Patents

Literature

84results about How to "High product concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

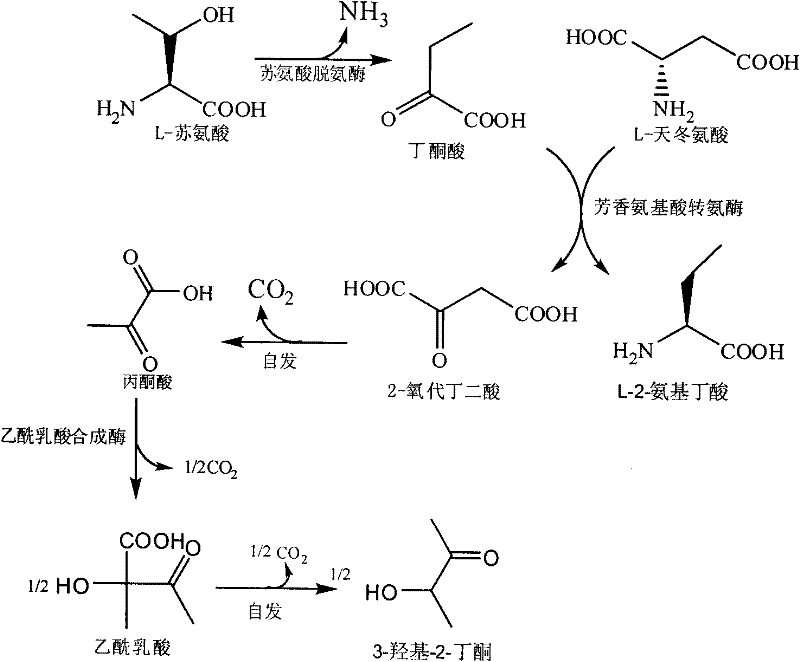

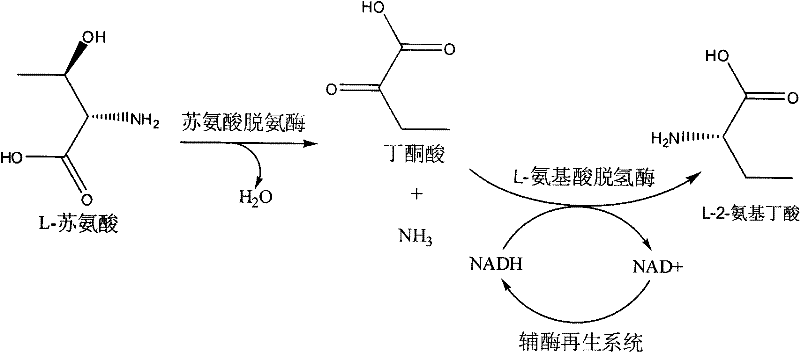

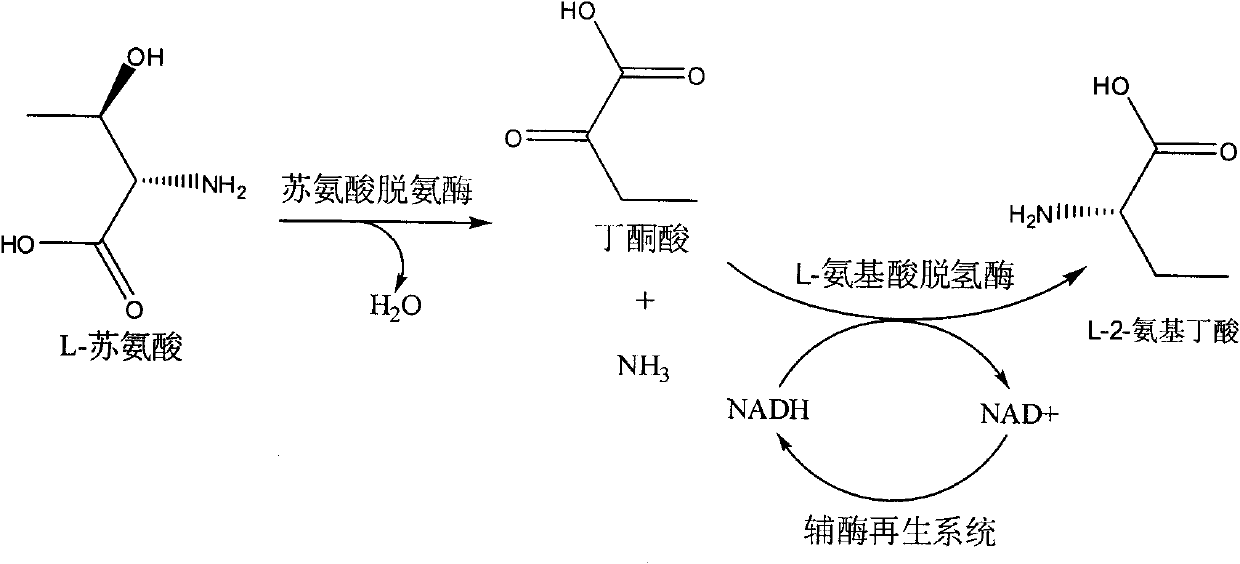

Method for producing L-2-aminobutyric acid

The invention discloses a method for producing L-2-aminobutyric acid, and the method comprises the following step: catalyzing L-threonine utilized as a raw material through an enzyme catalysis system consisting of threonine deaminase, L-amino acid dehydrogenase and coenzyme regeneration systems, thus producing the L-2-aminobutyric acid. The method for producing theL-2-aminobutyric acid has the advantages that the raw material is low in price, the property is stable, and the production cost of the L-2-aminobutyric acid can be greatly lowered, the conversion rate and product concentricity are high, no influence caused by byproducts exists, and the method is suitable for industrialization application.

Owner:湖州颐盛生物科技有限公司

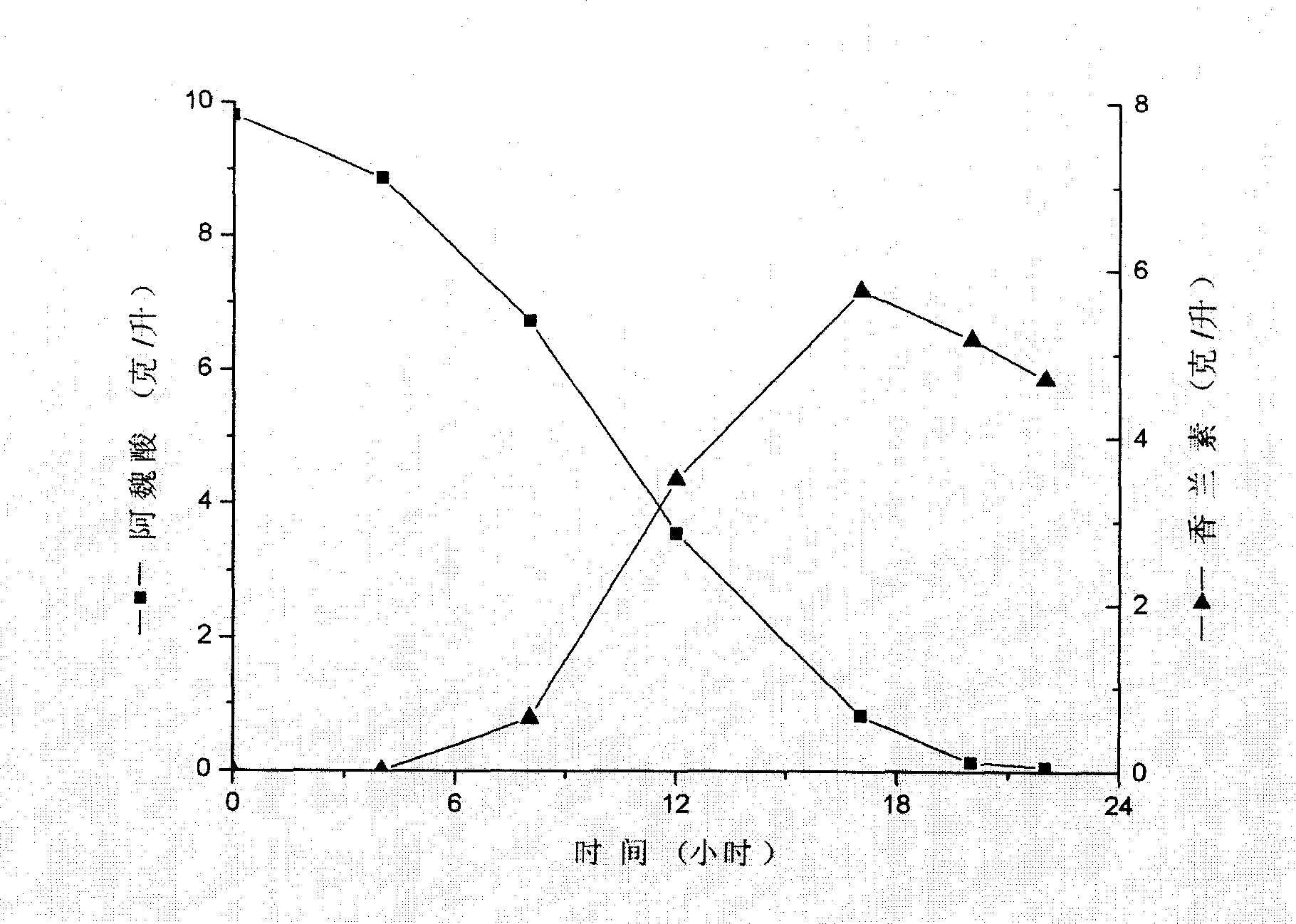

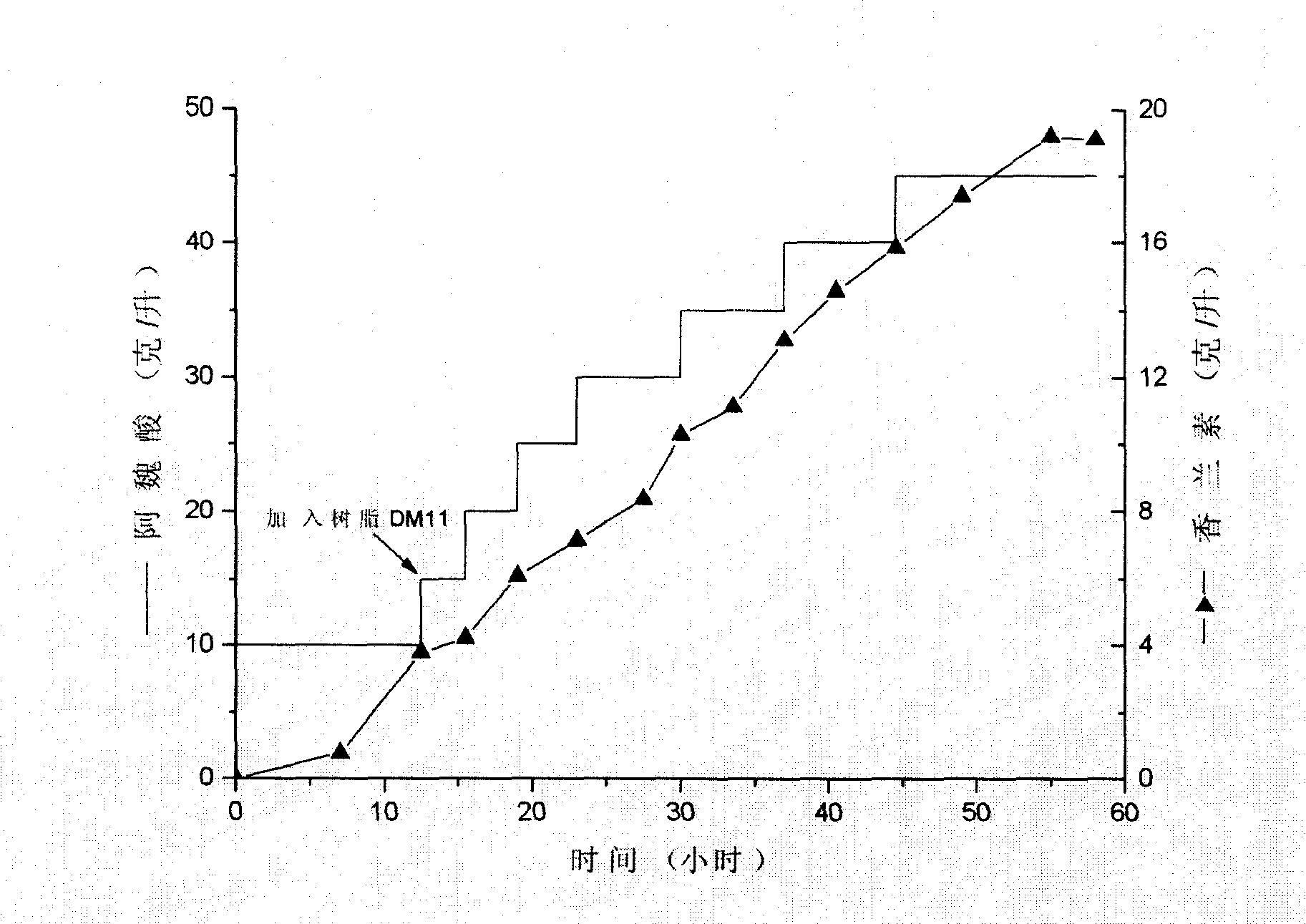

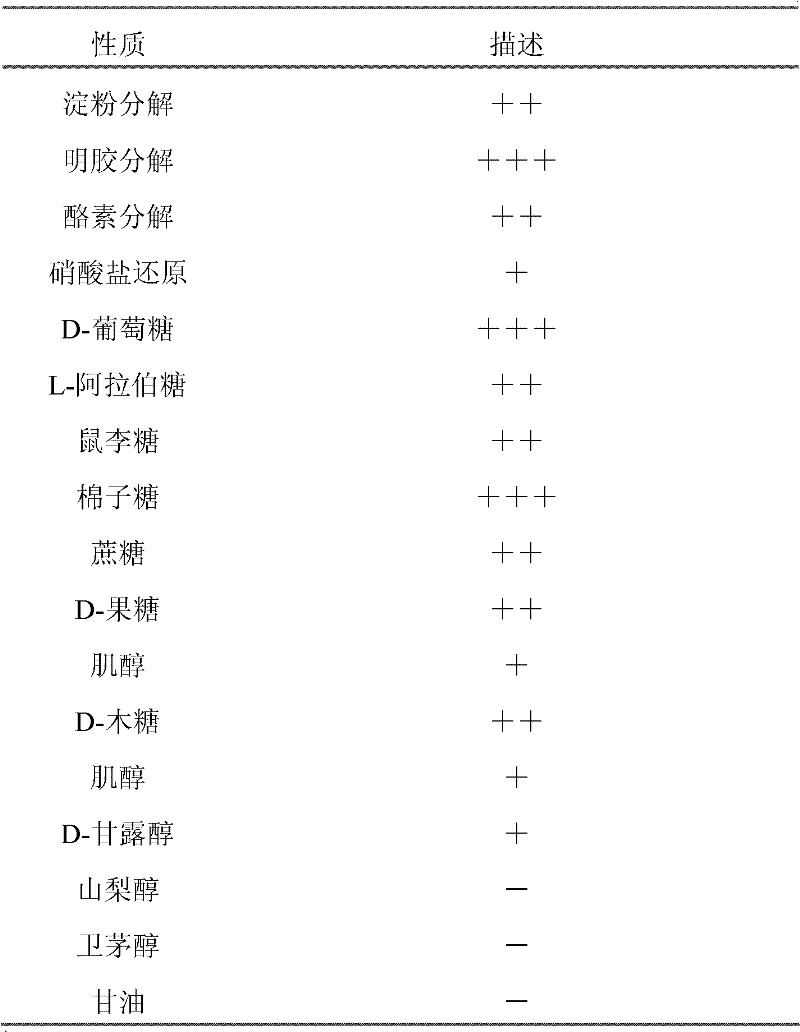

Streptomycete and method for producing vanillin by using the same to biologically transform ferulic acid

ActiveCN101165168AReduce pollutionMild reaction conditionsBacteriaMicroorganism based processesHigh concentrationChemical synthesis

The present invention is one Streptomyces strain and the process of utilizing the Streptomyces strain in converting ferulic acid to produce high concentration vanillin. The Streptomyces strain is Streptomyces sp.V-1 in the preservation number of CCTCC M 206065. In the GY converting culture medium with the Streptomyces strain, ferulic acid may be converted to produce high concentration vanillin fermenting liquid. Adding macroporous adsorption resin DM11 into the converting culture medium can increase the concentration of vanillin fermenting liquid greatly. The present invention has the advantages of less environmental pollution, high product concentration, less side products, short production period, low cost, etc.

