mL of sesame oil to the garlic, and stir at a constant speed for 2 minutes to obtain a garlic-vegetable oil mixture;

[0053] (3) Put the mixture in an iron pot, control the temperature at 160°C, and stir fry evenly for 1 minute;

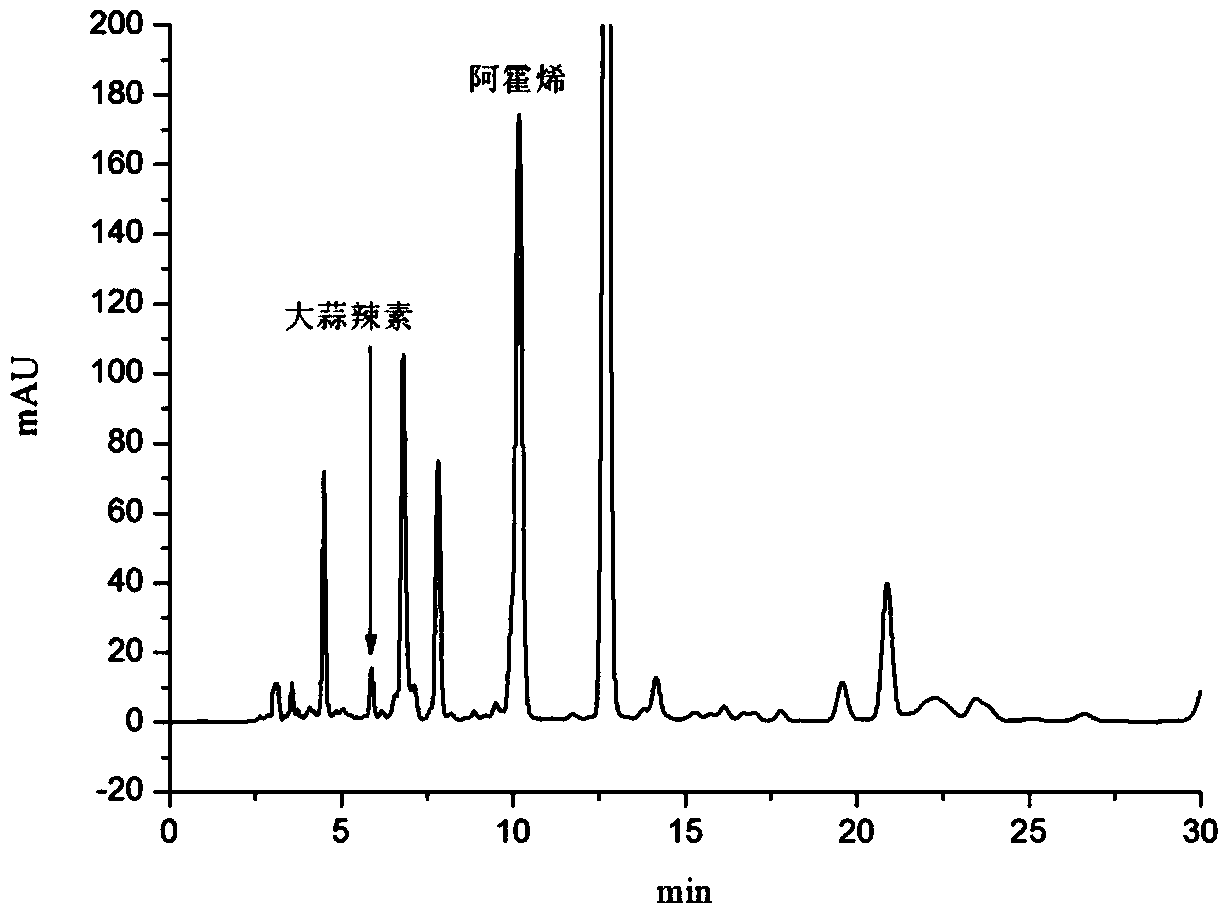

[0054] (4) The stir-fried mixture was filtered through a 100-mesh sieve to separate and obtain 198 g of garlic grains with increased ajoene content and 95 mL of ajoene-rich vegetable oil. As detected by HPLC, the content of ajoene in the processed garlic grains was 0.009358%, which was 5.33 times of that in untreated garlic; 20.01 times of content.

[0055] Table 3 Example 3 HPLC detection result

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com