Escherichia coli immobilizing method and method for producing L-lysine through fed-batch fermentation of immobilized escherichia coli

A technology of Escherichia coli, fed-feed fermentation, applied in microorganism-based methods, biochemical equipment and methods, immobilized on/in organic carriers, etc., can solve the problems of small force and easy shedding, Escherichia coli restriction, etc., Achieve high production efficiency, stable fermentation, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

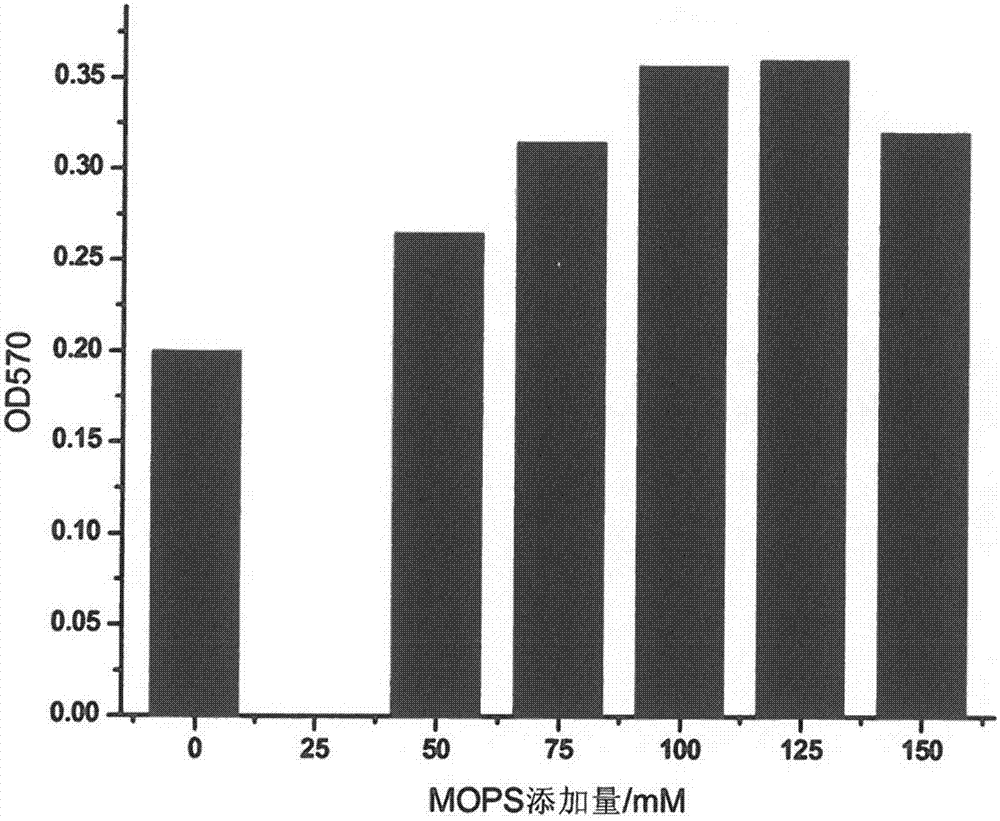

[0039] (1) Cut the synthetic sponge into 1*1*1cm 3 The small cubes were soaked in 75% ethanol aqueous solution for 1 to 3 hours, washed in deionized water for 3 to 5 times, and then added to a 500ml Erlenmeyer flask according to the carrier addition amount of 10g / L. The Erlenmeyer flask was equipped with pre- Fermentation medium 50ml, then add MOPS of 6 different concentrations of 0, 50, 75, 100, 125, 150mM respectively, at least 3 parallel samples for each concentration, sterilize by high temperature and high pressure steam at 115°C for 15min;

[0040] Pre-fermentation medium formula: glucose 20g / L, peptone 1.5g / L, ammonium sulfate 0.5g / L, dipotassium hydrogen phosphate 0.5g / L, yeast extract 1g / L, manganese sulfate 0.2g / L, ferrous sulfate 0.4g / L, magnesium sulfate 0.1g / L, solvent is water, pH6.8~7.2.