Owner:APPLE FLAVOR & FRAGRANCE GRP +2

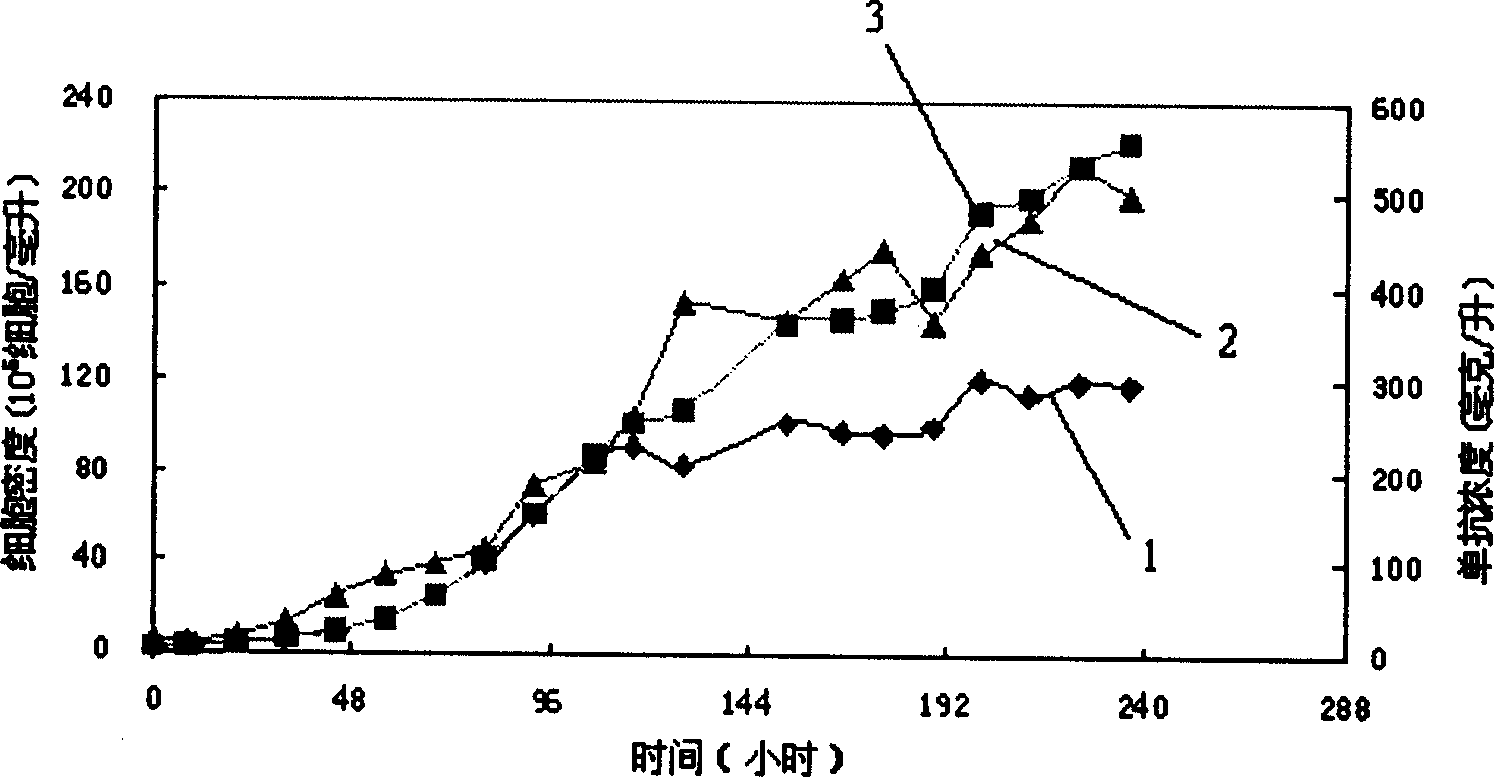

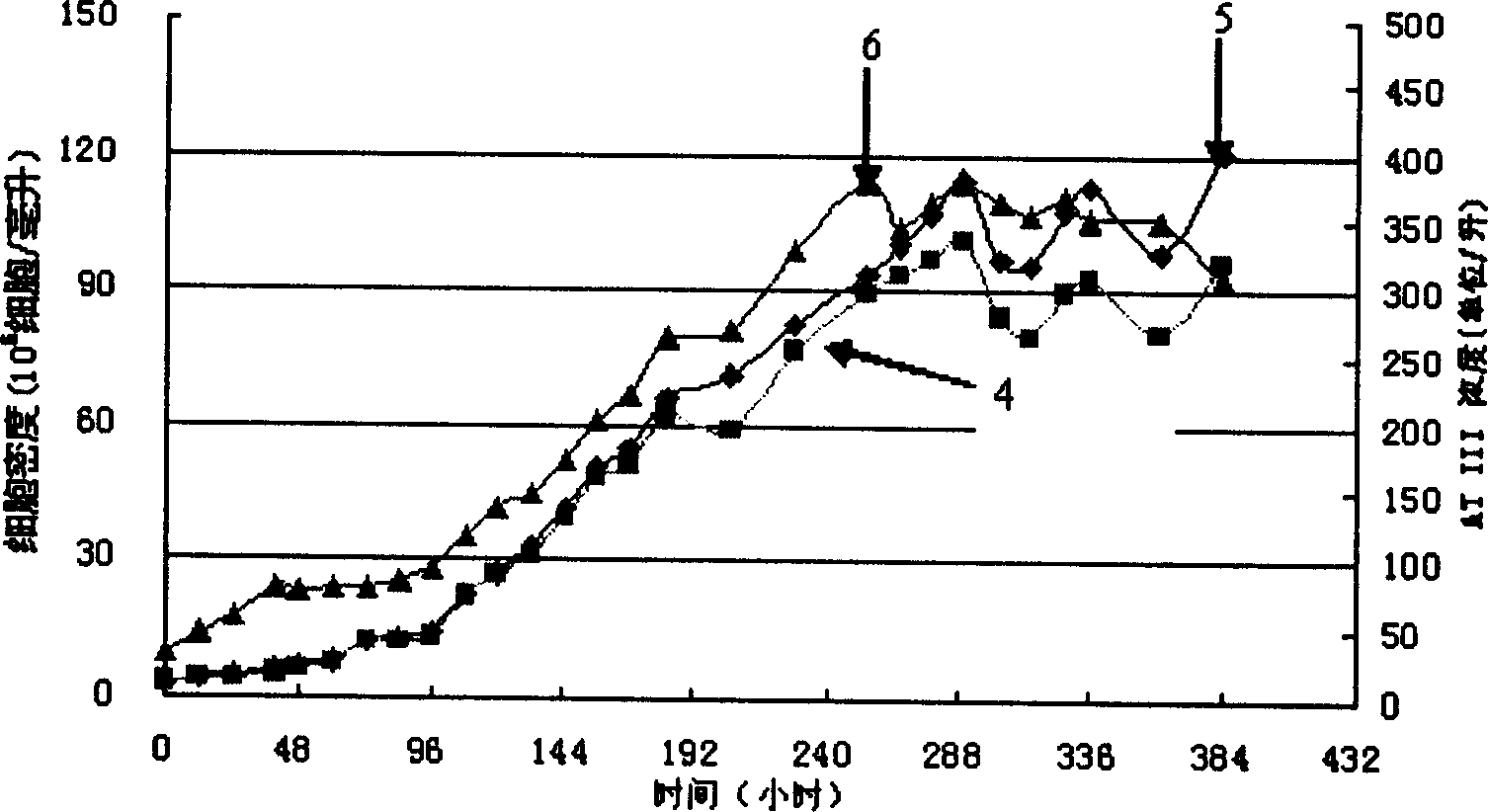

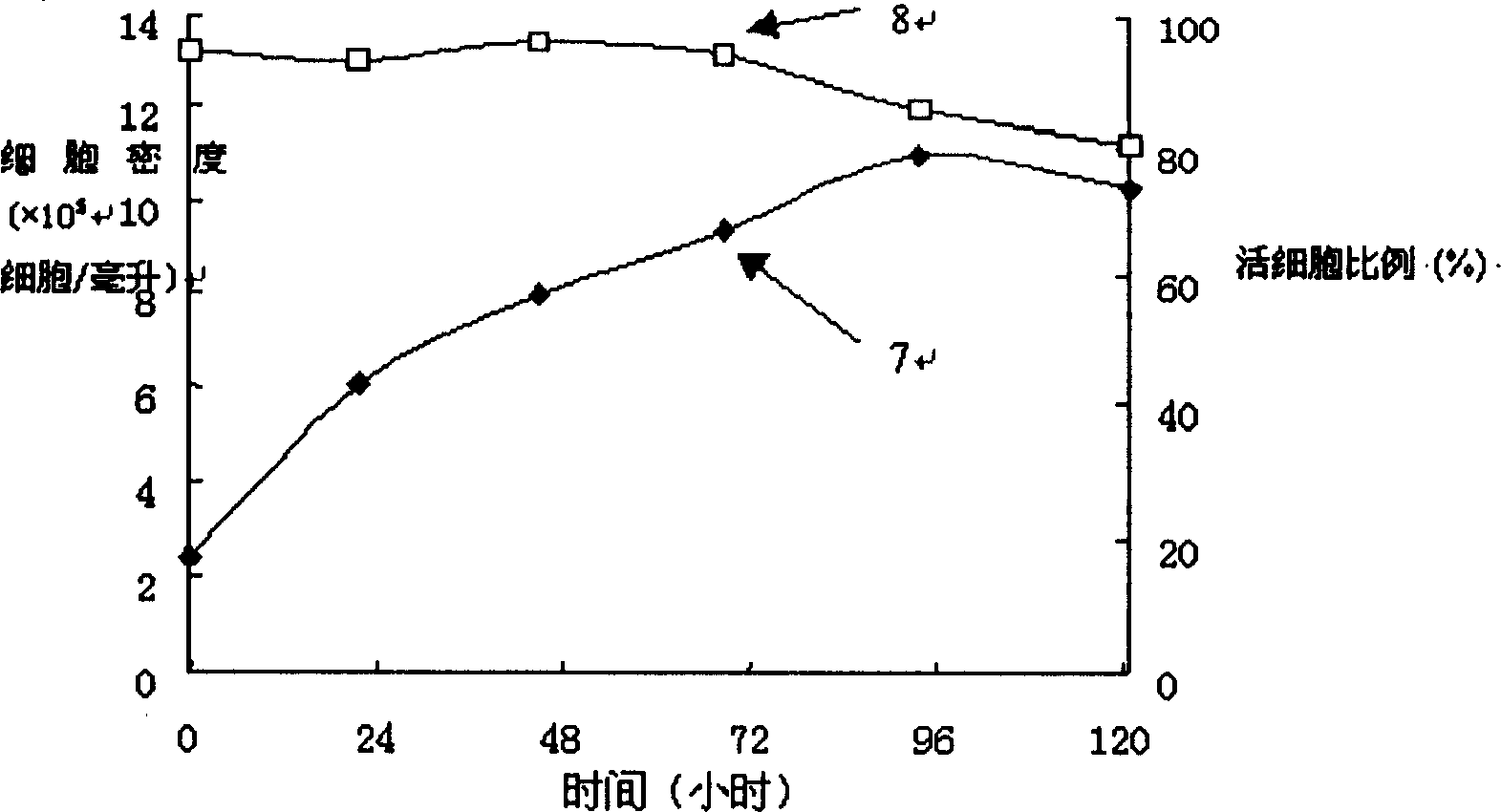

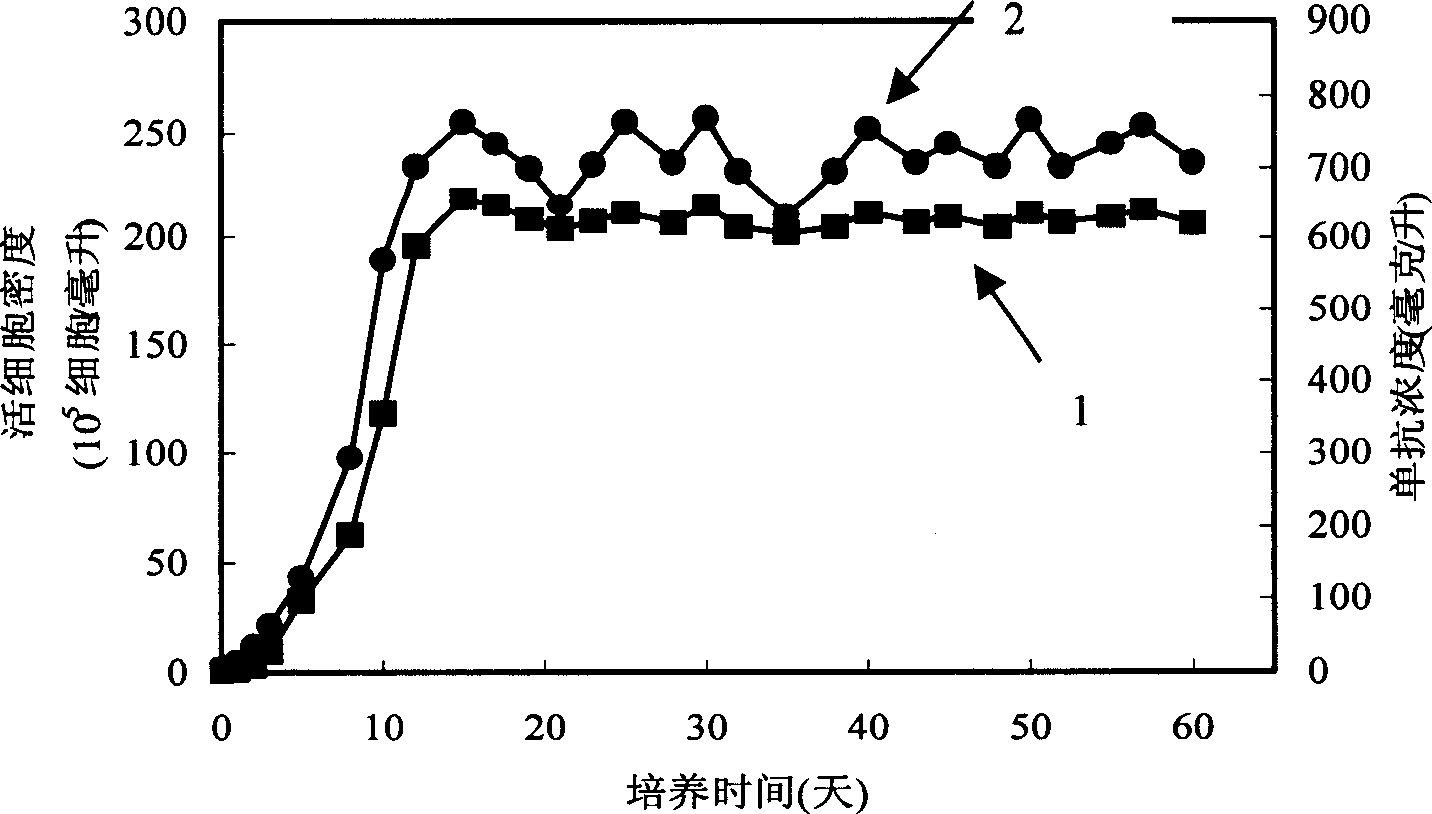

Non-serum culture medium for multiple animal cell large-scale culture

InactiveCN1778902ASupport growthSupports long-term subcultureAnimal cellsHigh densityEssential amino acid

The invention opened non-serum mediums which can proper to culture many kinds of the animal cells. The character of it is to use the DMEM / F12 as the base medium, then add the growth factor, hormone, the essential amino acid and the microelement. It has the functions: (1) it can support many cells and clones; (2) it is same as the serum medium in the growth of the cell and the expression of the product; (3) it support the long heritable culture; (4) it is benefit for the isolation of the product because it contains less protein; (5) it is cheap. We can get the high density of the cells and the product concentration using the medium.

Owner:EAST CHINA UNIV OF SCI & TECH

Separation of tropical candiyeast strain and production of xylitol

ActiveCN1982460AHighlight substantiveSignificant progressMicroorganism based processesGenetic engineeringFiberHydrolysate

Separation of tropical moniliasis strain and production of xylitol are disclosed. The process is carried out by amplification culturing to obtain seed liquid, preparing hemicellulose hydrolyte culture medium, circulating and reutilizing. It has excellent sugar-tolerance and mithridatism. It could be used above time times.

Owner:唐传生物科技(厦门)有限公司

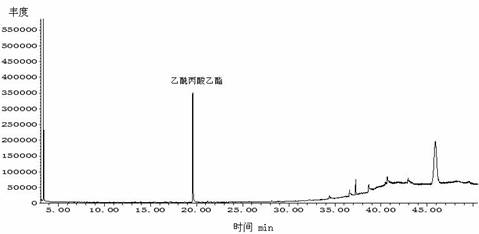

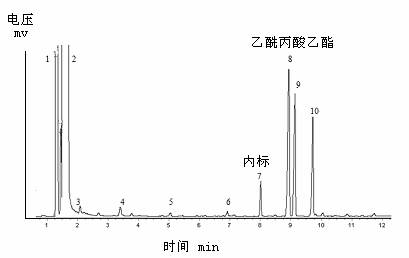

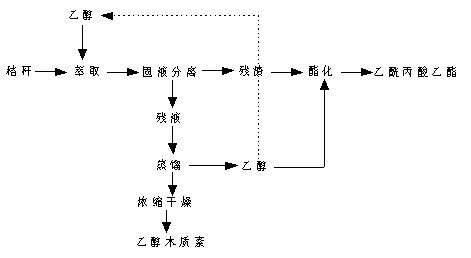

Method for preparing ethyl levulinate by using straw-type biomass

ActiveCN102659594AIncrease profitHigh product concentrationPreparation by ester-hydroxy reactionLignin derivativesCelluloseAlcohol

The invention belongs to the technical field of preparation of ethyl levulinate and particularly relates to a method for preparing ethyl levulinate by using straw-type biomass. According to the method, lignin in cellulose biomass is removed by ethanol extraction, alcoholysis esterification is performed, and both ethanol lignin and ethyl levulinate are obtained, so the utilization rate of raw materials is improved. Moreover, the method has the advantages of short reaction time, less side reaction and high product concentration.

Owner:ZHENGZHOU UNIV

Streptomyces and multi-antibiotics metabolic regulation fermentation process

ActiveCN102643764AImprove fermentation titerGood control effectBacteriaMicroorganism based processesStreptomyces aureochromogenesInorganic salts

The invention discloses a streptomyces and a multi-antibiotics metabolic regulation fermentation process. According to the method, nutrient media components are optimized, inorganic salt is added to disturb a metabolic network of streptomyces aureochromogenes, and a target production way is strengthened, so that the generation of products is promoted. Meanwhile, the multi-antibiotics fermentationprocess is optimized, and a method of flowing-feeding glucose is adopted for a feed supplement batch fermentation method, so that the fermentation unit and the production output are greatly improved,and the production cost is reduced.

