Plasma display screen manufacturing method and plasma display screen

A technology of a plasma display screen and a manufacturing method, which is applied in the field of gas discharge, can solve the problem of difficult removal of contamination of a dielectric protective film, and achieves the effects of uniform overall surface state, stable optoelectronic performance of the screen, and removal of impurity gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions in the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings in the embodiments of the present invention, but the following embodiments and accompanying drawings are only used to understand the present invention, rather than limit the present invention, the present invention can A multitude of different implementations are defined and covered by the claims.

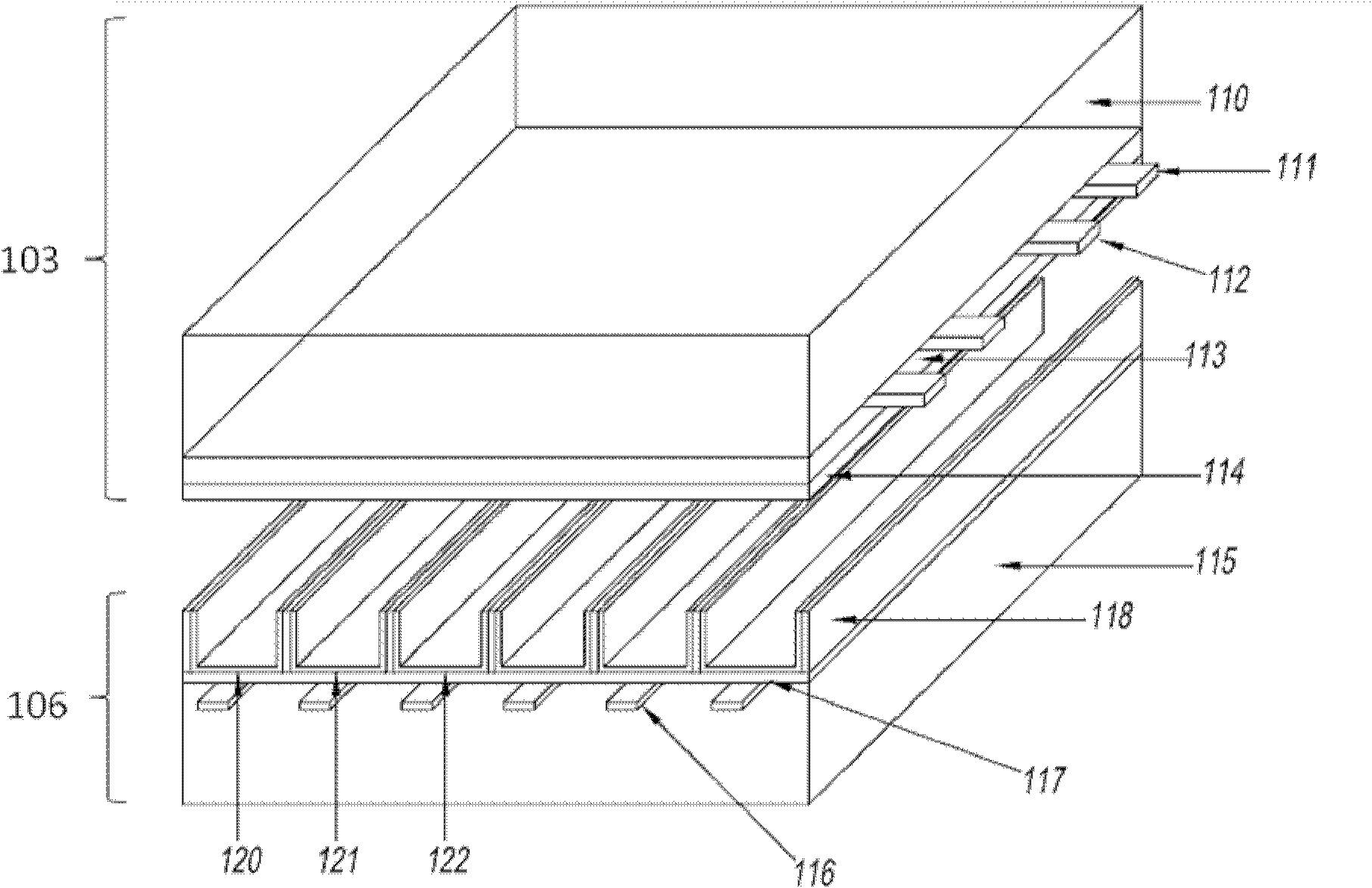

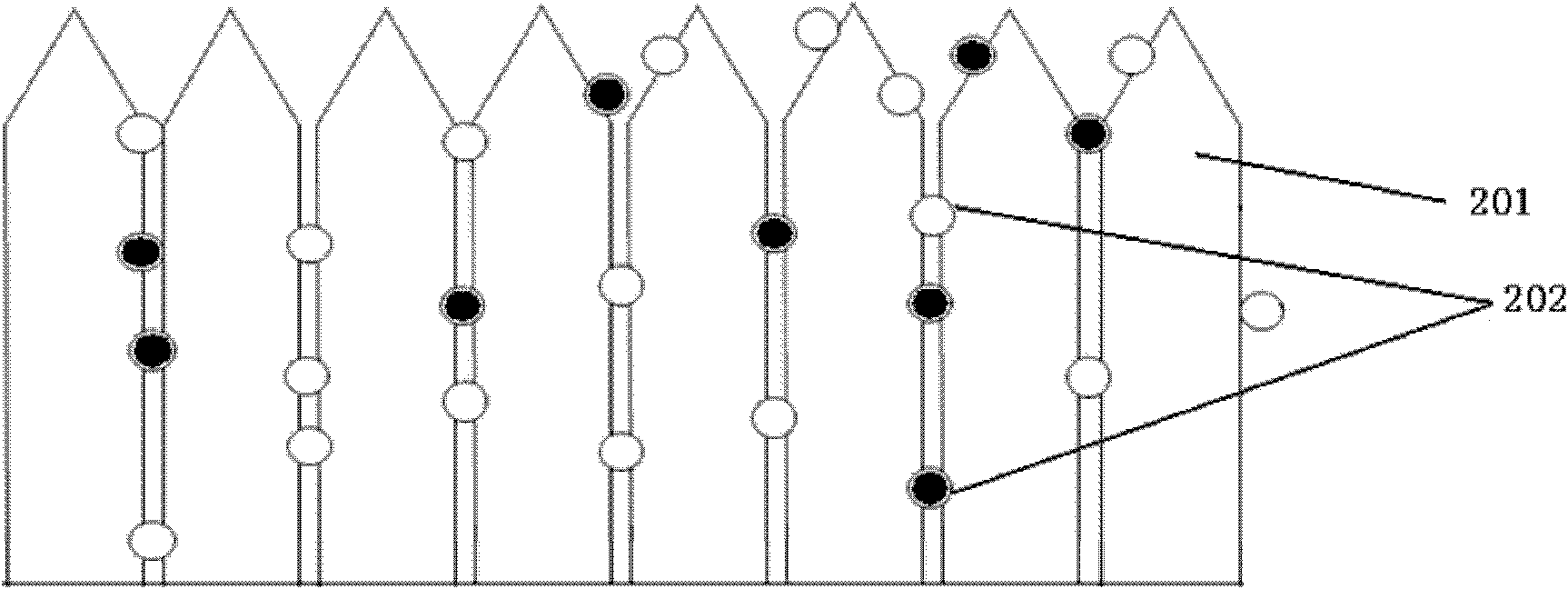

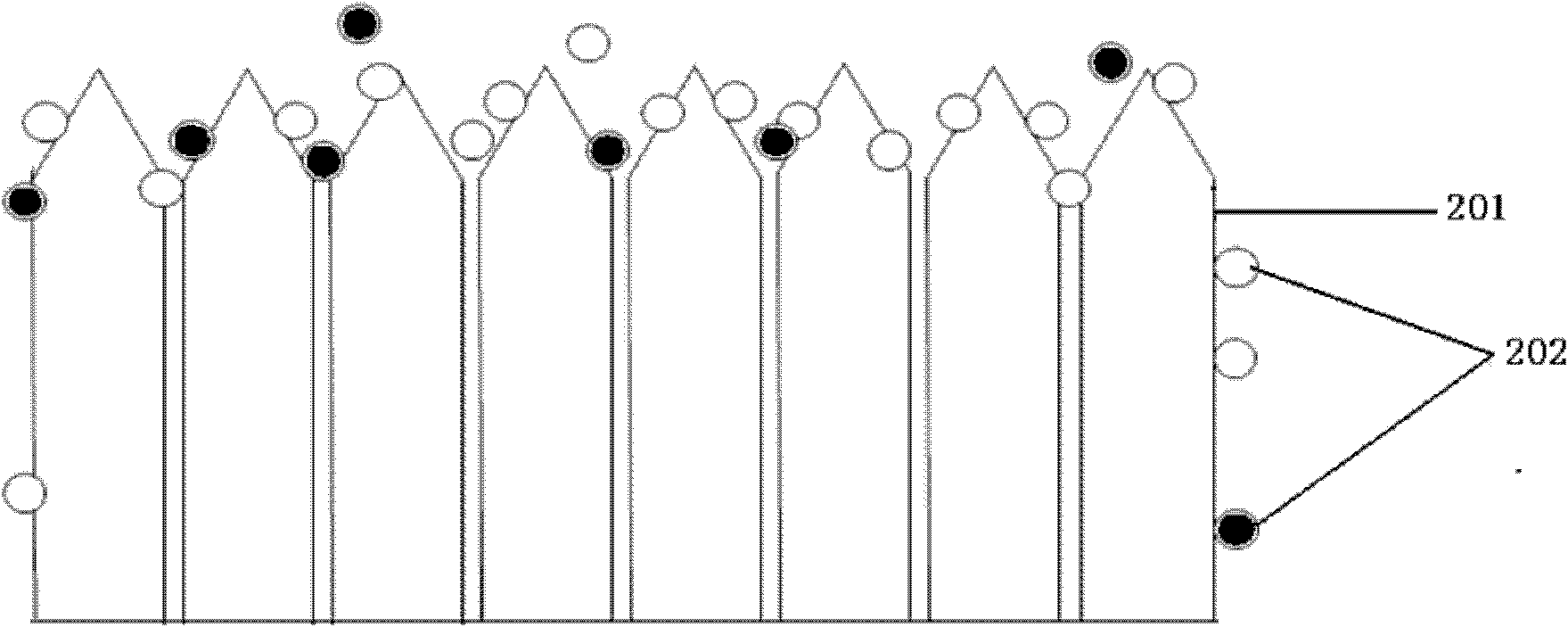

[0032] In a typical implementation of the present invention, a method for manufacturing a plasma display screen is provided, including making a front substrate, making a rear substrate, and subsequent processing, and the subsequent processing includes: aligning the front substrate and the rear substrate close, carry out the first sealing and discharge, fill in the working gas, and carry out the first aging; cut the exhaust pipe of the plasma display screen, conduct the second sealing and discharge of the plasma display screen afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com