[0041] (2) Wash the L-lysine producing strain Escherichia coli preserved on the slant with sterile physiological saline, and insert the bacterium suspension into the sterilize...

Embodiment 2

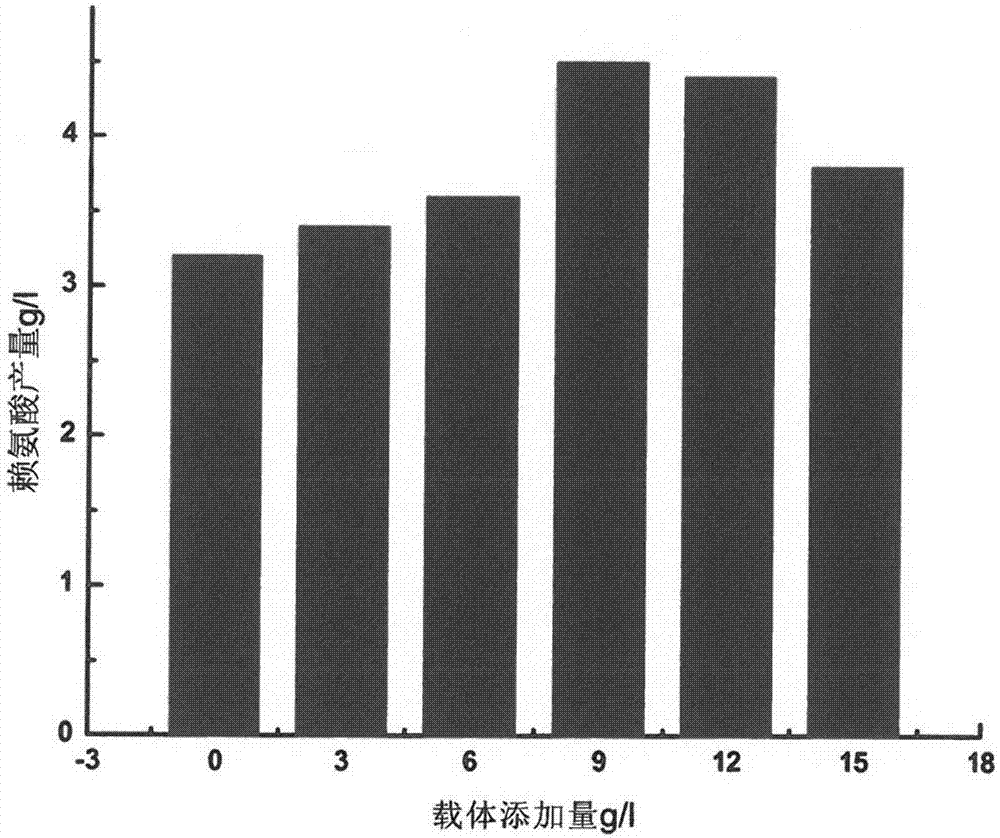

[0048] (1) Cut the synthetic sponge into 1*1*1cm 3 Small cubes were soaked in 75% ethanol aqueous solution for 1 to 3 hours, washed in deionized water for 3 to 5 times, and then added to the In the shake flask pre-fermentation medium (50ml seed medium / 500ml Erlenmeyer flask), at least 3 parallel samples are added for each carrier, sterilized by high temperature and high pressure steam at 115°C for 15min; the formula of the shake flask pre-fermentation medium is the same as in the example 1.

[0049] (2) The activation culture process of Escherichia coli is the same as step (2) in Example 1.