Owner:NANJING UNIV OF TECH

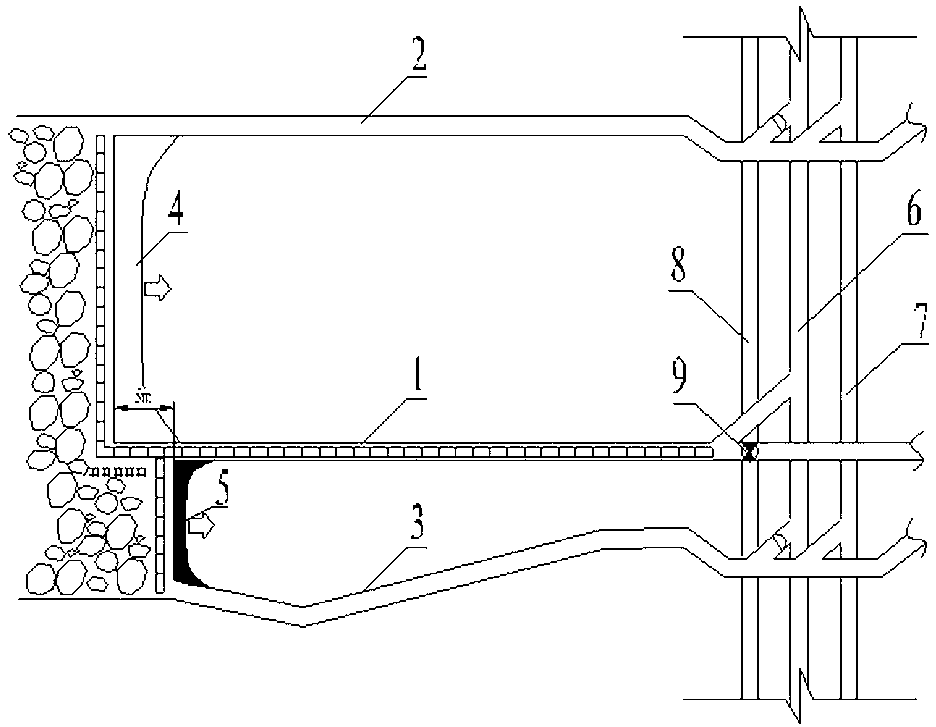

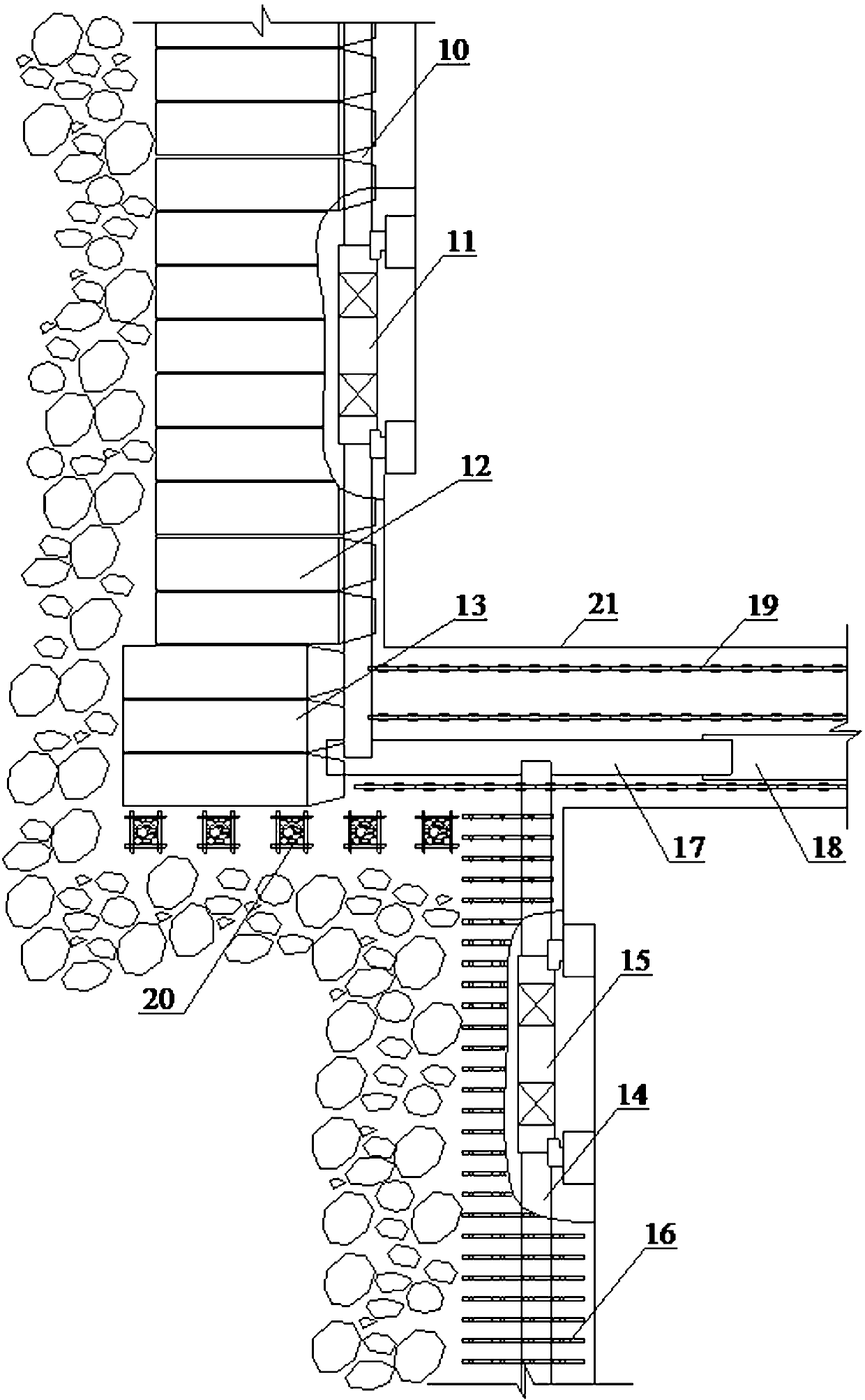

Comprehensive-conventional mechanical mining double-unit face coal mining method under complicated geological conditions

InactiveCN103104260AImprove mining efficiencyHigh recovery rateUnderground miningSurface miningCoal briquetteLength variation

The invention provides a comprehensive-conventional mechanical mining double-unit face coal mining method under complicated geological conditions. Directed at mining of coal resources in irregular sections under complicated geological conditions, the method includes: arranging an equal length comprehensive mechanical mining face on the upper part of a coal briquette in a section, arranging an unequal length conventional mechanical mining face on the lower part of the coal briquette according to the remaining coal briquette shape in the section, making use of three section drifts to prepare two stope faces so as to form a double unit mining form between the equal length comprehensive mechanical mining face and the unequal length conventional mechanical mining face, advancing the two faces in a coordinated way, and always keeping the conventional mechanical mining face ahead of the comprehensive mechanical mining face by 5m, and when the length of the conventional mechanical mining face varies, increasing or decreasing the number of single hydraulic props and articulated roof beams in the conventional mechanical mining face or properly adjusting the prop space based on required support density so as to adapt to the face length variation. The method provided in the invention achieves arrangement of the equal length comprehensive mechanical mining face during irregular coal briquette mining under complicated geological conditions, simultaneously recovers coal resources to the utmost, and improves the mechanization level of coal mining under complicated geological conditions.

Owner:HUNAN UNIV OF SCI & TECH

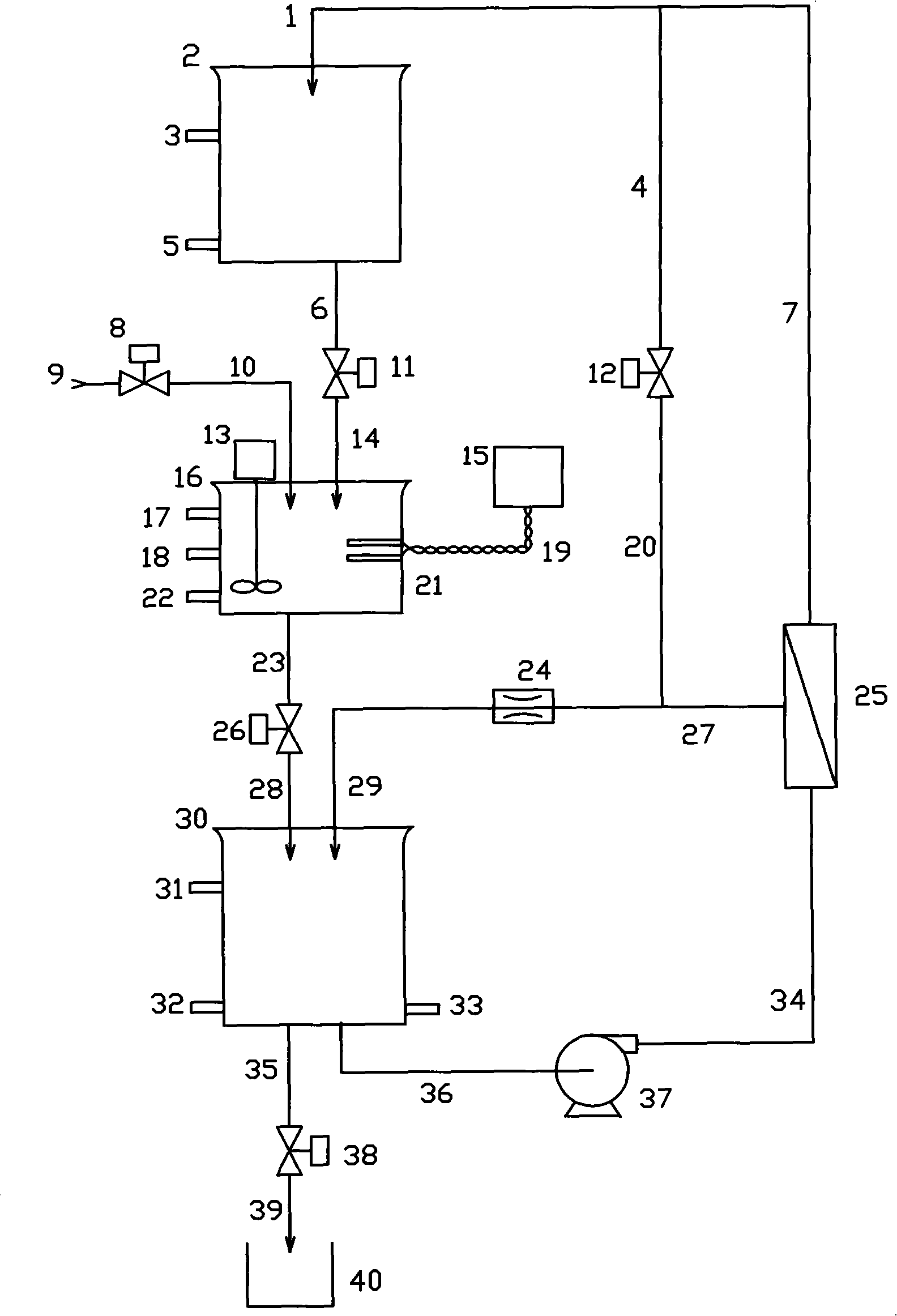

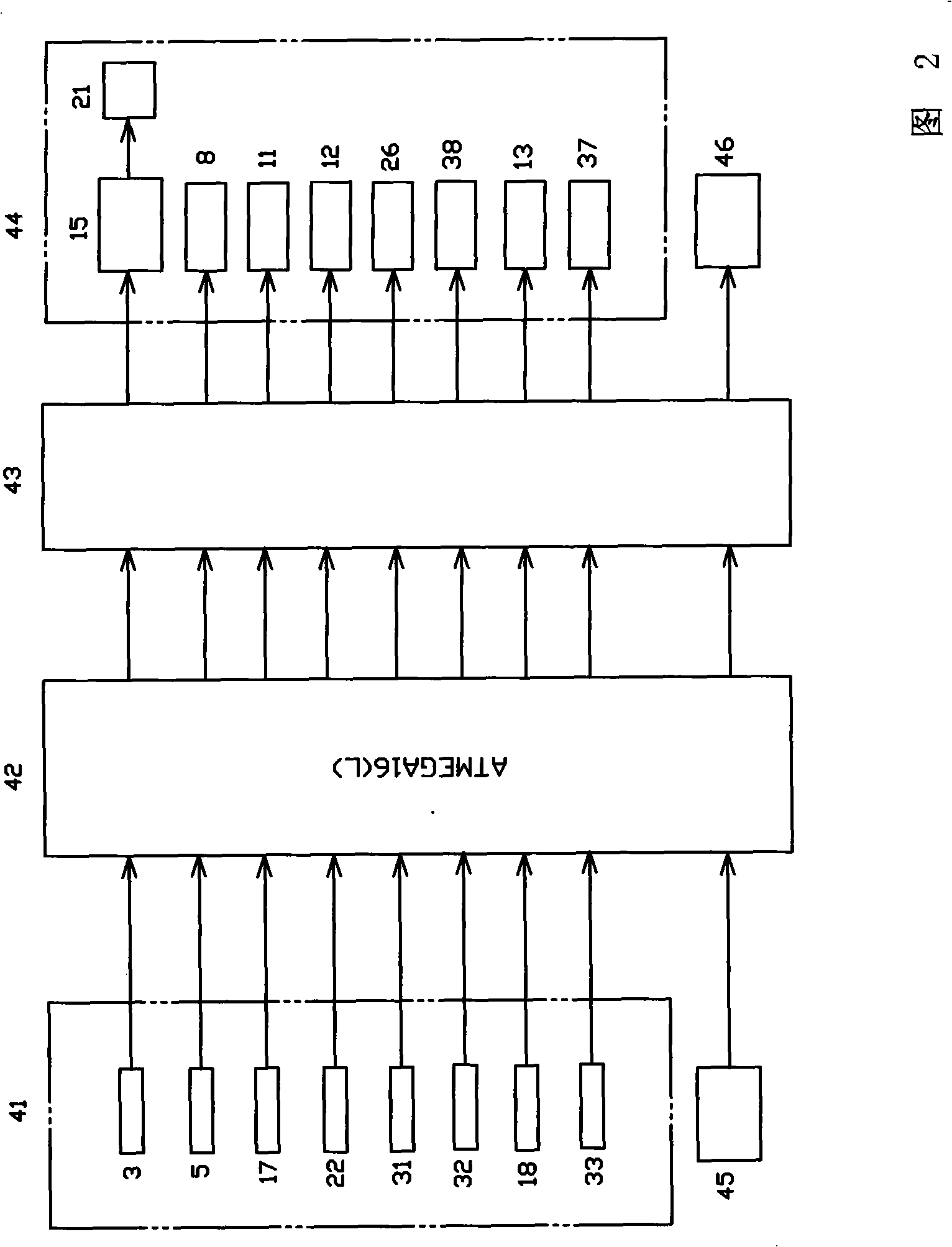

Production equipment and method of nano silver colloid

ActiveCN101264520AHigh product concentrationImprove efficiencyMixing methodsMixer accessoriesHigh concentrationSilver electrode

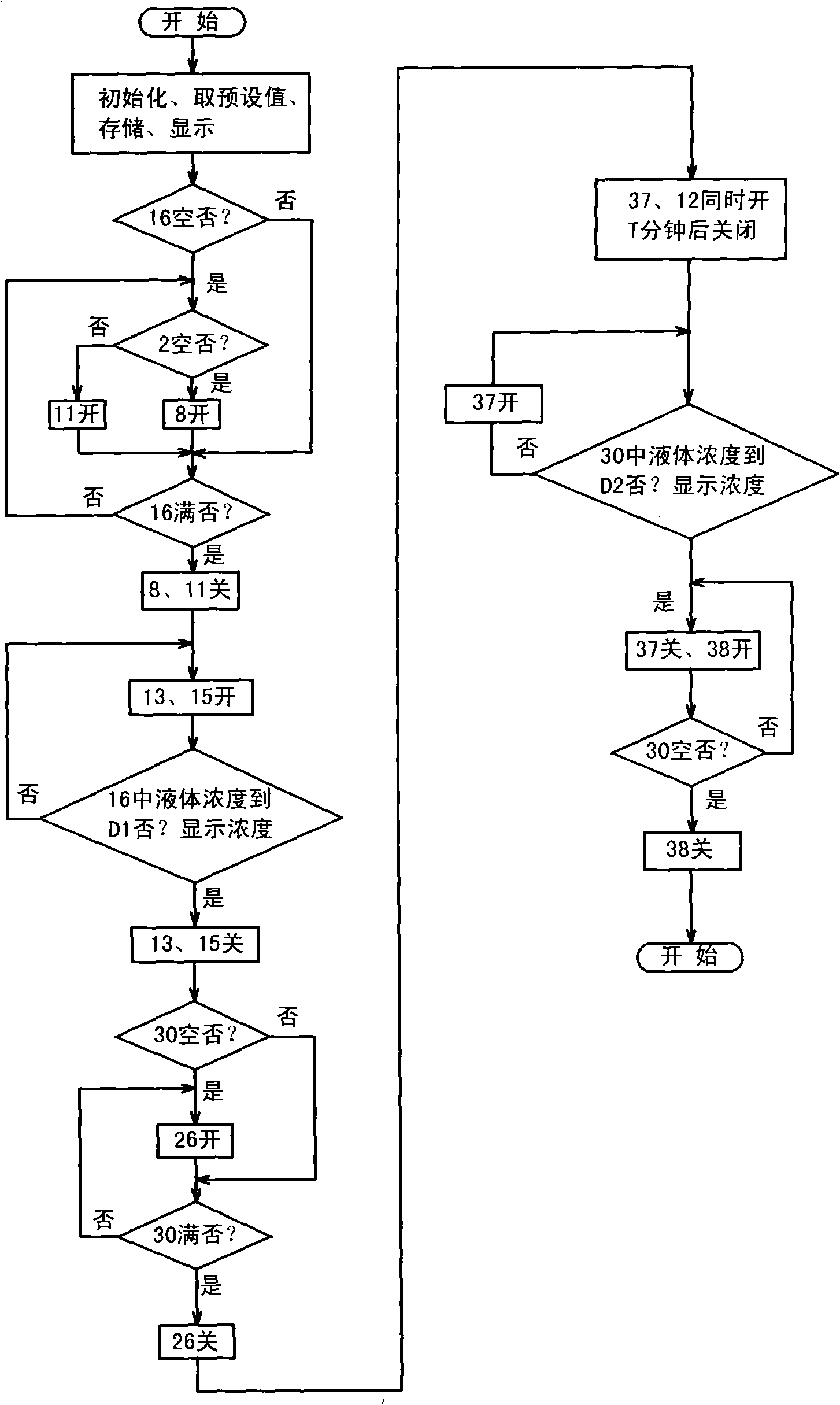

The invention discloses a nano-silver gel manufacturing equipment and method, in particular to a nano-silver gel manufacturing equipment and method, in which concentration is monitored automatically by a monolithic computer, and the technologies of silver electrode-stable electric-current technology and reverse osmosis separation are combined, aiming to solve the problems in prior art that the concentration of the nano-silver gel produced directly by silver electrode-stable electric current method and equipment is too low and no real-time concentration monitor is provided. The nano-silver gel manufacturing equipment and method has the advantages of low cost, high efficiency, green environmental protection, normal temperature production, no waste emission, no compound residue and high concentration.

