High-concentration biomass slurry as well as preparation method and application thereof

A biomass slurry, high-concentration technology, applied in the direction of biofuel, waste fuel, lignin derivatives, etc., can solve the problems of difficult feeding and transportation, loss of fluidity, low slurry concentration, etc., to improve the overall operating efficiency and economic benefits, increase product concentration, and reduce process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

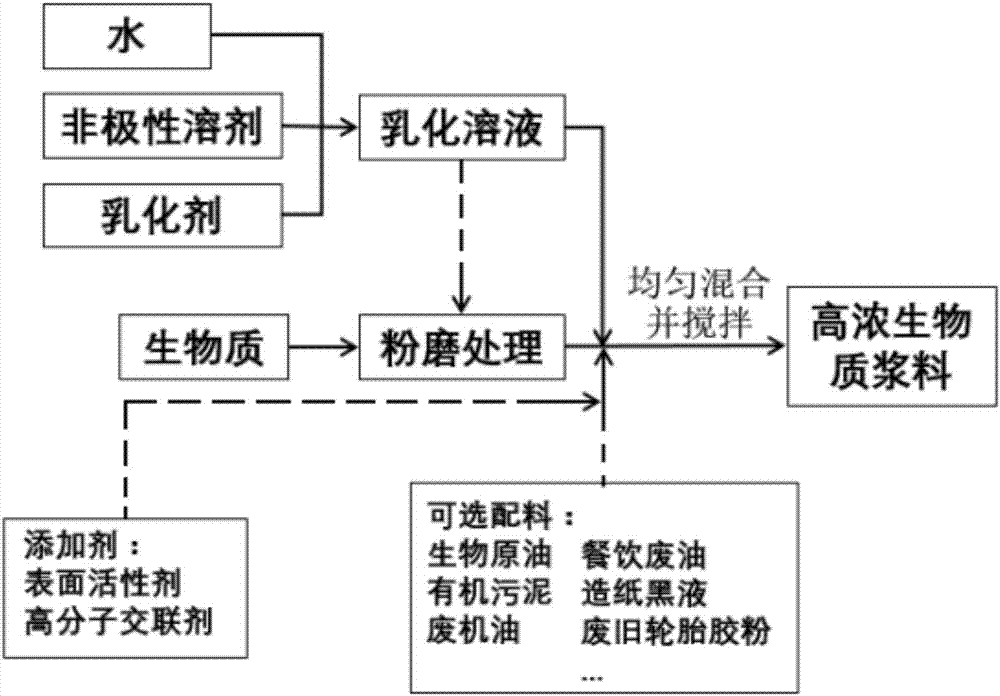

Method used

Image

Examples

Embodiment 1

[0043] The composition and preparation method of the high-concentration biomass slurry provided in this example are as follows:

[0044] 1) 100kg of Fischer-Tropsch synthesis water phase product (the main component is water, containing a small amount of water-soluble alcohol, aldehyde, acid and other organic substances), 15kg of waste engine oil, and 3kg of OP-10 and Tween-80 compound emulsifier (Hydrophilic-lipophilic balance value is 9.0) mixed and prepared into an emulsified solution, the heating temperature is controlled at 75°C, and the stirring speed is controlled at 1000r / min;

[0045] 2) 270kg of shaped biomass particles (particle density of 1.4g / cm 3 ) the powder obtained after pulverizing is mixed with the 118kg emulsified solution obtained in step 1);

[0046] 3) Add 1.5kg of alkylsulfonate and 0.5kg of polyethylene oxide (additive), and stir to form a high-concentration biomass slurry.

Embodiment 2

[0048] 1) Mix 240kg of synthetic gas purification waste water, 20kg of catering waste oil, and 4kg of OP-10 and oleic acid triethanolamine compound emulsifier (hydrophilic-lipophilic balance value is 9.7) to form an emulsified solution, heating temperature Control at 80°C, and control the stirring speed at 1100r / min;

[0049] 2) 200kg of wheat straw granules (the particle density after compression is 0.7g / cm 3 ) Grinding and refining pulp in 3-stage series double-disk mills, adding 264kg of emulsified solution obtained in step 1) during the refining process;

[0050] 3) Add 2kg of lignosulfonate (additive) and 20kg of dried municipal sludge (optional ingredients) with a solid content of 80wt% to the slurry to form a high-concentration biomass slurry.

Embodiment 3

[0052] 1) Mix 250kg of naphtha and 2kg of glyceryl monostearate / Tween-20 compound emulsifier (hydrophilic-lipophilic balance value is 8.1) to prepare an emulsified solution. The heating temperature is controlled at 70°C and the stirring speed is Control at 900r / min;

[0053] 2) 180kg of branches and branches are crushed into sawdust (the particle density is 0.9g / cm 3 ) mixed with the 252kg emulsified solution obtained in step 1);

[0054] 3) Add 1.8 kg of alkyl sulfonate and 0.2 kg of polystyrene sulfonate (additive) and 10 kg of papermaking black liquor (optional ingredients) with a solid content of 60 wt%, and stir to form a high-concentration biomass slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com