[0050] (3) Insert the inoculum amount of activated Escherichia coli into the shake flask pre-fermentation medium of step (1) according to the volume ratio of 10%, the culture temperature is 37°C, the shaking table speed is 200r / min, and the culture time is 20 ~24h. At the end of the cultivation, use the SBA-40E biosensor to detect the amount of L-lysine. For the test results, see fig...

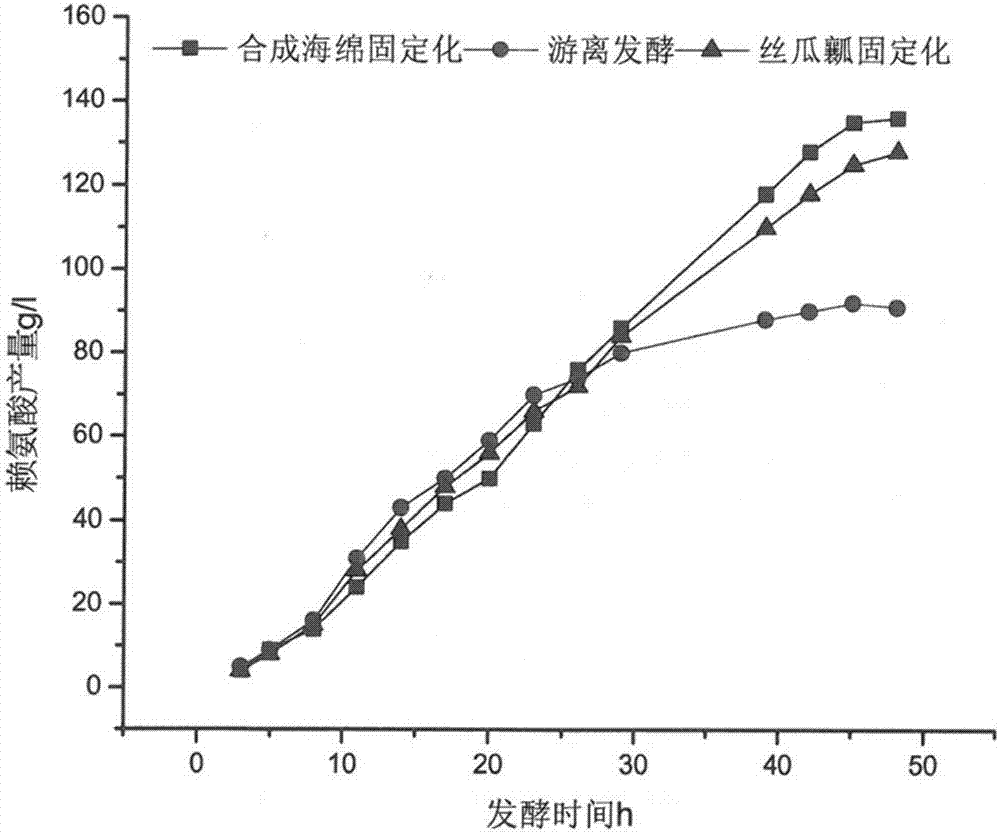

Embodiment 3

[0052] (1) Shake flask seed culture: wash the L-lysine producing strain Escherichia coli preserved on the slant with sterile physiological saline, and insert the bacterial suspension into a 500ml triangle containing 50ml seed medium according to the inoculum size of 5% by volume Cultivate in the bottle, the culture temperature is 35°C, the shaker speed is 190r / min, the culture time is 20-24h, the formula of the shake flask seed medium is the same as

[0053] Example 1.

[0054] (2) Pre-fermentation culture: when the OD600 of the culture solution in the shake flask reaches 5, the inoculation amount of 5% by volume is inserted into a pre-fermentation tank that has sterilized bacteria in advance and is equipped with a pre-fermentation medium, and the ventilation rate is controlled during the pre-fermentation process 0.03~0.08L / (min L), stirring speed 100~1000rpm, adjust ventilation volume and stirring speed to control dissolved oxygen DO≥25%, temperature 35℃, ammonia water contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com