Owner:ZHEJIANG SANHE NANOMETER SCI & TECH

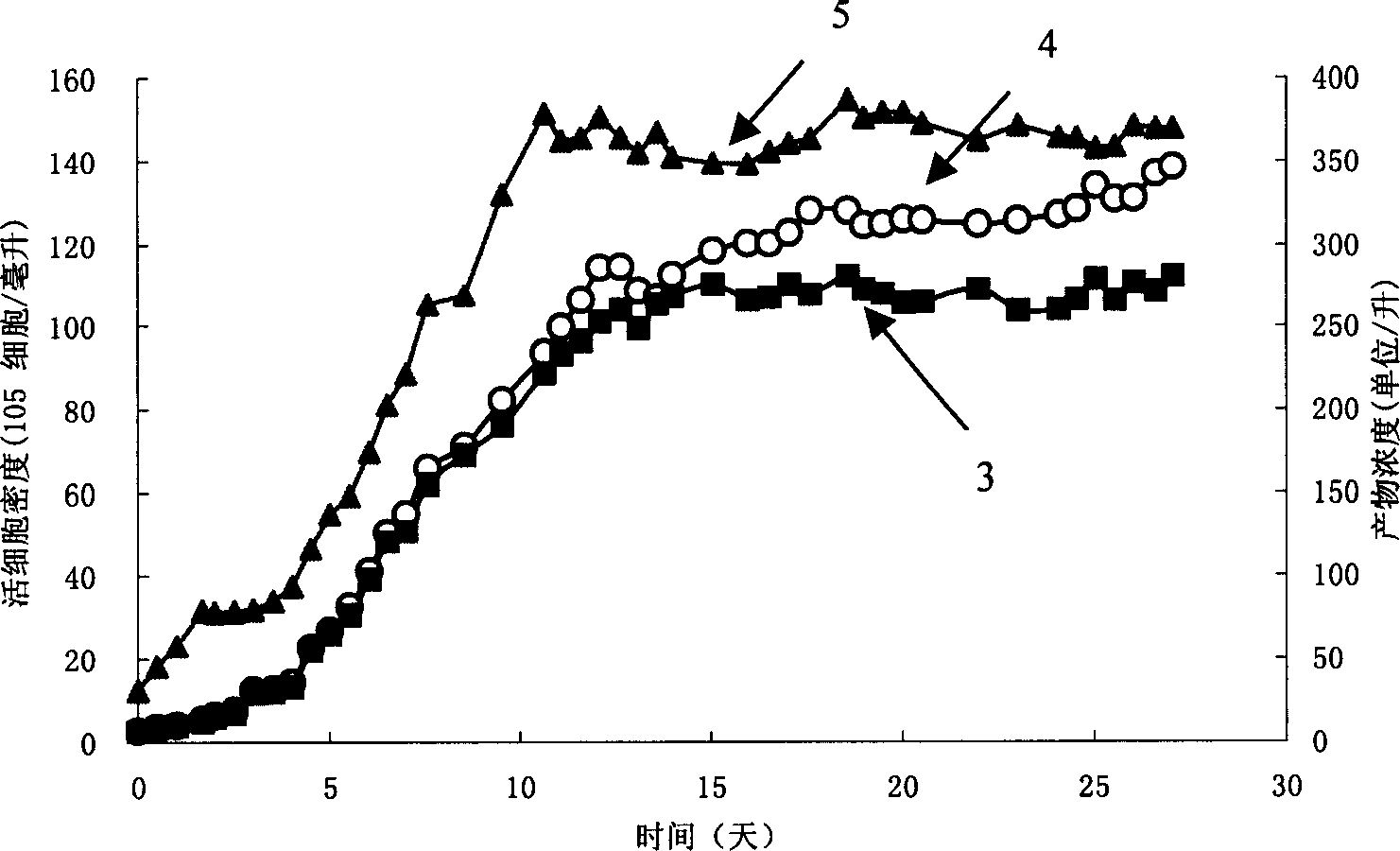

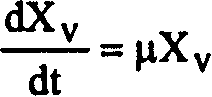

High-density continous pouring culture of animal cell

The invention opened a high density filling culture method of the animal cells. It study the metabolic rule of the cell growth, the nutrient consumption and the metabolic byproduct accumulation by studying theirs dynamics to determine and control the optimal nutritive condition. It feed the nutrient quality of cell growth by the stoichiometric relationship and the filling culture. The process can control the nutrient in a proper low concentration, so we can get the high density of the cells and the product concentration.

Owner:EAST CHINA UNIV OF SCI & TECH

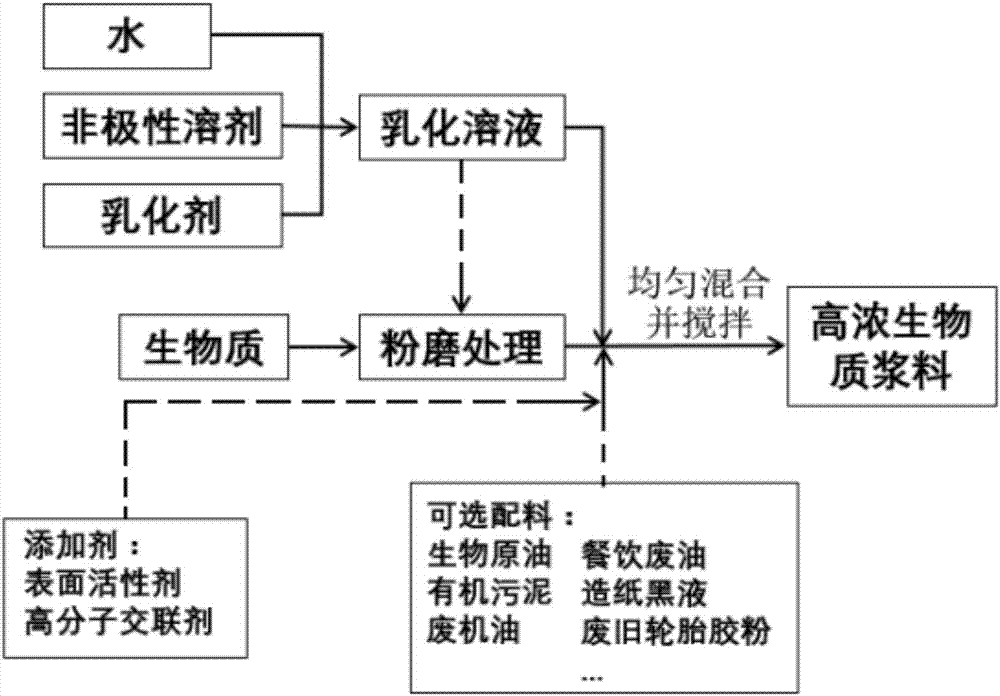

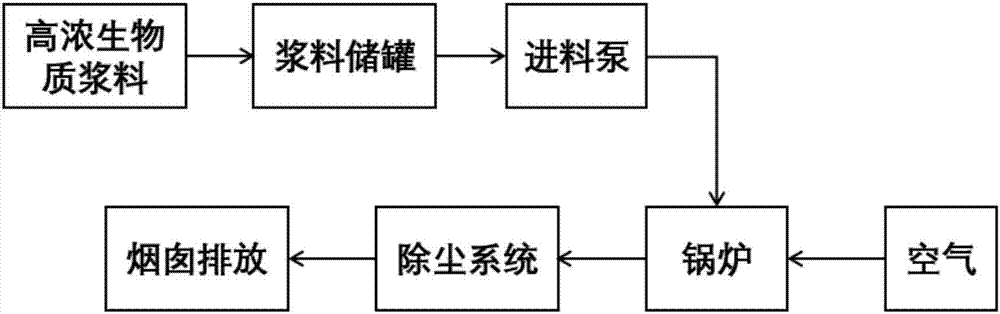

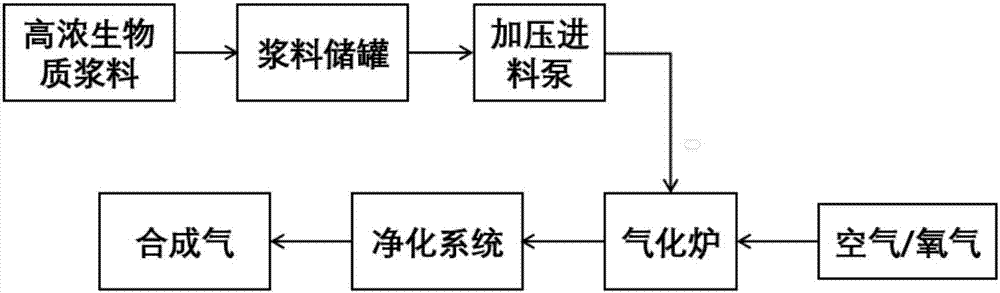

High-concentration biomass slurry as well as preparation method and application thereof

ActiveCN106967469AImprove overall operating efficiency and economic benefitsHigh product concentrationBiofuelsSolid fuelsSolventSurface modification

The invention discloses high-concentration biomass slurry as well as a preparation method and application thereof. The high-concentration biomass slurry is mainly obtained by carrying out surface modification of an emulsified solution on biomass particles; a swelling effect of the biomass particles is effectively inhibited, so that the high-concentration biomass slurry is formed. The preparation method of the high-concentration biomass slurry comprises the following steps: blending a nonpolar solvent, an emulsifying agent and selectable water into a stable emulsified solution under the conditions of heating and stirring; secondly, uniformly mixing crushed biomass particles with the emulsified solution, or adding the emulsified solution in the process of breaking and grinding biomass, and enabling the surfaces of the particles to be modified. The invention also provides the application of the high-concentration biomass slurry in the fields such as biomass power generation and preparation of synthetic gas by using the biomass. According to the high-concentration biomass slurry disclosed by the invention, the high-concentration biomass slurry is obtained by modifying the biomass particles; the obtained slurry can be conveyed to a downstream working procedure at lower energy consumption by adopting a slurry pump, and high-pressure stable feeding is realized.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Preparing process for mixed solvent of hydrogen peroxide operating fluid by anthraquinone method

InactiveCN1583546AIncrease production capacityHigh product concentrationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSolventUrea

The invention relates to a preparing process for mixed solvent of hydrogen peroxide operating fluid by anthraquinone method, and the mixed solvent is comprised by aromatic hydrocarbon, trioctyl phosphate, tetrabutyl urea. The volume percent ratios of each components are: 70% to 80% aromatic hydrocarbon, 5% to 25% trioctyl phosphate, 5% to 25% tetrabutyl urea. The operating fluid made up by the three-component solvent is used in the hydrogen peroxide preparing process by anthraquinone method, and comparing with traditional two-component solvent made up by aromatic hydrocarbon-trioctyl phosphate, the invention has larger producing capacity of peroxide, and the product thereof has higher concentration.

Owner:LIMING RES INST OF CHEM IND

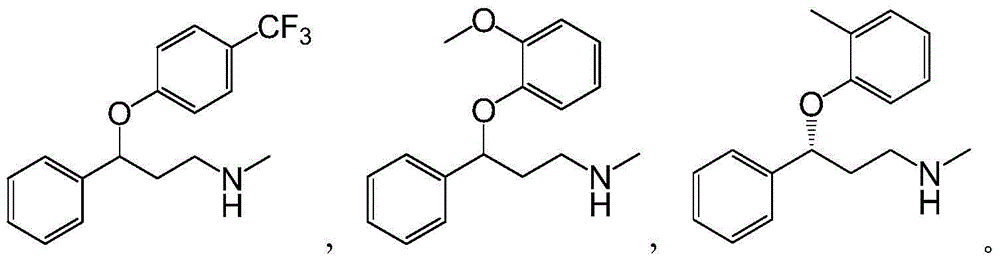

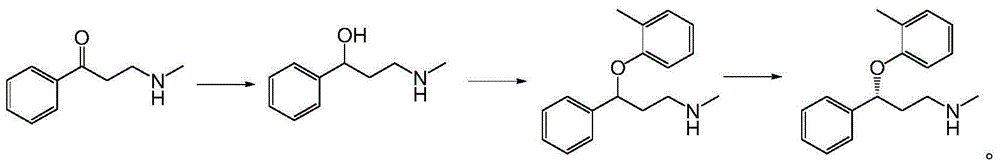

Applications of alcohol dehydrogenase in asymmetric reduction

ActiveCN104805142AHigh product concentrationHigh optical purity of the productFermentationAlcohol dehydrogenaseChemical synthesis

The invention discloses an enzyme-chemical synthetic method used for preparing chiral alcohol via asymmetric reduction with alcohol dehydrogenase, and further discloses a method used for preparing medicines, especially tomoxetine, of single configuration, with the chiral alcohol, wherein the medicines possesses a 3-aryloxy-3-aryl propylamine structure. Reaction conditions are mild; raw material cost is low; the method is friendly to the environment; reaction yield is high; product optical purity is high; and the method possesses obvious advantages compared with conventional asymmetric reduction preparation methods.

