Heat treatment method for x80 elbow welded joints with excellent low temperature toughness

A heat treatment method and welding joint technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of complex process, large environmental pollution, harsh operating environment, etc., and achieve simplified operation process, good tensile elongation, and simple effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

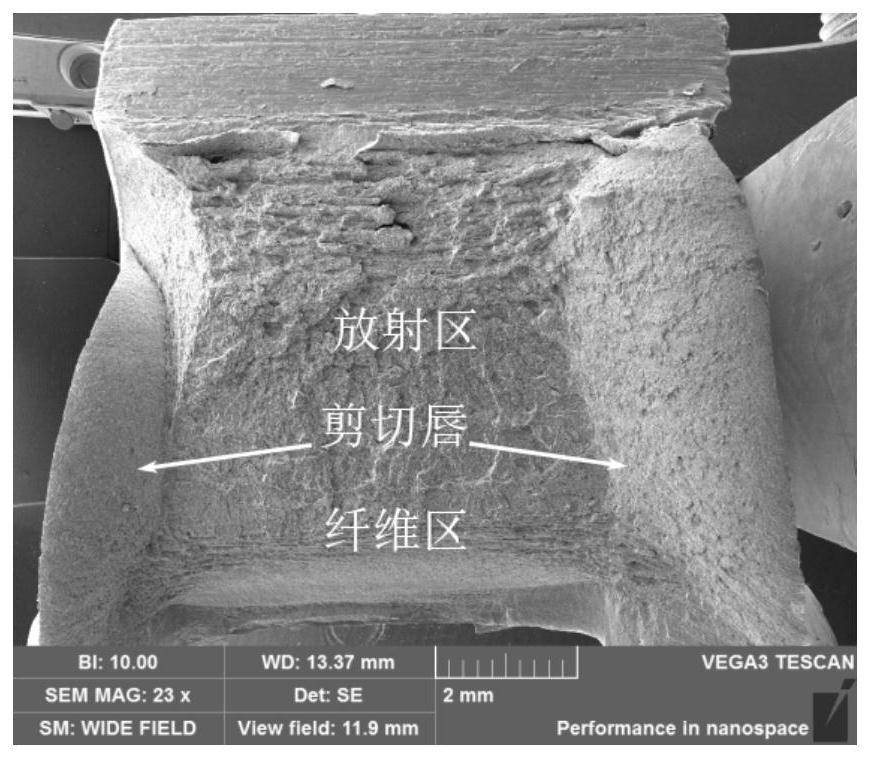

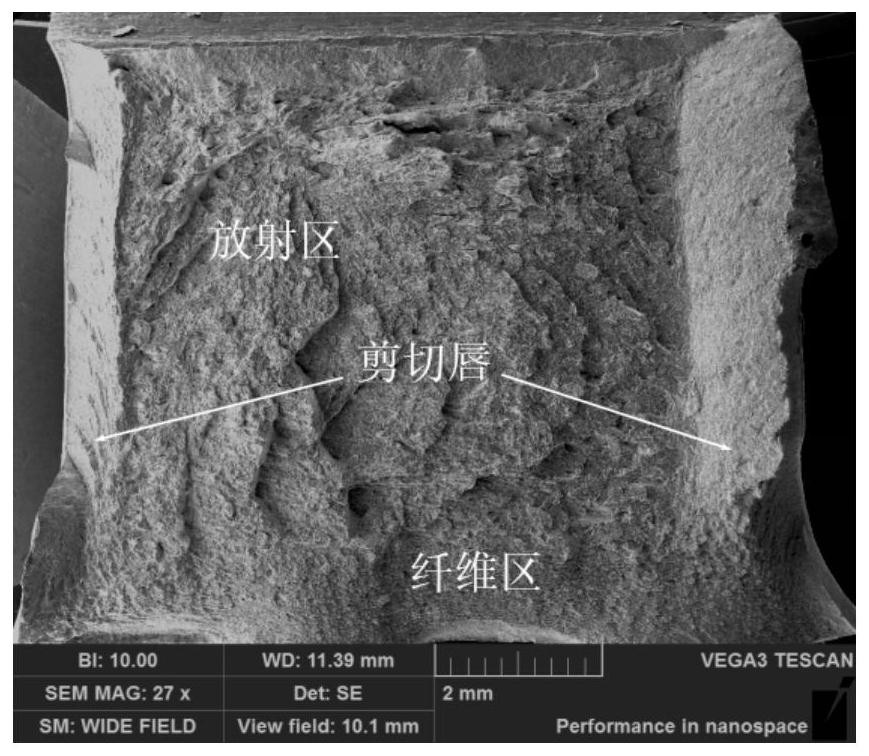

Image

Examples

Embodiment 1

[0029] Step 1, choose X80 pipeline steel, the components according to mass percentage are as follows: C is 0.02%, Si is 0.1%, Mn is 1.25%, P is 0.018%, S is 0.004%, Nb is 0.04%, and Ti is 0.1% , Al is 0.18%, V is 0.10%, Ni is 0.10%, Mo is 0.15%, Cu is 0.2%; Cr is 0.02%, Bi is 0.005%, the balance is Fe, and the carbon equivalent Ceq is 0.31; using standard grades NS-2 submerged arc welding wire three-wire two-layer two-pass welding, the welding process temperature is 180°C, and the heat input is 30kJ / cm;

[0030] Step 2: Bending the straight-welded main pipe obtained by the submerged arc welding method with intermediate frequency induction overall heating, the normalizing heating temperature is 880°C, the advancing speed is 10mm / min, and the cooling method is air cooling to room temperature;

[0031] Step 3: Perform overall tempering treatment on the elbow welded joints obtained in step 2: the heating instrument is a box-type resistance furnace, the tempering temperature is 630...

Embodiment 2

