Array substrate, display panel and display device

A technology for array substrates and display areas, which is applied in the direction of instruments, semiconductor devices, electrical components, etc., and can solve problems such as large thickness of protective layer, inability to realize electrical connection between gold fingers and bonding pads, insufficient deformation of conductive particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

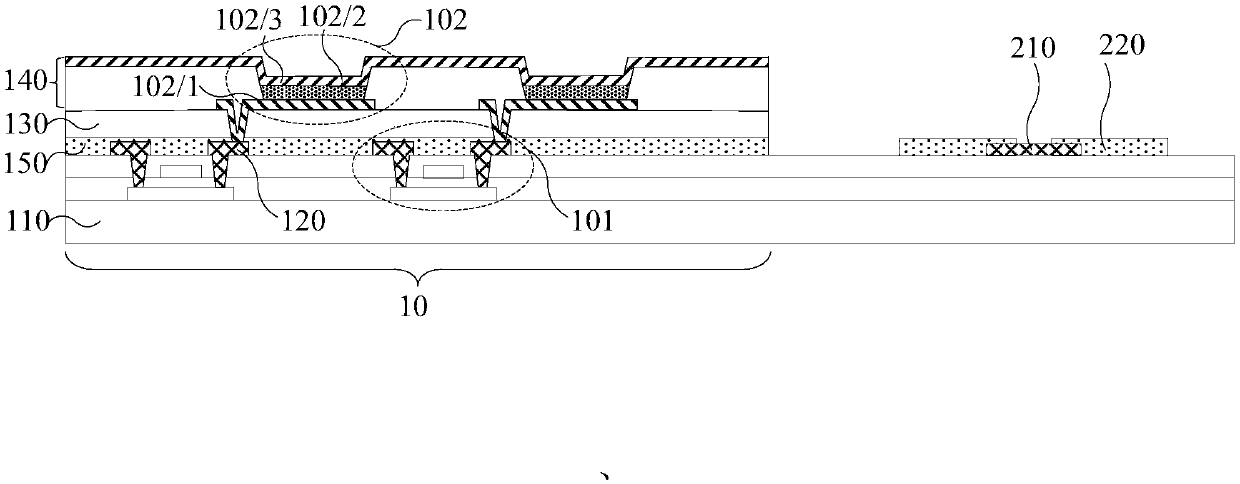

[0020] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, Features and their functions are described in detail below.