Owner:ABIOCHEM BIOTECH CO LTD

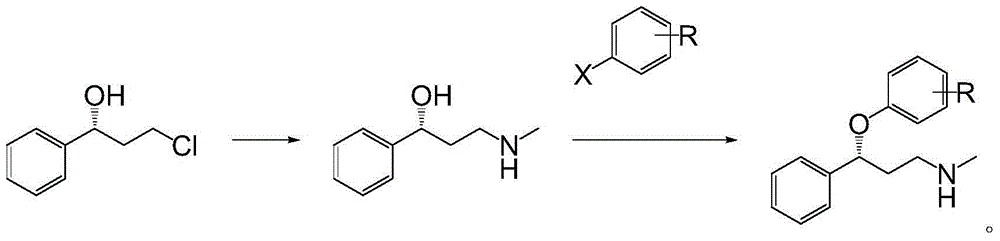

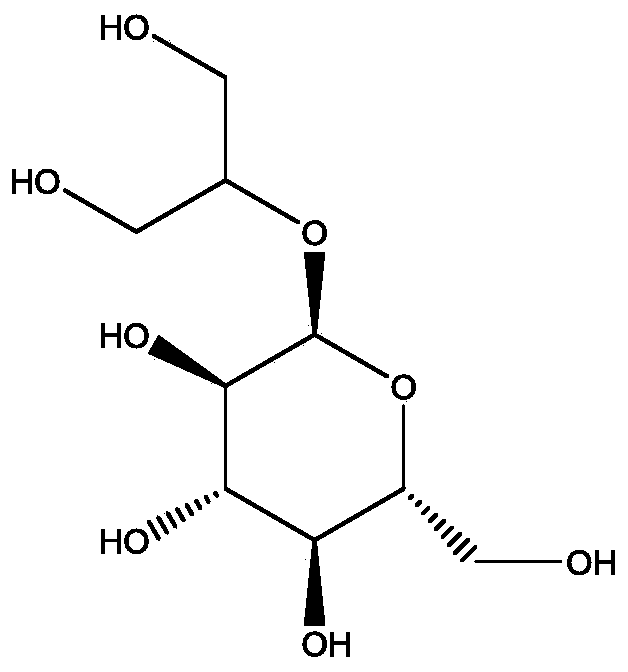

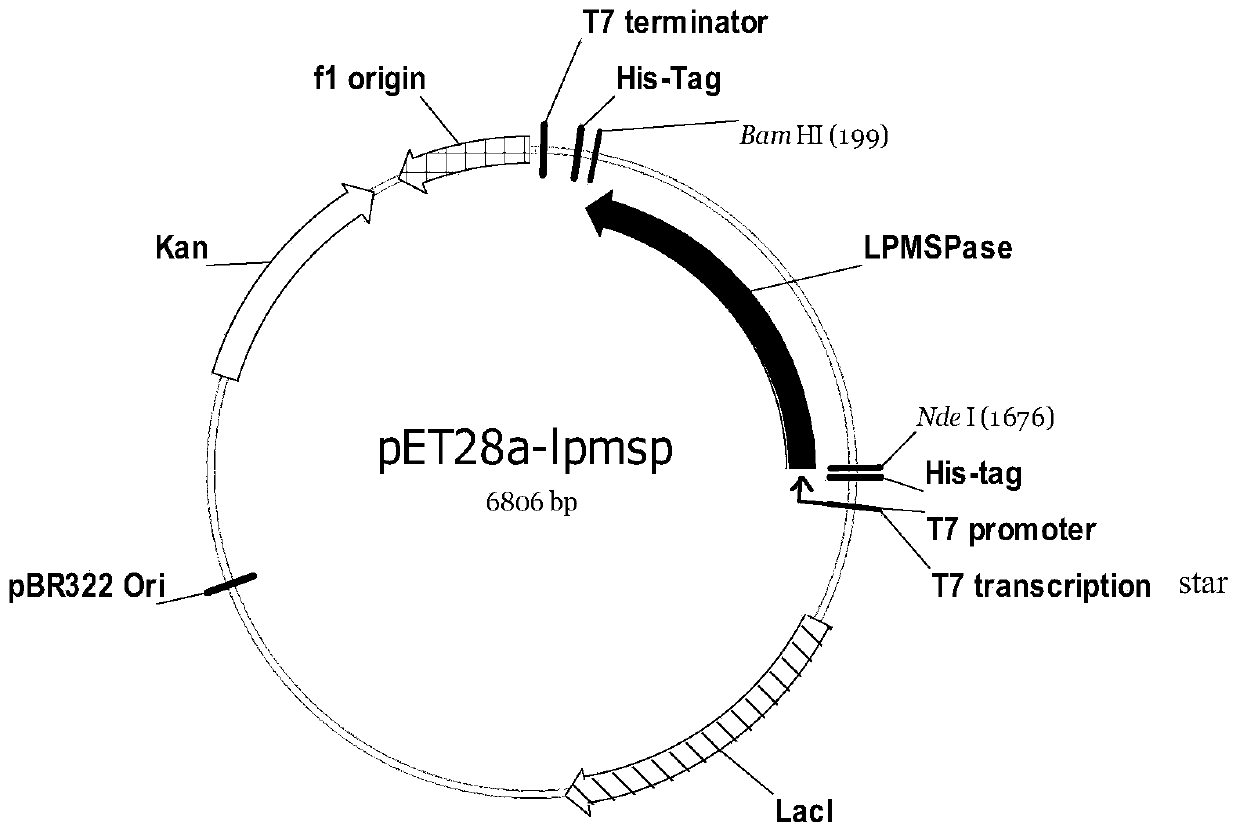

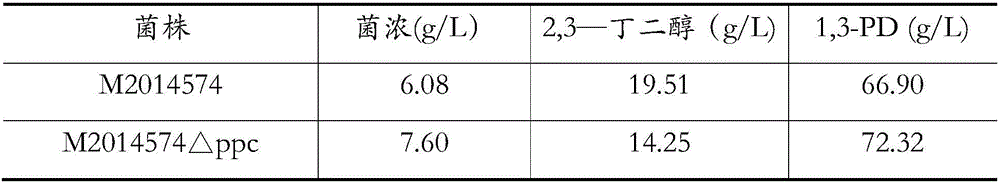

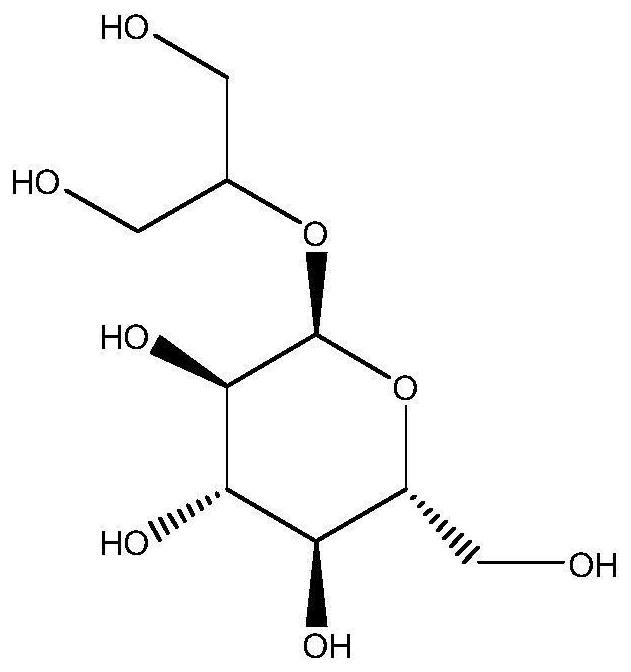

Application of glycerol-2-alpha-glucosylase in preparing 2-alpha-glyceryl glucoside

ActiveCN109988799AHigh catalytic activityHigh 2-alpha-GG contentHydrolasesFermentationEscherichia coliRecombinant escherichia coli

The invention discloses an application of glycerol-2-alpha-glucosylase in preparing 2-alpha-glyceryl glucoside, wherein an amino acid sequence of the glycerol-2-alpha-glucosylase is shown in SEQ ID NO.2. The recombinant Escherichia coli IEF-bpmsp208 for producing 2-alpha-GG can efficiently synthesize sucrose phosphorylase in cells, glycerol and sucrose are taken as substrates to efficiently catalyze the glycosylation reaction of glycerol, after 18-24 hours of reaction, a 2-alpha-GG solution with a conversion rate of more than 10% can be obtained, the conversion rate of the substrate sucrose ismore than 92%, the product concentration of the 2-alpha-GG is high, the conversion rate is high, and the separation and purification of the 2-alpha-GG are facilitated.

Owner:ZHEJIANG UNIV OF TECH

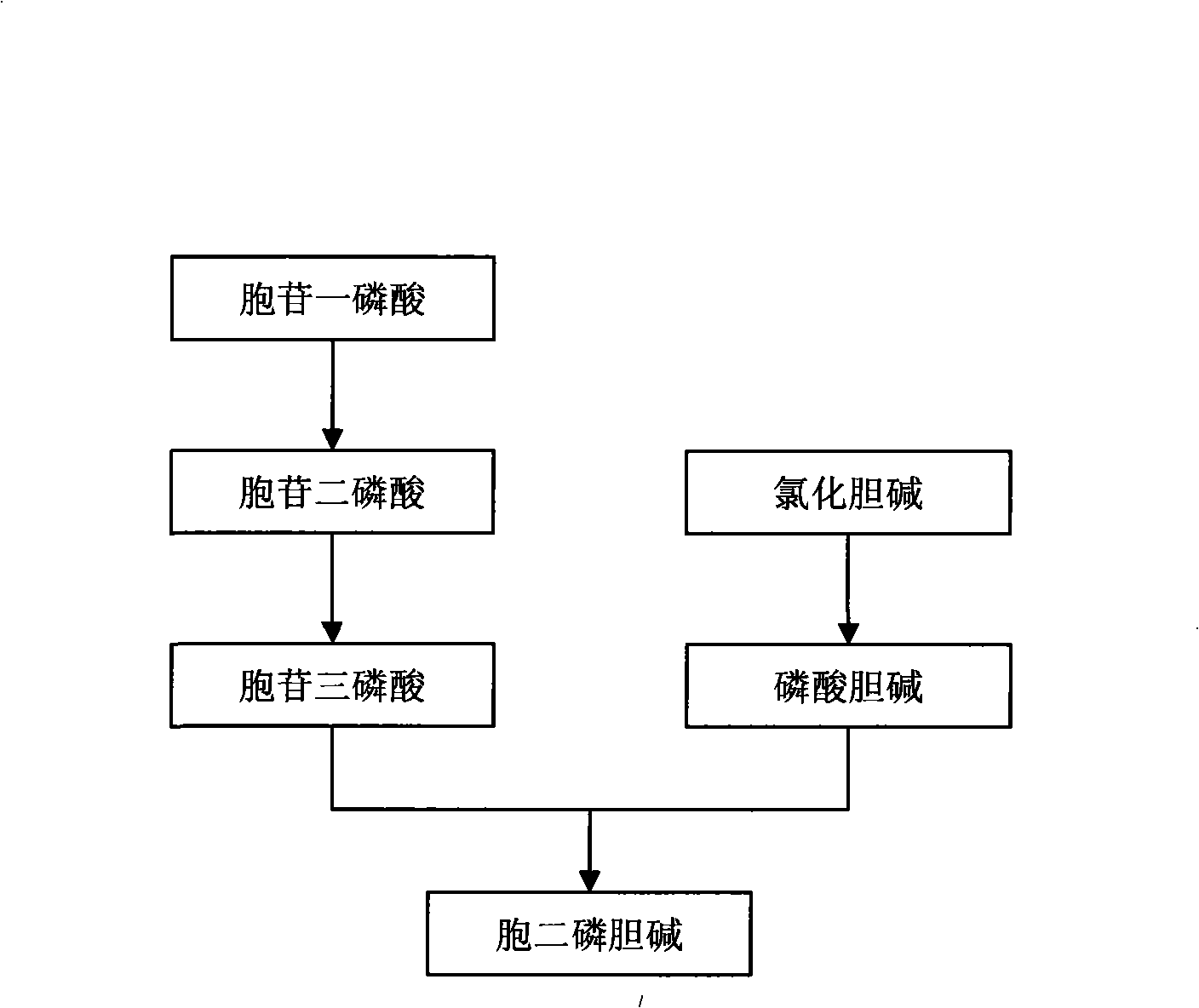

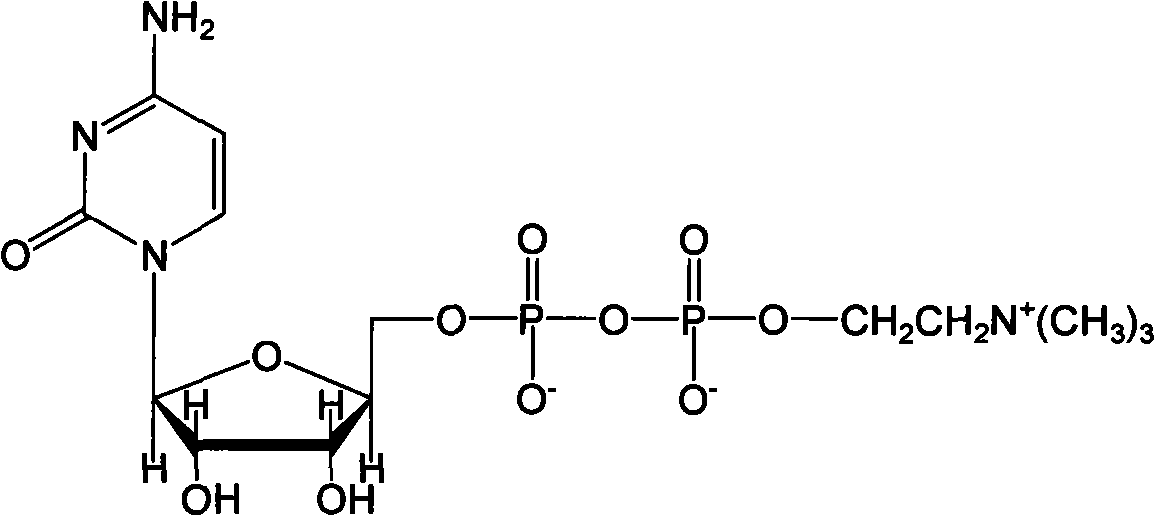

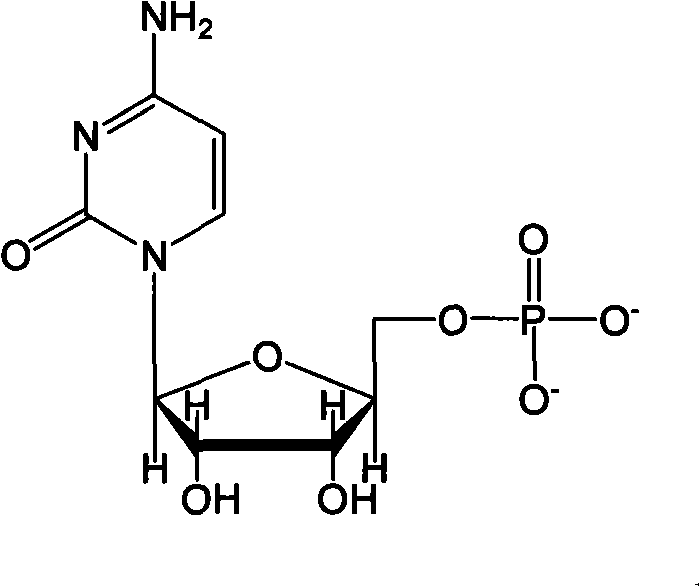

Method for preparing citicoline

InactiveCN101538598AIncrease profitAvoid investmentMicroorganism based processesFermentationPhosphate ionPhosphorylation

The invention discloses a method for preparing citicoline. The method comprises the following steps of taking choline chloride, phosphate ions and cytidine monophosphate or a precursor thereof as substrates, taking glucose, fructose, sucrose or maltose as an energy donor, adding a small-molecule chemical effect substance and utilizing the yeast-cell whole cells with permeability to catalyze and prepare the citicoline. By building a metabolic network model and metabolic flow analysis, adopting the small-molecule chemical effect substance to regulate and control metabolic flow so as to improve the efficiency of energy self-coupling and choline phosphorylation and utilizing the yeast cells with permeability to efficiently prepare the citicoline, the method has the advantages of greatly increasing product concentration and raising the utilization ratio of the substrates.

Owner:NANJING UNIV OF TECH

Mutant strain capable of realizing high-efficiency production of low-molecular pulullan and application thereof

ActiveCN107760608AEfficient productionIncrease production capacityFungiMicroorganism based processesBiotechnologyFermentation broth

The invention discloses a mutant strain capable of realizing high-efficiency production of low-molecular pulullan and application thereof, belonging to the technical field of mutagenesis of strains. The Aureobasidium pullulans UVMU6-1 capable of realizing high-efficiency production of low-molecular pulullan in the invention has an access number of CGMCC No.13178. The invention also provides application of the Aureobasidium pullulans UVMU6-1 to production of low-molecular pulullan. The strain provided by the invention has high pulullan production capability and can effectively improve the yieldof pulullan and reduce production cost; since the strain has low viscosity during fermentation, the concentration of produced pulullan in fermentation broth is high, and fermentation cost is effectively reduced; and a production method for producing pulullan via the strain is mild in conditions and friendly to environment, and the produced pulullan is green, natural, etc.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

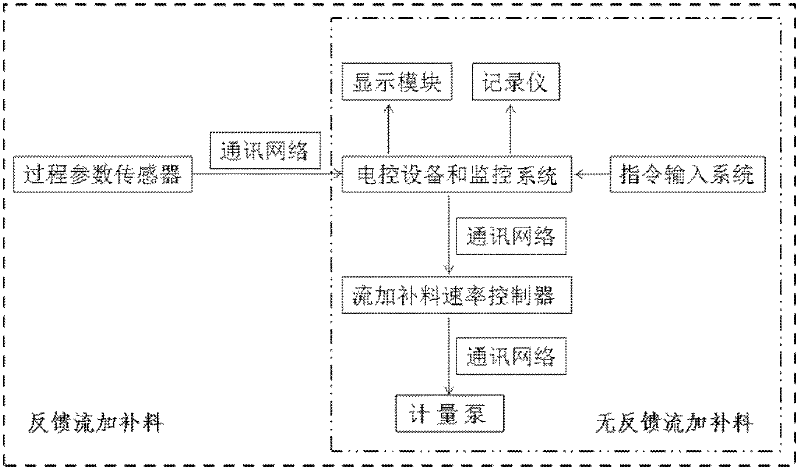

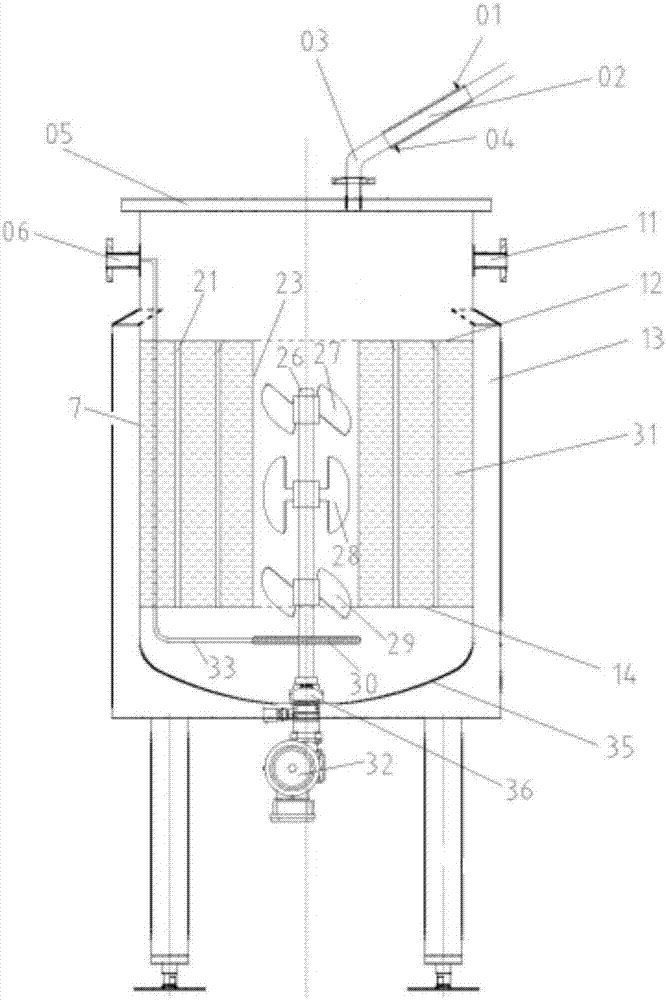

Accurate measurement fed-batch device for fermentation tank and fed-batch method for high-concentration solution

InactiveCN102533540AReduce laborReduce dilutionBioreactor/fermenter combinationsBiological substance pretreatmentsHigh concentrationFiltration

The invention relates to an accurate measurement fed-batch device for a fermentation tank and a fed-batch method for a high-concentration solution. The fed-batch device comprises the fermentation tank, a membrane filter, a measuring pump, a fed-batch tank, valves and an electronic monitoring system. A fed-batch tube valve, a filter rear valve, the membrane filter, a measuring pump liquid outlet valve, the measuring pump, a measuring pump liquid inlet valve and the fed-batch tank are connected in sequence through a pipeline from the fermentation tank; an exhaust steam valve is connected onto one side of the fermentation tank of the measuring pump liquid outlet valve by a pipeline; one end of a steam valve is connected onto one side of the filter rear valve of the fed-batch tube valve through a pipeline; the other end of the steam valve is connected with a steam pipeline S; and another exhaust steam valve is connected onto one side of the fermentation tank of the fed-batch tube valve through a pipeline. A fed-batch material is a low-water activity high-concentration solution, and bacteria in fed-batch liquid are removed by filtration by a membrane filtration method without steam sterilization. According to indicative indexes in the fermentation process, such as fermentation time, pH, foam height and fermentation respiratory quotient, accurate measurement fed-batch feed supplement is performed through the electronic monitoring system. The control precision of feed supplement amount reaches 1 percent or less. The accurate measurement fed-batch device is suitable for different-scale fermentation tanks for experiments and production.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Method for producing L-2-aminobutyric acid

The invention discloses a method for producing L-2-aminobutyric acid, and the method comprises the following step: catalyzing L-threonine utilized as a raw material through an enzyme catalysis system consisting of threonine deaminase, L-amino acid dehydrogenase and coenzyme regeneration systems, thus producing the L-2-aminobutyric acid. The method for producing theL-2-aminobutyric acid has the advantages that the raw material is low in price, the property is stable, and the production cost of the L-2-aminobutyric acid can be greatly lowered, the conversion rate and product concentricity are high, no influence caused by byproducts exists, and the method is suitable for industrialization application.

