Vehicle-specific phosphating solution and preparation method thereof

A phosphating solution and vehicle technology, which is applied in the coating process of metal materials, etc., can solve the problems of not being suitable for low-temperature phosphating, high phosphating temperature, impact resistance of paint film or weak adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

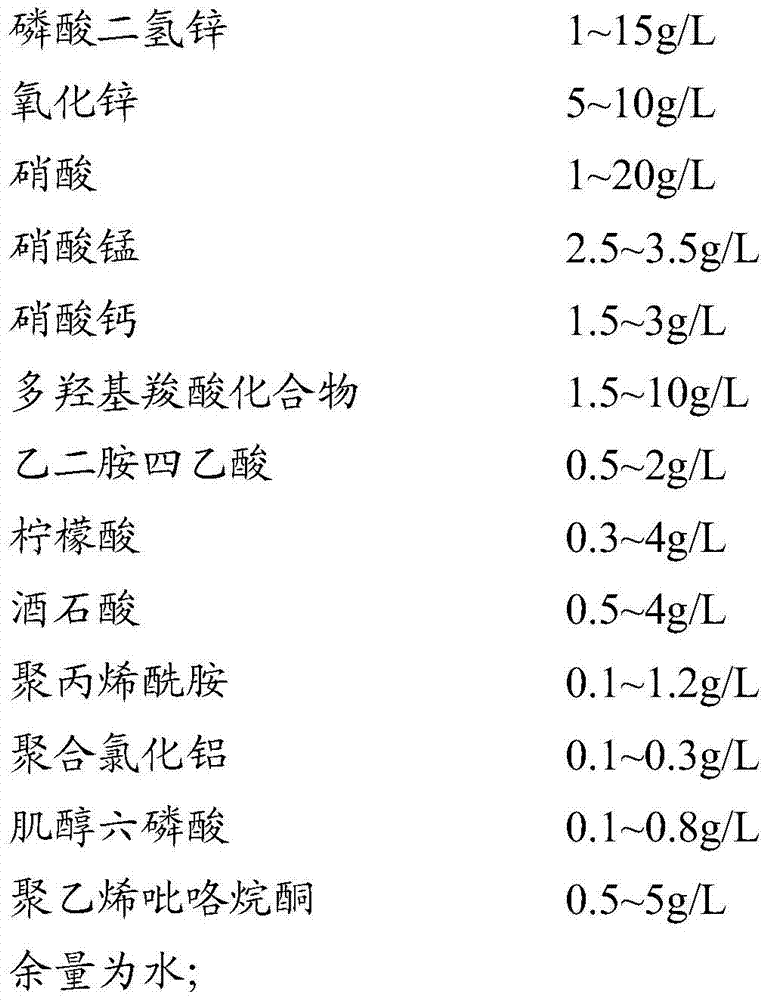

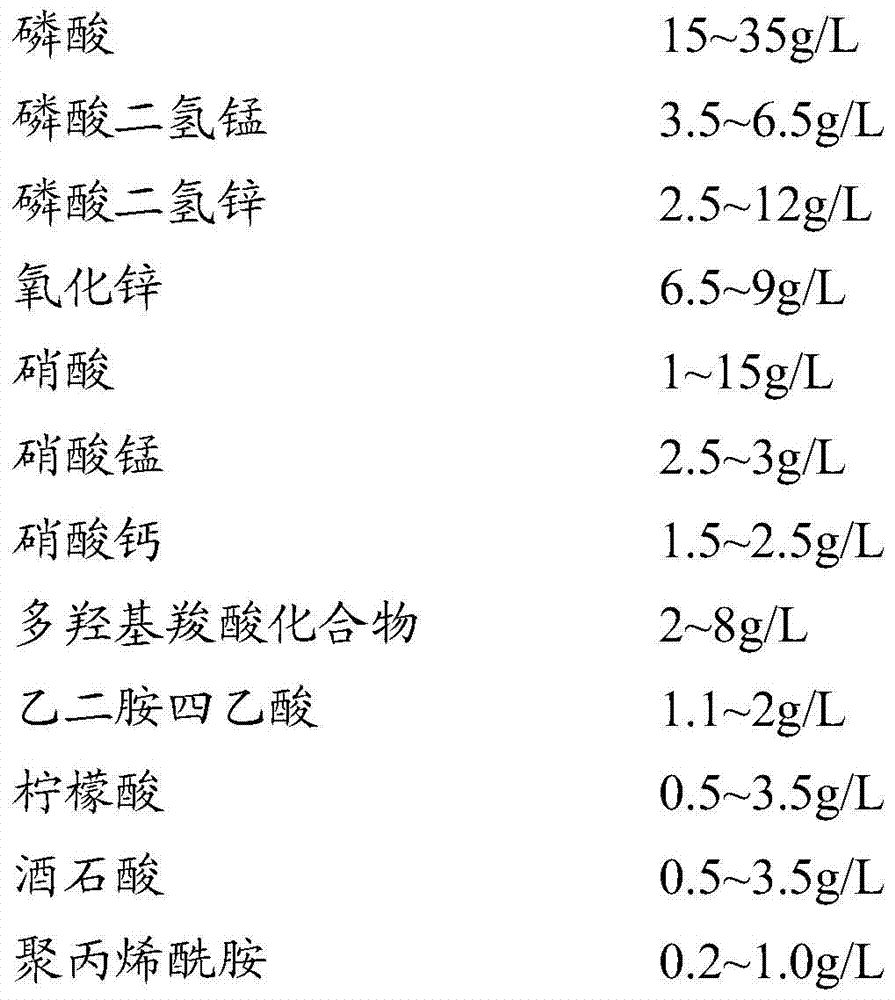

Method used

Image

Examples

Embodiment 1

[0021] According to the volume of the phosphating solution, calculate the amount of each component. Based on 1000L phosphating solution, first add water to 45% of the volume of the phosphating tank, add 6.5kg of zinc oxide, and 15kg of phosphoric acid with a mass concentration of 85%. 15kg of nitric acid, 1.1kg of ethylenediaminetetraacetic acid, 0.7kg of citric acid, 0.5kg of tartaric acid and 0.2kg of phytic acid with a mass concentration of 75% were added in sequence, and stirred evenly, then 2.5kg of calcium nitrate and 3kg of manganese nitrate were added , 12kg of zinc dihydrogen phosphate, 6.5kg of manganese dihydrogen phosphate and 3.5kg of polyvinylpyrrolidone were stirred and dissolved, and then 0.3kg of polyaluminium chloride, 1.0kg of polyacrylamide and 8kg of polyhydroxy carboxylic acid compound were added successively, and polyhydroxy carboxylic acid compound The composition is HEDP 22wt%, polyacrylic acid 4wt%, water 74wt%, finally add water to the specified volum...

Embodiment 2

