Method for comprehensively utilizing fly ash

A technology for fly ash and lime, which is applied in the field of comprehensive utilization of fly ash, can solve the problem that the value of fly ash is not fully utilized, and achieve the effects of environmental friendliness, high potential and low calcium content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Present embodiment adopts fly ash, main chemical composition (mass percentage, wt%) is: aluminum oxide (Al 2 o 3 )50.7%, silicon dioxide (SiO 2 )38.3%, sodium oxide (Na 2 O) 0.37%, calcium oxide (CaO) 3.61%, iron oxide (Fe 2 o 3 ) 2.17%, titanium dioxide (TiO 2 ) 1.81%, and its aluminum-silicon ratio is 1.19.

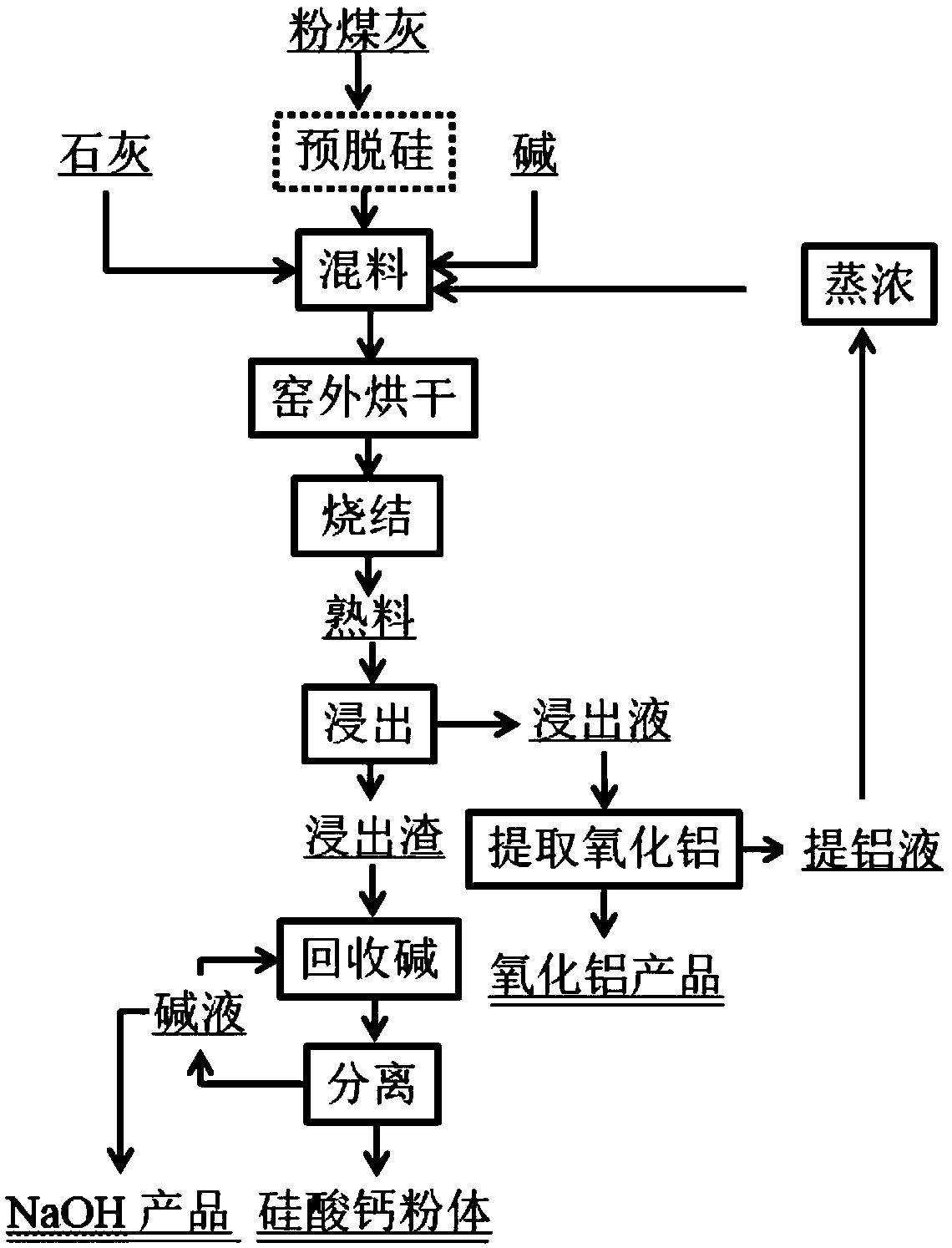

[0066] according to figure 1 Process processing:

[0067] S1 Mixing ingredients: After desiliconization, fly ash is mixed with a small amount of lime, carbon soda and circulating mother liquor, and mixed with circulating mother liquor in a ball mill according to the ratio of L / S=3, and then dried outside the kiln.

[0068] The lime that the mixed batching of step S1 is used and replenishing soda carbon are common industrial grade products; X N =0.5;X C = 1.0.

[0069] S2 sintering: the dried raw materials are sintered at 1100°C for 1 hour, and sintered clinker is obtained after the reaction.

[0070] S3 leaching reaction: the sintered clinker is subjec...

Embodiment 2

[0077] Present embodiment adopts fly ash, main chemical composition (mass percentage, wt%) is: aluminum oxide (Al 2 o 3 )38.18%, silicon dioxide (SiO 2 )32.86%, sodium oxide (Na 2 O) 0.07%, calcium oxide (CaO) 11.60%, iron oxide (Fe 2 o 3 )3.01%, titanium dioxide (TiO 2 ) 1.81%, and its aluminum-silicon ratio is 1.16.

[0078] according to figure 1 Process processing:

[0079] S1 Mixing ingredients: After desiliconization, the fly ash is mixed with a small amount of lime, carbon soda and circulating mother liquor, mixed with the circulating mother liquor in a ball mill according to the ratio of L / S=3, and then dried outside the kiln;

[0080] The lime that the mixed batching of step S1 is used and make up caustic soda are common industrial grade products; X N = 1.0; X C = 1.0.

[0081] S2 sintering: sintering the dried raw materials at 1150°C for 1 hour, and obtaining sintered clinker after the reaction;

[0082] S3 leaching reaction: the sintered clinker is subjected...

Embodiment 3

[0090] Present embodiment adopts fly ash, main chemical composition (mass percentage, wt%) is: aluminum oxide (Al 2 o 3 ) 42.11%, silicon dioxide (SiO 2 ) 45.90%, sodium oxide (Na 2 O) 0.37%, calcium oxide (CaO) 2.21%, iron oxide (Fe 2 o 3 ) 2.02%, titanium dioxide (TiO 2 ) 1.39%, and its aluminum-silicon ratio is 1.19.

[0091] according to figure 1 Process processing:

[0092] S1: After desiliconization, the fly ash is mixed with a small amount of lime, carbon soda and circulating mother liquor, mixed evenly with the circulating mother liquor in a ball mill according to the ratio of L / S=3, and then dried outside the kiln;

[0093] The lime that the mixed batching of step S1 is used and replenishing soda carbon are common industrial grade products; X N = 1.0; X C = 1.5.

[0094] S2: The dried raw materials are sintered at 1150° C. for 1 hour, and sintered clinker is obtained after the reaction.

[0095] S3: The sintered clinker is subjected to leaching reaction, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com