Owner:湖州颐盛生物科技有限公司

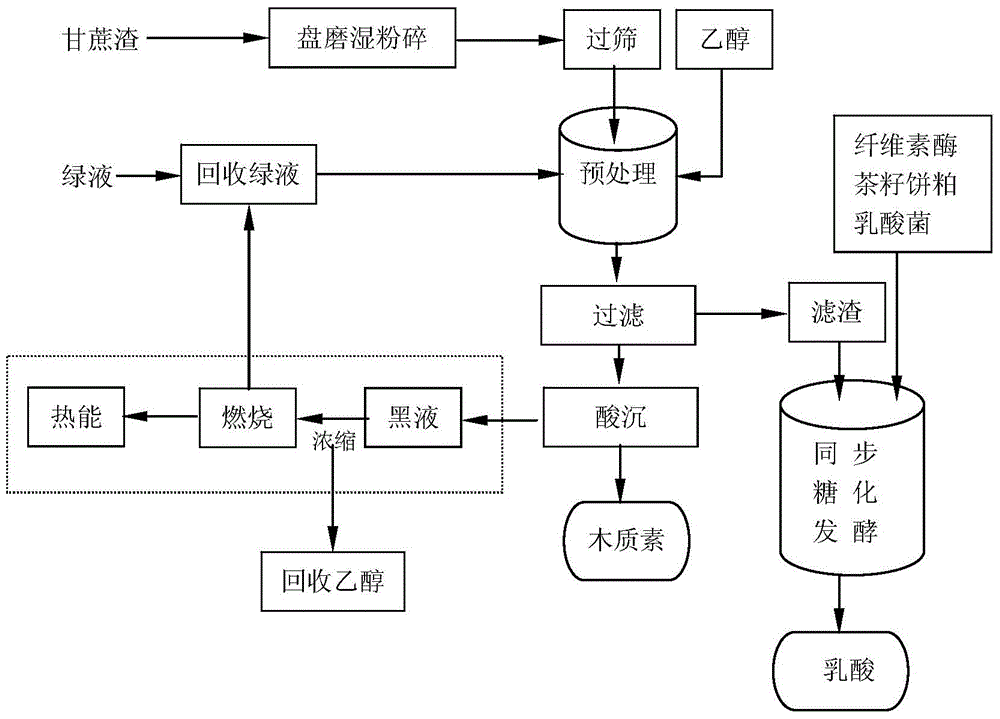

Method for producing lactic acid from bagasse

InactiveCN104694587ALarge amount of resourcesReduce lossesMicroorganism based processesFermentationCellulaseLACTIC ACID/UREA

The invention discloses a method for producing lactic acid from bagasse. The method comprises the following steps: grinding and filtering bagasse: adding water to the bagasse, carrying out wet grinding on the bagasse by virtue of a disc mill and sieving the bagasse; carryin gout green liquor-ethanol coupling pretreatment: carrying out a pretreatment course in a pressure-proof reaction kettle, adding the ground bagasse to the reactor and adding a green liquor, wherein heating temperature is 140-145 DEG C and reaction duration is 2-4h; filtering after the pretreatment so as to obtain solid residues; carrying out synchronous saccharification and fermentation: adding cellulase and lactobacillus strain to the solid residues obtained from pretreatment in a mode of taking the solid residues as a fermentation substrate, and reacting at 45 DEG C at pH value of 4.8-5.0 for 72-96h so as to produce the lactic acid. The method for producing the lactic acid from bagasse disclosed by the invention is high in conversion rate of hydrolyzing cellulase into cellulose and semi-cellulose; and the utilization rate of bagasse resource component is high and production cost is low.

Owner:BEIJING FORESTRY UNIVERSITY

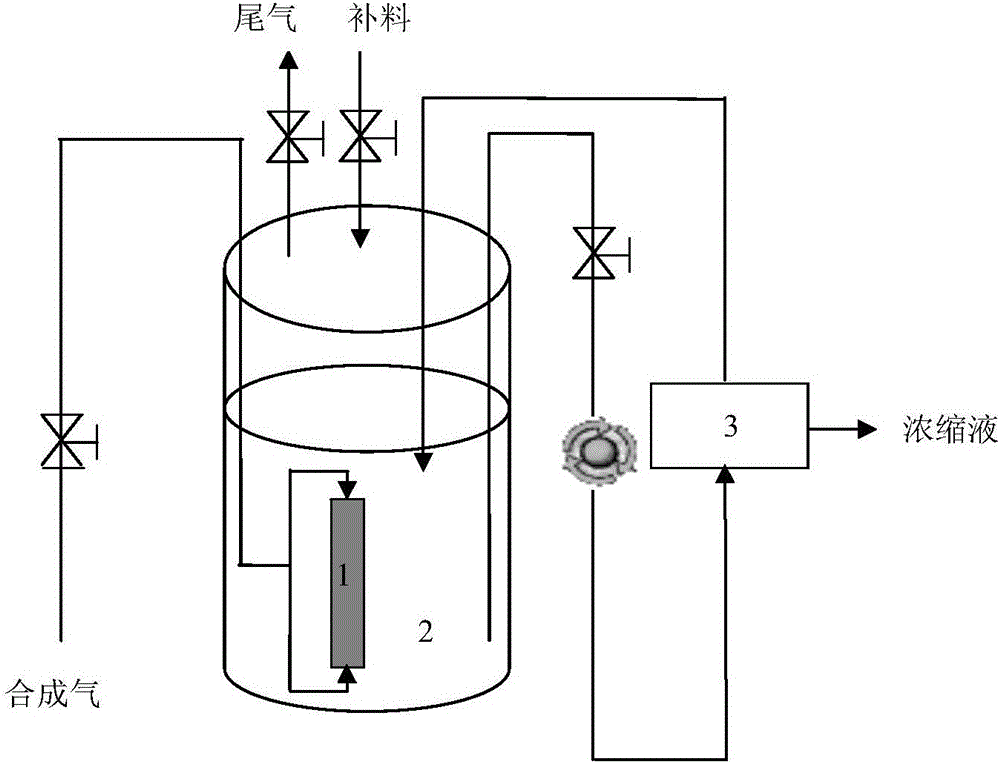

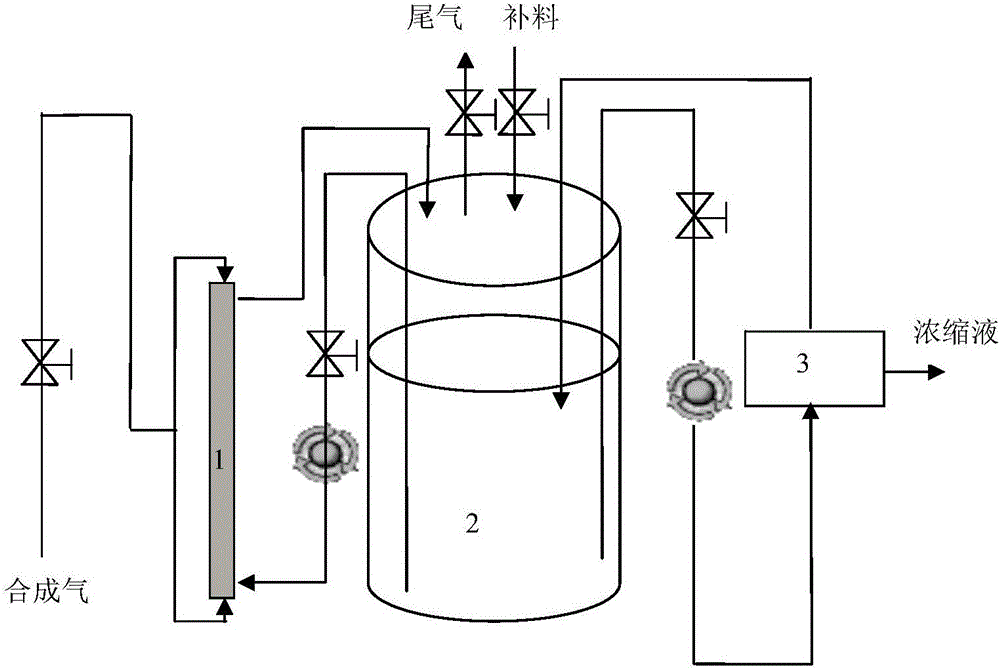

System for fermenting synthesis gas to produce alcohol and processing method thereof

InactiveCN106754259AIncrease membrane areaLower the air supply unitBioreactor/fermenter combinationsBiological substance pretreatmentsAlcoholMembrane technology

The invention provides a system for fermenting synthesis gas to produce alcohol and processing method thereof. The system comprises a bubble-free gas supply membrane component, a bioreactor and a pervaporation membrane component, wherein the bubble-free gas supply membrane component is placed in or out of the bioreactor, the gas inlet of the bubble-free gas supply membrane component is connected with the synthesis gas; a fermentation liquor outlet of the bioreactor is connected with a feed port of the pervaporation membrane component, a trapped liquor outlet of the pervaporation membrane component is connected with a material inlet of the bioreactor. The system and method provided by the invention improve the gas liquor transmission efficiency, the gas utilization efficiency, the microorganism cell concentration and the product concentration in a mixed gas fermentation process by use of the bubble-free gas supply membrane technology in double-end or single-end gas inlet, and in combination with a fermentation technology in fermentation-pervaporation separation coupling; the material consumption of cell culture is lowered, the cell concentration in the fermentation process is improved, the fermentation efficiency and the product concentration are improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

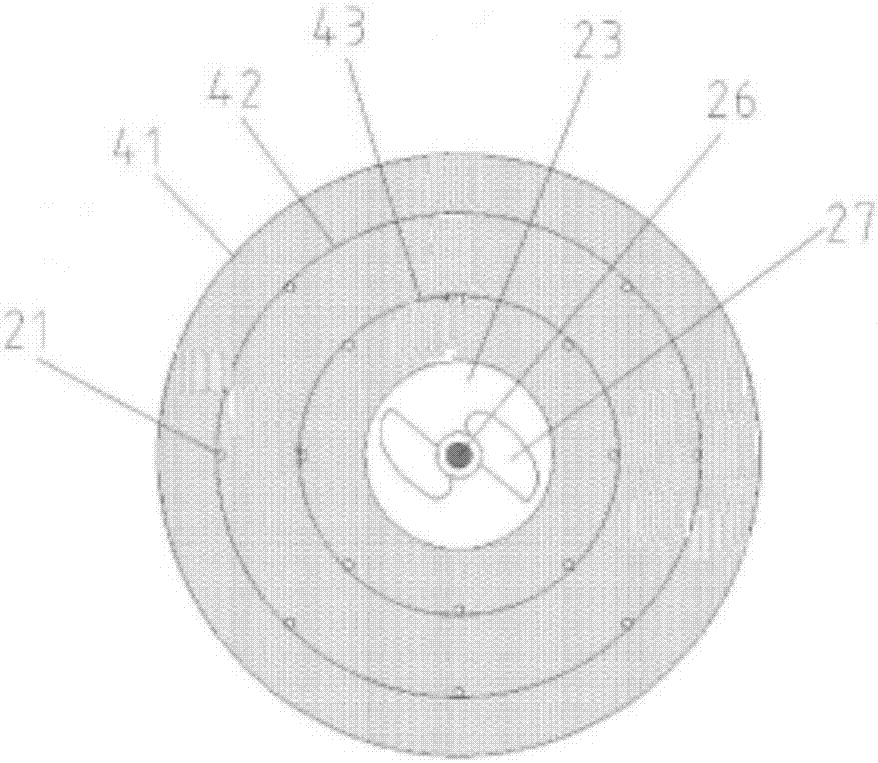

Fixed bed type cell bioreactor

ActiveCN108004122ATo offer comfortImprove mass transfer efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsHigh cellCulture fluid

The invention discloses a fixed bed type cell bioreactor which comprises a stirring device, a ventilation device, an exhaust device, a supplementing device, a fixed bed device, a water jacket interlayer and a controller. The fixed bed device is composed of an outer ring cylindrical shell, a middle ring cylindrical shell, an inner ring cylindrical shell, a hollow cylindrical flow guiding tube, an upper cover plate, a lower cover plate and a hollow flow guiding tubule; the defect that an existing fixed bed type cell bioreactor is not sufficient in cell density and mass transfer efficiency is overcome, the bioreactor is applicable to the adherent cell cultivation mode, the nutrient solution and oxygen mass transfer efficiency can be better improved, and the higher cell density and product concentration are achieved.

