Battery component of new-energy electric automobile

A technology for battery components and electric vehicles, applied in electric vehicle charging technology, electric vehicles, battery pack components, etc., can solve the problems of increasing the economic burden of vehicle owners and difficult to achieve dense coverage of charging sites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] according to Figure 1 to Figure 12 As shown, this embodiment is a new energy electric vehicle battery assembly, including a battery case 2 with an upper end opening, a case cover 21 fixedly connected to the upper end of the battery case, and a battery case installed on the battery case and the case cover. A lithium battery (not shown) in the space between the boards.

[0059] Electric mortise locks 4 are respectively installed on the side walls of the two long sides near the front and rear ends of the battery housing, and the inner wall of the battery installation groove corresponds to the position of each electric mortise lock. fixed jack T1.

[0060] The middle position of the bottom of the battery housing is formed with a circular mobile vehicle installation cavity 22 with the opening facing downwards, and a mobile vehicle 5 for moving the battery assembly is installed in rotation at the lower end of the mobile vehicle installation cavity.

[0061] The mobile vehi...

Embodiment 2

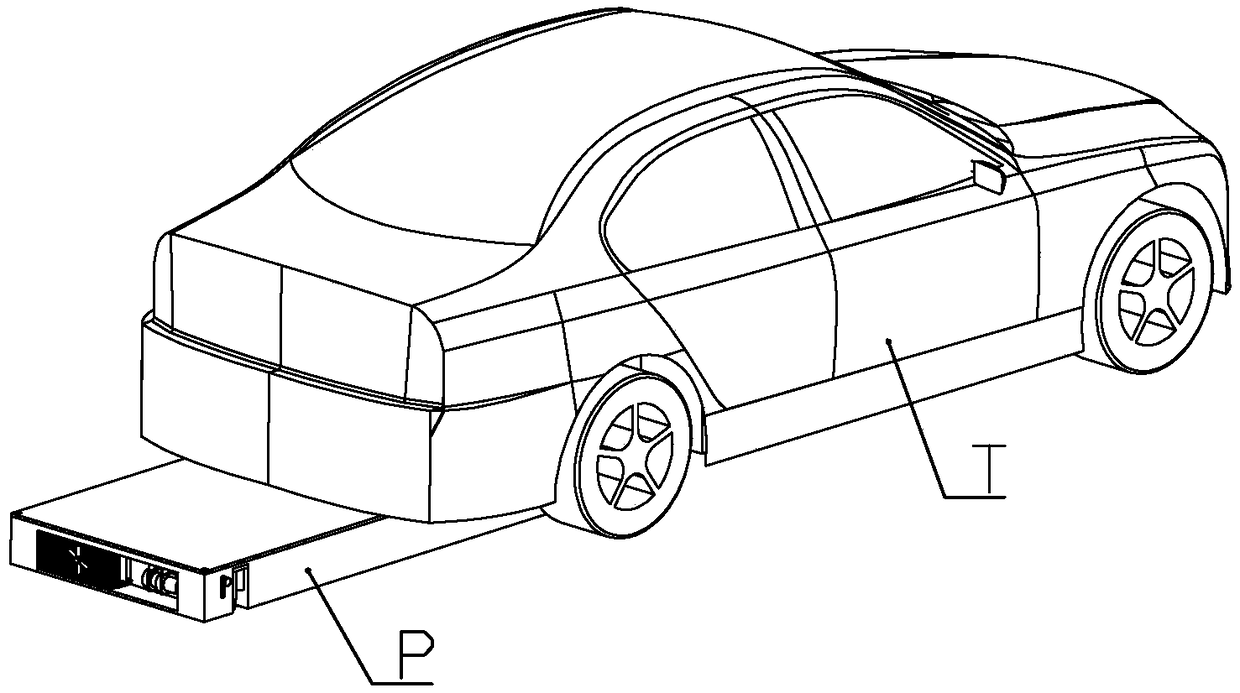

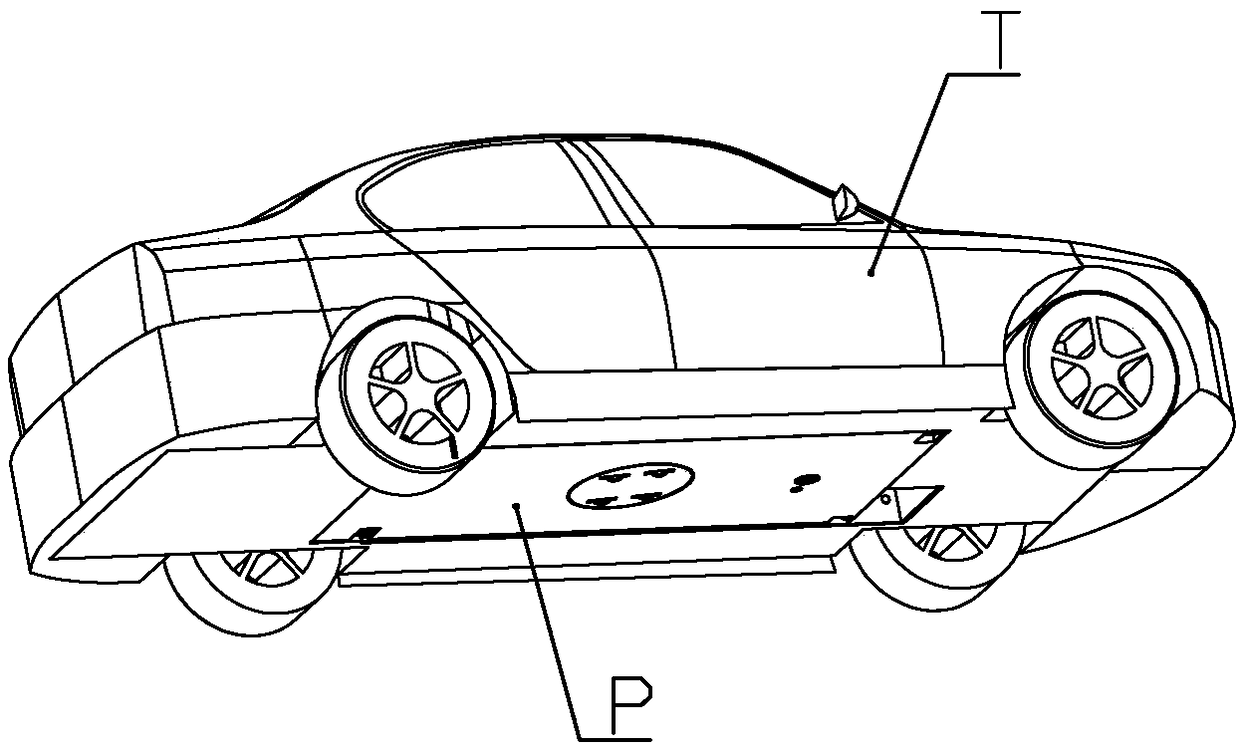

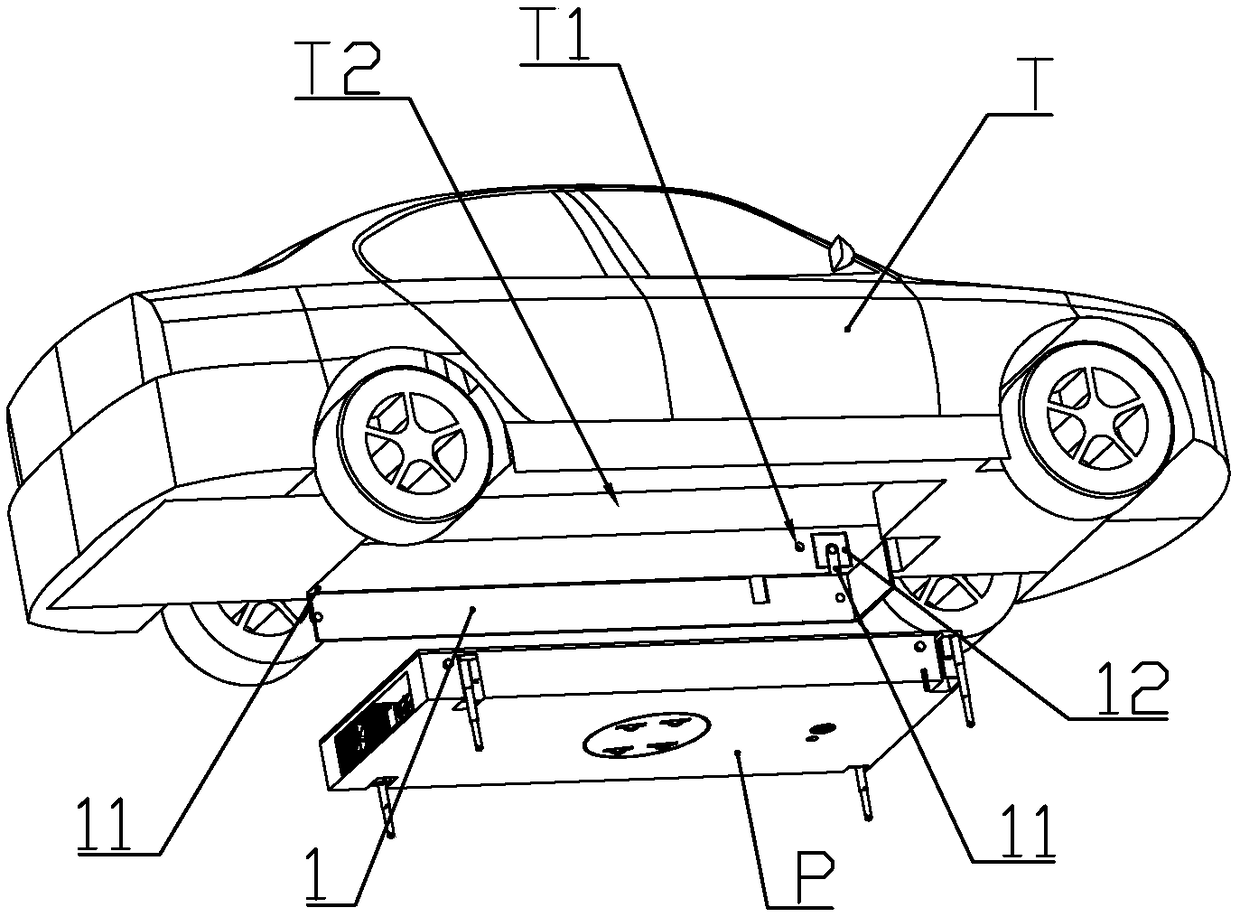

[0076] according to Figure 1 to Figure 12 As shown, this embodiment is a new energy electric vehicle using the battery assembly of Embodiment 1, including a vehicle body T, and a battery assembly P in the shape of a rectangular sheet is detachably installed at the lower end of the vehicle body.

[0077] The lower end of the vehicle body is provided with a battery installation groove T2 for accommodating the battery assembly, and a battery installation slot T2 is installed on the left side of the battery installation groove along the length direction of the vehicle body for connecting the battery assembly and the battery assembly when the battery assembly is installed in the battery installation groove. The positioning baffle 1 aligned with the battery installation slot.

[0078]The front end of the left side wall in the battery installation groove is equipped with a baffle motor 12 that drives the positioning baffle to extend or retract; the two ends of the positioning baffle...

Embodiment 3

[0106] This embodiment makes the following improvements on the basis of Embodiment 1 or 2: an upper connection capacitor cavity 211 is formed on the cover plate of the housing at a position different from that of the mobile car, and an upper connection capacitor cavity 211 is slidably installed in the upper connection capacitor cavity. Electric connection seat 6, described upper connection electric seat upper end is equipped with 2-3 ring-shaped upper connection electric electrodes 61 concentrically arranged; In the middle of described upper connection electric seat upper end, electric connection permanent magnet 62 is installed; The outer wall of the lower part of the seat is connected with more than two limit heads 63, and the side wall of the upper connection capacitor cavity is formed with a sliding limit groove 2112 that is slidably connected with each of the limit heads; the side wall of the upper connection capacitor cavity is also formed There is a connection port 2111,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com