[0023] Calculate the amount of each component according to the volume of the phosphating solution required. In terms of 1000L phosphating solution, first add water to 45% of the volume of the phosphating tank, add 10kg of zinc oxide, 35kg of phosphoric acid with a mass concentration of 85%, Add 16kg of nitric acid, 0.7kg of ethylenediaminetetraacetic acid, 3.5kg of citric acid, 0.6kg of tartaric acid and 0.8kg of phytic acid with a mass concentration of 75% in sequence, and stir evenly, then add 1.5kg of calcium nitrate and 2.5kg of manganese nitrate , zinc dihydrogen phosphate 15kg, manganese dihydrogen phosphate 6kg and polyvinylpyrrolidone 4.6kg were stirred and dissolved and then added polyaluminum chloride 0.1kg, polyacrylamide 0.6kg and polyhydroxy carboxylic acid compound 6kg, polyhydroxy carboxylic acid compound The composition is 22wt% of HEDP, 4wt% of polyacrylic acid and 74wt% of water. Finally, water is added to make up the volume to the specified volume, stirred ev...

Embodiment 3

[0025] According to the volume of the phosphating solution, calculate the amount of each component. In terms of 1000L phosphating solution, first add water to 45% of the volume of the phosphating tank, add 6kg of zinc oxide, 35kg of phosphoric acid with a mass concentration of 85%, Add 13kg of nitric acid, 2kg of ethylenediaminetetraacetic acid, 0.5kg of citric acid, 2.6kg of tartaric acid and 0.1kg of phytic acid with a mass concentration of 75% in sequence, and stir evenly, then add 3.0kg of calcium nitrate, 2.5kg of manganese nitrate, 12.0 kg of zinc dihydrogen phosphate, 4 kg of manganese dihydrogen phosphate and 3.0 kg of polyvinylpyrrolidone were stirred and dissolved, and then 0.2 kg of polyaluminum chloride, 0.9 kg of polyacrylamide and 8 kg of polyhydroxy carboxylic acid compound were added successively. The composition is 20wt% of HEDP, 4wt% of polyacrylic acid, and 76wt% of water. Finally, water is added to make up the volume to the specified volume, stirred evenly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com