Owner:黄山市中新生物科技有限公司

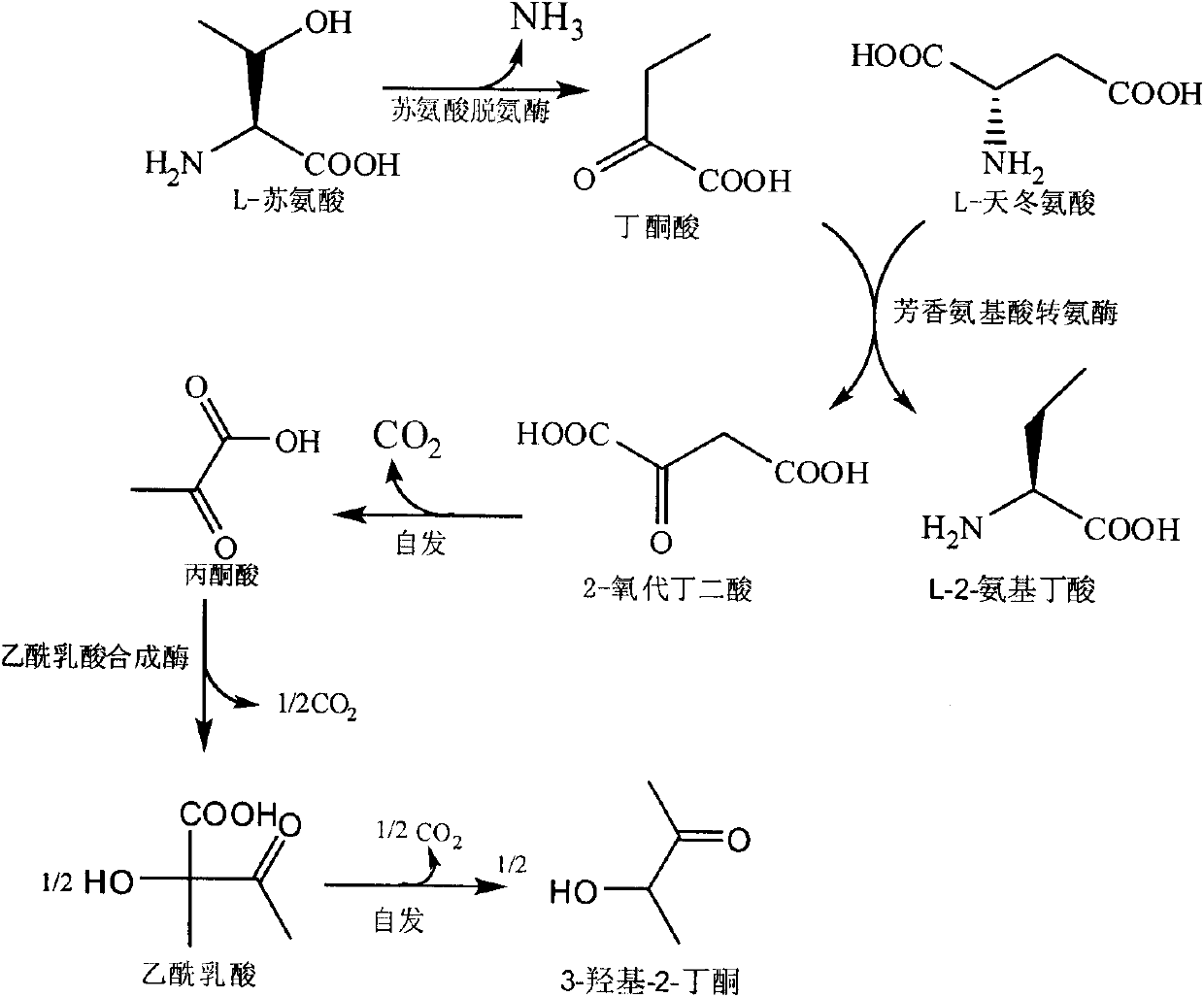

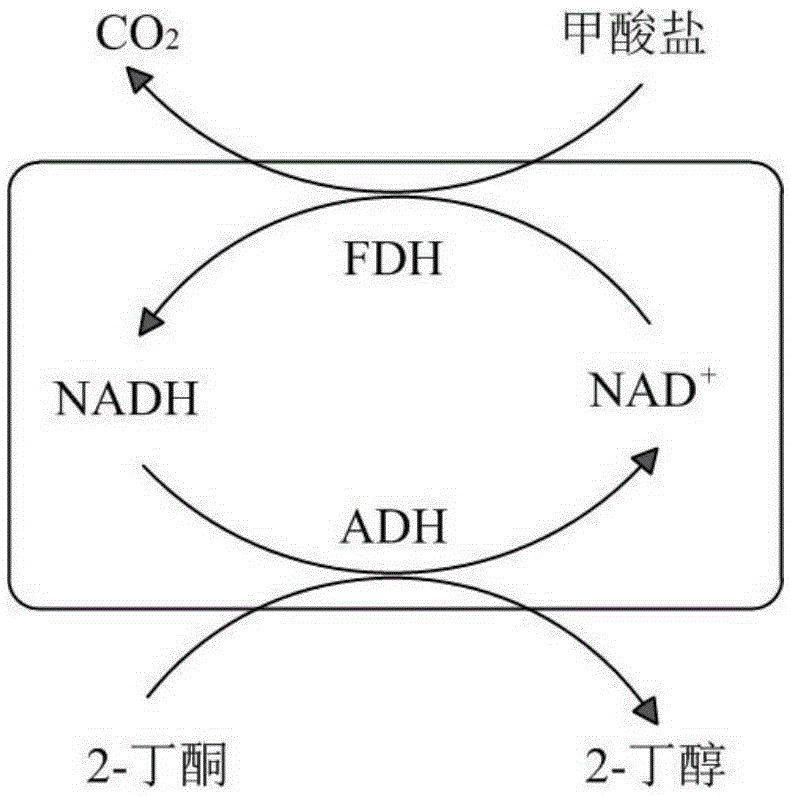

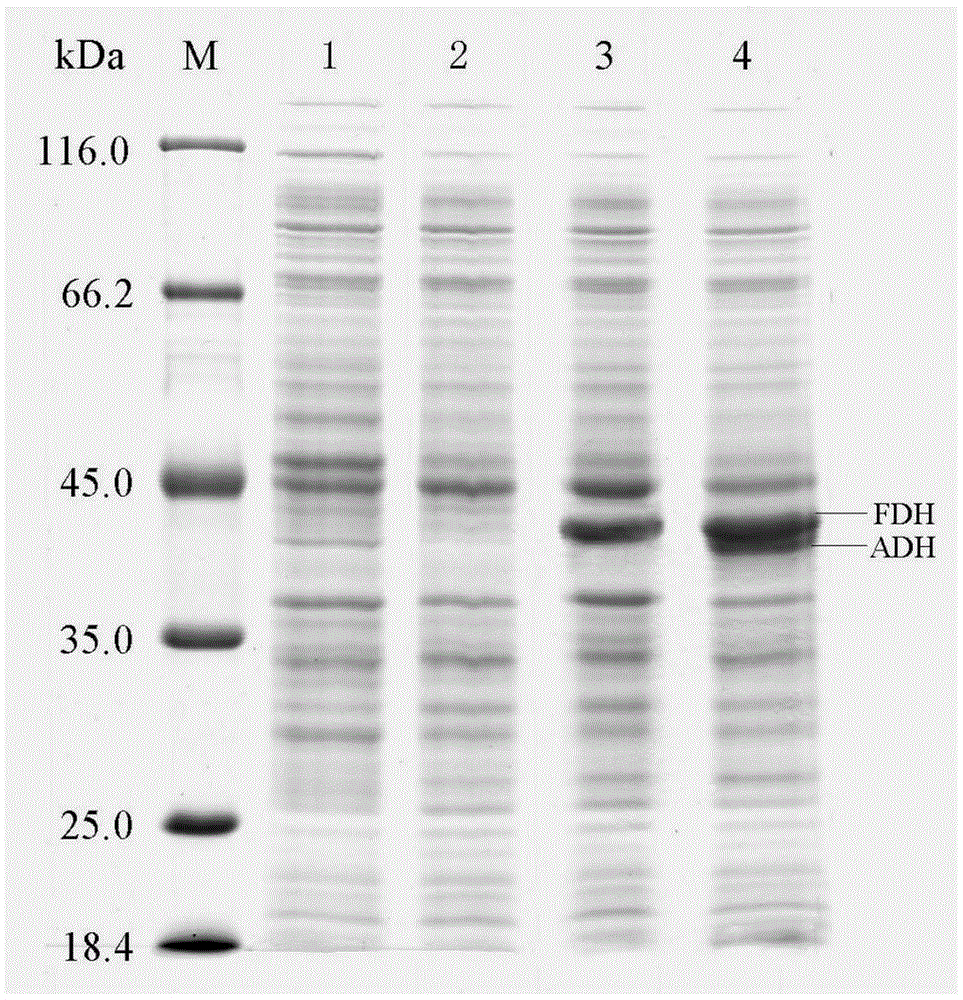

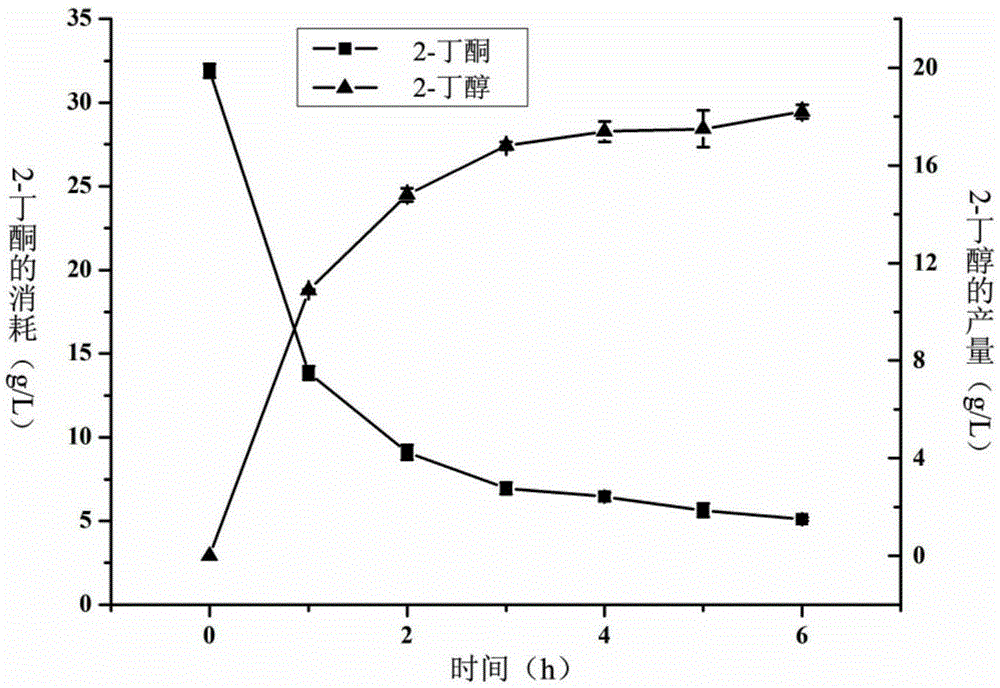

Recombinant escherichia coli and application thereof to 2-butanol production

ActiveCN105274041AAchieve regenerationLow costBacteriaMicroorganism based processesEscherichia coliRecombinant escherichia coli

The invention discloses recombinant escherichia coli. The recombinant escherichia coli is named Escherichia coli BL21 / pETDuet-fdh-adh and contains formate dehydrogenase fdh and alcohol dehydrogenase adh, wherein the nucleotide sequence of the fdh gene is as shown in SEQ ID No. 1, and the nucleotide sequence of the adh gene is as shown in SEQ ID No. 2. The recombinant escherichia coli is preserved in China Center for Type Culture Collection on September 23rd, 2015, and the preservation number of the recombinant escherichia coli is CCTCC No. M2015572. The invention further discloses application of the recombinant escherichia coli to 2-butanol production which uses the recombinant escherichia coli as a catalyst to catalyze 2-butanone to produce 2-butanol. Experiments prove that the concentration of the 2-butanol produced by using the recombinant escherichia coli can reach above 18.2 g / L (conversion rate reaches 0.68g / g), cofactor regeneration is achieved, and promising industrial application prospect is achieved.

Owner:SHANDONG UNIV

Method for preparing high value-added phenol products from pulping black liquor

The invention discloses a method for preparing high value-added phenol products from pulping black liquor. According to the method, the pulping black liquor is directly subjected to hydrothermal conversion after being simply treated, the yield of the phenol products is high, the product selectivity is good and the method has great industrial popularization value. The method comprises steps as follows: (1) the pulping black liquor is diluted by 5-10 times, adjusted with a pH agent until the pH ranges from 2 to 3 and then left to stand, and a supernatant layer and a lignin layer are obtained; (2) a sulfonating agent is added to the lignin layer solution in the step (1) after the supernatant layer is removed and stirred uniformly, and then the lignin layer solution is transferred to a reaction kettle for a hydrothermal conversion reaction; (3) after the reaction ends, a solution obtained after the reaction is filtered, filtrate is extracted with an extracting agent, and the high value-added phenol products are obtained after evaporation under reduced pressure.

Owner:QILU UNIV OF TECH

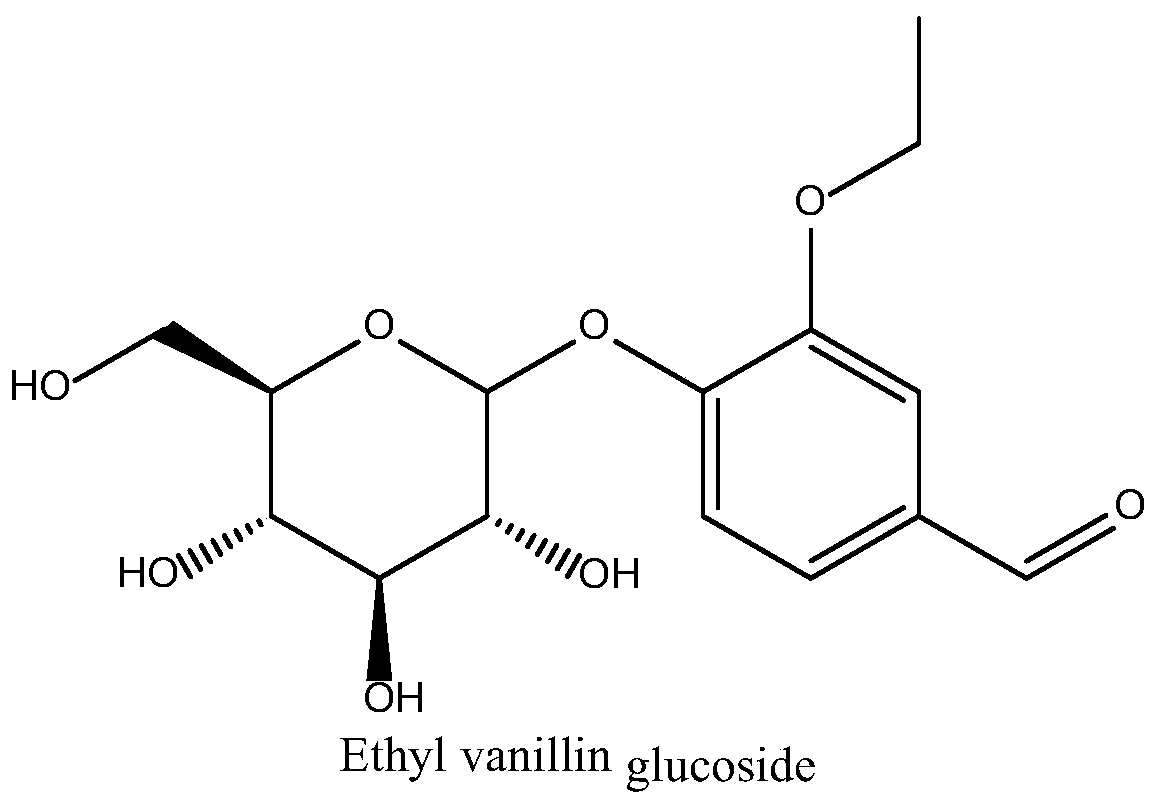

Application of glucosyltransferase in production of ethyl vanillin-alpha-D-glucoside

ActiveCN109762794AImprove catalytic conversion efficiencyHigh product concentrationTransferasesFermentationMicrobial agentEthyl vanillin

The invention discloses application of glucosyltransferase in production of ethyl vanillin-alpha-D-glucoside. The amino acid sequence of the glucosyltransferase is shown as SEQ ID NO.2. According to the application, the fermentation liquor obtained by fermentation culture of engineering bacteria containing a glucosyltransferase coding gene is taken as a microbial agent, maltose and ethyl vanillinare taken as substrates, and the pH value is 6.0-8.5, conversion reaction is executed under the condition of 20-40 DEG C, and after the reaction is completed, the reaction liquid is separated and purified to obtain the ethyl vanillin-alpha-D-glucoside. The microbial agent disclosed by the invention is used for biocatalytic production of the ethyl vanillin-alpha-D-glucoside, the substrate conversion rate is 80% or above, and the product concentration of the ethyl vanillin-alpha-D-glucoside is high, the conversion rate is high, and recovery and purification the ethyl vanillin-alpha-D-glucoside prepared by a biological method are facilitated.

