Improved biosynthesis method for 1, 3-propylene glycol

A technology of biosynthesis and propylene glycol, which is applied in the field of bioengineering, can solve the problems of no reports, etc., and achieve the effect of fast bacterial growth and high product concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

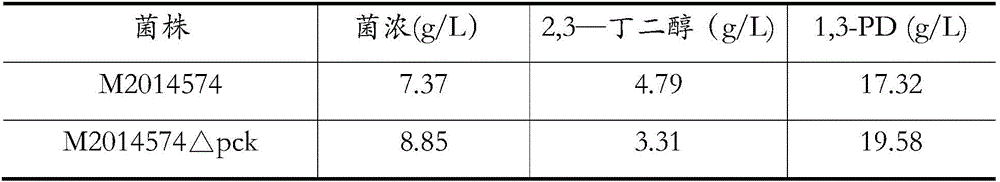

[0021] Example 1. Knocking out pck reduces the formation of the by-product 2,3-BD and promotes the growth of bacteria and the synthesis of 1,3-PD

[0022] M2014574 strain was cultured overnight at 37° C. in LB medium (0.5% yeast extract, 1% tryptone, 1% NaCl, pH 7.0), and the genome was extracted. Using the extracted M2014574 genome as a template, primers were designed based on the pck gene (locus_tag: KPN_03773) on the genome sequence of Klebsiella pneumoniae MGH 78578 registered in NCBI (LOCUS: NC_009648), and the target item was recovered after the PCR reaction. The band was sequenced, and the gene analysis was performed on the target band after sequencing, and the similarity with the pck gene on MGH 78578 was 100%. The pck gene (1623bp) of the M2014574 genome was knocked out by means of homologous recombination, and the obtained recombinant strain was M2014574△pck.

[0023] M2014574 and M2014574△pck were inoculated in 250ml Erlenmeyer flasks at 37°C for anaerobic and micr...

Embodiment 2

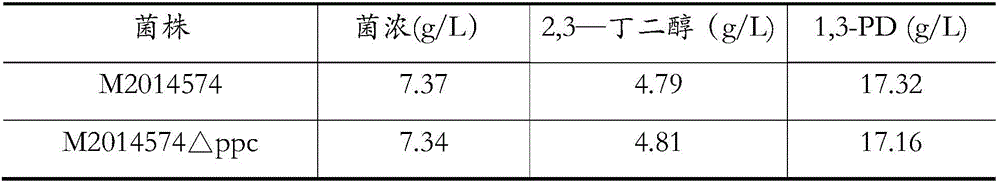

[0027] Example 2. Knocking out the ppc gene has almost no effect on the growth of the bacteria, and the synthesis of 2,3-butanediol and 1,3-PD

[0028]M2014574 strain was cultured overnight at 37° C. in LB medium (0.5% yeast extract, 1% tryptone, 1% NaCl, pH 7.0), and the genome was extracted. Using the extracted M2014574 genome as a template, primers were designed based on the ppc gene (locus_tag: KPN_04245) on the genome sequence of Klebsiella pneumoniae MGH 78578 registered in NCBI (LOCUS: NC_009648), and the target item was recovered after the PCR reaction. Bands were sequenced, and the target bands were analyzed for genes after sequencing. The similarity with the ppc gene on MGH 78578 was 100%. The pck gene (2676bp) of the M2014574 genome was knocked out by means of homologous recombination, and the obtained recombinant strain was M2014574△ppc.

[0029] M2014574 and M2014574△ppc were respectively inoculated in 250ml Erlenmeyer flasks for anaerobic and microaerobic cultur...

Embodiment 3

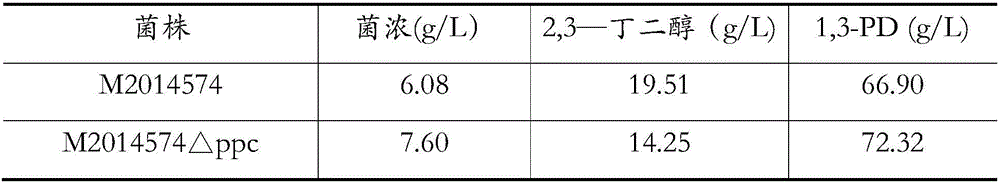

[0033] Example 3: After knocking out the pck gene, the generation of the by-product 2,3-butanediol was significantly reduced and the synthesis of the product 1,3-PD was promoted on the 5L reactor

[0034] The 5L reactor fermentation experiment was as follows: the strains (M2014574△pckc, M2014574) were inserted into a 250ml shake flask (50ml liquid volume) for seed cultivation for 20 hours, and then inserted into a 5L fermenter (2L fermentation liquid volume), The fermentation process was controlled according to the process conditions shown below.

[0035] The initial glycerol concentration is 60g / L, the fermentation temperature is 35°C; the ventilation rate is 1.0vvm; the stirring speed is 20rpm; the pH value is controlled by adding NaOH solution to 5.5-7.5 during the fermentation process. In each period of fermentation, the glycerin concentration is controlled at 10-60 g / L by supplementing glycerin solutions with different concentrations, and the fermentation ends in 30 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com