[0033] Step 1, choose X80 pipeline steel, the composition according to mass percentage is as follows: C is 0.03%, Si is 0.2%, Mn is 1.58%, P is 0.016%, S is 0.002%, Nb is 0.07%, and Ti is 0.2% , Al is 0.2%, V is 0.18%, Ni is 0.2%, Mo is 0.19%, Cu is 0.1%; Cr is 0.01%, Bi is 0.004%, the balance is Fe, and the carbon equivalent Ceq is 0.35; the standard grade is adopted NS-2 submerged arc welding wire three-wire two-layer two-pass welding, the welding process temperature is 160°C, and the heat input is 33kJ / cm;

[0034] Step 2: Bending the straight-welded main pipe obtained by the submerged arc welding method with intermediate frequency induction overall heating, the normalizing heating temperature is 920°C, the advancing speed is 13mm / min, and the cooling method is air cooling to room temperature;

[0035] Step 3, conduct overall tempering treatment on the elbow welded joint obtained in step 2: the heating instrument is a box-type resistance furnace, the tempering temperature i...

Embodiment 3

[0037] Step 1, choose X80 pipeline steel, the components according to mass percentage are as follows: C is 0.04%, Si is 0.2%, Mn is 1.86%, P is 0.015%, S is 0.001%, Nb is 0.08%, and Ti is 0.2% , Al is 0.31%, V is 0.35%, Ni is 0.23%, Mo is 0.28%, Cu is 0.15%; Cr is 0.01%, Bi is 0.005%, the balance is Fe, and the carbon equivalent Ceq is 0.42; the standard grade is adopted NS-2 submerged arc welding wire three-wire two-layer two-pass welding, the welding process temperature is 120°C, and the heat input is 38kJ / cm;

[0038] Step 2: Bending the straight-welded main pipe obtained by the submerged arc welding method with intermediate frequency induction overall heating, the normalizing heating temperature is 940°C, the advancing speed is 16mm / min, and the cooling method is air cooling to room temperature;

[0039]Step 3, conduct overall tempering treatment on the elbow welded joint obtained in step 2: the heating instrument is a box-type resistance furnace, the tempering temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com