Owner:SHENZHEN SHINESKY BIOLOGICAL TECH CO LTD

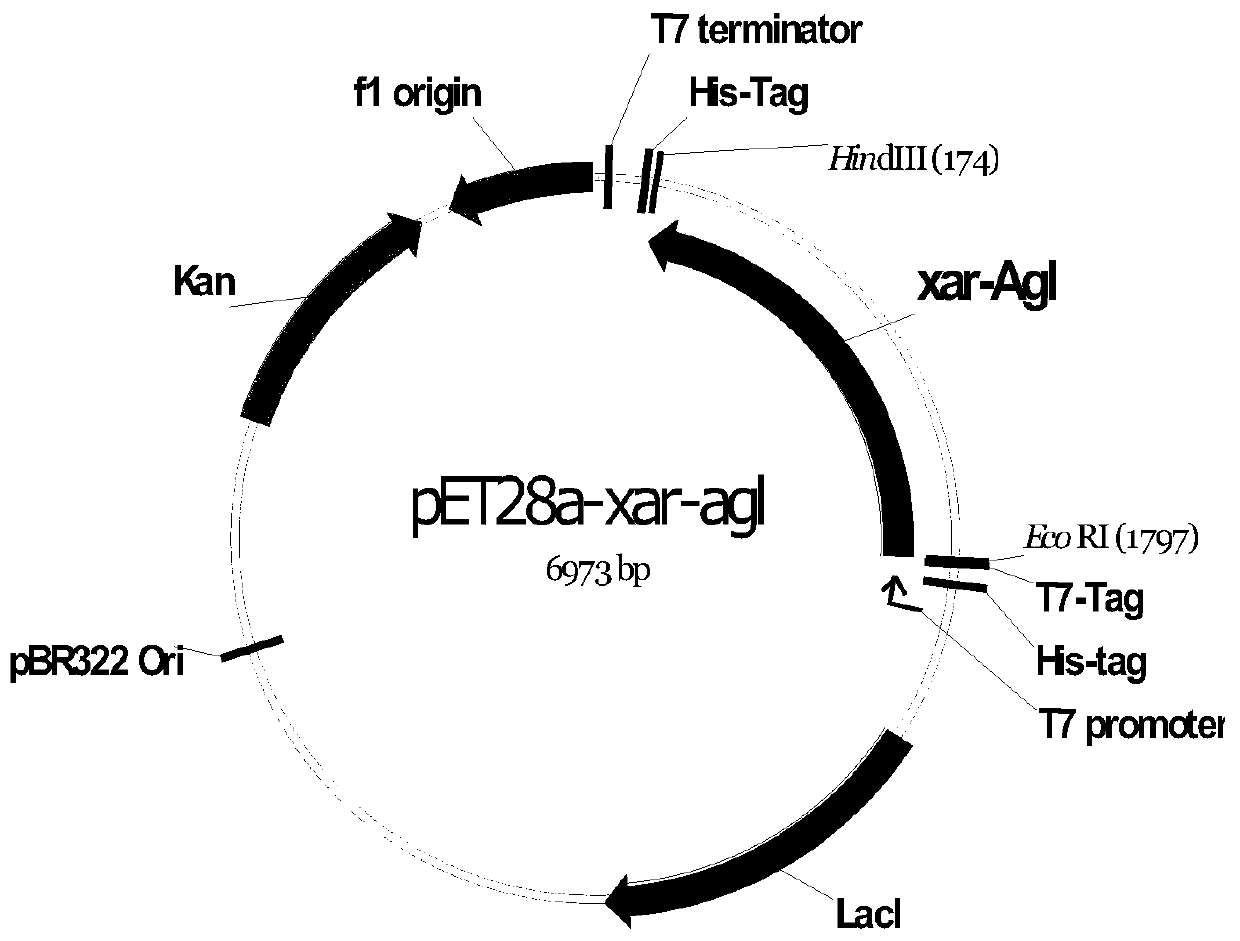

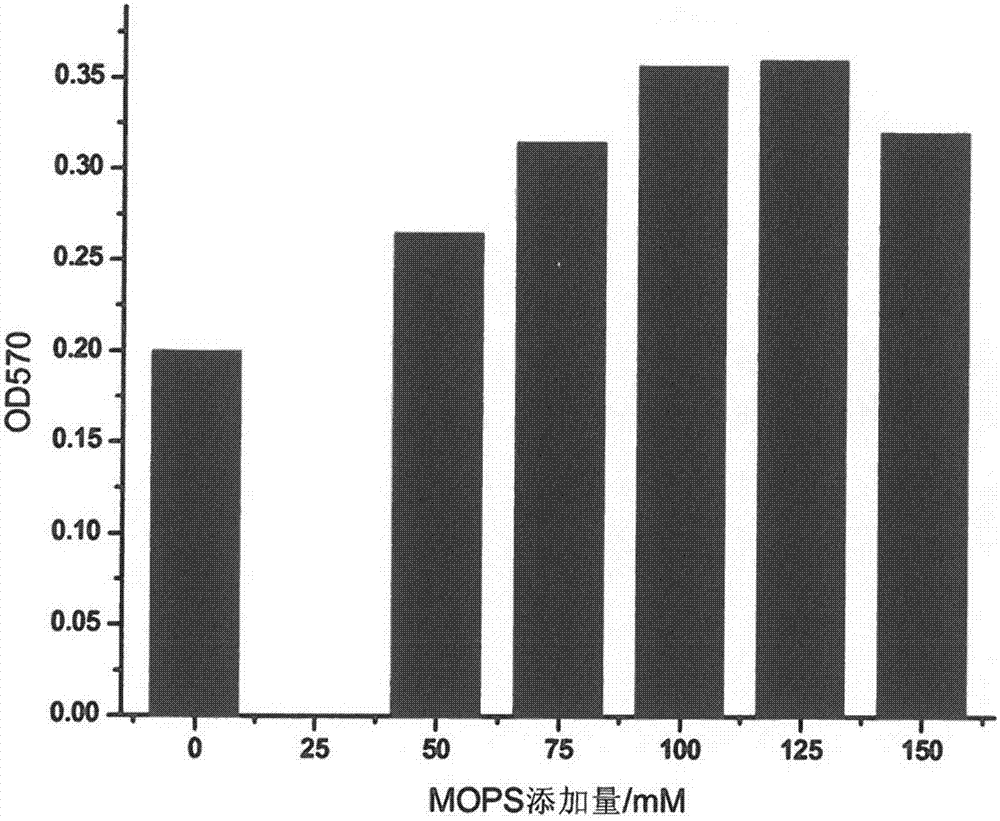

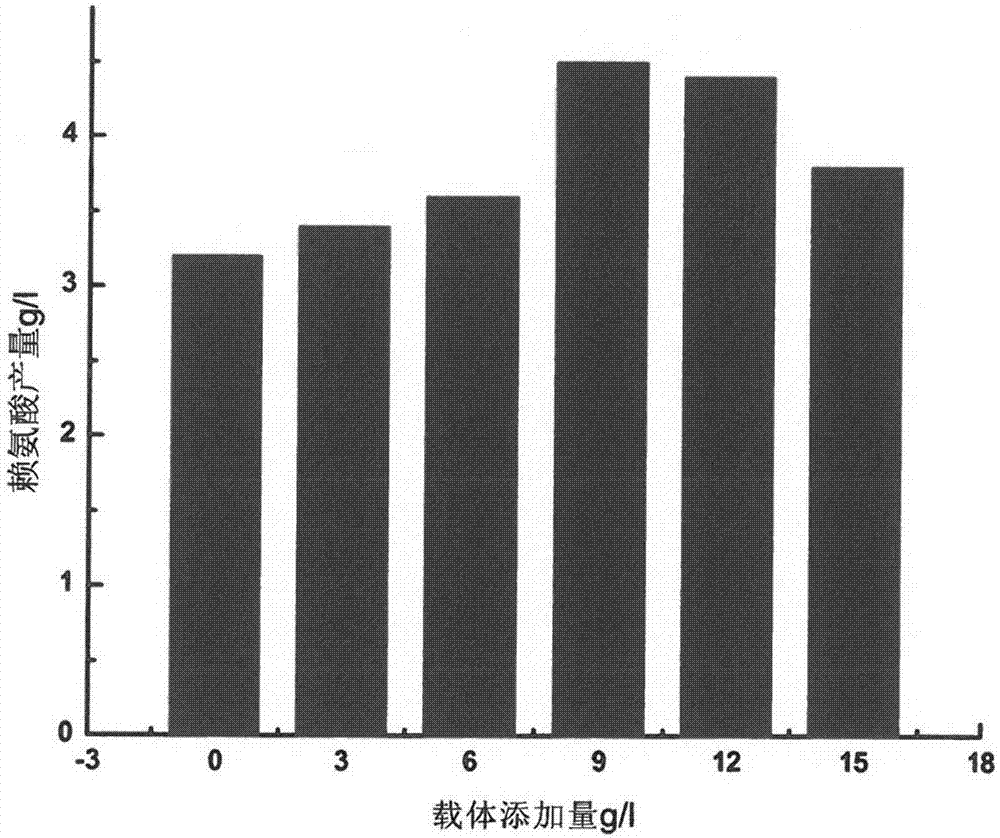

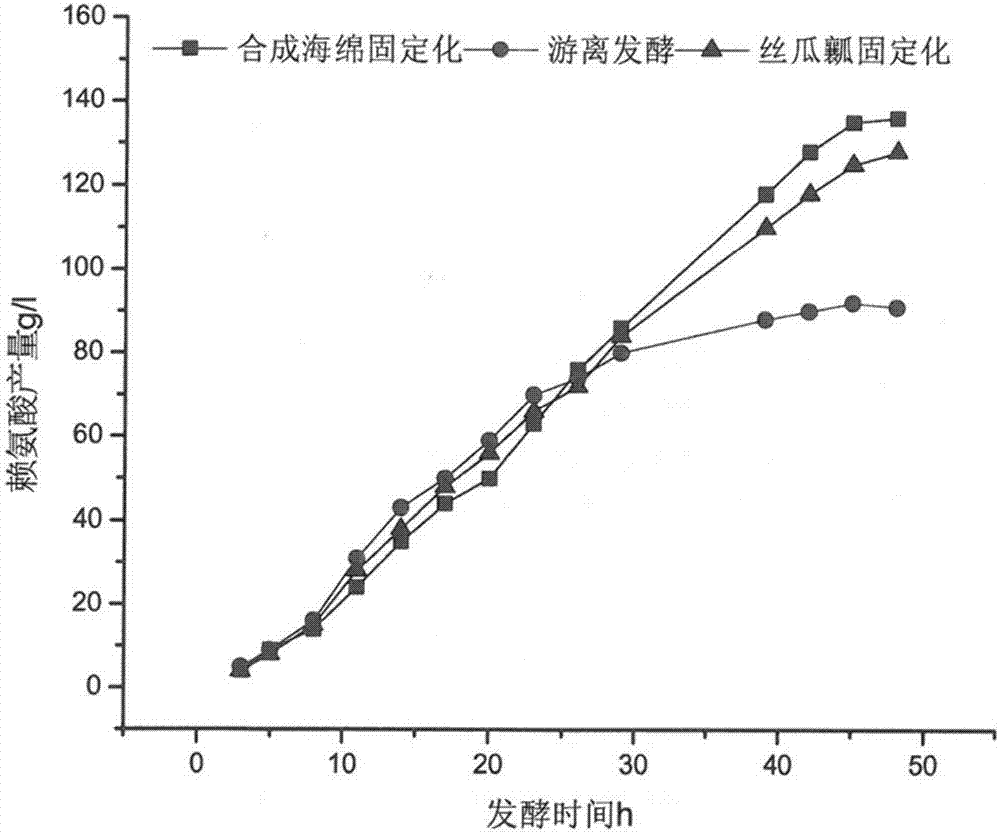

Escherichia coli immobilizing method and method for producing L-lysine through fed-batch fermentation of immobilized escherichia coli

ActiveCN107446909AImprove adhesionLarge adsorption capacityBacteriaMicroorganism based processesEscherichia coliAdditive ingredient

The invention discloses an escherichia coli immobilizing method which comprises the following steps: feeding the activated escherichia coli into a container with a culture medium, a pretreated porous mesh material and MOPS, and performing immobilizing culture so as to adsorb the escherichia coli on the porous mesh material in the immobilizing culture process. The invention also discloses a method for producing L-lysine through fed-batch fermentation of immobilized escherichia coli, which comprises a fermentation process and a fed-batch process, wherein the nutritional ingredients adopted in the fed-batch process are glucose and ammonium sulfate. The MOPS can enhance the adhesion effect of escherichia coli on the surface of the immobilizing material; the L-lysine is fermented by use of the immobilized escherichia coli; the L-lysine concentration is increased to 136g / L from 90g / L of free cell fermentation; by repeating the fermentation by 8 batches, higher production efficiency of L-lysine still can be maintained, and the final L-lysine yield of each batch is 150g / L on average.

Owner:NANJING TECH UNIV

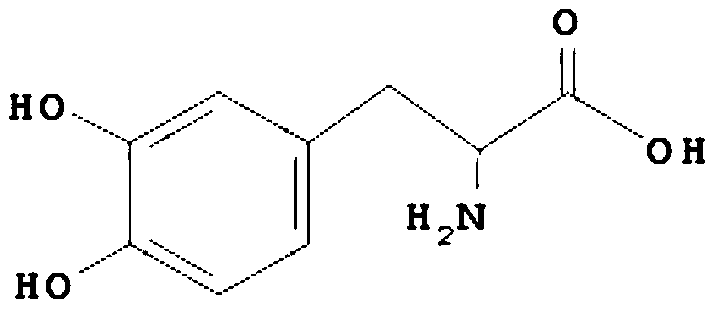

Method for improving efficiency of catalytic production of L-dopa by tyrosine phenol lyase

PendingCN110055291AImprove conversion rateHigh product concentrationFermentationCarbon-carbon lyasesKanamycinSulfite salt

The invention relates to a method for improving the efficiency of catalytic production of L-dopa by tyrosine phenol lyase. The method is characterized by comprising the steps: (1) selecting a single colony, inoculating a test tube containing an LB culture medium with the single colony, adding kanamycin (50 mg / L) at the temperature of 30-37 DEG C, at the speed of 220 rpm, culturing for 12-16 h, andthus obtaining primary seeds; (2) inoculating a shaking flask containing a fermentation culture medium with the primary seeds, and culturing for 10-12 h; (3) centrifuging, collecting bacteria to obtain the bacteria, breaking cells by ultrasound, and centrifuging at high speed to obtain a supernatant enzyme liquid; and (4) adding an enzyme solution into a substrate solution, stirring evenly, and carrying out sealed oscillation reaction at the temperature of 25 DEG C, wherein the substrate solution comprises 14-16 g / L of sodium pyruvate, 10-12 g / L of catechol, 50-60 g / L of ammonium acetate, 2-5g / L of sodium sulfite, and 1-3 g / L of EDTA, and the pH is adjusted to 7.5-8.5. The concentration of the reaction product reaches 20 g / L or more, and 10-30 g / L of L-dopa crystals are added to induce the product to crystallize in advance. The method greatly improves the conversion rate and the product concentration, improves the product quality, has simple process, low cost and high yield, and hasthe application value of industrial production.

Owner:ZHEJIANG UNIV OF TECH +1

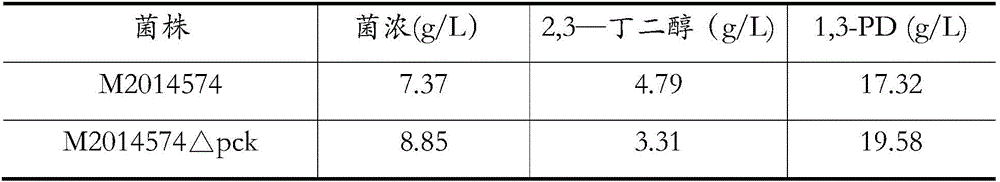

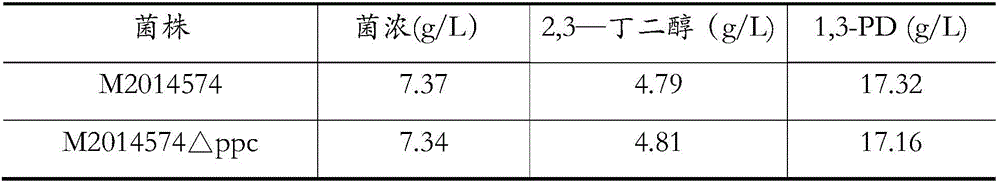

Improved biosynthesis method for 1, 3-propylene glycol

ActiveCN106191136ABacteria grow fastHigh product concentrationMicroorganism based processesFermentationPropylene glycolIsopropylene glycol

The invention discloses an improved biosynthesis method for 1, 3-propylene glycol. The improved biosynthesis method includes knocking out genes pck in Klebsiella pneumoniae to efficiently convert glycerin so as to produce the 1, 3-propylene glycol. The improved biosynthesis method has the advantages that synthesis of 2, 3-propylene glycol which is a byproduct can be reduced to a great extent after the genes pck are knocked out, and accordingly the level of production for converting the glycerin by the aid of the Klebsiella pneumonia to generate the 1, 3-propylene glycol can be upgraded.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for separation and purification of lecithin and cephalin

InactiveCN1546496AHigh product concentrationHigh stationary phase utilizationPeptide preparation methodsPhosphatide foodstuff compositionsChromatographic separationAlcohol

The invention relates to a segregation and purification technology, in particular a method for separation and purification of lecithin and cephalin, wherein the mixture with main constituents of lecithine and cephalin obtained by pre-processing natural phosphatide is used as the raw material, silica gel is used as the fixed phase, methylene chloride - methanol is used as the mobile phase, aminoethyl alcohol is used as displacer for replaced chromatographic separation.

Owner:WUHAN UNIV

Application of a glycerol-2-α-glucosylase in the preparation of 2-α-glycerol glucoside

ActiveCN109988799BHigh catalytic activityHigh 2-alpha-GG contentHydrolasesFermentationEscherichia coliSucrose phosphorylase

The invention discloses the application of a glycerol-2-α-glucosylase in the preparation of 2-α-glycerol glucoside. The amino acid sequence of the glycerol-2-α-glucosylase is represented by SEQ ID NO.2 Show; The recombinant Escherichia coli that produces 2-α-GG of the present invention, i.e. recombinant Escherichia coli (Escherichia coli) IEF-bpmsp208 can efficiently synthesize sucrose phosphorylase in the cell, take glycerol and sucrose as substrates, efficiently catalyze glycerol Glycosylation reaction, reaction for 18-24 hours, more than 10% 2-α-GG solution can be obtained, and the conversion rate of substrate sucrose is greater than 92%, the product concentration of 2-α-GG is high, and the conversion rate is high , which is beneficial to the separation and purification of 2‑α‑GG.

Owner:ZHEJIANG UNIV OF TECH

Method for producing recombinant human epidermal growth factor by using gene engineering colibacillus

InactiveCN1400313ASimple separation processShorten the production cycleBacteriaPeptide preparation methodsEscherichia coliCuticle

The method for producing recombinant human epidermal growth factor by using genetically-engineered colibacillus includes the following steps: engineering bacterium fermentation: activating stored colibacillus by means of culture medium, fermenting main medium and introducing the human epidermal growth factor into fermentation cutlure liquor; expanding bed adsorption; centrifugalizing fermentationculture liquor, adding supernatant fluid into the expanding bed to make adsorption and collecting elution peak containing human epidermal growth factor; gel separation; adding collected eluent into gel chromatographic column, separating and collecting human epidermal growth factor elution peak; freezing, sublimating and drying; freezing collected liquor at -40 deg.C, sublimating and drying so as to obtain the invented product.

Owner:ZHEJIANG UNIV

Method for preparing vanillin by virtue of immobilized biological membrane

InactiveCN103981225AImprove toleranceUniform distribution of surface voidsMicroorganism based processesFermentationBiotechnologyHigh concentration

The invention relates to a method for preparing vanillin by virtue of an immobilized biological membrane. The method comprises the following steps: (1) connecting at least one biological membrane reactor filled with fiber carriers with a fermentation tank in series; (2) putting a fermentation medium in the fermentation tank, and then sterilizing the fermentation tank and the biological membrane reactor; (3) inoculating a slant culture of a ring of well-grown bacillus subtilis B7-S ((i)Bacillus subtilis( / i)B7-S) into a shake flask with the fermentation medium for shaking culture, so as to obtain a fermentation liquor; (4) allowing the fermentation liquor to circulate constantly between the biological membrane reactor and the fermentation tank by virtue of a pump, replacing with a fresh fermentation medium till the concentration of the vanillin is not increased, and continuing to ferment to produce the vanillin, wherein the time spent for each circulation of fermentation liquor is not more than 0.5 hour. The method can be used for effectively improving the production efficiency of the vanillin, has the advantages of producing the product with high concentration and being stable in production of each batch, and is suitable for industrial production of the vanillin.

Owner:甘肃省商业科技研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com