Medium and low temperature denitration catalyst and preparation method thereof

A low-temperature denitration and catalyst technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve problems such as loss of activity, difficulty in applying industrial flue gas environment, catalyst deactivation, etc. The effect of improving low temperature activity, strong resistance to hydrothermal degradation, and high N2 selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

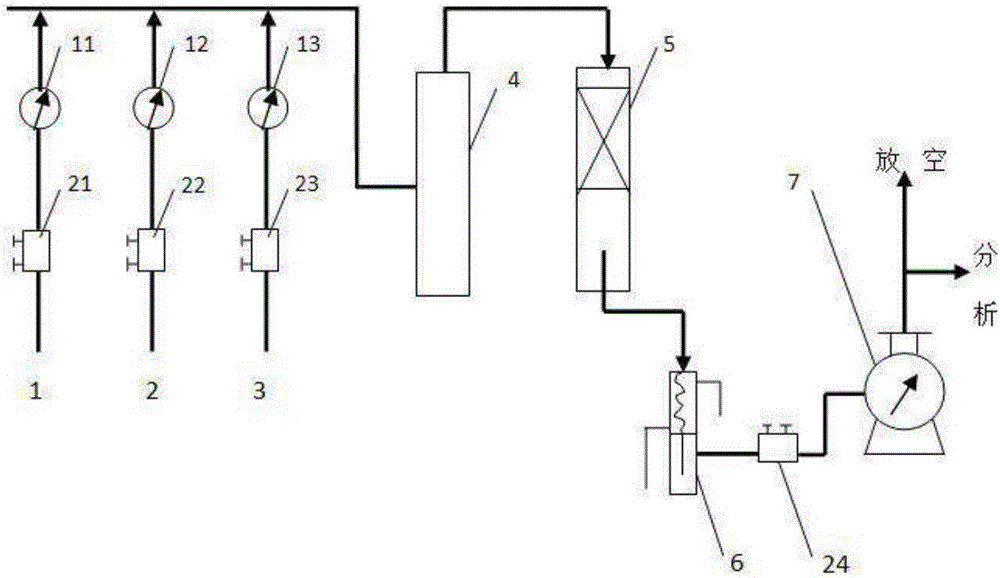

Image

Examples

Embodiment 1

[0034] The components of the low-temperature denitration catalyst in this example are as follows:

[0035] 70 parts of ultrafine titanium dioxide, 5 parts of strontium-doped cerium-manganese perovskite composite oxide, 2 parts of vanadium pentoxide, 5 parts of tungsten trioxide, 6 parts of molybdenum trioxide, 5 parts of tin oxide, and 5 parts of glass fiber.

[0036] The specific preparation method of the above-mentioned medium and low temperature denitration catalyst is as follows:

[0037] 1) Preparation of strontium-doped cerium-manganese perovskite-type composite oxide: Dissolve 9.4g of strontium nitrate, 171.9g of cerium nitrate, and 165g of manganese nitrate into 3000L of deionized water, stir to dissolve completely and mix evenly; add 346.7g Citric acid is stirred to dissolve; add 110g of polyethylene glycol (20% aqueous solution), and stir to make it evenly mixed with the above substances; stir and react at 80°C for 4h in a constant temperature water bath until the vi...

Embodiment 2

[0043] The components of the low-temperature denitration catalyst in this example are as follows:

[0044] 60 parts of ultrafine titanium dioxide, 15 parts of strontium-doped cerium-manganese perovskite composite oxide, 2 parts of vanadium pentoxide, 5 parts of tungsten trioxide, 6 parts of molybdenum trioxide, 2 parts of tin oxide, and 5 parts of glass fiber.

[0045] The specific preparation method of the above-mentioned medium and low temperature denitration catalyst is as follows:

[0046] 1) Preparation of strontium-doped cerium-manganese perovskite-type composite oxide: Dissolve 8.5g of strontium nitrate, 156.3g of cerium nitrate, and 150g of manganese nitrate into 3000L of deionized water, stir to dissolve completely and mix evenly; add 315.2g citric acid and stir to dissolve it; add 100g of polyethylene glycol (20% aqueous solution), stir to make it mix with the above substances evenly; stir and react at 70°C for 5h in a constant temperature water bath until the viscos...

Embodiment 3

[0052] The components of the low-temperature denitration catalyst in this example are as follows:

[0053] 50 parts of ultrafine titanium dioxide, 25 parts of strontium-doped cerium-manganese perovskite composite oxide, 2 parts of vanadium pentoxide, 5 parts of tungsten trioxide, 6 parts of molybdenum trioxide, 1 part of tin oxide, and 5 parts of glass fiber.

[0054] The specific preparation method of the above-mentioned medium and low temperature denitration catalyst is as follows:

[0055] 1) Preparation of strontium-doped cerium-manganese perovskite-type composite oxide: Dissolve 7.7.g strontium nitrate, 140.7g cerium nitrate, and 135g manganese nitrate into 3000L deionized water, stir to dissolve completely and mix evenly; add 283.7g Add 120g of polyethylene glycol (20% aqueous solution) and stir to make it mix with the above substances; stir and react at 90°C for 3h in a constant temperature water bath until the viscosity of the reaction solution increases significantly,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com