Tension-torsion test specimen fixture

A test piece and fixture technology, which is applied in the field of material mechanics testing machine, can solve the problem of unifying the shape of the test piece that is difficult to achieve, and achieve the effect of good clamping effect, simple and novel structure, and no mechanical operation noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

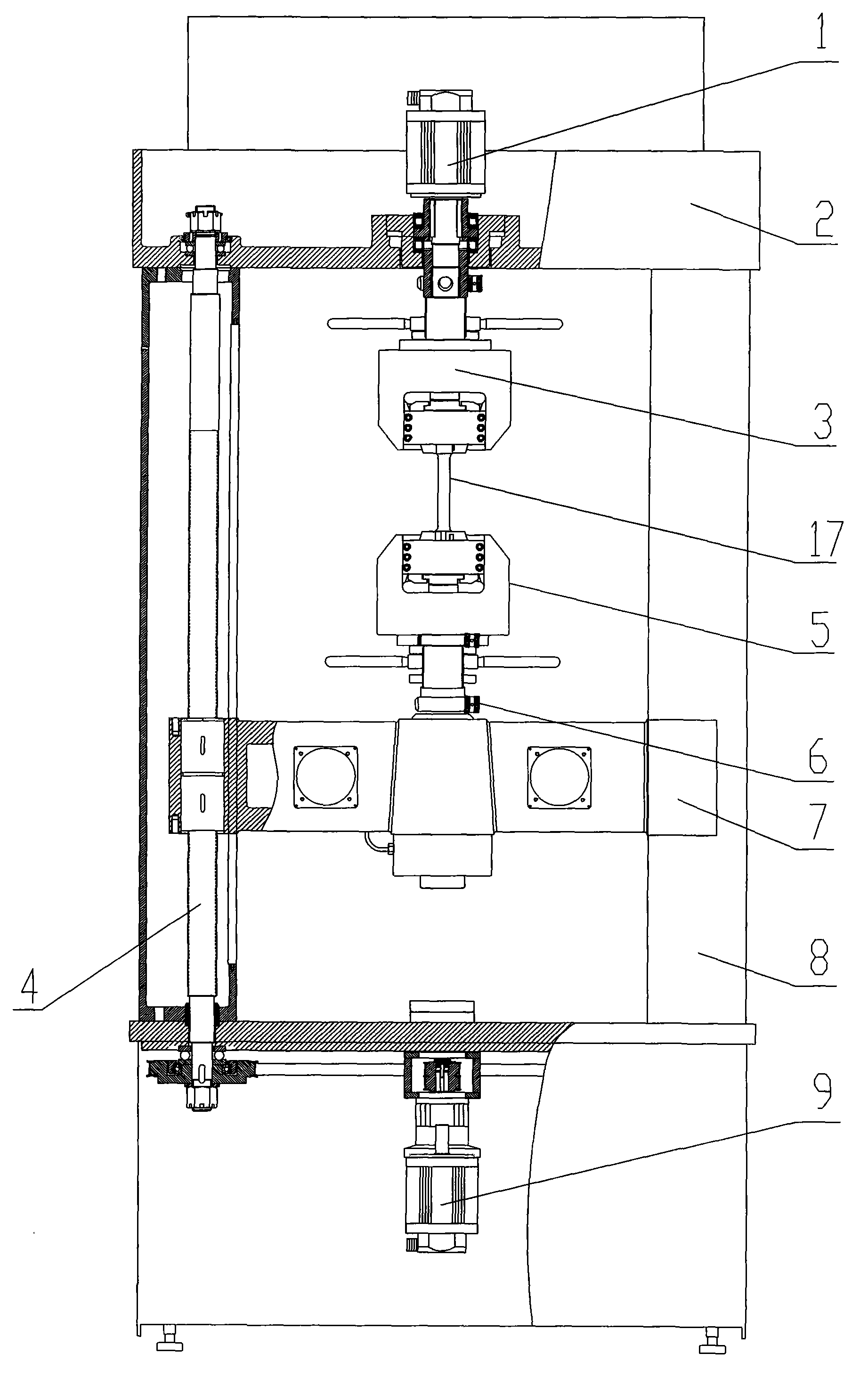

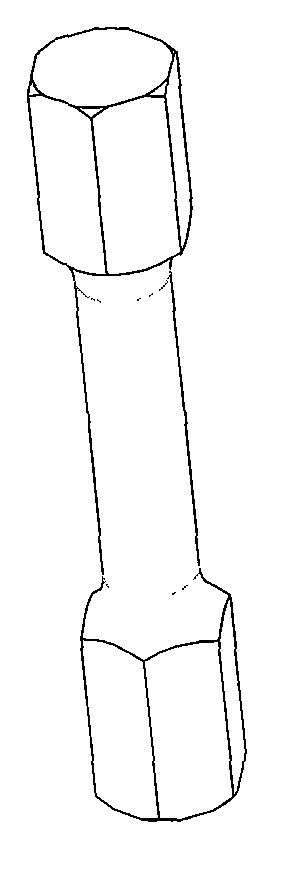

[0029] Example 1 as figure 1 , Figure 4 to Figure 9 , Figure 12 and Figure 13 As shown, a clamp for pulling and torsion test piece comprises an upper clamp 3, a lower clamp 5 and a pull and torsion test piece 17, and the upper clamp 3 and the lower clamp 5 are respectively provided with an upper jaw and a lower jaw, The upper clamping section 22 of the tensile and torsion test piece 17 is fixed by the upper jaw of the upper clamp 3, and the lower clamping section 23 of the tensile and torsion test piece 17 is fixed by the lower jaw of the lower clamp 5. The upper clamping section 22 of the test piece 17 is provided with an upper test piece keyway 19, the lower clamping section 23 is provided with a lower test piece keyway 21, and the upper jaw of the upper chuck 3 is provided with a corresponding keyway 19 for the upper test piece. The upper jaw keyway, the lower jaw of the lower chuck is provided with the lower jaw keyway corresponding to the lower test piece keyway 21...

Embodiment 2

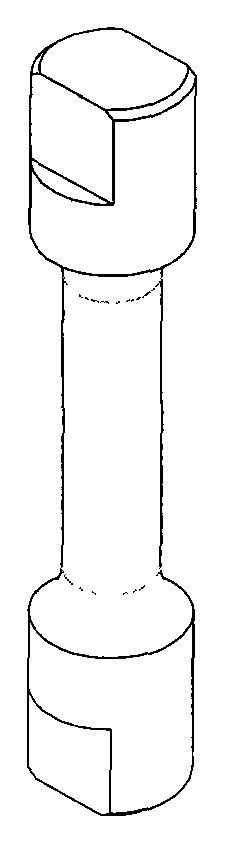

[0032] Example 2 as Figure 10 , Figure 11 , Figure 14 and Figure 15 As shown, the upper test piece keyway 19 described in embodiment 2 is an upper test piece keyway, and the upper jaw is provided with a corresponding upper jaw keyway, and the upper test piece keyway and the upper jaw keyway are provided with key 18; the lower test piece keyway 21 is also a lower test piece keyway, and the lower jaw is also provided with a corresponding lower jaw keyway, and the lower test piece keyway and the corresponding lower jaw keyway are also equipped with key 18. Other structures of embodiment 2 are the same as embodiment 1.

[0033] When using the tension and twist test piece clamp of the present invention, release the handle 12, and the spring 14 bounces the limit block 26, so that the upper jaw (lower jaw) is opened, that is, the left half jaw and the right half jaw are separated left and right, and put in Pull and twist the test piece 17, hold the handle 12 to rotate the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com