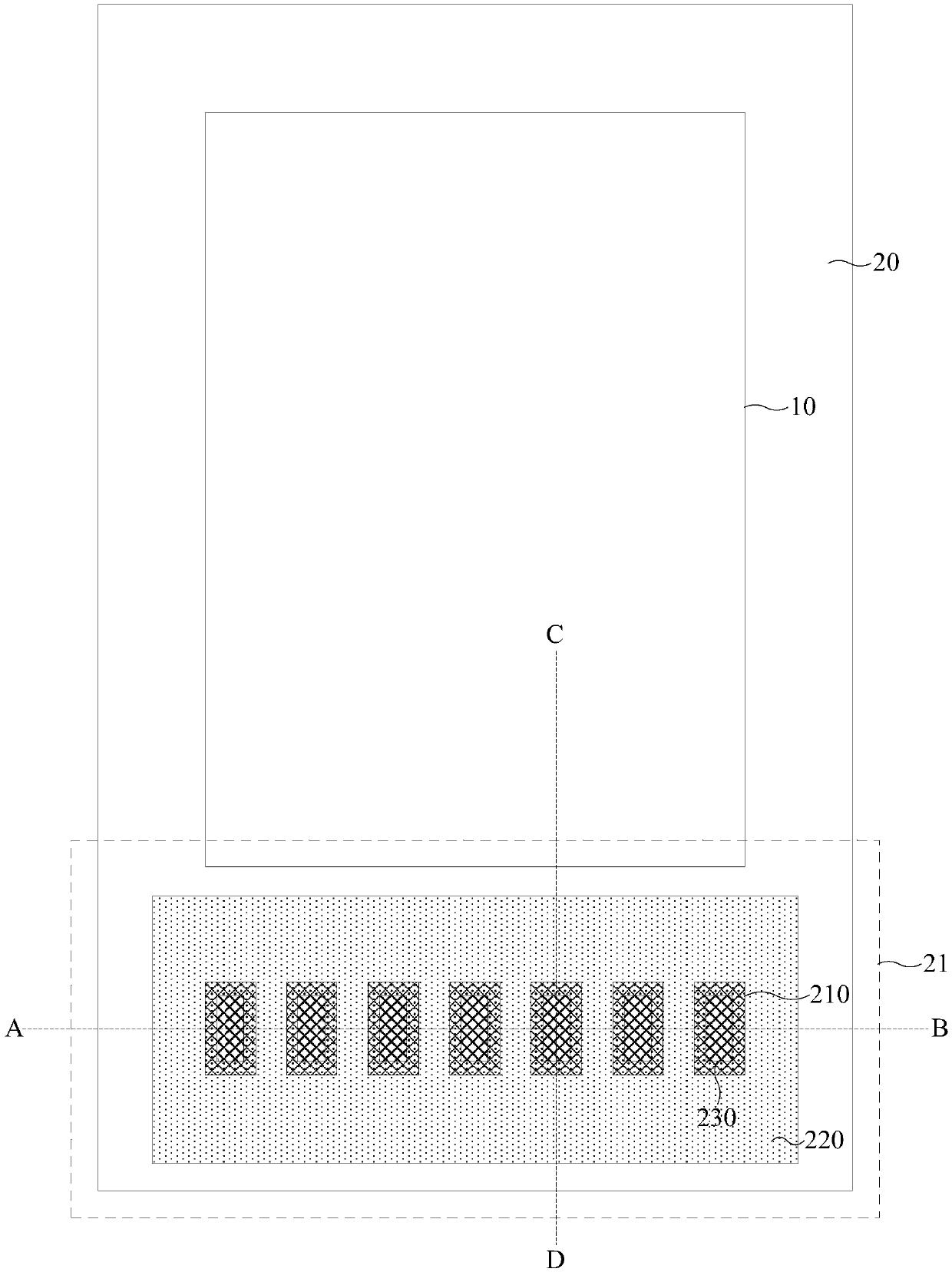

[0021] An embodiment of the present invention provides an array substrate, and the array substrate includes a display area and a non-display area arranged around the display area;

[0022] The non-display area includes a binding area located on one side of the display area, and the binding area is provided with a plurality of binding pads;

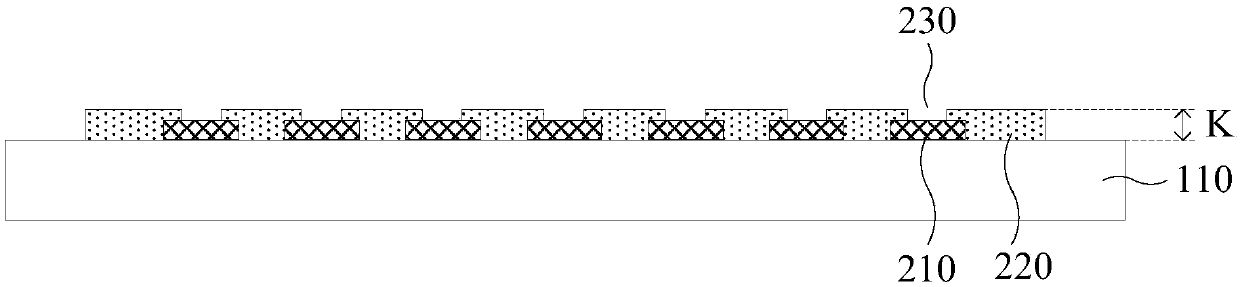

[0023] The array substrate includes a substrate, and a protective layer is formed on a side of the bonding pad away from the substrate, and the protective layer includes a plurality of openings, and the openings are connected to the bonding pad one by one. Correspondingly, the opening penetrates the protective layer to expose a part of the surface corresponding to the bonding pad;

[0024] The thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com