Battery slurry solid content test device and test method

A test device and test method technology, applied in the direction of weighing by removing certain components, can solve the problems that copper and aluminum foil cannot be reused, affect the test results, and the copper and aluminum foil is easy to oxidize, so as to avoid storage stability and reduce spillage. Splashing and low oxidation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

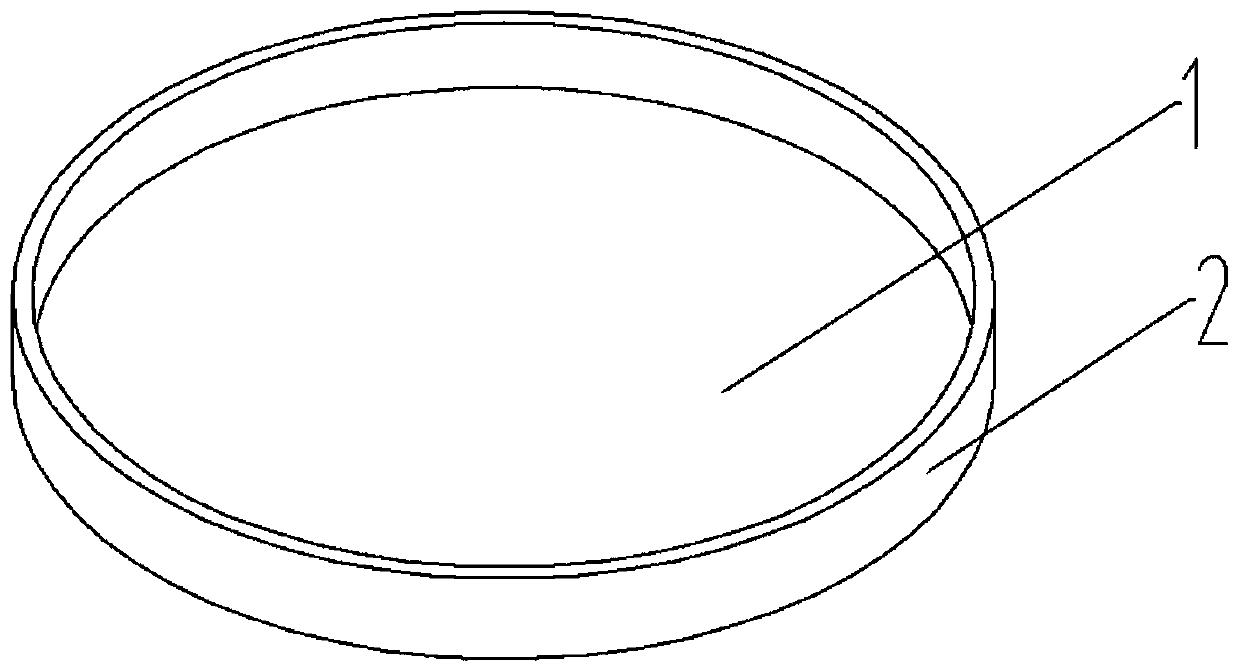

[0020] Please refer to figure 1 As shown, the present invention discloses a battery slurry solid content test device, specifically a concave tray, the concave tray includes a circular tray bottom with a diameter of 5 cm and an outer edge; the outer edge is 1 cm higher than the bottom of the tray On the one hand, the design of this size avoids easy spillage of the battery slurry to be tested during placement and measurement, and on the other hand, it achieves a balance of convenience in taking and placing; the design of the bottom of the circular tray does not have too many corners, and it is easy to clean.

[0021] The concave tray is prepared from a composite material, and the specific preparation raw materials of the composite material include the following components: C: 0.03%, Si: 0.6%, Mn: 2%, Cr: 19.0%, Ni: 9%, N : 1.0%, Fe: 68.37%.

Embodiment 2

[0023] Please refer to figure 1 As shown, the present invention discloses a battery slurry solid content testing device, specifically a concave tray, the concave tray includes a circular tray bottom with a diameter of 5.5 cm and an outer edge; the outer edge is higher than the tray bottom 1cm; on the one hand, the design of this size avoids easy spillage of the battery slurry to be tested during placement and measurement, and on the other hand, it achieves a balance of convenience in taking and placing; the design of the circular tray bottom does not have too many corners, which is easy to clean.

[0024] The concave tray is prepared from a composite material, and the specific preparation raw materials of the composite material include the following components: C: 0.06%, Si: 0.8%, Mn: 2.1%, Cr: 22.0%, Ni: 11.5%, N : 1.2%; Fe: 62.34%.

Embodiment 3

[0026] Please refer to figure 1 As shown, the present invention discloses a battery slurry solid content test device, specifically a concave tray, the concave tray includes a circular tray bottom with a diameter of 6 cm and an outer edge; the outer edge is 1.5 cm higher than the bottom of the tray. cm; on the one hand, the design of this size avoids easy spillage of the battery slurry to be tested during placement and measurement, and on the other hand, it achieves a balance of convenience in taking and placing; the design of the bottom of the circular tray does not have too many corners, which is easy to clean.

[0027] The concave tray is prepared from a composite material, and the specific preparation raw materials of the composite material include the following components: C: 0.05%, Si: 0.7%, Mn: 2.05%, Cr: 20.5%, Ni: 10%, N : 1.1%; Fe: 65.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com